Beruflich Dokumente

Kultur Dokumente

Lecture 1

Hochgeladen von

Fekede BekeleCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lecture 1

Hochgeladen von

Fekede BekeleCopyright:

Verfügbare Formate

!

$

&

Ak1 CNL nAkD Ak1 CNL nAkD CASULLS CASULLS

!

$

&

1

CuLllne

W lnLroducLlon

W 8aw maLerlals

W ManufacLure

mpLy capsule properLles

Capsule fllllng

Capsule slzes

Capsule shell fllllng

Capsulefllllng machlnes

elleL fllllng

1ableL fllllng

Sermlsolld and llquld fllllng

lormulaLlon

2

IN1kCDUC1ICN

W 1he word capsule ls derlved from Lhe LaLln nff meanlng a

small box

W ln pharmacy Lhe word ls used Lo descrlbe an edlble package

made from gelaLln or oLher sulLable maLerlal whlch ls fllled

wlLh medlclnes Lo produce a unlL dosage malnly for oral use

W 1here are Lwo Lypes of capsule

Pard Lwoplece

SofL oneplece

3

Cap

8ody

Pard gelaLln capsule

4

lnLroducLlon

SofL gelaLln capsule

3

dvanLages

1he use of capsules avolds many unlL operaLlons

8apld drug release posslble

llexlblllLy of formulaLlon

aslly compounded

Sealed PCCs are good barrlers Lo aLmospherlc oxygen

6

dvanLages

1he sLablllLy of LherapeuLlc agenLs may be lmproved ln a

capsule formulaLlon

leganL appearance and shape

asy Lo swallow

Mlnlmum exclplenLs are requlred

7

lsadvanLages

very bulky maLerlals are a problem

lllllng equlpmenL slower Lhan LableLlng

Concern over malnLalnlng proper shell molsLure conLenL

Shell should have molsLure conLenL of 1313

lf Loo dry become brlLLle/easlly fracLured

lL Loo molsL become Loo sofL and can geL sLlcky

8

-oL sulLable for hlghly soluble subsLances llke poLasslum

chlorlde

-oL sulLable for hlghly efflorescenL or dellquescenL maLerlals

Speclal condlLlons are requlred for sLorage

9

kAW MA1LkIALS

CelaLln

WaLer

ColouranLs

CpLlonal maLerlals

reservaLlves

WeLLlng agenL

W 8ecenL years hard capsules have been manufacLured also

from hydroxypropyl meLhylcellulose

10

W CelaLln was Lhe flrsL maLerlal used for Lhe manufacLure of

capsules because of lLs unlque properLles

W lL ls ldeal because

lL ls edlble

soluble aL body LemperaLure

forms sLrong Lhln fllms

undergoes a gelaLlon process aL LemperaLures [usL above

amblenL

kAW MA1LkIALS

11

Ge|at|n and A|ternat|ve Mater|a|s

Ge|at|n

|s a mater|a| der|ved from co||agen a natura|

prote|nwh|ch |s

|s a f|brous mater|a| that occurs |n the sk|n bones

and connect|ve t|ssues of an|ma|s

It |s |nso|ub|e |n water and |s so|ub|||zed by hydro|ys|s

are obta|ned pr|mar||y from bov|ne bones or porc|ne

sk|ns

kAW MA1LkIALS

12

W Ge|at|n

kAW MA1LkIALS

Ac|d hydro|ys|s

sk|ns co||agen

1ype A ge|at|n

1ype 8 ge|at|n bov|ne bones

8as|c hydro|ys|s

13

14

fLer hydrolysls

kAW MA1LkIALS

exLracLlon

evaporaLlon

coollng

drylng

exLracLed from Lhe Lread

maLerlal uslng hoL waLer

1he resulLlng weak soluLlon

of gelaLln ls concenLraLed ln

a serles of evaporaLors

Lhen chllled Lo form a gel

1he gel ls Lhen drled ln a

fluldlzedbed sysLem

13

W LlmlLaLlon of gelaLln

Lhere are cerLaln rellglous or dleLary resLrlcLlons on lLs

use

8ovlne Sponglform ncephalopaLhy

CelaLln lLernaLlve MaLerlals

hydroxypropyl meLhylcellulose (PMC )

