Beruflich Dokumente

Kultur Dokumente

Interpersonal Dynamics of Industrial Buying Behavior

Hochgeladen von

Nitika AggarwalOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Interpersonal Dynamics of Industrial Buying Behavior

Hochgeladen von

Nitika AggarwalCopyright:

Verfügbare Formate

Interpersonal dynamics of industrial buying behavior

Purchasing function

International material shortage Cost of material and energy Nationalistic moods Conflicting social goals Profit squeeze Higher government regulation

Purchasing planning

Purchasing is now an assets mgmt process Asset management team includes the procurement specialist, cost/price analyst and engineers

Material requirement planning

The firm estimates the future sale, schedules and orders parts and materials Aim is that inventory should not be too small or too large An input might be used multiple times in a production schedule thus ordering becomes complex.

Material management department: purchasing, transportation, inventory control, receiving and production control MRP today is computerized

Ideal materials requirement plan

Maruti Udyog

Standard products like nuts and bolts Manufactured goods like moulded dashboards, steering wheels, tyres and tubes Capital equipment like cranes etc

Lunch box making activity

Benefits of MRP

controlled inventory level lesser production cost timely deliveries efficiency in operations

Just in Time purchasing

Manufacturer maintain least inventory levels by relying on one supplier who could deliver frequent shipments (sometimes daily) Needs long term one supplier relationship Cost factors are less important and material specification are flexible

Example of JIT-GM

General Motors (GM) in the USA has (approximately) 1700 suppliers who ship to 31 assembly plants scattered throughout the continental USA. These shipments total about 30 million metric tons per day and GM spends about 1,000 million dollars a year in transport costs on these shipments. When GM moved to JIT there were simply too many (lightly loaded) trucks attempting to deliver to each assembly plant. GM's solution to this problem was to introduce consolidation centres at which full truckloads were consolidated from supplier deliveries. This obviously involved deciding how many consolidation centres to have, where they should be, their size (capacity) and which suppliers should ship to which consolidation centres (suppliers can also still ship direct to assembly plants). As of 1990 some 20% by weight of shipments go through consolidation centres and about 98% of suppliers ship at least one item through a consolidation centre. All this has been achieved without sacrificing the benefits of JIT.

Example of JIT Dell

Dells approach to JIT is different in that they leverage their suppliers to achieve the JIT goal. Dell is able to provide exceptionally short lead times to their customers, by forcing their suppliers to carry inventory instead of carrying it themselves They then demand short lead times on components so that products can be simply assembled by Dell quickly and then shipped to the customer. For the same Dell has Dependable suppliers with the ability to meet Dells demanding lead time requirements. A seamless system that allows Dell to transmit its component requirements so that they will arrive at Dell in time to fulfill its lead times. A willingness of suppliers to keep inventory on hand allowing Dell to be free of this responsibility.

Centralized purchase

Selective teams Extensive knowledge Cost factors and vendors are known Bulk purchase brings cost effectiveness Long term supply and supplier relationship Lack expertise and specialization of material which is done at local level

Joint decision making

Characteristic of the firm

Size of the firm (employees): As size increase, number of influencers increase as a large firm has specialized functional areas. Firms orientation (profits versus non profit): More influencers in non profit firms for safeguarding interests and accountability Maximum participation in new task buying

Buying centre interaction patters

Vertical involvement Lateral involvement Extensibility: Number of people involved Connectivity :communication about purchase

Purchase situation influence :Greater the complexity of the purchase, greater the vertical involvement, lateral involvement and extensibility. The more complex the written processes of the firm , more the lateral involvement and extensity and lesser connectivity

Psychological factors in individual decision making

Difference in role: purchase department looks at economy and engineers at quality Difference in information exposure Perceived risk in vendor selection

Risk management in purchases

Reduce uncertainty: visit plants and cross check Select the most reliable supplier Reduce the risk by multiple suppliers

Conflict resolution in Joint decision making

Competing (win loose): win ones own concern Lets do it my way Accommodating (loose-win): Satisfying other concerns I see your point of view Collaborating (win win) : fully satisfy both parties Maybe we can work this point out Avoiding: side stepping the issue I dont want to talk about it Compromising (loose loose) A agreement reached not satisfying either party Lest split the difference

Power in conflict resolution

Reward versus coercive power Legitimate power (position) Expert power

Buying committee (Decision making unit )

Used when purchasing is centralized Reseller market: Food seller form a committee Institution :have temporary buying committee Commercial market :engineers, procurement and account specialists

Evaluation of supplier performance

Categorical method: evaluation on subjective factors by committees Weighted point method: Weights to different factors and the composite performance index is developed

