Beruflich Dokumente

Kultur Dokumente

Welding QC 11 - Defects

Hochgeladen von

Exsan OthmanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Welding QC 11 - Defects

Hochgeladen von

Exsan OthmanCopyright:

Verfügbare Formate

TWI

voot

ThE WtLDiNO L\STITLT|E

SECTION11

T\MI

wct

THE WETDTNGTNS"TTTUTE

DEFECTSWHICH MAY BE DETECTEDBY

SU RFA CEI NS P E CT IO N

Defectswhich may be detectedby visuarinspectioncan be groupedunder four

headings.

1.

Cracks

2.

Surfaceirregularities

3.

Contour defects

4.

Root defects

-Lntgoa-eeeEs suchas cavities

solidincrusions

wi[ be deartwithduringmacroscopic

examination

'-

WELDINGTECHNOLOGY

Issue0191

1l.1

T\VI

T1 wELDIv-c-u.{STm,.TE-

SurfaceCracks

60 0 1 5 "

Crack

A linear discontinuity

produced-,/'7

by fracture.

e/acKsmay be

longitudinal,

in the weld metal,

r.e. centreline

longitudinal.

in the parentmetal

',1.'-"i-' ." :-z

.:l, :;

i

: \^ .. ^. -...

I

t-l t,.i...

i^*-1 .. -':..

transverse

"*ral'.1" :' :'1:''

:.-.:l

l ,

, - .1 1

I r i. l'1 '

i

,..

...4...,r-

'i'^;h

rl.

ts-*.

;

. :-.r2*--J

.,-r- : i.r.-a1 r-"..J,^

\.i_r-'o\

'

\

:

1

:\

]-'-Ftrg?irr

-i

l 2 reri'1 , e.'.-';"- ' : L . , - ,. i , ;

1 11.2 -.+

,l

r,D{,*_.^,,,..utsa1.

,.A ^--i-

.--

WELDINGTECHNOLOGY

lssue 0lgl

,'

TWI

wct

THE WELDING INSTFrLTE

Surfacelrregularities

6 . r -: 1 ' ' - ' - , ' . , '

"r '-:

6 0 0 0 6 * U n d e r c u t - .. -' - . : , .

-:

-.,tt.

' ' .,

an irresutalsiooV;.;ii

todtr;

run in the parentmetalor in

previouslydepositedweld

metal.

-"'

l't:'

''

rrr

r . _.

'

5*'

{:

{.

'J

.+---:--{

'

60 007*

'

-.---,1

Sr:.c.,-i r'.

An imperfectionat the toe or.

ile^:

root of a weld causedby metal . . _,.-\

?'l'"'

i .'. :.\'r -)"-i

flowing on to the surfaceof the i:

parent metal without fusingto it. .;,Tr,

".._.,.,,_;,

l

i'-r : ,

\

i

60 038

.-''.''-!<-*

i

Overtap

a:_

Crater pipe --A depressiondue to shrinkage+ etrc F,--.:_,

at the end of a run where the .:-..'.... ).r,

a_Lt)t

Cmtet grya

10031

j2 104

Spatter

Stray flash

(lfrgvarcinsl

r-l-1 ..

. , , _ -- r

WELDING TECHNOLOGY

Issue Ol91

,:(-tJa.,

!," ;.

.j i-.?]:5

!-!a

tt.o

TWI

wot

TTIE wE t.DrNG r*-siirrt:

Contour Defects

60 003

00000'

Incompletely filled groove _ ,, . ,

A c o n t i n u o u so r i n t e i m i t t e n _t ,

channel in the sur_face

of a weld,

r u n n i n g a l o n g i t s l e n g t h ,d u e

to

rnsufficientweld metal. The

c h a n n e lm a y b e a l o n g t h e

c e n t r eo . a l o n g o n e o r b o t h

: ,,\)\:

edges of the weld.

. . -

B u l b o u sc o n t o u r

(not BS 499 term)

-t

,00'

' :

^. :--

Unequal legs - poa,

(notBS 499rerm) \

. . - -t.a = e . f

V a r i a t i o no f l e g l e n g t ho n a f i l l e t

weid.

