Beruflich Dokumente

Kultur Dokumente

Final Inspection

Hochgeladen von

P. LakshmanakanthOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Final Inspection

Hochgeladen von

P. LakshmanakanthCopyright:

Verfügbare Formate

Final Inspection

Introduction

Final inspection consists of inspecting finished garments from the consumers point of view; size measurement; form fitting (putting garments on the proper-size mannequins to see if they properly fit the labeled sizes); and live modeling if necessary (again to see if the garments properly fit the labeled sizes).

Final inspection may occur before or after garments are packed in polybags and boxes. If it is done after garments are packed, then proper size and style markings on the package can also be checked. In any case, there should be a list of points to be checked in a garment, including a table of finished measurements. For example such a list is shown for mens dress shirts in the below table

Final Inspection - Quality Specifications for Mens Dress Shirts.

Location

1. Collar

Inspect for

Both points same length (+1/8 in.). Stripes, plaids, checks, or pattern should match on both points. Uniformly stitched, no puckering, skipped or broken stitches, or raw edges. Should lay flat. and Properly spaced, no puckering or fullness. Buttonholes properly sewed, no cut stitches. No broke buttons. Located so stripes, plaids, or patterns match (+1/8 in.). Top of the pocket horizontal. Uniformly stitched, no puckering, skipped or broken stitches, or raw edges. Corners securely tacked. Stripes, plaids, checks or patterns should match (+1/8 in.). Should lay flat Uniformly stitched, no puckering, skipped or broken stitches, or raw edges. Stitching 1/16 in. from edge. Pleats (if any) properly placed. Uniformly stitched, no puckering, skipped or broken stitches, or raw edges. Should lay flat. Stripes, plaids, checks, or patterns should match (+1/8 in.). Uniformly stitched, no puckering, skipped or broken stitches, or raw edges.

1. 1.

Buttons Buttonholes Pocket

1. 1.

Hems Yoke and Shoulder

1.

Side Seams

1.

1.

Cuff

Finished appearance

Stripes, Plaids, checks or patterns should match the sleeve (+1/8 in.). Uniformly stitched, no puckering, skipped or broken stitches, or raw edges.

Clean of all loose thread. No oil/dirt stains. Free of any fabric defect. No shade difference within a shirt from part to part (panel to panel).

Measurements for mens L/S dress shirts.

Some possible defects in garments with diagrams

Left side is off grain to the seam

Poor Stitching : Loops pulled to one side

Poor Collar: Collar is not smooth and there are tucks where the collar and lapels join together.

Zipper is unattractive because facing does not cover it completely

Zipper is unattractive because facing does not cover it completely

Armhole seam is unattractive because gathers caught in seam

Hem is unattractive because gathers and stitching show on the outside

Unattractive seam because of puckering

Pocket opening is too loose

Material is caught in armhole seam

Opening is uneven at the bottom

Top button hole is too large for the button

Control of proper size is extremely important because no matter how well a garment is made, unless it fits properly, it will be useless from a customers point of view. Control of garment dimensions will not guarantee that the garments will fit right, look right, and feel right. Fit is dependent on pattern shape, proportion, and dimension as well as proper grain. Poor cutting and inaccurate sewing can result in poor or not fit at all.

Checking garment for size, appearance, fit drape, and so on by putting them on appropriate mannequins is called form fitting, whereas the checking those items by having someone try them on is called live modeling. Form fitting and live modeling will contribute significantly toward assuring that the garments in question fit right, look right, and feel right for their intended sizes.

Das könnte Ihnen auch gefallen

- Spreading and Cutting of Apparel ProductsDokument43 SeitenSpreading and Cutting of Apparel ProductsDaniela JakimovaNoch keine Bewertungen

- What Is The Best Final Inspection ProcedureDokument2 SeitenWhat Is The Best Final Inspection ProcedureSayed Aasim JawaidNoch keine Bewertungen

- Naisargi SCAP End TermDokument11 SeitenNaisargi SCAP End TermNaisargiNoch keine Bewertungen

- Qualitysystemsforgarment 131231022007 Phpapp01Dokument52 SeitenQualitysystemsforgarment 131231022007 Phpapp01tristinalinh100% (1)