Factor Quality

Weight 40

Delivery

30

Actual performance 90% acceptable (90/100 =0.9) 90% on schedule

Performance score 0.9 * 40=36

0.9*30=27 Total composite score =63

Jagdish Sheth model

Das könnte Ihnen auch gefallen

- Consulting Interview Case Preparation: Frameworks and Practice CasesVon EverandConsulting Interview Case Preparation: Frameworks and Practice CasesNoch keine Bewertungen

- SCM Unit 2 NotesDokument24 SeitenSCM Unit 2 NotesNisha PradeepaNoch keine Bewertungen

- Procurement & Outsourcing StrategiesDokument60 SeitenProcurement & Outsourcing StrategiesMohit Gupta50% (2)

- Purchasing Lecture For SCM Class 1Dokument42 SeitenPurchasing Lecture For SCM Class 1aamirjewaniNoch keine Bewertungen

- Eng Man and Eco Lec 5Dokument51 SeitenEng Man and Eco Lec 5Zeeshan HaiderNoch keine Bewertungen

- 1-Thiết kế chuỗi cung ứng (xác định có những bên nào tham gia vào chuỗi cung ứng, nhiệm vụ của họ là gì) Producers Dokument8 Seiten1-Thiết kế chuỗi cung ứng (xác định có những bên nào tham gia vào chuỗi cung ứng, nhiệm vụ của họ là gì) Producers Trung TrinhNoch keine Bewertungen

- Table of Content: PurchasingDokument9 SeitenTable of Content: PurchasingLilCent MmanuelNoch keine Bewertungen

- Institute of Management Studies: Outsourcing and ProcurementDokument20 SeitenInstitute of Management Studies: Outsourcing and ProcurementMahath MohanNoch keine Bewertungen

- Global SourcingDokument7 SeitenGlobal SourcingMAGOMU DAN DAVIDNoch keine Bewertungen

- Case 7Dokument4 SeitenCase 7Viễn Nguyễn KýNoch keine Bewertungen

- What Is Make-Or-Buy Decision?: Sa VeDokument9 SeitenWhat Is Make-Or-Buy Decision?: Sa VepriyankabgNoch keine Bewertungen

- Quantity Purchase 22234Dokument7 SeitenQuantity Purchase 22234Mohammad FaizuNoch keine Bewertungen

- Purchasing and Vendor ManagementDokument53 SeitenPurchasing and Vendor Managementnarenmadhav100% (1)

- Supply Chain Management Includes The Supply, Storage, and Movement ofDokument13 SeitenSupply Chain Management Includes The Supply, Storage, and Movement ofAnisetty NareshNoch keine Bewertungen

- Characteristics of A Purchasing Manager: (1) Knowledge of Various MaterialsDokument5 SeitenCharacteristics of A Purchasing Manager: (1) Knowledge of Various MaterialsAnuj SinghNoch keine Bewertungen

- Purchasing and Materials Management PDFDokument210 SeitenPurchasing and Materials Management PDFShueab Mujawar100% (1)

- Chapter 4 CRM in B2B MarketsDokument6 SeitenChapter 4 CRM in B2B MarketsKrutika MishraNoch keine Bewertungen

- FinalAssignmentDokument5 SeitenFinalAssignmentAB BANoch keine Bewertungen

- Make or Buy Research MaterialsDokument22 SeitenMake or Buy Research MaterialsDr Nagaraju VeldeNoch keine Bewertungen

- Unit-V Sourcing, Transportation and Pricing ProductsDokument32 SeitenUnit-V Sourcing, Transportation and Pricing ProductsSachin KhotNoch keine Bewertungen

- Supply Chain ManagementDokument20 SeitenSupply Chain ManagementŞermin ŞahinNoch keine Bewertungen

- Analyzing Business MKT & Business Buying Behaviour - Tue - 05-Oct-10Dokument47 SeitenAnalyzing Business MKT & Business Buying Behaviour - Tue - 05-Oct-10Darshil DoshiNoch keine Bewertungen

- Purchasing MethodsDokument5 SeitenPurchasing MethodsAnil YellumahanthiNoch keine Bewertungen

- Purchasing and Material Management PDFDokument60 SeitenPurchasing and Material Management PDFAlfred Allotey PappoeNoch keine Bewertungen

- SCM Udemy NotesDokument6 SeitenSCM Udemy NotesPraphulNoch keine Bewertungen

- UNIT 4 NotesDokument20 SeitenUNIT 4 NotesTT GAMER VBKNoch keine Bewertungen

- Material Planning and BudgetingDokument4 SeitenMaterial Planning and Budgetinghpeter195798Noch keine Bewertungen

- CH-3 Materials MGMTDokument17 SeitenCH-3 Materials MGMTkitababekele26Noch keine Bewertungen

- Topic 8Dokument29 SeitenTopic 8Mohamed K MarahNoch keine Bewertungen

- Purchasing Organization and Sourcing StrategyDokument5 SeitenPurchasing Organization and Sourcing StrategyDayalNoch keine Bewertungen