N . B . U n e q u a lj e g l e n g t h sm a y

oe specified as part of the

d e s i g n - i n w h i c h c a s et h e y a r e

not defects.

1 a

AA

WELDING TECHNOLOGY

lssue ol gl

TWI

wot

THE \I'ELDINC NSTrI.LTE

Root Defects

60 022* lncomplete roor penetration

_ a

Failureof weld metal,o "o"nd

)1 ,,, ,.-,

i

lnto the root of a joint.

>../^

l-.._ ^

rO 020

-J 004'

Lack of root fusion

i)

.-

._

":':iri[-?-.

, "

rl u\j

j , t

I

,

r - ,

, - ; -

'

- .\

I

Lackof ,nio"'u'i,nu

..ootof ,-t,r..=^^:,.,.r-.;

jcin:.

-;--.-,---_

Shrinkage groove .-

flF

i

-L

r y .. .: . .:. ;. ;r' .i

A shallowgroovecausedB,.^/'.,-' t.-.'-_l ..,..,i,_..

contractionin the metalalonns.,\\.,...._.

eachside of a penetratron

bead.

60 039

Burnthrough

(melt through)

A localisedcollapseof rhe

motten pool due to excesstve

Penetration,resultingin a hole

rn the weld run.

%--izzzz

WELDINGTECHNOLOGY

IssueOlgt

l l

T\4/I

ti

'j

zm_

TTE \I'ELDTNC

QUESTIONS

REVIEW OF DEFECTS

Ql

02

Q3

Name two (p) cracl</planar

defects found wjthin

Give two (2) maincauses

of excesspenetration

Sketch a)

b)

Q4

Q5

the weld metal.

lncomplete filled groove

Lack of sidewall

fusion at the weld

toe

Givethree(3) main

causesof undercut

Give three possible

causes of lack of

side waJlfusion

QS1,1I

LIVSTM.]

Das könnte Ihnen auch gefallen

- Brittle Fracture in Steel StructuresVon EverandBrittle Fracture in Steel StructuresG.M. BoydNoch keine Bewertungen

- WJ 1980 08 s226 PDFDokument7 SeitenWJ 1980 08 s226 PDFaltieri1Noch keine Bewertungen

- Non-Destructive Testing: Proceedings of the 4th European Conference, London, UK, 13- 17 September 1987Von EverandNon-Destructive Testing: Proceedings of the 4th European Conference, London, UK, 13- 17 September 1987Noch keine Bewertungen

- Weld Symbols On DrawingsDokument25 SeitenWeld Symbols On Drawingshombre.muerto5959100% (2)

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesVon EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNoch keine Bewertungen

- Weld Nugget Development and Integrity in Resistance Spot Welding of High-Strength Cold-Rolled Sheet SteelsDokument8 SeitenWeld Nugget Development and Integrity in Resistance Spot Welding of High-Strength Cold-Rolled Sheet SteelsgrandecaciqueNoch keine Bewertungen

- Elastic Stability of Circular Cylindrical ShellsVon EverandElastic Stability of Circular Cylindrical ShellsBewertung: 5 von 5 Sternen5/5 (1)

- Modeling ultrasonic testing nodular cast iron nuclear fuel insertsDokument14 SeitenModeling ultrasonic testing nodular cast iron nuclear fuel insertsCarlos Ortega JonesNoch keine Bewertungen

- Case Histories in Vibration Analysis and Metal Fatigue for the Practicing EngineerVon EverandCase Histories in Vibration Analysis and Metal Fatigue for the Practicing EngineerBewertung: 4.5 von 5 Sternen4.5/5 (3)

- C.coek - Info - Failure of A Conveyor Trunnion Shaft On A CentrifuDokument12 SeitenC.coek - Info - Failure of A Conveyor Trunnion Shaft On A CentrifuilfakeNoch keine Bewertungen

- Hard Metals Production Technology and Research in the U.S.S.R.Von EverandHard Metals Production Technology and Research in the U.S.S.R.S. I. BashkirovNoch keine Bewertungen

