Beruflich Dokumente

Kultur Dokumente

Thiago Mikail - Apresentação I

Hochgeladen von

Thiago Mikail De OliveiraOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Thiago Mikail - Apresentação I

Hochgeladen von

Thiago Mikail De OliveiraCopyright:

Verfügbare Formate

Thiago Mikail de Oliveira Halliburton Energy Services Associated Technical Professional - TCP Aracaju - SE, Brazil

TCP Tubing Conveyed Perforating

Agenda

A view from Service Quality

Influence factors in perforation design Well Deviation Interval Testing or Permanent Completion for production Well balancing Completion objective TCP Basic Equipment Bar Drop Firing Heads MFH/ Model II/ Model III Pressure Actuated Firing Heads Lets get some detail on TDF Pressure Actuated Firing Heads KVII Valves and Vented Subs

2011 Halliburton. All Rights Reserved.

Tom Peters view of Service Quality -

WOW

Regina, The Cleaner (who also cooked cakes!) Hotel with Teddy Bear couch, bath tub, in the bed Kingfisher Airlines may I clean your glasses? Marta Vieira dos Santos playing in your team...

2011 Halliburton. All Rights Reserved.

Tom Peters view of Service Quality -

WOW

Exceeding the expectations of the customer. The basic idea is to bring the element of surprise into your business. The concept of Wow! yells out, "Surprise! Aren't you glad you bought from me, decided to do business with our company, etc.!"

2011 Halliburton. All Rights Reserved.

Tom Peters view of the future of Service Quality -

WOW

Would you ... Hire someone else for cleaning your house? Preffer staying at Deca? Flying with TAM or GOL? Substitute Marta by Adriano in your team?

2011 Halliburton. All Rights Reserved.

We have a strategic plan. Its called doing things.

Herb Kelleher (CEO of SouthwestAirlines)

2011 Halliburton. All Rights Reserved.

TCP/ Design Influence Factors

Well Deviation

Deviation higher than 60 degress are not likely done with wireline deliverable guns; Also DogLegs must be considered.

With such deviation can I locate the guns in the right point?

2011 Halliburton. All Rights Reserved.

TCP/ Design Influence Factors

Test or Production

Formation tests, normally done on appraisal/ exploration and wildcat wells, used for economic analysis Well permanent completion so that the well produces just after the perforating.

For how long will be the equipment downhole? Will it be a temporary, permanent or workover completion?

2011 Halliburton. All Rights Reserved. 8

TCP/ Design Influence Factors

Perforating Interval

Time (hours)

Runs

Whats the estimated operation time? Be carefull with HMX!

2011 Halliburton. All Rights Reserved. 9

TCP/ Design Influence Factors

Well Balancing

Formation pressure < Wellbore pressure = Overbalance

Formation pressure > Wellbore pressure = Underbalance Formation pressure << Wellbore induced pressure = Extreme Overbalance (EOB);

Wellbore pressure

Formation pressure

1

2 3

2011 Halliburton. All Rights Reserved.

10

TCP/ Design Influence Factors

Well Balancing

Formation pressure < Wellbore pressure = Overbalance

Formation pressure > Wellbore pressure = Underbalance Formation pressure << Wellbore induced pressure = Extreme Overbalance (EOB);

Wellbore pressure

Formation pressure

2 1 3

2011 Halliburton. All Rights Reserved.

11

TCP/ Design Influence Factors

Well Balancing

Formation pressure < Wellbore pressure = Overbalance

Formation pressure > Wellbore pressure = Underbalance Formation pressure << Wellbore induced pressure = Extreme Overbalance (EOB);

Wellbore pressure

Formation pressure

3 1 2

2011 Halliburton. All Rights Reserved.

12

TCP/ Design Influence Factors

Well Balancing

Casing Diameter Cement Sheath Casing Perforation Spacing (Dependent on Shot Density)

Crushed Zone

Perforation Diameter

Balanced Perforation Length (Cement to End of Perforation)

Entrance Hole Diameter in Casing j = Phase Angle

2011 Halliburton. All Rights Reserved.

Underbalance 3500 psi

13

TCP/ Design Influence Factors

Completion Objectives

Formation / Completion Type Consolidated - Natural completion Consolidated Stimulated Unconsolidated with Sand Control Damaged Remedial

