Beruflich Dokumente

Kultur Dokumente

Marie Curie Presentation

Hochgeladen von

Swaroop Kumar NallagalvaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Marie Curie Presentation

Hochgeladen von

Swaroop Kumar NallagalvaCopyright:

Verfügbare Formate

IMPROVING

DIRECT TORQUE CONTROL

USING MATRIX CONVERTERS

Technical University of Catalonia.

Electronics Engineering Department.

Colom 1, Terrassa 08222, Catalonia, Spain

University of Malta.

Department of Electrical Power and Control

Engineering.

Msida MSD 06, Malta

Research Student:

Carlos Ortega Garca

Home Supervisor:

Dr. Antoni Arias Pujol

Malta Supervisor:

Dr. Cedric Caruana

2

Index

Introduction

Matrix Converters.

Direct Torque Control.

- Classical

- Using Matrix Converters.

Sensorless Control of a DTC drive using hf injection

Conclusions.

3

Introduction

Matrix Converters (MC)

Advanced circuit topology capable of generating AC-AC.

Load voltage with arbitrary amplitude and frequency, and

sinusoidal input/output waveforms.

Power Factor Correction (PFC).

No inductive or capacitive elements

are required, thus allowing a very

compact design.

A very good alternative to Voltage Source Inverters (VSI).

4

Direct Torque Control (DTC).

Simple and robust signal processing scheme.

No coordinate transformation and no PWM generation are

needed.

Quick and precise torque response.

The torque and flux modulus values and sector of the flux are

needed.

High torque ripple.

Introduction

5

High Frequency Signal Injection.

Non Model-Based method.

Avoids problems at low and zero speed due to the lack of

back-EMF.

No dependence of machine parameters.

Saliency required.

Introduction

6

Main objectives:

Improve the Direct Torque Control, regarding torque ripple,

using small vectors of Matrix Converters.

Analysis of different High Frequency signal Injection

methods for sensorless Direct Torque Control.

Introduction

7

A switch, S

ij

, i={A,B,C}, j={a,b,c} can

connect phase i of the input to phase j

of the load.

Switches states characterized by:

=

closed is switch if 1

open is switch if 0

ij

ij

ij

S

S

S

A mathematical model of the MC can be derived:

Voltage equations: Current equations:

(

(

(

(

(

(

=

(

(

(

) (

) (

) (

) ( ) ( ) (

) ( ) ( ) (

) ( ) ( ) (

) (

) (

) (

t v

t v

t v

t S t S t S

t S t S t S

t S t S t S

t v

t v

t v

C

B

A

Cc Bc Ac

Cb Bb Ab

Ca Ba Aa

cN

bN

aN

(

(

(

(

(

(

=

(

(

(

) (

) (

) (

) ( ) ( ) (

) ( ) ( ) (

) ( ) ( ) (

) (

) (

) (

t i

t i

t i

t S t S t S

t S t S t S

t S t S t S

t i

t i

t i

c

b

a

Cc Cb Ca

Bc Bb Ba

Ac Ab Aa

C

B

A

V

SB

S

Ab

S

Ac

V

SA

V

SC

M

L

f

L

f

L

f

R

f

Rf

Rf

S

Aa

S

Ba

S

Bb

S

Bc

S

Cb

S

Cc

S

Ca

C

f

C

f

C

f

Matrix Converter Input Filter

I

SB

I

SA

I

SC

I

a

I

b

I

c

I

B

I

A

I

C

V

aN

V

bN

V

cN

State of the Art

Matrix Converters

8

Since any output phase can be connected to any input phase, there are 27

possible switching configurations.

Applying Clarks transformation to all switching states, it can be found that

MC can generate:

- 18 active vectors, 6 rotating vectors, and 3 zero vectors.

Output line-to-neutral voltage vectors Input line current vectors

Matrix Converters

Sector

1

2

3

4

5

6

1,2, 3

4

,

5

,

7

,

8

,

9

a)

Sector

1

2 3

4

5

6

2

,

5

,

1

,

4

,

7

3

,

6

,

9

b)

State of the Art

9

Direct Torque Control

Stator flux

*

s

and torque T

*

e

references are compared with the

corresponding estimated values.

Both stator flux and torque errors,

E

and E

Te

, are processed by means

of hysteresis band comparators.

A proper VSI voltage vector is

selected.