- Ohe Rdso Eti Ohe49Dokument49 SeitenOhe Rdso Eti Ohe49hardeepsingh_08Noch keine Bewertungen

- The Key To Metal Bumping (Panel Beating, Auto Body Repair Bible)Dokument69 SeitenThe Key To Metal Bumping (Panel Beating, Auto Body Repair Bible)wulfgang2498100% (11)

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingVon EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNoch keine Bewertungen

- The Mechanisms of Formation of W e L D Defects in High-Frequency Electric Resistance W e L D I N GDokument6 SeitenThe Mechanisms of Formation of W e L D Defects in High-Frequency Electric Resistance W e L D I N Gilze86Noch keine Bewertungen

- Methods of Working Coal and Metal Mines: Planning and OperationsVon EverandMethods of Working Coal and Metal Mines: Planning and OperationsBewertung: 3 von 5 Sternen3/5 (2)

- Ad 0655039Dokument93 SeitenAd 0655039derjo5888Noch keine Bewertungen

- WJ 1983 02 s36Dokument9 SeitenWJ 1983 02 s36Rajesh KachrooNoch keine Bewertungen

- Metallurigcal Examinaiton of The Armour of A Panther TankDokument17 SeitenMetallurigcal Examinaiton of The Armour of A Panther Tankcjnjr1Noch keine Bewertungen

- Fatigue Fracture BehaviorDokument6 SeitenFatigue Fracture BehaviorDerek FongNoch keine Bewertungen

- Ultrasonic Inspection of Welds in Nozzles, Nodes, Curved Surfaces & TKY JointsDokument14 SeitenUltrasonic Inspection of Welds in Nozzles, Nodes, Curved Surfaces & TKY Jointsleonciomavarez100% (1)

- TWI CSWIP 3.1 Welding InspectorDokument81 SeitenTWI CSWIP 3.1 Welding Inspectormahmoeng100% (2)

- Australian Military Forces Identification ListDokument55 SeitenAustralian Military Forces Identification Listpercyolivas100% (1)

- Fatigue Crack Propagation in Stiffened Panels - Poe OCRDokument19 SeitenFatigue Crack Propagation in Stiffened Panels - Poe OCRRaniero FalzonNoch keine Bewertungen

- Shell Like Fractures in Continuously Cast SlabsDokument7 SeitenShell Like Fractures in Continuously Cast SlabsJose Marval RodriguezNoch keine Bewertungen

- Ponašanje Profila Konstrukcije Dentalnog Mosta Prema Silama OpterećenjaDokument5 SeitenPonašanje Profila Konstrukcije Dentalnog Mosta Prema Silama OpterećenjaKnjigeNoch keine Bewertungen

- Limiting strains in stretch forming of sheet metalDokument14 SeitenLimiting strains in stretch forming of sheet metalSaeed GhaffariNoch keine Bewertungen

- UNIC 503 Parts Manual PDFDokument212 SeitenUNIC 503 Parts Manual PDFAmos ChikwengoNoch keine Bewertungen

- UNIC 503 Parts Manual PDFDokument212 SeitenUNIC 503 Parts Manual PDFAmos ChikwengoNoch keine Bewertungen

- FisaTehnologica-3 2 FT2 - 87Dokument67 SeitenFisaTehnologica-3 2 FT2 - 8717ges100% (1)

- Pocket Handbook For VI & Weld DiscontinuitiesDokument17 SeitenPocket Handbook For VI & Weld Discontinuitiesixotee100% (2)

- Failure Torsion StrapsDokument46 SeitenFailure Torsion StrapsMarcvs LewisNoch keine Bewertungen

- UNF Vs BSFDokument18 SeitenUNF Vs BSFJonathan GentNoch keine Bewertungen

- Telephone Installation SpecificationDokument20 SeitenTelephone Installation SpecificationMUHAMMAD KHUDRI BIN HALIM BASHAH, IR. (JKR)100% (1)

- Tubular Welded JointsDokument6 SeitenTubular Welded Jointsmyst3rioNoch keine Bewertungen

- Fillet Weld Research Paper - For UndercuttingDokument7 SeitenFillet Weld Research Paper - For UndercuttingHemantNoch keine Bewertungen