Shot Density

Perforation Diameter Phasing Penetration

1

4 3 2

2

3 1 4

2

1 3 4

2

4 3 1

Not so much room for HSD in Sergipe

2011 Halliburton. All Rights Reserved.

14

TCP/ Equipments

Crossover No Go

(4 to 7 inches)

Mechanical Firing Head

Aka standard or Model I; NO-GO 18 ft.lbs is enough to shear the retainer in the Firing Pin mandatory use of DID

Firing Pin

HTI Det. Cord Support Tube Centralizer

Connection to the Guns

2011 Halliburton. All Rights Reserved.

15

TCP/ Equipments

MFH Related Equipment

- Drop Bar (1,25 OD) / Roller

Roller Bars

.875 Fishing Neck

30 deg of deviation. Recommended 40 deg. of deviation or dogleg Mandatory

Brass indent plug

2011 Halliburton. All Rights Reserved. 16

TCP/ Equipments

MFH Related Equipment

- DID - Detonator Interrupt Device

It does NOT prevents the firing head to detonate; but,

Pin Spirol

Eutectic Material

Firing Pin HTI Booster Detonating Cord

Allows detonation to proceed to guns only when above 117 F (consider 135 F for BHT)

2011 Halliburton. All Rights Reserved.

17

TCP/ Equipments

Model II-D Firing Head

Bar struck + 1500 psi in tubing to actuate;

NO-GO

Firing Pin

Heavy mud or deviated wells Max 20000 psi

Dogs Release Piston Firing

Pin Firing

HTI

Model III

2011 Halliburton. All Rights Reserved. 18

II

TCP/ Equipments

Model III-D Firing Head

Bar struck + 250 psi in tubing to actuate;

NO-GO

Firing Pin

Heavy mud or deviated wells Max 8000 psi

Dogs Release Piston Firing

Pin Firing

HTI

Model III

2011 Halliburton. All Rights Reserved. 19

II

TCP/ Equipments

Time Delay Firer (TDF)

Uses a delay fuse (4 ~ 6 minutes) / can add NO-GO more (EDA);

Maximum under/overbalance Heavy mud.

Firing Pin Shear set Primer Delay Element

2011 Halliburton. All Rights Reserved.

20

TCP/ Equipments

TDF Steps

Equipment Limit

Keep in mind that that the pining goal for TDF is to have a number of number of pins which would not allow the Firing Head to be easily detonated by the various pressures which are inherent to the job antecipated pressures. But, in the other hand, the design should allow that customers equipment be enough to supply pressure to fire the guns.

TDF Operation Safety Margin Antecipated Pressure

2011 Halliburton. All Rights Reserved.

21

TCP/ Equipments

TDF Steps

Prepare the Work

Have customer / well information Calculate the number of pins / prepare TDF List and have material preparation Testing Procedure Connecting and RIH procedure;

Testing and Running

Proceed with Detonation

How to actuate the Firing Head How to detect fire Misfire Procedures

2011 Halliburton. All Rights Reserved.

22

TCP/ Equipments

TDF Steps Prepare the Work

Customer / Well Information

Well Temperature: 220 F True vertical depth (TVD) at Plug Back: 10,000 True vertical depth at perforations: 9,500 9,550 Type of fluid and weight: mud / 12.1 ppg Hydrostatic (annular) 10,000 x 12.1 ppg x 0.052 = 6,292 psi Hydrostatic: (tubing will determine how is the balance in the perf) 5,000 psi Maximum surface pressure allowed by customer: (consider maximum pressure by the pump and other restrictions) 5,000 psi Other pressure operated tools: Fass Fill 700 psi | Select Test 1,200 psi Pressure tests: Pressure required to break circulation: : 700 psi

2011 Halliburton. All Rights Reserved.

23

TCP/ Equipments

TDF Steps Prepare the Work

List and prepare material

TDF 2 bottom mounted Vented Bull Plug (100005232) TDF 2 (100005231)

EDA 2 (100005229) + Primer (116970) + Delay Element (100008016) XOVER 3 3/8" BOX X 2 1/2" PIN (100005278) + PAI pra DCI (100005238) + DCI (100005307) XOVER 3 3/8 PIN x 4 5/8 PIN (100005264)