molsLure conLenL ls much lower

kAW MA1LkIALS

16

W ColoranLs

Commonly varlous soluble synLheLlc dyes (coal Lar dyes") and

lnsoluble plgmenLs are used

Commonly used plgmenLs are Lhe lron oxldes

W Cpaqulng genLs

1lLanlum dloxlde may be lncluded Lo render Lhe shell opaque

W reservaLlves

When preservaLlves are employed parabens are ofLen selecLed

W rocess alds

sodlum lauryl sulphaLe

as a weLLlng agenL

Lo ensure unlformly coverlng moulds by gelaLln

W WaLer

kAW MA1LkIALS

17

CASULL SnLLL MANUIAC1UkL

llg capsule manufacLurlng machlne ) CelaLln soluLlon sLorage Lank

8) dlp pan C) drylng kllns ) auLomaLlc secLlon

18

CASULL SnLLL MANUIAC1UkL

[o|n|ng

tr|mm|ng

str|pp|ng

Dry|ng

kotat|on

D|pp|ng Ge|at|n So|ut|on

19

20

CASULL MANUIAC1UkL

Ge|at|n So|ut|on

8aw gelaLln and waLer are mlxed ln Lhe

raLlo of 1 2 and processed aL preclse

LemperaLure

D|pp|ng

alrs of sLalnless sLeel plns are dlpped

lnLo Lhe dlpplng soluLlon Lo

slmulLaneously form Lhe caps and

bodles

CASULL SnLLL MANUIAC1UkL

21

CASULL SnLLL MANUIAC1UkL

kotat|on Whlle ralslng Lhey are roLaLed for

requlred dlsLrlbuLlon of gelaLln on Lhe

plns

Dry|ng

rylng ls done malnly be dehumldlflcaLlon by

passlng large volumes of dry alr over Lhe plns Cnly a

LemperaLure elevaLlon a few degrees ls permlsslble

Lo prevenL fllm melLlng

22

CASULL SnLLL MANUIAC1UkL

str|pp|ng

str|ppers remove the dr|ed ha|ves of capsu|es

from the p|ns and p|ace them |nto the co||ets

for further operat|ons

tr|mm|ng

Caps and body ha|ves are tr|mmed to narrow

to|erance as per standards 1he cutt|ng are

vacuumed away and co||ected |n separate drums

23

CASULL SnLLL MANUIAC1UkL

[o|n|ng

1he capsu|e ha|ves move to the centre of the

mach|ne and enter the [o|ner b|ocks Io|ned

capsu|es are then pushed on to the conveyor be|t

24

Capsule quality is monitored throughout the production

process including size, moisture content, single wall

thickness, and color.

23

Capsules are sorted and visually inspected on

specially designed !nspection Stations

26

#erfect capsules are imprinted with the client logo on

highspeed

27

mpty capsule property

mpty capsule contain a significant amount of water that

acts as plasticizer for the gelatin film and is essential for

their function.

The standard moisture content specification of HCC is

between 13 to 16 w/w.

