Beruflich Dokumente

Kultur Dokumente

Rich Gas Case: V Const, L Const

Hochgeladen von

Muhammad Haris HamayunOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rich Gas Case: V Const, L Const

Hochgeladen von

Muhammad Haris HamayunCopyright:

Verfügbare Formate

Absorption in packed towers: Rich gases case

Rich gas case: Vconst, Lconst

Consider an absorption column;

Consider a mass transfer process in a section of

the column dZ (cross-section of the column is S)

L

a

,x

a

V

a

,y

a

V

b

,y

b

L

b

,x

b

Z

dZ

SdZ y y a K

y

Vdy

dN

y A

*) (

1

*

=

=

S

Absorption in packed towers: Rich gases case

y x y

k

y

k

m

K

) 1 ( 1

*

+ =

i

i

y

y

y y

y

=

1

1

ln

] 1 [ ] 1 [

1

Rich gas case: Vconst, Lconst

L

a

,x

a

V

a

,y

a

V

b

,y

b

L

b

,x

b

Z

S

}

=

b

a

y

y

y

a K y y y

Vdy

S

Z

*

*) )( 1 (

1

Absorption in packed towers: Rich gases case

Example:

McCabe, Smith, Harriott: Chapter 18

Seader Hanley: Chapter 6

Absorption in packed towers: Rich gases case

Prescriptive design process

1) Establish equilibrium relation y*=mx

Absorption in packed towers: Rich gases case

Prescriptive design process

1) Establish equilibrium relation y*=mx

2) Operating line. In case of rich gases both V and L change and

it is more convenient to work in terms of pure carrier

gas V and pure solvent stream L

) 1 ( ' x L L =

) 1 ( ' y V V =

Absorption in packed towers: Rich gases case

Prescriptive design process

1) Establish equilibrium relation y*=mx

2) Operating line. In case of rich gases both V and L change and

it is more convenient to work in terms of pure carrier

gas V and pure solvent stream L

plot y vs x

|

|

.

|

\

|

=

|

|

.

|

\

|

y

y

y

y

V

x

x

x

x

L

b

b

b

b

1 1

'

1 1

'

Absorption in packed towers: Rich gases case

y

x

(mole fraction of A in L)

(mole fraction of A in V)

x

a

x

b

y

y

b

equilibrium line

x*

b

3) For several values of y on

the operating line find:

y*

y 1

* y

* 1 y

Absorption in packed towers: Rich gases case

y

x

(mole fraction of A in L)

(mole fraction of A in V)

x

a

x

b

y

y

b

equilibrium line

x*

b

3) For several values of y on

the operating line find:

y*

| |

| | a k

a k

x x

y y

y

x

i

i

=

i

y

i

i

y

y

y y

y

=

1

1

ln

] 1 [ ] 1 [

1

i

y

a k

y

a k

m

a K

y x y

) 1 ( 1

*

+ =

Absorption in packed towers: Rich gases case

3) Continued:

4) Find the term:

) 1 (

'

y

V

V

=

a K y y y

V

y

*

*) )( 1 (

Absorption in packed towers: Rich gases case

5) Integrate

A

=

a K y y y

y V

S

Z

y

*

*) )( 1 (

1

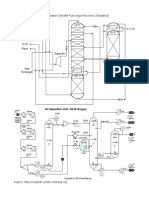

Absorption in packed towers:

Seader, Hanley

P A

GV log

dry

Loading point

Flooding point

Design considerations: Pressure drop and flooding

G mass flow per unit area (GV-gas, GL-liquid)

Liquid inlet

Liquid outlet Gas inlet

Gas outlet

Some flooding description

A visual build-up of liquid on the upper

surface of the packed bed

A rapid increase in liquid hold-up with

increasing gas rate

Formation of a continuous liquid phase above

the packing support plate

A considerable entrainment of liquid in

the outlet vapour

Filling of the voids in the packed bed with liquid

Design considerations: Pressure drop and flooding

(McCabe, Smith, Harriott)

Design considerations: Pressure drop and flooding

GV

GL

Pressure drop analysis: Eckert graph

) (

1 . 0 2

V L V

p

v F GV C

Pressure drop in

inH2O/ft of packing

(brackets: mm H20/

m of packing)