TDF 3 3/8 bottom mounted Vented Bull Plug (100005217) TDF 3 3/8 (100005230) + Primer (116970)

EDA 3 3/8 (100009426) + Primer (116970)+ Elemento de Retardo (100008016) Kit para Minigun (100005272) + PAI pra DCI (100005238) + DCI (100005307) XOVER 3 3/8 PIN x 4 5/8 PIN (100005264)

2011 Halliburton. All Rights Reserved.

24

TCP/ Equipments

TDF Steps Prepare the Work

TDF Calc 1/2

Casing Pressure + Maximum of any other pressure applied (break circulation, testing tools, pressure test of any equipments). 1. Determine the Maximum Pressure applied that must not actuate 2. How much pressure each pin handle Uses Batch and temperature to determine nominal pressure/pin in the charts refer for TCP web page to look for. Allow 5% tolerance Use a safety factor (for instance 1,000 psi for <= 10,000 psi in step 1). Divide (Step 1 Pressure + Safety Factor) /( pin * 0.95) - tolerance of 5% in step 2). 3. Calculate number of pins

2011 Halliburton. All Rights Reserved.

25

TCP/ Equipments

TDF Steps Prepare the Work

TDF Calc 2/2

Round number of pins calculated in step 3 up. Multiply then by their nominal pressure (with temperature reduction) . Calculate also +- 5% tolerance.

5. Check safety factor

Check if -5% tolerance in step 4 has the safety factor for not allowing detonation with the pressure calculated in step 1.

Remember that surface pressure is what you calculated in step 4 hydrostatic pressure already in the borehole.

4. Calculate how much is nominal pressure in the pins

6. Calculate max and minimum surface pressure .

2011 Halliburton. All Rights Reserved.

26

TCP/ Equipments

TDF calculation example 1/2

1. Determine the Maximum Pressure applied before Fass Fill at 700 psi, Select Test at 1200 psi, and break circulation is 700 psi | Hydrostatic in casing is 6292 psi. So, it would be 7492 psi.

2. How much pressure each pin handle

970 psi/pin 7,2% temp. = 900.16 psi/pin + 5% tolerance = 945.17 psi/pin - 5% tolerance = 855.15 psi/pin

3. Calculate number of pins

7492 psi + 1000 psi (safety factor)/ 855.15 pin = 8492/ 855.15 = 10 pins (round up!)

2011 Halliburton. All Rights Reserved.

27

TCP/ Equipments

TDF calculation example 2/2

4. Calculate how much is nominal pressure in the pins 10 pins x 900.16 psi/pin x 945.17 psi/pin x 855.15 psi/pin = 9,001.6 psi = 9,451.7 psi = 8,551.5 psi

5. Check safety factor

Minimun pressure that pins can handle (step 4) maximum pressure applied before (step 1) = 8,551.5 7,492 = 1,059.5 psi (> 1000 psi = Ok)

6. Calculate max and minimum surface pressure

Max pressure in step 4 Tubing Hydro = 9,452.7 5,000 = 4,452.7 psi (but add more 500 psi to allow more tolerance) = 4,952.7 psi

Min pressure in step 4 Tubing Hydro = 8,551.5 5,000 = 3,551.5 psi (but add more 500 psi to allow more tolerance) = 4,051.5 psi

2011 Halliburton. All Rights Reserved.

28

TCP/ Equipments

Testing Procedure

Do not install the delay element and lower plug assembly into housing until the pressure test is done; Fill with water and pressure 2,500 psi or half the shear value of the shear pins (in this example 8,551.5 psi /2 = 4,275.75 psi. Therefore, it will remain 2,500 psi as the maximum; Trap this pressure and hold for 10 minutes.

2011 Halliburton. All Rights Reserved.

29

TCP/ Equipments

Connecting and RIH procedure

Only install the firing head when all guns are already connected. In the case of being top mounted, use clean fluid between the firing head and the BIT; RIH at 15 seconds with 30 of pipe; Circulating the well or pump down operations should not be higher than 400 psi; Be aware of your safety margins... Monitor the well activities to stay within them.