- QMS - F.02 Fabric Inspection Training ModuleDokument22 SeitenQMS - F.02 Fabric Inspection Training ModuleDebashishDolonNoch keine Bewertungen

- TrainingDokument29 SeitenTrainingNavodita Singh100% (1)

- Fabrics Faults or DefectsDokument13 SeitenFabrics Faults or DefectsGopal KrishnanNoch keine Bewertungen

- Cutting SOPDokument8 SeitenCutting SOParvindtiwari21Noch keine Bewertungen

- Spreading and Cutting - Material PDFDokument27 SeitenSpreading and Cutting - Material PDFSowmya50% (4)

- Fabric Inspection ProcedureDokument6 SeitenFabric Inspection ProcedureMayan DynastyNoch keine Bewertungen

- QCM - Quality Control in Garments Industry by SatexDokument21 SeitenQCM - Quality Control in Garments Industry by Satexsatex100% (1)

- An Overview of QualityDokument18 SeitenAn Overview of QualityIndika DissanayakeNoch keine Bewertungen

- Sampling ProcessDokument9 SeitenSampling ProcessSauumye ChauhanNoch keine Bewertungen

- Fabric InspectionDokument20 SeitenFabric InspectionHarrison Kan100% (1)

- Fabric Finishing:: Finishing Faults/Defects - Different Types of Textile Finishing Faults/Defects With Their CausesDokument31 SeitenFabric Finishing:: Finishing Faults/Defects - Different Types of Textile Finishing Faults/Defects With Their CausesGemeda GebinoNoch keine Bewertungen

- Uaq Assignment 2Dokument10 SeitenUaq Assignment 2YashNoch keine Bewertungen

- Global URBN Fabric and Apparel Testing Manual 2.25.2019Dokument81 SeitenGlobal URBN Fabric and Apparel Testing Manual 2.25.2019THYAGUNoch keine Bewertungen

- Fabric InspectionDokument7 SeitenFabric InspectionAbhijeet Kumar100% (1)

- Understanding Apparel Quality: Topic - Inspection of A GarmentDokument32 SeitenUnderstanding Apparel Quality: Topic - Inspection of A GarmentMard Geer100% (1)

- Sample Section:It Is The First Section Of: Garment Manufacturing ProcessDokument6 SeitenSample Section:It Is The First Section Of: Garment Manufacturing ProcesssantumysoreNoch keine Bewertungen

- Fabric Defect Reading MaterialDokument6 SeitenFabric Defect Reading MaterialAnoop Singh100% (1)

- Defects in GarmentsDokument2 SeitenDefects in GarmentsAbul HasanNoch keine Bewertungen

- Apparel Quality Management: Assignment Ii Total Quality Management Practices in Opex Group, BangladeshDokument11 SeitenApparel Quality Management: Assignment Ii Total Quality Management Practices in Opex Group, BangladeshShivani JayanthNoch keine Bewertungen

- Fabric InspectionDokument7 SeitenFabric Inspectionmamun_ipekuet100% (1)

- Fabric DefectsDokument30 SeitenFabric Defectsaparna_ftNoch keine Bewertungen

- Department of Fashion TechnologyDokument22 SeitenDepartment of Fashion TechnologyAbhishek YadavNoch keine Bewertungen

- KQATEX1 Apparel Textile Requirements 150310Dokument17 SeitenKQATEX1 Apparel Textile Requirements 150310Ammar Maqsood100% (1)

- Snap & Popper Att ProcessDokument25 SeitenSnap & Popper Att ProcessprashantmithareNoch keine Bewertungen

- Sample ActivityDokument5 SeitenSample ActivityHasan TarekNoch keine Bewertungen

- Assignment On An Overview of Quality and Quality Control in Textile IndustryDokument9 SeitenAssignment On An Overview of Quality and Quality Control in Textile IndustryZAyedNoch keine Bewertungen

- Defects in GarmentsDokument11 SeitenDefects in GarmentsChodathKulangareth BhagavathiTempleNoch keine Bewertungen

- Sample Room DepartmentDokument5 SeitenSample Room DepartmentRajib DasNoch keine Bewertungen

- Industrial EngineeringDokument32 SeitenIndustrial Engineeringpradeep_vsp1077100% (1)

- F-02 Fabric Inspection ManualDokument13 SeitenF-02 Fabric Inspection Manualzoomerfins22100% (1)