Flooding line

Design considerations: Diameter of packed towers

L/V=GL/GV

Design considerations: Diameter of packed towers

Sinnott

McCabe, Smith

Harriott

* Moderate to high pressure distillation =

0.4 to 0.75 in water / ft packing

= 32 to 63 mm water / m packing

* Vacuum Distillation =

0.1 to 0.2 in water / ft packing

= 8 to 16 mm water / m packing

* Absorbers and Strippers =

0.2 to 0.6 in water / ft packing

= 16 to 48 mm water / m packing

Design considerations: Diameter of packed towers

Given L, V (mass flow rates) Select pressure drop

) (

) (

1 . 0 2

V L V

p

v F GV C

select packing GV D

Design considerations: Diameter of packed towers

Given L, V (mass flow rates)

) (

) (

1 . 0 2

V L V

p

v F GV C

GV=GV(flooding)/2 D

at flooding velocity

Example of using pressure drop correlations to estimate

geometrical parameters of the packed column

Specify the packing type and column dimensions for a column that will be

used to remove chlorine from a gas stream using an organic solvent.

The vapor flow is 7000 kg/h, the average vapor density is 4.2 kg/m3.

The liquid flow is 5000 kg/h, the average liquid density is 833 kg/m3.

The liquid's kinematic viscosity is 0.48 centistokes (4.8 x 10-7 m2/s)

Design considerations: Diameter of packed towers

First, we evaluate the x-axis of the graph above:

(L/V)(vapor density/liquid density)

0.5

= (5000/7000)(4.2/833)

0.5

= 0.0507

5 . 1

) (

1 . 0 2

=

V L V

p

v F GV C

* Moderate to high pressure distillation =

0.4 to 0.75 in water / ft packing

= 32 to 63 mm water / m packing

* Vacuum Distillation =

0.1 to 0.2 in water / ft packing

= 8 to 16 mm water / m packing

* Absorbers and Strippers =

0.2 to 0.6 in water / ft packing

= 16 to 48 mm water / m packing

Design considerations: Diameter of packed towers

5 . 1

) (

1 . 0 2

=

V L V

p

v F GV C

F

p

packing factor,

accounts for structure of

packing and decreases

with increasing void fraction

F

p

=24 for 2 inch Pall

rings

Design considerations: Diameter of packed towers

Correlations for HTU

L G OG

H

L

mV

H H + =

Sinnott

Correlations for HTU

Cornell

Correlations for HTU

Cornell

Sinnott

Sinnott

Correlations for HTU

Correlations for HTU

Correlations for HTU

Design of packed towers

1) Calculate NTU

distillation/

absorption from dilute gas

}

b

a

y

y

y y

dy

*

y

y y

a b

A

~

absorption from rich gas

}

b

a

y

y

y y y

dy y

*) )( 1 (

) 1 (

2) Select packing: defines size, packing factor Fp, specific surface area, void

fraction etc

Design of packed towers

3) Pressure drop, diameter of the column

4) HTU from Cornell, or Onda methods

5)

D

OG OG

N H Z =

At this stage, height, diameter of the column and

the type of packing is known

Das könnte Ihnen auch gefallen

- Design of Packed Columns For Absorption and Distillation Processes - Prelecture SlidsDokument100 SeitenDesign of Packed Columns For Absorption and Distillation Processes - Prelecture SlidsHeat.Motion100% (9)

- Ch5 AbsorptionDokument56 SeitenCh5 AbsorptionGebrekiros ArayaNoch keine Bewertungen

- 8 Absorber DesignDokument16 Seiten8 Absorber DesignilhamriswandaaNoch keine Bewertungen

- ERT 313 Bioseparation Engineering Gas Absorption: Prepared By: Pn. Hairul Nazirah Abdul HalimDokument57 SeitenERT 313 Bioseparation Engineering Gas Absorption: Prepared By: Pn. Hairul Nazirah Abdul HalimVenkateswara RamakrishnanNoch keine Bewertungen

- Southern Marine Engineering Desk Reference: Second Edition Volume IVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INoch keine Bewertungen

- Remove Volatile Compounds with Air Stripping TowersDokument31 SeitenRemove Volatile Compounds with Air Stripping TowersSivamani SelvarajuNoch keine Bewertungen

- Gas Absorption in Packed Tower (S1 2015) (Note)Dokument51 SeitenGas Absorption in Packed Tower (S1 2015) (Note)venkieeNoch keine Bewertungen