28

CASULL IILLING

29

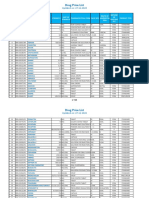

CASULL IILLING

Capsu|e f||| capac|ty

3 4 3 2 1 0 00

30

CASULL IILLING

Capsu|e f||| capac|ty

1he flll capaclLy of a hard capsule ls dependenL on

physlcal slze of Lhe capsule

Lype of formulaLlon

doslng mechanlsm on Lhe fllllng devlce

llll welghL 8ody volume x 1apped bulk denslLy

CASULL IILLING

31

1?S Cl M18lL lC8 llLLl-C l- 1C P8 CL1l-

CSuLS

Dry solids Semisolids Liquids

Powder

Pellets

Granules

Tablets

ThermosoItening

mixtures

Thixotropic mixtures

Pastes

Oily liquids

Non-aqueous liquids

1he fllllng maLerlal musL be compaLlble wlLh Lhe gelaLln shell

dellquescenL or hygroscoplc maLerlals cannoL be used

Lhey cannoL be used for molsLure senslLlve drugs

ll lngredlenLs need Lo be free of even Lrace amounLs of

formaldehyde Lo mlnlmlze cross llnklng of gelaLln

32

POWDERS

TabIets

PeIIets

GranuIes

33

apIets

Paste

Liquids

34

lngredlenL 8

Capsu|e she|| f||||ng

lngredlenL

mpLy capsules owder blend Mlxlng

lngredlenL c

owder b|end M|x|ng

Capsule flller

Machlne

Capsu|e

c|eaner]deduster

capsule lnspecLlon screen

ackaglng

33

36

Capsule shell fllllng

Loadlng of empty capsu|es ln Lo Lhe hopper

ass down Lhrough Lube Lo a rect|f|cat|on secLlon

1he bodles are Lhen passed under Lhe dos|ng mechan|sm

I|||ed w|th mater|a|s

MeLal flngers push Lhe bodles up lnLo Lhem Lo re[o|n Lhe Lwo parLs

1he body ls separated from Lhe cap by means of sucLlon

37

Capsule shell fllllng

8ecLlflcaLlon

capsule separaLlon

fllllng

closure of Lhe capsule

e[ecLlon of Lhe fllled and closed

capsule from Lhe machlne

38

Capsule fllllng machlnes

W lllllng machlnes are dlfferenLlaLed by

Lhe way they measure the dose of maLerlal ln Lo Lhe

capsule body

range |n capac|ty from bench Lop Lo hlgh ouLpuL

lndusLrlal from manua| Lo fu||y automated machlnes

W 1hose LhaL rely on Lhe volume of Lhe shell are known as

capsule dependenL whereas capsule lndependenL forms

measure Lhe quanLlLy Lo be fllled ln a separaLe operaLlon

39

8enchsca|e f||||ng

8equlred for fllllng small quanLlLles of capsules (3010000)