2011 Halliburton. All Rights Reserved.

30

TCP/ Equipments

Proceed with detonation

9,952.7 Pressure (psi) 9,051.5 Pumping pressure Detonation

5,000

Tubing Hydrostatic

1 min 5 to 6 min Time (minutes)

2011 Halliburton. All Rights Reserved.

31

TCP/ Equipments

Detecting Fire

Noise and vibration in the column/ Shot detection systems;

Monitor surface pressure and bubble hose bucket for 30 minutes; Sudden annular pressure variation and stabilization;

2011 Halliburton. All Rights Reserved.

32

TCP/ Equipments

Detecting Fire

First indication: Noise and vibration in the column/ Shot detection systems

Tools

Shooting Detector (SAP 101323114)

2011 Halliburton. All Rights Reserved.

Audacity Software (freeware)

33

Accelerometers

TCP/ Equipments

Detecting Fire

First indication: Noise and vibration in the column/ Shot detection systems

Some considerations: system must be earthed!

Lab test in Aracaju 14/04/2011 Withouth the earth connected

With earth

2011 Halliburton. All Rights Reserved.

34

TCP/ Equipments

Detecting Fire

First indication: Noise and vibration in the column/ Shot detection systems

Arrangement for the test (in another room ~20 meters from computer)

Weak tap in the rack with a small screwdriver

2011 Halliburton. All Rights Reserved. 35

TCP/ Equipments

Detecting Fire

First indication: Noise and vibration in the column/ Shot detection systems

Test in the base:

Claps just beside the sensor

Weak tap in the rack just beside the sensor

Weak tap in the other side of the rack

2011 Halliburton. All Rights Reserved.

36

TCP/ Equipments

Detecting Fire

First indication: Noise and vibration in the column/ Shot detection systems

Limitations

1. Deviation and depth are critical factors;

2. The amount of casing/tubing contact may dampen the shock wave enough to cause difficulty in distinguishing the guns firing. 3. The type and condition of the fluid in the annulus may cause difficulty in hearing the guns fire (heavy mud versus water). 4. Background noise, created by pipe movement, subsurface pumps, etc. can make it difficult to determine when the guns fire. This occurs most often on offshore wells.

Where is more easily transfered sound and viabration?

2011 Halliburton. All Rights Reserved.

37

TCP/ Equipments

Detecting Fire

First indication: Noise and vibration in the column/ Shot detection systems

Limitations

1. Deviation and depth are critical factors;

2. The amount of casing/tubing contact may dampen the shock wave enough to cause difficulty in distinguishing the guns firing.

3. The type and condition of the fluid in the annulus may cause difficulty in hearing the guns fire (heavy mud versus water). 4. Background noise, created by pipe movement, subsurface pumps, etc. can make it difficult to determine when the guns fire. This occurs most often on offshore wells.

X

38

2011 Halliburton. All Rights Reserved.

TCP/ Equipments

Detecting Fire

First indication: Noise and vibration in the column/ Shot detection systems

Limitations

1. Deviation and depth are critical factors; 2. The amount of casing/tubing contact may dampen the shock wave enough to cause difficulty in distinguishing the guns firing.

3. The type and condition of the fluid in the annulus may cause difficulty in hearing the guns fire (heavy mud versus water).

4. Background noise, created by pipe movement, subsurface pumps, etc. can make it difficult to determine when the guns fire. This occurs most often on offshore wells.

X

39

2011 Halliburton. All Rights Reserved.

TCP/ Equipments

Detecting Fire

First indication: Noise and vibration in the column/ Shot detection systems

Limitations

1. Deviation and depth are critical factors; 2. The amount of casing/tubing contact may dampen the shock wave enough to cause difficulty in distinguishing the guns firing. 3. The type and condition of the fluid in the annulus may cause difficulty in hearing the guns fire (heavy mud versus water).

4. Background noise, created by pipe movement, subsurface pumps, etc. can make it difficult to determine when the guns fire. This occurs most often on offshore wells.

2011 Halliburton. All Rights Reserved.

40

TCP/ Equipments

Detecting Fire

Second indication: Sudden annular pressure variation and stabilization

Not only the formation will suffer from the millions of psi in the detonation. Also the packer will.

2011 Halliburton. All Rights Reserved.

41

TCP/ Equipments

Detecting Fire

Third indication: bubble hose and well pressure.