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsVon EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsNoch keine Bewertungen

- BallastDokument7 SeitenBallastDian ArinaNoch keine Bewertungen

- AbsorberDokument22 SeitenAbsorberNAGARAJAN A R [CB.EN.U4CHE17035]Noch keine Bewertungen

- Hypoelliptic Laplacian and Orbital Integrals (AM-177)Von EverandHypoelliptic Laplacian and Orbital Integrals (AM-177)Noch keine Bewertungen

- Activated Sludge - Types of Processes and Modifications: 1 ConventionalDokument33 SeitenActivated Sludge - Types of Processes and Modifications: 1 ConventionalJon Bisu DebnathNoch keine Bewertungen

- C*-Algebra Extensions and K-Homology. (AM-95), Volume 95Von EverandC*-Algebra Extensions and K-Homology. (AM-95), Volume 95Noch keine Bewertungen

- Lab Manual of Hydraulics PDFDokument40 SeitenLab Manual of Hydraulics PDFJULIUS CESAR G. CADAONoch keine Bewertungen

- Dictionary of Water and Waste ManagementVon EverandDictionary of Water and Waste ManagementBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Design of Packed Column 3q Sy2010 11Dokument65 SeitenDesign of Packed Column 3q Sy2010 11abderrahimnNoch keine Bewertungen

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportVon EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNoch keine Bewertungen

- Absorber Design Process PDFDokument16 SeitenAbsorber Design Process PDFhortalemosNoch keine Bewertungen

- Advanced Flow AssuranceDokument123 SeitenAdvanced Flow AssuranceThành Bk100% (5)

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsVon EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNoch keine Bewertungen

- Rate-Base Method For Packed Columns: Capacity Limitations of Trayed TowersDokument34 SeitenRate-Base Method For Packed Columns: Capacity Limitations of Trayed Towersscribdtroll1Noch keine Bewertungen

- Bab I Pendahuluan: Tower Yang Dilengkapi Dengan Pemasukan Gas Dan Ruang Didistribusikan PadaDokument11 SeitenBab I Pendahuluan: Tower Yang Dilengkapi Dengan Pemasukan Gas Dan Ruang Didistribusikan PadaNia Adha RyantieNoch keine Bewertungen

- Chapter 5 - Absorption (Part 1)Dokument41 SeitenChapter 5 - Absorption (Part 1)La Casa JordanNoch keine Bewertungen

- Flow of Water by Notch and WeirsDokument15 SeitenFlow of Water by Notch and WeirsCik Tiem Ngagiman93% (29)

- Designing a Horizontal Reflux DrumDokument15 SeitenDesigning a Horizontal Reflux DrumArfel Marie FuentesNoch keine Bewertungen

- Gas AbsorptionDokument17 SeitenGas AbsorptionRhea MambaNoch keine Bewertungen

- Air Stripping Design ReportDokument17 SeitenAir Stripping Design ReportShawn MauldinNoch keine Bewertungen

- 2a - Packed ColumnsDokument55 Seiten2a - Packed ColumnsDoaa Badarneh100% (1)

- Bollard Pull CalculationsDokument7 SeitenBollard Pull CalculationsᎮᏂᎩᏗᎥ ᏇᏗᎥ ᏗᏬᏁᎶ75% (4)

- Design of Packed Column (3q Sy2010-11)Dokument65 SeitenDesign of Packed Column (3q Sy2010-11)Lin Xian XingNoch keine Bewertungen

- Ch8 Steady Incompressible Flow in Pressure Conduits (PartB)Dokument66 SeitenCh8 Steady Incompressible Flow in Pressure Conduits (PartB)avinash_friends21Noch keine Bewertungen

- Viscous Flow in Pipes: OverviewDokument40 SeitenViscous Flow in Pipes: OverviewPaulo BuenoNoch keine Bewertungen

- 4 Absorption PDFDokument36 Seiten4 Absorption PDFHoongNoch keine Bewertungen

- Orifice Plate Long ReportDokument16 SeitenOrifice Plate Long ReportLuqman HakimNoch keine Bewertungen

- Che 4009 Transport Phenomena Assignment # 1Dokument7 SeitenChe 4009 Transport Phenomena Assignment # 1Bao-Ngoc HoangNoch keine Bewertungen