The flux vector reference and the

hysteresis band tracks a circular

trajectory, thus, the actual flux

follows its reference within the

hysteresis band in a zigzag path.

Look-up table

Flux and Torque Estimator

S

H

T

e

T

e

*

S

*

T

e

S

E

H

Te

E

Te

Voltage Source Inverter

I

A

I

B

V

o

S

A

S

B

S

C

S(n)

M

S(1)

S(2) S(3)

S(4)

S(5) S(6)

V

3

At

1

V

4

At

2

V

3

At

3

V

4

At

4

S

V

1

V

2

V

3

V

4

V

5

V

6

A

1

A

2

A

3

A

4

A

5

A

6

a) b)

sin | | | |

' 2

3

s r

s r

m

e

L L

L

p T =

10

Direct Torque Control using

Matrix Converters

Matrix converter generates a higher

number of output voltage vectors

with respect to a VSI.

Another variable, <sin |>, is

introduced to control the input

power factor.

Keeping this variable close to zero,

unity power factor operation is

possible.

A new hysteresis comparator is introduced which controls this variable.

Classical DTC using Matrix Converters

Voltage Vector

Table

Matrix

Converter

Flux and Torque

Estimator

S

H

|

T

e

T

e

*

S

*

T

e

S

I

A

I

B

V

o

S(n)

S

A

S

B

S

C

H

H

Te

<sin |>

E

Te

E

<sin |>

estimator

M

Direct Torque Control for Induction Motors Using Matrix Converters (CPE-05)

11

A new torque hysteresis comparator will provide

four different levels instead of three to distinguish

between small and large positive and negative

torque errors.

E

Te

H

Te

H

Te

E

Te

Large vectors will be used when

large torque error is detected.

When torque error is small, the small

voltage vector will be applied.

Zero vectors will be applied if small

torque error is detected and back

EMF imposes a variation in torque

towards its reference value.

The use of small vectors of Matrix Converters

Zero vect or applied Lowtorque slope

Small vect or applied Medium t orque slope

Upper t orque band

Lower t orque band

Large vect or applied High t orque slope

Upper t orque band

Lower t orque band

a) b)

Direct Torque Control using

Matrix Converters

12

Torque ripple performance.

Comparison between the classical use of MC in DTC and the proposed method.

Classical DTC using MC Proposed method

0.85 0.9 0.95 1

4

4.5

5

5.5

6

6.5

7

7.5

8

Time (s)

T

o

r

q

u

e

(

N

m

)

0.85 0.9 0.95 1

4

4.5

5

5.5

6

6.5

7

7.5

8

Time (s)

T

o

r

q

u

e

(

N

m

)

The use of small vectors of Matrix Converters

e

ref

=100% rated speed and T

L

=100% rated torque.

Direct Torque Control using

Matrix Converters

13

Torque ripple performance.

Comparison between the classical use of MC in DTC and the proposed method.

The use of small vectors of Matrix Converters

0 250 500 750 1000 1250 1500

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

0.5

Speed (rpm)

r

m

s

v

a

l

u

e

o

f

T

e

E

R

R

O

R

(

N

m

)

Classcal DTC using MC

Proposed method

The use of zero and large vectors in

the classical method leads into an

over/undershoot, more pronounced

as the speed increases.

Small vectors are more effective

keeping the torque within the its

reference bands.

Direct Torque Control using

Matrix Converters

14

Sensorless Control

Saliency

o

|

g

max

g

min

u

r

u

(a)

(b)

g

max

g

min

L

m

u

r(elec)

Asymmetry in the machine.

Magnetizing inductance variation.

Asymmetry in the rotor Rotor Position.

( )

( )

(

=

(

t

t

V

v

v

i

i

i

s i

s i

e

e

|

o

cos

sin

( ) ( )

( ) ( )

(

A +

A +

=

(

t L t L

t L t L

L L

V

i

i

i r s i s

i r s i s

qs ds i

i

s i

s i

e u e

e u e

e

|

o

2 sin sin

2 cos cos

15

Sensorless Control

o| frame rotating injection.

Straightforward in vector

controlled drives.

The carrier can be

superimposed to the

voltage reference.

v

ds

*

i

qs

*

i

ds

*

Voltage

Source

Inverter

i

abc

i

o|

PMSM

flux position

estimate

+

-

-

+

abc

o|

u

e

+

+

+

+

dq

o|

dq

o|

PI

PI

i

ds

i

qs

v

qs

*

v

os

*

v

|s

*

v

osi

v

|si

i

o|

e

i

e

i

tan

-1

e

j2e

i

t

e

-je

i

t

i

o|

i

io|

i

ipos

Synchronous filter

Band-pass

filter

High-pass

filter

2u

r

16

Sensorless Control

o| injection in a DTC drive.