- Sans 1200 HaDokument3 SeitenSans 1200 Hafilipe100% (1)

- Weld Defects in Austenitic Stainless Steel Sheets-Effect of Welding ParametersDokument8 SeitenWeld Defects in Austenitic Stainless Steel Sheets-Effect of Welding ParametersVijaykumar powarNoch keine Bewertungen

- ME2201 Manufacturing Technology IDokument6 SeitenME2201 Manufacturing Technology ImsloveindiaNoch keine Bewertungen

- WJ 1982 07 s222 Chevron CrackingDokument7 SeitenWJ 1982 07 s222 Chevron CrackingamitNoch keine Bewertungen

- 19660015720Dokument69 Seiten19660015720Shankar PediredlaNoch keine Bewertungen

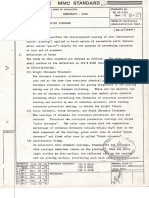

- No.29 MMC Standard-Zinc Electroplating Standard. MS82-3701Dokument7 SeitenNo.29 MMC Standard-Zinc Electroplating Standard. MS82-3701Alejandro Tique100% (1)

- Joint Clear TolerancesDokument4 SeitenJoint Clear TolerancesLora BoydNoch keine Bewertungen

- Brosur - Konduktor Voksel PDFDokument33 SeitenBrosur - Konduktor Voksel PDFAndika Handy100% (1)

- Aft Fuselage Jig Process Sheet-2Dokument7 SeitenAft Fuselage Jig Process Sheet-2asderbvaNoch keine Bewertungen

- 9th Circuit Appeal - DKT 17 - Appellant's Opening Brief - 9th Circuit AppealDokument48 Seiten9th Circuit Appeal - DKT 17 - Appellant's Opening Brief - 9th Circuit AppealHonor in Justice100% (1)

- Twi - Welding Inspection - SteelsDokument209 SeitenTwi - Welding Inspection - Steelsenels77Noch keine Bewertungen

- Fastener FailuresDokument3 SeitenFastener FailuresWylliam Diel WagnerNoch keine Bewertungen

- Armament ResearchDokument38 SeitenArmament ResearchAmiVolat100% (2)

- Vibrations of Orthotropic Sandwich Conical Shells With Free EdgesDokument14 SeitenVibrations of Orthotropic Sandwich Conical Shells With Free EdgesunlockvnNoch keine Bewertungen

- Arc Stud WeldingDokument5 SeitenArc Stud WeldingKhwanas LuqmanNoch keine Bewertungen

- Holden VL Series Service Manual SupplementDokument10 SeitenHolden VL Series Service Manual SupplementmattNoch keine Bewertungen

- Case Studies in Engineering Failure Analysis: Wei Sha, Savko MalinovDokument7 SeitenCase Studies in Engineering Failure Analysis: Wei Sha, Savko MalinovriessanandaNoch keine Bewertungen

- Radiograph Interpretation of Casting DefectsDokument5 SeitenRadiograph Interpretation of Casting DefectsDavid MacatangayNoch keine Bewertungen

- Stealth Satellites A StudyDokument249 SeitenStealth Satellites A StudyvonlolzorNoch keine Bewertungen

- Api 5l 2004Dokument15 SeitenApi 5l 2004Pavanirohit ReddyNoch keine Bewertungen

- Non-Destructive Testing of High-Pressure Gas PipelinesDokument10 SeitenNon-Destructive Testing of High-Pressure Gas PipelinesAnonymous qGtdQZcuNoch keine Bewertungen

- Oto 99022Dokument157 SeitenOto 99022jobinhoeljovenNoch keine Bewertungen

- Adobe Scan Apr 11, 2023Dokument11 SeitenAdobe Scan Apr 11, 2023Girish RoyNoch keine Bewertungen

- PETRONAS Employee Medical Top-Up PlanDokument2 SeitenPETRONAS Employee Medical Top-Up PlanExsan OthmanNoch keine Bewertungen

- A-Health Advance - Application Form With InstructionsDokument14 SeitenA-Health Advance - Application Form With InstructionsExsan OthmanNoch keine Bewertungen