- Process Flow Chart of Banswara Garment Kadaiya Unit AvinashDokument23 SeitenProcess Flow Chart of Banswara Garment Kadaiya Unit AvinashakashNoch keine Bewertungen

- Defects in GarmentsDokument16 SeitenDefects in GarmentsarivaazhiNoch keine Bewertungen

- Faults in The Knitted FabricsDokument11 SeitenFaults in The Knitted FabricsShwetaLoonkarPitliya100% (2)

- Cutting SOPDokument4 SeitenCutting SOPSayed Aasim Jawaid100% (1)

- Processed Fabric InspectionDokument5 SeitenProcessed Fabric InspectionTamrat TesfayeNoch keine Bewertungen

- Quality Control of Garments Cutting SectionDokument6 SeitenQuality Control of Garments Cutting SectionarifulseuNoch keine Bewertungen

- Fabric RelaxationDokument2 SeitenFabric RelaxationNahid50% (4)

- QCM - Quality Control in Garments IndustryDokument21 SeitenQCM - Quality Control in Garments IndustrysatexNoch keine Bewertungen

- SM QA ChildrenswearDokument58 SeitenSM QA Childrenswearnaveenerotex100% (1)

- Garment Defect AnalysisDokument21 SeitenGarment Defect AnalysisIndranil Saha100% (10)

- Production Planning and Control in GarmentsDokument2 SeitenProduction Planning and Control in Garmentskbalabala100% (1)

- SpreadingDokument39 SeitenSpreadingPratik MinjNoch keine Bewertungen

- Sampling and Sampling Process: Presented BYDokument16 SeitenSampling and Sampling Process: Presented BYGaurav SinghNoch keine Bewertungen

- Basic Technical SOP For Cutting SectionDokument8 SeitenBasic Technical SOP For Cutting SectionMonower MithuNoch keine Bewertungen

- Fabric Inspection Under 4Dokument5 SeitenFabric Inspection Under 4texcons677150% (2)

- Flow Process in Garment IndustryDokument5 SeitenFlow Process in Garment IndustryMeeta AroraNoch keine Bewertungen

- Garments Working ProcessDokument10 SeitenGarments Working ProcessAbu UmarNoch keine Bewertungen

- WASH & GARMENT DYE SOP Denim & CasualDokument17 SeitenWASH & GARMENT DYE SOP Denim & CasualTwaha M&S100% (1)

- Fabric Inspection Using 4point SystemDokument6 SeitenFabric Inspection Using 4point Systemramf2000lkNoch keine Bewertungen

- Carr and Latham's Technology of Clothing ManufactureVon EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerBewertung: 4 von 5 Sternen4/5 (1)

- Detailed Sewing GuideDokument11 SeitenDetailed Sewing GuideterriNoch keine Bewertungen

- Gene RL Guidelines ClothingDokument3 SeitenGene RL Guidelines ClothingTran AnhdaoNoch keine Bewertungen

- Characteristics of Well Finished GarmentsDokument8 SeitenCharacteristics of Well Finished GarmentsAnonymous UoRu4sNoch keine Bewertungen

- Garment FittingDokument13 SeitenGarment FittingImran AslamNoch keine Bewertungen

- Pantalón de Pijama Pantalon Mono Patron Gratis Instrucciones Costura Simplicity 0501 PATTERNDokument6 SeitenPantalón de Pijama Pantalon Mono Patron Gratis Instrucciones Costura Simplicity 0501 PATTERNarnaldo_rivera_24Noch keine Bewertungen

- Principles of FittingDokument7 SeitenPrinciples of FittingOmer Farooq100% (4)

- Guidelines For Quality Assurance SystemDokument20 SeitenGuidelines For Quality Assurance SystemP. LakshmanakanthNoch keine Bewertungen

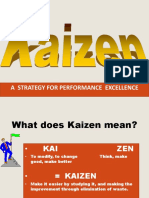

- KaizenDokument50 SeitenKaizenP. Lakshmanakanth100% (2)

- Stitch ClassesDokument47 SeitenStitch ClassesP. Lakshmanakanth97% (37)

- ISO - IntroductionDokument15 SeitenISO - IntroductionP. LakshmanakanthNoch keine Bewertungen