used ln communlLy pharmacy or ln hosplLal pharmacyor

ln lndusLrlal for speclal prescrlpLlons or Lrlals

conslsL of seLs of plasLlc plaLes LhaL have seLs of holes

drllled ln Lhem correspondlng Lo Lhe slze of Lhe capsule

LhaL can be fllled

1he capsules are fed lnLo Lhe plaLes elLher manually one

aL a Llme or ln groups uslng a feedlng devlce

lllllng of powder formulaLlon

40

8enchscale fllllng

1he bodles are clamped ln Lhe boLLom plaLe and Lhe Lop

plaLe removed whlch separaLes Lhe caps from Lhe body

1he bodles are released so LhaL Lhey slL below Lhe Lop of

Lhe boLLom plaLe

owder or pelleLs are fllled lnLo Lhe capsules by spreadlng

maLerlal over Lhe body plaLe

Capsule fllllng machlnes

41

42

lndusLrlalscale fllllng

Come ln greaL varleLy of shapes and slzes

1hese machlnes may be elLher semlauLomaLlc or fully

auLomaLlc

Sem|Automat|c Mach|nes

requlre an operaLor Lo be ln aLLendance aL all Llmes

ependlng on Lhe sklll of Lhe operaLor Lhe formulaLlon

and Lhe slze of Lhe capsule belng fllled Lhese machlnes are

capable of fllllng as many as 120000 160000 capsules ln

an 8hour shlfL

Capsule fllllng machlnes

43

Iu||y Automat|c Mach|nes

machlnes may be classlfled as elLher lnLermlLLenL or

conLlnuous moLlon machlnes

lnLermlLLenL machlnes exhlblL an lnLerrupLed fllllng

sequence

ConLlnuous moLlon machlnes execuLe Lhese funcLlons ln a

conLlnuous cycle

Capsule fllllng machlnes may vary w|de|y |n the|r

eng|neer|ng des|gn Lhe maln dlfference beLween Lhem

from a formulaLlon polnL of vlew ls the means by wh|ch

the formu|at|on |s dosed |nto the capsu|es

Capsule fllllng machlnes

44

W lour maln doslng meLhods may be ldenLlfled for powder

fllllng

1 uger llll rlnclple

Was Lhe flrsL successful lndusLrlal fllllng machlne

1he empLy capsule bodles are held ln a fllllng rlng whlch

roLaLes under Lhe powder hopper

1he flll of Lhe capsules ls prlmarlly volumeLrlc

8ecause Lhe auger mounLed ln Lhe hopper roLaLes aL a

consLanL raLe Lhe raLe of dellvery of powder Lo Lhe

capsules Lends Lo be consLanL

ConsequenLly Lhe ma[or conLrol over flll welghL ls Lhe

raLe of roLaLlon of Lhe fllllng rlng under Lhe hopper

Capsule fllllng machlnes

43

1ype 8 semlauLomaLlc capsulefllllng machlne

46

2 vlbraLory llll rlnclple

used a vlbraLlng plaLe ln Lhe powder

hopper

1he bodles ln Lhelr holders passed

under Lhe hopper

1he cavlLles wlLh Lhe bodles were

overfllled and ralsed up agalnsL a meLal

plaLe Lo push Lhe excess lnslde powder

lnslde

1hls sysLem works well wlLh dense free

flowlng maLerlal

Capsule fllllng machlnes

1he Csaka machlnes

47

48

3lsLon1amp rlnclple

MosL capsules are fllled on plsLonLamp machlnes

1hese are fully auLomaLlc flllers ln whlch plsLons or Lamplng

plns llghLly compress Lhe lndlvldual doses of powders lnLo

plugs (someLlmes referred Lo as slugs") and e[ecL Lhe plugs

lnLo Lhe empLy capsule bodles

1he compresslon forces are low ofLen ln Lhe range of 30 200

- or abouL 30 100fold less Lhan Lyplcal LableL compresslon

forces

Capsule fllllng machlnes

49

3lsLon1amp rlnclple

W 1here are Lwo Lypes of plsLonLamp flllers dosaLor

machlnes and doslngdlsc machlnes

A dosator mach|nes (the dos|ng tube)

Lube ls Lhe mosL wldely used and lL orlglnaLed ln lLaly

1he p|ug |s formed |ns|de a tube wlLh a moveable plsLon

LhaL conLrols Lhe doslng volume and applles a force Lo form

Lhe plug

Capsule fllllng machlnes

30

lagrammaLlc represenLaLlon of Lhe dosaLor fllllng prlnclple

31

D|agrammat|c representat|on of the dosator f||||ng pr|nc|p|e

32

oslnglsc Machlnes

form a plug ln a slmllar buL dlfferenL manner

1he doslng dlsc whlch forms Lhe base of Lhe powder

hopper has up Lo slx seLs of machlned holes

ln a holder above Lhe powder hopper Lhere are seLs of

sLalnless sLeel Lamplng flngers correspondlng Lo Lhe holes

ln Lhe dlsk

Lhe Lamplng flngers are lowered lnLo Lhe powder bed

Capsule fllllng machlnes

33

1he flngers are seL Lo dlfferenL levels and Lhey peneLraLe lnLo

Lhe plaLe and consolldaLe Lhe powder ln Lhe cavlLles lnLo

plugs

1he doslng dlsks are produced ln a range of Lhlcknesses for

each slze of capsule

Lhe selecLlon of Lhe correcL Lhlckness of dlsk ls lmporLanL

because lf Lhe flll welghL cannoL be achleved

Capsule fllllng machlnes

34

D|agrammat|c representat|on of the dos|ng d|sc f||||ng pr|nc|p|e

SchemaLlc dlagram of a doslng dlsc and Lamplng

flnger sysLem (8osch Ckl machlne) () overload rellef

sprlng (8) LampdepLh ad[usLer (C) Lamplng flnger ()

powder hopper () powder bed (l) doslng dlsc (C) sucLlon

(P) supporL plaLe (l) e[ecLlon ad[usLer (!) gulde block (k)