Flux and Torque processed

errors, H

s

and H

Te

, converted

directly to switching signals.

No voltage command =>

Difficult to inject.

Injection directly modifying the

vector pattern imposed by the

DTC switching table.

V

4

V

5

V

4

V

6 V

n

V

n

V

n

+

1

V

n

+

1

xK xK

T

z

T

i

Voltage Vector

Table

Stator Flux

and

Torque

Estimator

S

H

T

e

T

e

*

S

* E

H

Te

E

Te

Voltage

Source

Inverter

i

abc

i

o|

S

A

S

B

S

C

S(n)

PMSM

Injection

algorithm

VSI

+

PMSM

hf Model

abc/o|

i

io|

VSI

+

Fundamental

Estimator

Synchronous

filter

i

fo|

+

-

-

-

-

+

+

+

High bandwidth of hysteresis controllers.

Difficult to inject outside of this bandwidth.

Decoupling of fundamental and hf currents is necessary

17

Sensorless Control

o| injection in a DTC drive.

Steady state at 375 rpm Speed reversal.

Comparison between real and estimated position

0 0.05 0.1 0.15 0.2

-4

-2

0

2

4

Time (s)

M

o

d

e

l

b

a

s

e

d

a

n

g

l

e

e

s

t

i

m

a

t

e

(

r

a

d

)

0 0.05 0.1 0.15 0.2

-4

-2

0

2

4

Time (s)

I

n

j

e

c

t

i

o

n

m

e

t

h

o

d

a

n

g

l

e

e

s

t

i

m

a

t

e

(

r

a

d

)

0 0.1 0.2 0.3 0.4 0.5 0.6

-4

-2

0

2

4

Time (s)

M

o

d

e

l

b

a

s

e

d

a

n

g

l

e

e

s

t

i

m

a

t

e

(

r

a

d

)

0 0.1 0.2 0.3 0.4 0.5 0.6

-4

-2

0

2

4

Time (s)

I

n

j

e

c

t

i

o

n

m

e

t

h

o

d

a

n

g

l

e

e

s

t

i

m

a

t

e

(

r

a

d

)

18

Conclusions

Advantages of Matrix Converters over the traditional VSI has

been combined with the advantages of the DTC scheme.

The use of small vectors of the MC has been investigated.

High frequency injection in a DTC drive has been presented.

19

Thank you.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- JSRDokument3 SeitenJSRSwaroop Kumar NallagalvaNoch keine Bewertungen

- Artificial Neural Networkon ElectricalDokument21 SeitenArtificial Neural Networkon ElectricalSwaroop Kumar NallagalvaNoch keine Bewertungen

- Aptransco - Cgg.gov - in Documents ElectricalDokument697 SeitenAptransco - Cgg.gov - in Documents ElectricalSharath Teja ReddyNoch keine Bewertungen

- 2006 Tesis 49Dokument211 Seiten2006 Tesis 49Swaroop Kumar NallagalvaNoch keine Bewertungen

- Appendix-I: Bus Data For Ieee-14 Bus SystemDokument13 SeitenAppendix-I: Bus Data For Ieee-14 Bus SystemSwaroop Kumar NallagalvaNoch keine Bewertungen

- Power System ProtectionDokument23 SeitenPower System Protectionmqahtany1Noch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 1xEV RF Optimization Guidelines R24Dokument83 Seiten1xEV RF Optimization Guidelines R24lady_sNoch keine Bewertungen

- Poetics: Ester Van Laar, Alexander J.A.M. Van Deursen, Jan A.G.M. Van Dijk, Jos de HaanDokument14 SeitenPoetics: Ester Van Laar, Alexander J.A.M. Van Deursen, Jan A.G.M. Van Dijk, Jos de HaanViveka AshokNoch keine Bewertungen

- STEEL STRUCTURES KHARGHAR SKYWALK AND NIFT INSTITUTE Ms PPT 2007Dokument30 SeitenSTEEL STRUCTURES KHARGHAR SKYWALK AND NIFT INSTITUTE Ms PPT 2007Harsh chhedaNoch keine Bewertungen