- Properties of Textile Fibres - EOTDokument11 SeitenProperties of Textile Fibres - EOTP. LakshmanakanthNoch keine Bewertungen

- Seam Classes: Superimposed SeamsDokument15 SeitenSeam Classes: Superimposed SeamsP. Lakshmanakanth50% (4)

- Sewing Machine Needles: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDokument38 SeitenSewing Machine Needles: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. Lakshmanakanth100% (5)

- Pile Fabrics - FsDokument20 SeitenPile Fabrics - FsP. Lakshmanakanth100% (1)

- Seam Classes: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDokument12 SeitenSeam Classes: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. Lakshmanakanth100% (2)

- SEAM CLASSES - Flat Seams and Stitching ClassesDokument13 SeitenSEAM CLASSES - Flat Seams and Stitching ClassesP. LakshmanakanthNoch keine Bewertungen

- Introduction To TEXTILES - Fibres, Classification, Properties and IdentificationDokument66 SeitenIntroduction To TEXTILES - Fibres, Classification, Properties and IdentificationP. Lakshmanakanth100% (11)

- Silk - Diff Types of Silk Fabrics and Its BehaviorDokument53 SeitenSilk - Diff Types of Silk Fabrics and Its BehaviorP. LakshmanakanthNoch keine Bewertungen

- Sewing Machine Beds: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDokument9 SeitenSewing Machine Beds: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. Lakshmanakanth100% (1)

- Lace & Net: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDokument17 SeitenLace & Net: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. LakshmanakanthNoch keine Bewertungen

- Seam Classes - Bound SeamsDokument21 SeitenSeam Classes - Bound SeamsP. Lakshmanakanth100% (3)

- Fabric Studies - 1st SetDokument30 SeitenFabric Studies - 1st SetP. Lakshmanakanth100% (1)

- Wool - Diff Types of Wool Fabrics and Its BehaviorDokument76 SeitenWool - Diff Types of Wool Fabrics and Its BehaviorP. Lakshmanakanth100% (2)

- Lapped Seams: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDokument10 SeitenLapped Seams: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. Lakshmanakanth100% (1)

- Knits: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDokument23 SeitenKnits: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. LakshmanakanthNoch keine Bewertungen

- Fabric Studies - 2nd SetDokument32 SeitenFabric Studies - 2nd SetP. Lakshmanakanth100% (3)

- Cotton - Diff Types of Cotton Fabrics and Its BehaviorDokument58 SeitenCotton - Diff Types of Cotton Fabrics and Its BehaviorP. Lakshmanakanth100% (2)

- Introduction To FabricsDokument10 SeitenIntroduction To FabricsP. LakshmanakanthNoch keine Bewertungen

- Procedures Practiced For Quality Control and Assurance in FusingDokument18 SeitenProcedures Practiced For Quality Control and Assurance in FusingP. Lakshmanakanth100% (1)

- Raw MTL - InspectionDokument23 SeitenRaw MTL - InspectionP. Lakshmanakanth100% (1)

- Textile Yarns: Prepared by P.Lakshmana Kanth Senior Faculty - IFTKDokument52 SeitenTextile Yarns: Prepared by P.Lakshmana Kanth Senior Faculty - IFTKP. Lakshmanakanth100% (1)

- Quality Standards and Quality GradeDokument44 SeitenQuality Standards and Quality GradeP. Lakshmanakanth100% (2)

- Introduction To Quality: Apparel Standards, Specifications and Quality ControlDokument7 SeitenIntroduction To Quality: Apparel Standards, Specifications and Quality ControlP. LakshmanakanthNoch keine Bewertungen

- Product Zones: Zoning Defects and AppearanceDokument24 SeitenProduct Zones: Zoning Defects and AppearanceP. LakshmanakanthNoch keine Bewertungen

- Quality SpecificationDokument26 SeitenQuality SpecificationP. Lakshmanakanth100% (3)

- Introduction - Quality & Its DefinitionsDokument27 SeitenIntroduction - Quality & Its DefinitionsP. LakshmanakanthNoch keine Bewertungen

- Helia Bebek PDFDokument23 SeitenHelia Bebek PDFAngela V100% (6)

- Health and Beauty Specialist Retailers in Peru AnalysisDokument2 SeitenHealth and Beauty Specialist Retailers in Peru AnalysisOctavio ChonNoch keine Bewertungen