Ok, they fired. Now lets wait for the fluid inlet.

2011 Halliburton. All Rights Reserved.

42

TCP/ Equipments

Misfire Procedures

1. Recalculate to ensure that maximum pressure was achieved and pressure was held at least 1 minute.

2.

Pressure up a second time to maximum actuating pressure to try to actuate firing head.

If second attempt was not successful pressure up to maximum allowable pressure. Keep in mind the tubulars, packer differentials and surface equipment. Repeat steps above to verify no gun detonation.

3.

2011 Halliburton. All Rights Reserved.

43

TCP/ Equipments

Misfire Procedures

4. Notify your immediate supervisor that you have had a misfire and will be pulling out of the hole with the guns.

5. Discuss with the company man, rig personnel, and other service company representatives, any procedures that will be performed on the well that will affect the hydrostatic pressure prior to pulling guns. 6. After the decision has been made by the Company man and specialist ensure that all valves are open to prevent pressure buildup at the firing head.

2011 Halliburton. All Rights Reserved.

44

TCP/ Equipments

Misfire Procedures

7. Visually monitor any procedures that will affect the hydrostatic. Be aware of what is going on at all times.

8. Know your safety margins and stay within them.

9. When the guns arrive at surface remove firing head and replace with thread protectors on the gun and firing head as soon as possible,

2011 Halliburton. All Rights Reserved.

45

TCP/ Equipments

KV-II Firing Head

Wells with open perforations; NO-GO High deviated wells;

Firing head and valve are adjusted to operate with the same pressure. Production Ports Piston Firing Shear Set Pin Firing HTI

2011 Halliburton. All Rights Reserved.

46

TCP/ Equipments

Fill Disc Assembly

Simple way to circulate clean fluids; Allows underbalance with swabbing operations, after setting the packer. Port Glass

2011 Halliburton. All Rights Reserved.

47

TCP/ Equipments

BPV Bar Pressure Vent

Cheap Underbalance; Minimum 1000 psi tubing pressure; With / without break plug. Sliding sleeve Air chamber Break plug Port

2011 Halliburton. All Rights Reserved.

48

TCP/ Equipments

MDBV Max. Differential Bar Vent

Maximum underbalance; since, Maximum 1000 psi tubing pressure (without certain about rathole pressure); With break plug. Silicon chamber

Break plug Sliding sleeve

Spring Port

2011 Halliburton. All Rights Reserved.

49

Comments / Questions and Suggestions

2011 Halliburton. All Rights Reserved.

50

Das könnte Ihnen auch gefallen

- Organizational Trust QuestionnaireDokument2 SeitenOrganizational Trust QuestionnaireStefan Veronescu100% (6)

- Dhs Training PlanDokument117 SeitenDhs Training PlanKar Gayee100% (1)

- FE 02-09 Intro To Drilling FluidsDokument53 SeitenFE 02-09 Intro To Drilling FluidsWilman Casallas100% (1)

- Functions of LeadershipDokument4 SeitenFunctions of Leadershipdr_tripathineerajNoch keine Bewertungen

- Labor Law GuideDokument14 SeitenLabor Law GuideMan2x SalomonNoch keine Bewertungen

- PDC BitsDokument75 SeitenPDC Bitsamin peyvand100% (1)

- Perforating 101Dokument152 SeitenPerforating 101John SeversonNoch keine Bewertungen

- HPHT Solutions Drilling and EvaluationDokument41 SeitenHPHT Solutions Drilling and EvaluationJohnSmithNoch keine Bewertungen

- 15 SP1230 HSE Specification - Medical Examination, Treatment and FacilitiesDokument86 Seiten15 SP1230 HSE Specification - Medical Examination, Treatment and Facilitiesbmkallarackal100% (3)

- Case Digest ManuelDokument4 SeitenCase Digest ManuelJohny TumaliuanNoch keine Bewertungen

- Well InterventionsDokument124 SeitenWell InterventionsTrue Story100% (1)

- Major Challenges in HPHT OperationsDokument14 SeitenMajor Challenges in HPHT OperationsJeffreyNoch keine Bewertungen

- Duct Leakage TestingDokument51 SeitenDuct Leakage Testingducatti996chNoch keine Bewertungen