- Procedure For Pipe Rack Load CalculationDokument25 SeitenProcedure For Pipe Rack Load CalculationSharun Suresh100% (6)

- Experiment 8Dokument9 SeitenExperiment 8Nor FhairnaNoch keine Bewertungen

- Flow Ovr WeirDokument9 SeitenFlow Ovr WeirniasandiwaraNoch keine Bewertungen

- Sep Era Tors SystemDokument14 SeitenSep Era Tors SystemJack KirujaNoch keine Bewertungen

- Pergamon: Chemical Engineering Science, Vol. 51, No. 10, Pp. 1725-1734, 1996Dokument10 SeitenPergamon: Chemical Engineering Science, Vol. 51, No. 10, Pp. 1725-1734, 1996gconstantinoNoch keine Bewertungen

- Design of Strippe1Dokument10 SeitenDesign of Strippe1Iqra MaqsoodNoch keine Bewertungen

- Convection SummaryDokument10 SeitenConvection SummarycacafaruqNoch keine Bewertungen

- Hydraulic Fracturing DesignDokument49 SeitenHydraulic Fracturing Designcrown21260% (5)

- Fluid Mechanics: University of LeedsDokument16 SeitenFluid Mechanics: University of LeedsHasitha MadusankaNoch keine Bewertungen

- Chap3-2e SO2 Absorption ExampleDokument8 SeitenChap3-2e SO2 Absorption Exampledarkelf_riderNoch keine Bewertungen

- Calculation and Design of Packed Column For AcidDokument14 SeitenCalculation and Design of Packed Column For AcidDavid LambertNoch keine Bewertungen

- ملخص انتاج م 3 هندسة نفطDokument31 Seitenملخص انتاج م 3 هندسة نفطlwrsaghqNoch keine Bewertungen

- Flow of Water by Notch and WeirsDokument15 SeitenFlow of Water by Notch and WeirsAngelica Joyce BenitoNoch keine Bewertungen

- Pipeline Systems: Monroe L. Weber-Shirk S Civil Environmental EngineeringDokument29 SeitenPipeline Systems: Monroe L. Weber-Shirk S Civil Environmental EngineeringLai YenNoch keine Bewertungen

- Packed Column Design GuideDokument64 SeitenPacked Column Design GuideChelsea Martinez100% (1)

- The Nhut SP2 Major ReportDokument16 SeitenThe Nhut SP2 Major ReportNhut NguyenNoch keine Bewertungen

- Absorption Tray TowersDokument28 SeitenAbsorption Tray Towerstalhawasim100% (1)

- Design of LPG Refigeration System: 1. Copper TubesDokument20 SeitenDesign of LPG Refigeration System: 1. Copper TubesJeevan Landge PatilNoch keine Bewertungen

- Zhao PeiDokument153 SeitenZhao PeiMuhammad Haris HamayunNoch keine Bewertungen

- CScasebook ASUDokument3 SeitenCScasebook ASUsvnaik14Noch keine Bewertungen

- Post Graduate Academic Calendar (2019-2020) : Fall SemesterDokument29 SeitenPost Graduate Academic Calendar (2019-2020) : Fall Semestermaryamsaleem430Noch keine Bewertungen

- Research Article Related To Advanced ExergyDokument13 SeitenResearch Article Related To Advanced ExergyMuhammad Haris HamayunNoch keine Bewertungen

- Single ColumnDokument12 SeitenSingle ColumnMuhammad Haris HamayunNoch keine Bewertungen

- Australia DataDokument9 SeitenAustralia DataMuhammad Haris HamayunNoch keine Bewertungen

- Carbon-Hydride Energy Storage System: Hajime Emori Toru KawamuraDokument6 SeitenCarbon-Hydride Energy Storage System: Hajime Emori Toru KawamuraMuhammad Haris HamayunNoch keine Bewertungen

- Relative Gain Array Calculator: Size of Matrix 1Dokument3 SeitenRelative Gain Array Calculator: Size of Matrix 1Muhammad Haris HamayunNoch keine Bewertungen

- Retrofit Design For Increasing The Processing Capacity of Distillation Columns 1. A Hydraulic Performance IndicatorDokument7 SeitenRetrofit Design For Increasing The Processing Capacity of Distillation Columns 1. A Hydraulic Performance IndicatorMuhammad Haris HamayunNoch keine Bewertungen