- Journal Publishing ProcessDokument1 SeiteJournal Publishing Processmohamedr55104Noch keine Bewertungen

- Chapter 5 (6) Concrete MaterialDokument134 SeitenChapter 5 (6) Concrete Materialraju_420034520Noch keine Bewertungen

- Communication Skills For Effective LeadershipDokument12 SeitenCommunication Skills For Effective LeadershipKovaNoch keine Bewertungen

- Acc Inter 3 AtsiriDokument9 SeitenAcc Inter 3 AtsiriZania Putri100% (1)

- Eurotuner February 2010 PDFDokument1 SeiteEurotuner February 2010 PDFJenniferNoch keine Bewertungen

- (Revised) Dale Carnegie-How To Win Friends and Influence People-Simon and Schuster (1981)Dokument12 Seiten(Revised) Dale Carnegie-How To Win Friends and Influence People-Simon and Schuster (1981)TomasUreñaNoch keine Bewertungen

- Probability and Statistics Ii Assignment I July 2019 PDFDokument3 SeitenProbability and Statistics Ii Assignment I July 2019 PDFDanielNoch keine Bewertungen

- 4naa7 4eeDokument2 Seiten4naa7 4eeDorottya HózsaNoch keine Bewertungen

- Soft Sculpture EventsDokument28 SeitenSoft Sculpture EventsAlabala BalaaNoch keine Bewertungen

- Key Term Arabic Meaning Link: Life ScienceDokument5 SeitenKey Term Arabic Meaning Link: Life ScienceReemNoch keine Bewertungen

- Balanced Cable Measurement Using The 4-Port ENADokument9 SeitenBalanced Cable Measurement Using The 4-Port ENAA. VillaNoch keine Bewertungen

- CertificateofAnalysis 2019 11 9 879766Dokument2 SeitenCertificateofAnalysis 2019 11 9 879766Trọng TínNoch keine Bewertungen

- Enabling Secure Broadband Access Anywhere Anytime Access Anywhere, AnytimeDokument4 SeitenEnabling Secure Broadband Access Anywhere Anytime Access Anywhere, AnytimeEmmanuelNoch keine Bewertungen

- MC68 HC05 B4 UDokument253 SeitenMC68 HC05 B4 Uflo724Noch keine Bewertungen

- Student Camps 2022 - Grade 6 Science Curriculum Based Test BookletDokument58 SeitenStudent Camps 2022 - Grade 6 Science Curriculum Based Test Bookletthank you GodNoch keine Bewertungen

- IB Biology Lab Report TemplateDokument6 SeitenIB Biology Lab Report TemplatebigbuddhazNoch keine Bewertungen

- I. Company Data 1.1. Company ProfileDokument19 SeitenI. Company Data 1.1. Company ProfileMhy AcajaNoch keine Bewertungen

- USDP Shehzore02Dokument39 SeitenUSDP Shehzore02Feroz GullNoch keine Bewertungen

- Procedure Issuing EtaDokument5 SeitenProcedure Issuing EtaCarlos FrançaNoch keine Bewertungen

- APAVE Tiger CP - UK - FINAL2Dokument1 SeiteAPAVE Tiger CP - UK - FINAL2AdrewhassTechnicaNoch keine Bewertungen

- Advanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniDokument94 SeitenAdvanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniSze Mian KuehNoch keine Bewertungen

- Pipeline Construction InspecDokument48 SeitenPipeline Construction InspecAliDadKhan100% (2)

- 63-9378 - Rev-F - Ultra Puck - Datasheet - Web - 63-9378 - Rev-F - Ultra-Puck - Datasheet - WebDokument2 Seiten63-9378 - Rev-F - Ultra Puck - Datasheet - Web - 63-9378 - Rev-F - Ultra-Puck - Datasheet - WebAradhana AradhanaNoch keine Bewertungen

- ROV Inspection and Intervention VesselDokument2 SeitenROV Inspection and Intervention VesselAhmad Reza AtefNoch keine Bewertungen

- BCO120Dokument3 SeitenBCO120erwin_simsensohnNoch keine Bewertungen

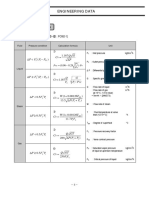

- Engineering Data: 2. CV CalculationDokument1 SeiteEngineering Data: 2. CV Calculationdj22500Noch keine Bewertungen