- Chapter 5 PDFDokument13 SeitenChapter 5 PDFMuhammad Areeb100% (1)

- The Seven Keys To World-Class ManufacturingDokument8 SeitenThe Seven Keys To World-Class ManufacturingSherif El-SherifNoch keine Bewertungen

- Make-or-Buy Decisions: Printable Version Download PDF Cite This PageDokument3 SeitenMake-or-Buy Decisions: Printable Version Download PDF Cite This PagebhagyasaiNoch keine Bewertungen

- Economics of Strategy: The Vertical Boundaries of The FirmDokument49 SeitenEconomics of Strategy: The Vertical Boundaries of The FirmSatya WahyuNoch keine Bewertungen

- Chapter 11 Summary OMDokument5 SeitenChapter 11 Summary OMKarthik SaiNoch keine Bewertungen

- Full MCQ SCMDokument87 SeitenFull MCQ SCMFidas RoyNoch keine Bewertungen

- Make-or-Buy Decisions - Strategy, Levels, DefinitionDokument4 SeitenMake-or-Buy Decisions - Strategy, Levels, DefinitionLilac NachumNoch keine Bewertungen

- Business Mkts Buying ProcessDokument19 SeitenBusiness Mkts Buying ProcessHemanshu KoradiaNoch keine Bewertungen

- Wayhan SCM Study Guide Exam 1Dokument6 SeitenWayhan SCM Study Guide Exam 1adegroot13Noch keine Bewertungen

- Assignment On Contracting: by Jawed MussaratDokument17 SeitenAssignment On Contracting: by Jawed MussarattehamiNoch keine Bewertungen

- What Is Organisational BuyingDokument6 SeitenWhat Is Organisational BuyingusmanNoch keine Bewertungen

- 7 Keys To Facility LocationDokument5 Seiten7 Keys To Facility LocationKimberly HolcombNoch keine Bewertungen

- Strategy Towards Buyers and Suppliers 17.9.19Dokument22 SeitenStrategy Towards Buyers and Suppliers 17.9.19AARTI PAREWANoch keine Bewertungen

- Make-or-Buy DecisionsDokument3 SeitenMake-or-Buy Decisionsnisky80100% (2)

- Agenda: Supply Chain Management Corporate OutsourcingDokument85 SeitenAgenda: Supply Chain Management Corporate OutsourcingQamarNoch keine Bewertungen

- Sourcing Strategies Can Make or Break A BusinessDokument16 SeitenSourcing Strategies Can Make or Break A BusinessnikhilNoch keine Bewertungen

- Chapter Three Material Managemnet-1Dokument14 SeitenChapter Three Material Managemnet-1Abenezer YohannesNoch keine Bewertungen

- Sales Forecasting: Just in TimeDokument5 SeitenSales Forecasting: Just in TimeRitika AgrawalNoch keine Bewertungen

- RelevantCosts F07Dokument16 SeitenRelevantCosts F07aymanaym0% (1)

- Supply Chain ManagementDokument4 SeitenSupply Chain ManagementJiaur Rahman0% (2)

- Economics of Strategy: The Vertical Boundaries of The FirmDokument49 SeitenEconomics of Strategy: The Vertical Boundaries of The FirmVanessa HartonoNoch keine Bewertungen

- Management Special Edition - 27Dokument16 SeitenManagement Special Edition - 27Nguyễn Minh TrangNoch keine Bewertungen

- By Gaurav Goyal Assistant Professor, Lmtsom, TuDokument28 SeitenBy Gaurav Goyal Assistant Professor, Lmtsom, TuSachin MalhotraNoch keine Bewertungen

- Module 4 Sourcing DecisionsDokument35 SeitenModule 4 Sourcing DecisionsFARYAL -Noch keine Bewertungen

- Make or Buy Decision ThesisDokument4 SeitenMake or Buy Decision Thesisvictoriadillardpittsburgh100% (2)

- Procurement Challenges and Solutions - Fleet and Transport ManagementDokument22 SeitenProcurement Challenges and Solutions - Fleet and Transport Managementtonderai mangozheNoch keine Bewertungen

- Costing Theory ImpDokument57 SeitenCosting Theory ImpHilary GaureaNoch keine Bewertungen

- Service Delivery ModelDokument3 SeitenService Delivery Modelrajani mahapatraNoch keine Bewertungen

- Chapter 02Dokument21 SeitenChapter 02ndc6105058Noch keine Bewertungen

- Supply Chain Chapter No 2Dokument8 SeitenSupply Chain Chapter No 2Simra SalmanNoch keine Bewertungen

- 1.1 Need For The ProjectDokument33 Seiten1.1 Need For The ProjectSaptha RishiNoch keine Bewertungen