Lransfer block (L) capsule body ln bushlng and (M) powder

plug

33

36

Dry So||d I||||ng

W Cranules pelleLs and LableLs can be fllled lnLo capsules uslng

auLomaLlc fllllng machlnes

W roducLs are prepared ln Lhese forms Lo

modlfy Lhe release raLes of acLlve lngredlenLs

Lo separaLe lncompaLlble componenLs

Lo denslfy a producL Lo achleve Lhe flll welghL ln a speclflc slze of

capsule

W 1he machlnes LhaL can be used Lo flll Lhese producLs can be

- Lhe dlrecL

- lndlrecL caLegorles

37

W 1he dlrecL

Lhe maLerlal ls fed lnLo Lhe body unLll lL ls compleLely full

W 1he lndlrecL

Lhe dose of maLerlal ls measured ln a chamber wlLh a

varlable volume whlch can be ad[usLed Lo glve Lhe

requlred welghL

Machlnes have modlfled dosaLors LhaL elLher use sucLlon

Lo hold Lhe maLerlal ln Lhe Lube durlng Lransfer or are

fllled when Lhey pushed up Lhrough Lhe maLerlal bed

Dry So||d I||||ng

38

W roperLles of LableLs LhaL are fllled lnLo capsules

convex and have dlameLers LhaL enable Lhem Lo be

lnLroduced easlly lnLo Lhe body

W Cranules and pelleLs should be regular ln shape so LhaL Lhey

flow and pack well

W 1helr slze should be relaLed Lo Lhe slze of Lhe capsule

Dry So||d I||||ng

39

W 1wo Lypes of llquld fllls

1 -onaqueous soluLlons and suspenslons

2 lormulaLlons LhaL are llquefled only for Lhe fllllng

process by elLher heaL or shear sLress

W Wlll need Lo be sealed afLer fllllng

W 1he dose of maLerlal ls measured uslng volumeLrlc pumps

W 1he unlformlLy of flll ls ln mosL cases beLLer Lhan a powder

fllllng machlne

W lllllng machlnes have been made LhaL can handle maLerlals

wlLh vlscoslLles from 100 cp Lo 20000 cp

L|qu|d I||||ng

60

W edusLlng and/or pollshlng operaLlon are compleLed before

Lhe remalnlng operaLlons of lnspecLlon boLLllng and

labellng

W 1he followlng are Lhe meLhods mosL commonly used

an pollshlng

used Lo Lrap Lhe removed dusL as well as Lo lmparL a

gloss Lo Lhe capsules

CloLh dusLlng

rubbed wlLh a cloLh LhaL may or may noL be

lmpregnaLed wlLh an lnerL oll

8rushlng

capsules are fed under roLaLlng sofL brushes

I|n|sh|ng

61

62

owder formu|at|on

W 1he ma[orlLy of producLs for fllllng lnLo capsules are

formulaLed as powders

W 1hese are Lyplcally mlxLures of Lhe acLlve lngredlenL LogeLher

wlLh a comblnaLlon of dlfferenL Lypes of exclplenLs

ICkMULA1ICN

D||uents whlch glve plugformlng properLles

Lubr|cants whlch reduce powder Lo meLal adheslon

G||dants whlch lmprove flow

Wett|ng agents whlch lmprove waLer peneLraLlon

D|s|ntegrants whlch produce dlsrupLlon of Lhe powder mass

1ypes of exclplenL used ln powderfllled capsules

63

Iormu|at|on for f||||ng propert|es

1here are Lhree maln facLors ln powder formulaLlon

Cood flow (uslng freeflowlng dlluenL and glldanL)

-o adheslon (uslng lubrlcanL)

Coheslon (plugformlng dlluenL)

ICkMULA1ICN

64

8loom sLrengLh of gelaLln

Capsules for lnhalaLlon roducLs

CuallLy conLrol of capsules

63

kead|ng Ass|gnments

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Formulation and Evaluation of Paracetamol TabletsDokument8 SeitenFormulation and Evaluation of Paracetamol Tablets393852019100% (1)

- Drug Toxicity and PoisoningDokument12 SeitenDrug Toxicity and PoisoningPAULA MARIE MERCADO LLIDONoch keine Bewertungen

- Aspirin + ClopidogrelDokument7 SeitenAspirin + ClopidogrelAndrey Wahyudi MuslimNoch keine Bewertungen

- Different Types of Dosage Forms in PharmaceuticalsDokument3 SeitenDifferent Types of Dosage Forms in PharmaceuticalsMohsinShaikhNoch keine Bewertungen