- Basicsofpumppresentation 140426101650 Phpapp02Dokument25 SeitenBasicsofpumppresentation 140426101650 Phpapp02Misbah437Noch keine Bewertungen

- Introduction To Drilling-Basic Operations & ToolsDokument68 SeitenIntroduction To Drilling-Basic Operations & ToolsanthonmirandasamdsNoch keine Bewertungen

- V45HP Coiled-Tubing InjectorDokument28 SeitenV45HP Coiled-Tubing InjectorEduardo UhrigNoch keine Bewertungen

- You Identify in Your Area of PracticeDokument12 SeitenYou Identify in Your Area of PracticeMaizatul Akmar IbrahimNoch keine Bewertungen

- HydraulicFracturing IIDokument4 SeitenHydraulicFracturing IIMohammadFaisalQureshiNoch keine Bewertungen

- Multibowl AgipDokument1 SeiteMultibowl AgipJonathan AguirreNoch keine Bewertungen

- RewardDokument76 SeitenRewardSoumaya HamdouniNoch keine Bewertungen

- Wire LineDokument9 SeitenWire LineAchmad Arief SolichinNoch keine Bewertungen

- Inspection Casing On Location Procedure22222222Dokument11 SeitenInspection Casing On Location Procedure22222222hamdi hamdiNoch keine Bewertungen

- TOS Slickline SOP V1.0Dokument16 SeitenTOS Slickline SOP V1.0Donald TchiroueNoch keine Bewertungen

- Bn67 Completion Schematic - Final 4 Apr 16Dokument1 SeiteBn67 Completion Schematic - Final 4 Apr 16sharil 9228Noch keine Bewertungen

- Special Services Presentation - 18 June 2018 Rev 1Dokument23 SeitenSpecial Services Presentation - 18 June 2018 Rev 1Juan CamachoNoch keine Bewertungen

- WellheadDokument2 SeitenWellheadRicardo Paz SoldanNoch keine Bewertungen

- NBC-1 Conceptual Well DesignDokument14 SeitenNBC-1 Conceptual Well DesignMulyono BanuNoch keine Bewertungen

- Rotary Cutters PDFDokument3 SeitenRotary Cutters PDFAlleyson AkinNoch keine Bewertungen

- Drilling Contracts: Contract Type Effect On Operator Effect On ContractorDokument206 SeitenDrilling Contracts: Contract Type Effect On Operator Effect On ContractorMohammed Zubair AhmedNoch keine Bewertungen

- Digital Trigger: Safe, On-Demand, Efficient and Recordable Perforating On SlicklineDokument32 SeitenDigital Trigger: Safe, On-Demand, Efficient and Recordable Perforating On SlicklineBizhar.Noch keine Bewertungen

- FSC Audit GuidelinesDokument86 SeitenFSC Audit GuidelinesroostercockburnNoch keine Bewertungen

- Kea Oilfield Engineering Pte LTDDokument9 SeitenKea Oilfield Engineering Pte LTDFabio ParceroNoch keine Bewertungen

- 5 - GrenCo - Company PresentationDokument34 Seiten5 - GrenCo - Company PresentationCluis KeNoch keine Bewertungen

- Acid TunnelingDokument3 SeitenAcid TunnelingFisher YohannesNoch keine Bewertungen

- CBL, TCP, GR Flow OperationDokument49 SeitenCBL, TCP, GR Flow OperationAkol MajookNoch keine Bewertungen

- Techniques of Artificial Lift For Viscous Oil ENI PDFDokument30 SeitenTechniques of Artificial Lift For Viscous Oil ENI PDFRichard More LeonNoch keine Bewertungen

- Causes of KicksDokument48 SeitenCauses of KicksAndrés LópezNoch keine Bewertungen

- Kadanwari Well Integrity Test ProgramDokument28 SeitenKadanwari Well Integrity Test ProgramsalmanNoch keine Bewertungen

- 1 Drilling Fluid Functions PropertiesDokument25 Seiten1 Drilling Fluid Functions PropertiesyasirismNoch keine Bewertungen

- Electrical Submersible Pump (ESP) : Presented by Win Nyunt AungDokument17 SeitenElectrical Submersible Pump (ESP) : Presented by Win Nyunt AungMurad AliyevNoch keine Bewertungen