- 7601ENG Project Guidelines Guidelines - Dec2018Dokument16 Seiten7601ENG Project Guidelines Guidelines - Dec2018Muhammad Haris HamayunNoch keine Bewertungen

- Exergy ArticleDokument17 SeitenExergy ArticleMuhammad Haris HamayunNoch keine Bewertungen

- Energy efficient control and optimisation techniques for distillation processesDokument225 SeitenEnergy efficient control and optimisation techniques for distillation processesMuhammad Haris HamayunNoch keine Bewertungen

- Carbon-Hydride Energy Storage System: Hajime Emori Toru KawamuraDokument6 SeitenCarbon-Hydride Energy Storage System: Hajime Emori Toru KawamuraMuhammad Haris HamayunNoch keine Bewertungen

- LNG PresentationDokument43 SeitenLNG PresentationcsNoch keine Bewertungen

- Profit and Loss Statement TemplateDokument3 SeitenProfit and Loss Statement TemplateMuhammad Haris HamayunNoch keine Bewertungen

- Exergy Analysis of ASU..Dokument14 SeitenExergy Analysis of ASU..Muhammad Haris HamayunNoch keine Bewertungen

- Health, Safety and Environment PPT: Associate Professor Dr. Noaman-Ul-HaqDokument6 SeitenHealth, Safety and Environment PPT: Associate Professor Dr. Noaman-Ul-HaqMuhammad Haris HamayunNoch keine Bewertungen

- Steady State OptimizationDokument12 SeitenSteady State OptimizationMuhammad Haris HamayunNoch keine Bewertungen

- (Archives of Thermodynamics) The Methodology of The Gas Turbine Efficiency CalculationDokument17 Seiten(Archives of Thermodynamics) The Methodology of The Gas Turbine Efficiency Calculationbsaid77Noch keine Bewertungen

- Minimizing Environmental Impacts and Costs of Thermodynamic Cycles Using Simulation and OptimizationDokument12 SeitenMinimizing Environmental Impacts and Costs of Thermodynamic Cycles Using Simulation and OptimizationMuhammad Haris HamayunNoch keine Bewertungen

- Chemical Engineering DraftDokument94 SeitenChemical Engineering DraftAnonymous P1opXVNoch keine Bewertungen

- Optimization Examples TitleDokument2 SeitenOptimization Examples TitleSyukri ShahNoch keine Bewertungen

- University Course ScheduleDokument56 SeitenUniversity Course ScheduleMuhammad Haris HamayunNoch keine Bewertungen

- Dist-011 Azeotropic DistillationDokument38 SeitenDist-011 Azeotropic DistillationmontoyazumaetaNoch keine Bewertungen

- 1 s2.0 S0255270117309662 MainDokument9 Seiten1 s2.0 S0255270117309662 MainMuhammad Haris HamayunNoch keine Bewertungen

- 235160Dokument116 Seiten235160Muhammad Haris HamayunNoch keine Bewertungen

- Modeling of Industrial Fluidized-Bed Reactors: Joachim Werther and Ernst-Ulrich HartgeDokument12 SeitenModeling of Industrial Fluidized-Bed Reactors: Joachim Werther and Ernst-Ulrich HartgeMuhammad Haris HamayunNoch keine Bewertungen

- Energy Systems of PakistanDokument95 SeitenEnergy Systems of PakistanMuhammad Haris HamayunNoch keine Bewertungen

- Process Flow SheetDokument1 SeiteProcess Flow SheetMuhammad Haris HamayunNoch keine Bewertungen

- Majid Majeed Akbar: Objective: Professional ExperienceDokument5 SeitenMajid Majeed Akbar: Objective: Professional ExperienceMuhammad Haris HamayunNoch keine Bewertungen

- The History of PumpsDokument8 SeitenThe History of Pumpsdhanu_aquaNoch keine Bewertungen

- NASA ERAST Program Develops High-Altitude UAVsDokument17 SeitenNASA ERAST Program Develops High-Altitude UAVsEgz AguilarNoch keine Bewertungen

- The Properties of WaterDokument6 SeitenThe Properties of WaterannisyaNoch keine Bewertungen

- Chapter 4.1 Basic Call Procedure (ED01 - 53 - EN)Dokument53 SeitenChapter 4.1 Basic Call Procedure (ED01 - 53 - EN)quaderbtech06Noch keine Bewertungen