- Langley City Vision Recommendations and Implementation Report JULY 18 2018Dokument64 SeitenLangley City Vision Recommendations and Implementation Report JULY 18 2018Roxanne HooperNoch keine Bewertungen

- Titanic VocabularyDokument4 SeitenTitanic VocabularyJolesha BoulwareNoch keine Bewertungen

- 03 - Par A - BridgesDokument109 Seiten03 - Par A - BridgesDhrubajyoti DattaNoch keine Bewertungen

- Ackroyd The House of Doctor DeeDokument158 SeitenAckroyd The House of Doctor DeeSuleimaNoch keine Bewertungen

- The Lemonade Detectives Trouble On The TrailDokument71 SeitenThe Lemonade Detectives Trouble On The TrailLamichelle CortezNoch keine Bewertungen

- Tailift FD (G) 15 35 Artison Series Parts ManualDokument308 SeitenTailift FD (G) 15 35 Artison Series Parts ManualJose Pereira0% (1)

- Fiat SDokument27 SeitenFiat SAzizul AnwarNoch keine Bewertungen

- Vessels PDFDokument24 SeitenVessels PDFtoshugoNoch keine Bewertungen

- Final Rose Bowl EIRDokument688 SeitenFinal Rose Bowl EIRSouthern California Public RadioNoch keine Bewertungen

- Full Download Brock Biology of Microorganisms 15th Edition Madigan Test BankDokument35 SeitenFull Download Brock Biology of Microorganisms 15th Edition Madigan Test Bankbeizatikeorar100% (20)

- Engine Core Arr GPDokument3 SeitenEngine Core Arr GPERIC ERICNoch keine Bewertungen

- 2719 Student Manual PDFDokument19 Seiten2719 Student Manual PDFdhanysiregarNoch keine Bewertungen

- Airworthiness Directive: ATR ATR 42-500 AircraftDokument1 SeiteAirworthiness Directive: ATR ATR 42-500 AircraftlakshmimurugesanNoch keine Bewertungen

- Memo On Sticker System 2020Dokument1 SeiteMemo On Sticker System 2020Anonymous yisZNKXNoch keine Bewertungen

- 017-ITC-056 (1) Reinforced Concrete Works For BridgesDokument11 Seiten017-ITC-056 (1) Reinforced Concrete Works For BridgesJuan Morales0% (1)

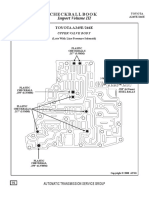

- Checkballbook: Import Volume IIIDokument10 SeitenCheckballbook: Import Volume IIIFS TRANSMISSÕESNoch keine Bewertungen

- CFD WaterjetDokument8 SeitenCFD WaterjettafocanNoch keine Bewertungen

- Rick Brant #23 Danger Below!Dokument188 SeitenRick Brant #23 Danger Below!PastPresentFuture100% (1)

- FO-003 Uncertainty Estimate - 1621923638Dokument2 SeitenFO-003 Uncertainty Estimate - 1621923638swapon kumar shillNoch keine Bewertungen

- Critical Appreciation of The Drainage Structure in C.M.C: Chapter - XiDokument57 SeitenCritical Appreciation of The Drainage Structure in C.M.C: Chapter - XiLucy OstaNoch keine Bewertungen

- Site Analysis PresentationDokument119 SeitenSite Analysis PresentationEvon LowNoch keine Bewertungen

- Fees Shipping InformationDokument15 SeitenFees Shipping InformationArdi UkaNoch keine Bewertungen

- Analisis Tingkat Ketepatan Waktu KRL Commuter LineDokument14 SeitenAnalisis Tingkat Ketepatan Waktu KRL Commuter LineRonaldo HutaurukNoch keine Bewertungen

- MMVDokument42 SeitenMMVHardik PatelNoch keine Bewertungen

- Tutorial 2 ConcreteDokument1 SeiteTutorial 2 ConcretepangkaiyunNoch keine Bewertungen

- PWD Schedule-Schedule of Rates of PWD (W.B) 2015 For Road Bridge Work (Vol-III) Wef 30.08.2018 PDFDokument367 SeitenPWD Schedule-Schedule of Rates of PWD (W.B) 2015 For Road Bridge Work (Vol-III) Wef 30.08.2018 PDFAlipurNoch keine Bewertungen

- BSEE Steel Catenary Riser Integrity Management ReportDokument26 SeitenBSEE Steel Catenary Riser Integrity Management ReportEyoma EtimNoch keine Bewertungen

- Logistic NotesDokument16 SeitenLogistic NotesFatima AliNoch keine Bewertungen

- Ece - Regulations List by TUVDokument1 SeiteEce - Regulations List by TUVDeepto BanerjeeNoch keine Bewertungen