- Methods of Perforating: Internal Use OnlyDokument26 SeitenMethods of Perforating: Internal Use OnlySeymur AkbarovNoch keine Bewertungen

- Velocity String Helps To Revive A Standing Gas Well in Saudi ArabiaDokument14 SeitenVelocity String Helps To Revive A Standing Gas Well in Saudi Arabiaerdal aydin100% (1)

- Yww7Pogiq - Understanding API 6a Gate ValvesDokument1 SeiteYww7Pogiq - Understanding API 6a Gate ValvesRuilin TanNoch keine Bewertungen

- KDN-16 Mudlogging Final Well ReportDokument52 SeitenKDN-16 Mudlogging Final Well ReportAhmedNoch keine Bewertungen

- Ask Echometer - Acoustic Techniques For Gaslift Wells - June 17 2020Dokument69 SeitenAsk Echometer - Acoustic Techniques For Gaslift Wells - June 17 2020Ivan BuenaVibraNoch keine Bewertungen

- Relay Digital Slickline SystemDokument7 SeitenRelay Digital Slickline SystemRaed fouadNoch keine Bewertungen

- Cement LoggingDokument58 SeitenCement Loggingahoua100% (1)

- Graficas de PerforacionDokument6 SeitenGraficas de PerforacionCatalina FloresNoch keine Bewertungen

- PCP AE1 - DAY 1.1 Introduction To PCP System and ComponentsDokument66 SeitenPCP AE1 - DAY 1.1 Introduction To PCP System and ComponentsCristhian LópezNoch keine Bewertungen

- Process Operability - ReliabilityDokument39 SeitenProcess Operability - ReliabilityshakerNoch keine Bewertungen

- Garden of Memories Vs NLRCDokument1 SeiteGarden of Memories Vs NLRCBeverlyn Jamison100% (2)

- Wireline ToolstringDokument1 SeiteWireline ToolstringJohnNoch keine Bewertungen

- Lidl Graduate Brochure 2012 2013Dokument17 SeitenLidl Graduate Brochure 2012 2013lollyo20Noch keine Bewertungen

- API Example No. 1 100 100 1000 0.465 78 130 178 0.650 4000 544 7000 1030 8000 12 0.094 25.0 EDokument3 SeitenAPI Example No. 1 100 100 1000 0.465 78 130 178 0.650 4000 544 7000 1030 8000 12 0.094 25.0 EashrafsaberNoch keine Bewertungen

- Assistant Slickline Operator 001Dokument3 SeitenAssistant Slickline Operator 001Muhammad shehryar KhanNoch keine Bewertungen

- Cabezal Multibowl Bes PROGRAMA 13 3/8" X 9 5/8" X 4 1/2": Instalations ToolsDokument1 SeiteCabezal Multibowl Bes PROGRAMA 13 3/8" X 9 5/8" X 4 1/2": Instalations ToolsJonathan AguirreNoch keine Bewertungen

- Introduction To Coiled Tubing: Module 00 - Day OneDokument7 SeitenIntroduction To Coiled Tubing: Module 00 - Day OneFauzan Rahman HaqNoch keine Bewertungen

- CMT Prac 2004 Sec 6 BReverse CementingDokument8 SeitenCMT Prac 2004 Sec 6 BReverse CementingcharlessimoNoch keine Bewertungen

- Fishing Best PracticesDokument11 SeitenFishing Best PracticesaungwinnaingNoch keine Bewertungen

- Asamera (South Sumatra) LTD Mechanical Status Production Engineering Department RB-22aDokument13 SeitenAsamera (South Sumatra) LTD Mechanical Status Production Engineering Department RB-22afauzan kartiyasaNoch keine Bewertungen

- Orifice Meter & Barton RecorderDokument46 SeitenOrifice Meter & Barton RecorderNoor AliNoch keine Bewertungen

- SCA2016-098 - Paper - D Whitby - NOV - Offshore Wireline Coring PDFDokument6 SeitenSCA2016-098 - Paper - D Whitby - NOV - Offshore Wireline Coring PDFdave_whitbyNoch keine Bewertungen