- Zetron Model 30 Instruction Manual EarlyDokument58 SeitenZetron Model 30 Instruction Manual EarlyOscar EscobarNoch keine Bewertungen

- PRJCTDokument10 SeitenPRJCTrpkn541Noch keine Bewertungen

- Zw3d2022 Lite Vs Cadbro 2022Dokument4 SeitenZw3d2022 Lite Vs Cadbro 2022Carlos LimaNoch keine Bewertungen

- Lateral Earth Pressure TheoryDokument45 SeitenLateral Earth Pressure TheoryAdel JamalNoch keine Bewertungen

- Part # Is 0032192-70: Eldorado Eldorado Eldorado Eldorado National National National NationalDokument1 SeitePart # Is 0032192-70: Eldorado Eldorado Eldorado Eldorado National National National NationalmnvijaybabuNoch keine Bewertungen

- Thermostats and Dial Thermometers PDFDokument252 SeitenThermostats and Dial Thermometers PDFAsep MustopaNoch keine Bewertungen

- Bots and Automation Over Twitter During The U.S. Election: CompropDokument5 SeitenBots and Automation Over Twitter During The U.S. Election: CompropRaninha MoraisNoch keine Bewertungen

- Solidworks SyllabusDokument7 SeitenSolidworks SyllabusArun SubramanianNoch keine Bewertungen

- YaskawaDokument375 SeitenYaskawaCristian IozsaNoch keine Bewertungen

- GuidewireClaimCenter Performance TestPlanDokument18 SeitenGuidewireClaimCenter Performance TestPlanshanthan117Noch keine Bewertungen

- Complex Instruction Set ComputerDokument17 SeitenComplex Instruction Set ComputerkangkanpaulNoch keine Bewertungen

- Control Valve and Steam Line PDFDokument19 SeitenControl Valve and Steam Line PDFRofi MuhammadNoch keine Bewertungen

- Udayanandan, Notes On Tensors PDFDokument56 SeitenUdayanandan, Notes On Tensors PDFhristos314Noch keine Bewertungen

- Messerschmitt Me 262 - Wikipedia, The Free Encyclopedia3Dokument5 SeitenMesserschmitt Me 262 - Wikipedia, The Free Encyclopedia3beta2009Noch keine Bewertungen

- LB2 UC30 Data Sheet enUS 80218564235Dokument5 SeitenLB2 UC30 Data Sheet enUS 80218564235Ahmed ShawkyNoch keine Bewertungen

- FTS ScaleoEUserManualEN 10 1082177Dokument2.044 SeitenFTS ScaleoEUserManualEN 10 1082177JNoch keine Bewertungen

- Datasheet SharePlexDokument2 SeitenDatasheet SharePlexBruno PóvoaNoch keine Bewertungen

- Sop Hydraulic Punch and ShearDokument1 SeiteSop Hydraulic Punch and ShearBorislav VulićNoch keine Bewertungen

- Oracle E-Business Suite Release 11i Upgrade To R12.1Dokument60 SeitenOracle E-Business Suite Release 11i Upgrade To R12.1Vladimir PacotaipeNoch keine Bewertungen

- Cutting A GemDokument18 SeitenCutting A Gemmobsivac100% (1)

- BPO2-Module 9 PROJECT PLANDokument16 SeitenBPO2-Module 9 PROJECT PLANJudame Charo ZozobradoNoch keine Bewertungen

- Mechanical Testing of MaterialsDokument38 SeitenMechanical Testing of MaterialsAanand Rishabh DagaNoch keine Bewertungen

- PI Digital Panel Indicator - B0Dokument7 SeitenPI Digital Panel Indicator - B0dtoxidNoch keine Bewertungen

- Seedburo Germinator Controls and Monitoring InstrumentsDokument2 SeitenSeedburo Germinator Controls and Monitoring InstrumentsJhony Rengifo SolsolNoch keine Bewertungen

- Dwarkadas J Sanghvi College of Engineering Provisional Merit ListDokument4 SeitenDwarkadas J Sanghvi College of Engineering Provisional Merit ListSharth NairNoch keine Bewertungen

- Torque Specifications: Service Specifications - Ra60F Manual TransmissionDokument1 SeiteTorque Specifications: Service Specifications - Ra60F Manual TransmissionPedro Javier Castro SanchezNoch keine Bewertungen