- Innosept Asbofill ASR 01Dokument2 SeitenInnosept Asbofill ASR 01Freddy SalinasNoch keine Bewertungen

- Test Engleza Clasa 1Dokument3 SeitenTest Engleza Clasa 1Miruna TarabegaNoch keine Bewertungen

- SzczesuilDokument24 SeitenSzczesuilRahul AwaghadeNoch keine Bewertungen

- English 2 (Perak's PMR Trial 2012)Dokument4 SeitenEnglish 2 (Perak's PMR Trial 2012)Shi Ying SeowNoch keine Bewertungen

- PPEs StandardsDokument3 SeitenPPEs Standardstpchowo100% (1)

- How To Make A SIMS PlumbobDokument5 SeitenHow To Make A SIMS PlumbobShelby GohNoch keine Bewertungen

- Free Knitting Pattern Lion Brand Vanna's Choice Hooded Vest: Pattern Number: L0009ADDokument8 SeitenFree Knitting Pattern Lion Brand Vanna's Choice Hooded Vest: Pattern Number: L0009ADknova100% (1)

- Marketing Strategy of StarbucksDokument57 SeitenMarketing Strategy of Starbucksdan_obd726100% (2)

- Daftar Barang Cussons NurjayaDokument3 SeitenDaftar Barang Cussons NurjayabadriNoch keine Bewertungen

- Welcome To My PresentationDokument53 SeitenWelcome To My PresentationDipayon SahaNoch keine Bewertungen

- Tugas 3 BHS InggrisDokument4 SeitenTugas 3 BHS Inggriskarman nelitiNoch keine Bewertungen

- Fabrics-store-Chelsea - Linen Raglan Tee Pattern-1Dokument26 SeitenFabrics-store-Chelsea - Linen Raglan Tee Pattern-1Marina ASNoch keine Bewertungen

- Pizza Recipe: Cooked Pizza SauceDokument14 SeitenPizza Recipe: Cooked Pizza Saucerana1184Noch keine Bewertungen

- Supply Chain Management in Canadian Tire: Jie Wang, Ph.D. PMP, (P.E.)Dokument66 SeitenSupply Chain Management in Canadian Tire: Jie Wang, Ph.D. PMP, (P.E.)Rocking Heartbroker DebNoch keine Bewertungen

- Homes and EstatesDokument212 SeitenHomes and EstatesCharles NedderNoch keine Bewertungen

- Participants Catalogue For Nurnberg Toy Fair 2013Dokument32 SeitenParticipants Catalogue For Nurnberg Toy Fair 2013Smita Sawant BholeNoch keine Bewertungen

- Bigbang Sardines CompanyDokument4 SeitenBigbang Sardines CompanyDiana Mae Dabu100% (1)

- An Analysis of Global Supply Chain Management - Indian PerspectiveDokument58 SeitenAn Analysis of Global Supply Chain Management - Indian PerspectiveujwaljaiswalNoch keine Bewertungen

- Mkt101 ReportDokument22 SeitenMkt101 ReportDheena Zaeem100% (1)

- Harmonica JacketDokument59 SeitenHarmonica JacketLucía BenitoNoch keine Bewertungen

- Market Survey On Branded Furnitures (Spacewood)Dokument21 SeitenMarket Survey On Branded Furnitures (Spacewood)dacchuNoch keine Bewertungen

- Knit Prod Dev ProjectDokument67 SeitenKnit Prod Dev Projectshuvo792Noch keine Bewertungen

- Reasons of Failure of Candia Milk in PakistanDokument3 SeitenReasons of Failure of Candia Milk in PakistanMuneeb Sikander100% (8)

- Philippine KakaninDokument3 SeitenPhilippine KakaninmixprintNoch keine Bewertungen

- Course 224 - 2Dokument59 SeitenCourse 224 - 2Mardiyya SuleimanNoch keine Bewertungen

- Spreading ModeDokument8 SeitenSpreading ModeTom KattoorNoch keine Bewertungen

- Ctid 314 Lesson IDokument16 SeitenCtid 314 Lesson IMary CitizenNoch keine Bewertungen

- Special Types of MilkDokument31 SeitenSpecial Types of MilkPallavi100% (1)