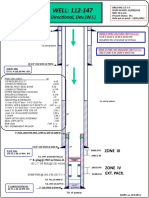

- WELL: 112-147: Directional, Dev. (W.I.)Dokument15 SeitenWELL: 112-147: Directional, Dev. (W.I.)Mostafa KorttamNoch keine Bewertungen

- Petroline Easy Adjust JarDokument11 SeitenPetroline Easy Adjust Jarabbas1368100% (1)

- Sand Pump Bailer - Flapper TypeDokument2 SeitenSand Pump Bailer - Flapper TypeDias IrsaNoch keine Bewertungen

- PTS Slick E Line Brochure 2018 PDFDokument5 SeitenPTS Slick E Line Brochure 2018 PDFfelipeNoch keine Bewertungen

- Bop Pressure Test ReportDokument1 SeiteBop Pressure Test ReportsamNoch keine Bewertungen

- 02 WH & XTreeDokument47 Seiten02 WH & XTreeilkerkozturkNoch keine Bewertungen

- CPS 010Dokument33 SeitenCPS 010João Paulo GalvãoNoch keine Bewertungen

- Hoshman HPHT Guidance 4 17 15Dokument27 SeitenHoshman HPHT Guidance 4 17 15John SeversonNoch keine Bewertungen

- 2012 Contracts Slides CH 6Dokument84 Seiten2012 Contracts Slides CH 6lindajkangNoch keine Bewertungen

- Serv Let ControllerDokument2 SeitenServ Let ControllerAbhishekShuklaNoch keine Bewertungen

- University of GlasgowDokument13 SeitenUniversity of GlasgowAllison Nadine MarchandNoch keine Bewertungen

- Employees Compensation ProgramDokument30 SeitenEmployees Compensation ProgramEunnice M. MagculangNoch keine Bewertungen

- Statistics ON Industrial Disputes, Closures, Retrenchments and Lay-Offs in India During The Year, 2014Dokument168 SeitenStatistics ON Industrial Disputes, Closures, Retrenchments and Lay-Offs in India During The Year, 2014Anonymous 5IbiMBvsNoch keine Bewertungen

- Coolie - Project ReportDokument16 SeitenCoolie - Project Reportsidrocks21Noch keine Bewertungen

- Unit 20 Managing Sales Personnel: ObjectivesDokument12 SeitenUnit 20 Managing Sales Personnel: ObjectivesfarhanNoch keine Bewertungen

- Guide To Nursing Management and Leadership 8th Edition Tomey Test Bank DownloadDokument8 SeitenGuide To Nursing Management and Leadership 8th Edition Tomey Test Bank Downloadjoshuagwyndssc100% (32)

- David M. Alper: Highlights of ExperienceDokument3 SeitenDavid M. Alper: Highlights of ExperienceDavidNoch keine Bewertungen

- Research Document Srishti - NandaDokument80 SeitenResearch Document Srishti - NandaAmit KumarNoch keine Bewertungen

- Isp 3025aDokument2 SeitenIsp 3025aAkhtar AshrafNoch keine Bewertungen

- Core 12 Human Resource Management IV Sem BBA SLDokument52 SeitenCore 12 Human Resource Management IV Sem BBA SLGS FilmsNoch keine Bewertungen

- District Attorney's Marc Nuno DecisionDokument9 SeitenDistrict Attorney's Marc Nuno DecisionKristin LamNoch keine Bewertungen

- Job Application and Cover LettersDokument1 SeiteJob Application and Cover LettersDyah AgNoch keine Bewertungen

- IIBMS / ISBM / KSBM / IIBM / ISMS / Case Study AnswersDokument111 SeitenIIBMS / ISBM / KSBM / IIBM / ISMS / Case Study AnswersAravind 9901366442 - 9902787224Noch keine Bewertungen

- QLD Health - June 1Dokument169 SeitenQLD Health - June 1ElliotfishmanNoch keine Bewertungen

- BD HSG Idiomatic ExpressionsDokument6 SeitenBD HSG Idiomatic ExpressionsheobilNoch keine Bewertungen

- PrefaceDokument37 SeitenPrefacesaikat_25Noch keine Bewertungen

- Sarkis 2014Dokument6 SeitenSarkis 2014druga godinaNoch keine Bewertungen