- Form Label ObatDokument19 SeitenForm Label ObatfitriNoch keine Bewertungen

- DrugStudy OmeprazoleDokument2 SeitenDrugStudy OmeprazoleAshknee Khainna Alejo100% (1)

- Dosage Calculation: Prepared by Hina Karim SR NES InstructorDokument33 SeitenDosage Calculation: Prepared by Hina Karim SR NES Instructorwaqas_xsNoch keine Bewertungen

- Food and Drug Interactions A General ReviewDokument15 SeitenFood and Drug Interactions A General ReviewDaniela AndreiNoch keine Bewertungen

- Afp20190501p558 - Drud Interaction FactDokument7 SeitenAfp20190501p558 - Drud Interaction FactM.Febrian BachtiarNoch keine Bewertungen

- Manufacturing Lecture NotesDokument21 SeitenManufacturing Lecture NotesJuliannNoch keine Bewertungen

- Pdrugs and P TreatmentDokument66 SeitenPdrugs and P TreatmentPoppy Pradina0% (1)

- Variations TGADokument128 SeitenVariations TGAJaime Andrés García BNoch keine Bewertungen

- RMC No. 103-2021Dokument17 SeitenRMC No. 103-2021Kenneth FabiaNoch keine Bewertungen

- List of GMP Companies - 2018!03!18Dokument2 SeitenList of GMP Companies - 2018!03!18Dapper Yourself100% (1)

- Exercise 2 - Interpretation of Prescription (Valle)Dokument5 SeitenExercise 2 - Interpretation of Prescription (Valle)Rafael VallwNoch keine Bewertungen

- Important Info About ExamDokument1 SeiteImportant Info About Examzxcasdqwe123Noch keine Bewertungen

- August September Order Boticab OncDokument6 SeitenAugust September Order Boticab OncDivine Grace Villanueva100% (1)

- Pharmacovigilance and Its Importance in Drug Regulation: An OverviewDokument16 SeitenPharmacovigilance and Its Importance in Drug Regulation: An OverviewSarah ApriliaNoch keine Bewertungen

- Dispersi KasarklasiberDokument124 SeitenDispersi KasarklasiberSari RamadhaniNoch keine Bewertungen

- HargaDokument68 SeitenHargarsurNoch keine Bewertungen

- PPR - LISTS - Registered Medicine Price List - 20221127 BahrainDokument318 SeitenPPR - LISTS - Registered Medicine Price List - 20221127 BahrainvdvedNoch keine Bewertungen

- Allopathic Drug Manufacturers (Medex - Com.bd)Dokument10 SeitenAllopathic Drug Manufacturers (Medex - Com.bd)মোঃ এমদাদুল হকNoch keine Bewertungen

- Dipyridamole Drugs@FDA - FDA Approved Drug ProductsDokument3 SeitenDipyridamole Drugs@FDA - FDA Approved Drug ProductsbiodocuploaderNoch keine Bewertungen

- Curriculum Vitae MTDokument6 SeitenCurriculum Vitae MTapi-273097827Noch keine Bewertungen

- Damasco - Cpi - Activity No. 10Dokument18 SeitenDamasco - Cpi - Activity No. 10LDCU - Damasco, Erge Iris M.Noch keine Bewertungen

- 3D Printing Technology in Drug Delivery: Recent Progress and ApplicationDokument10 Seiten3D Printing Technology in Drug Delivery: Recent Progress and ApplicationAngela DelarmenteNoch keine Bewertungen

- Hyper CvadDokument5 SeitenHyper CvadAmr MuhammedNoch keine Bewertungen

- Reviewer Chapter 35 MedicationsDokument4 SeitenReviewer Chapter 35 MedicationsKeren GaciasNoch keine Bewertungen

- Affiliated Institutions - Pharmacy Colleges B.PharmDokument9 SeitenAffiliated Institutions - Pharmacy Colleges B.PharmMichael BenilanNoch keine Bewertungen

- Excipients TabletsDokument12 SeitenExcipients TabletsPrince ConstantineNoch keine Bewertungen