- TUBE INSPECTION SOLUTIONS: SELECTION GUIDEDokument28 SeitenTUBE INSPECTION SOLUTIONS: SELECTION GUIDEAkhileshNoch keine Bewertungen

- Engineering Your Future PDFDokument605 SeitenEngineering Your Future PDFExsan OthmanNoch keine Bewertungen

- RFET Technique Detects Local and Gradual DefectsDokument4 SeitenRFET Technique Detects Local and Gradual DefectsExsan OthmanNoch keine Bewertungen

- Astm C 871Dokument5 SeitenAstm C 871Exsan Othman100% (2)

- Farris Valve ManualDokument11 SeitenFarris Valve ManualsumsolcaggNoch keine Bewertungen

- April 2015. Any New Application Form Must Reach Us Before The Stipulated DateDokument1 SeiteApril 2015. Any New Application Form Must Reach Us Before The Stipulated DateExsan OthmanNoch keine Bewertungen

- Farris Series 2600Dokument96 SeitenFarris Series 2600johngoff100% (1)

- Senarai Nama Arkitek BerdaftarDokument150 SeitenSenarai Nama Arkitek BerdaftarCgu Bola Tampar83% (6)

- P91 T91 Engl PDFDokument3 SeitenP91 T91 Engl PDFparmodrtkNoch keine Bewertungen

- SSI Guideline V3 PDFDokument34 SeitenSSI Guideline V3 PDFSyed Mohd FirdausNoch keine Bewertungen

- Astm C 692 PDFDokument7 SeitenAstm C 692 PDFExsan Othman100% (1)

- MetrodeHandbook - ZavarivanjeDokument416 SeitenMetrodeHandbook - ZavarivanjetonicmiraNoch keine Bewertungen

- AWS Specifications For Filler MaterialDokument9 SeitenAWS Specifications For Filler MaterialExsan OthmanNoch keine Bewertungen

- AWS Weld Symbol ChartDokument1 SeiteAWS Weld Symbol ChartExsan OthmanNoch keine Bewertungen

- EPA RMP OSHA PSM State Law SummaryDokument1 SeiteEPA RMP OSHA PSM State Law SummaryExsan OthmanNoch keine Bewertungen

- Asmt C 795Dokument4 SeitenAsmt C 795Exsan OthmanNoch keine Bewertungen

- MaterialsDokument181 SeitenMaterialsExsan OthmanNoch keine Bewertungen

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Dokument6 SeitenCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNoch keine Bewertungen

- Nozzle Design Tool AnalysisDokument2 SeitenNozzle Design Tool AnalysisArt G. EnziNoch keine Bewertungen

- Calculation Minimum Required Thickness For Bending Pipe r2Dokument11 SeitenCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanNoch keine Bewertungen

- Pipeline DataDokument4 SeitenPipeline DataExsan OthmanNoch keine Bewertungen

- 300 - F&D Head Design Tool Ver E4.01Dokument1 Seite300 - F&D Head Design Tool Ver E4.01Honey TiwariNoch keine Bewertungen

- Material CharacteristicsDokument4 SeitenMaterial CharacteristicsExsan OthmanNoch keine Bewertungen

- Piping CalDokument13 SeitenPiping CalglazetmNoch keine Bewertungen

- Mechanical Design SpreadsheetDokument1 SeiteMechanical Design SpreadsheetHoney TiwariNoch keine Bewertungen

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDokument1 SeiteHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNoch keine Bewertungen

- XcfbrochuDokument6 SeitenXcfbrochuuniversal8888Noch keine Bewertungen

- Parition WorksDokument46 SeitenParition WorkslavekushNoch keine Bewertungen

- Project Design Calculation SheetDokument11 SeitenProject Design Calculation SheetAbdullah RamadanNoch keine Bewertungen

- Slide 13 Bending and FormingDokument68 SeitenSlide 13 Bending and Formingjohn doeNoch keine Bewertungen

- Can Crusher InstructionsDokument10 SeitenCan Crusher Instructionsgary.nolan100% (3)

- Fabric care symbols explainedDokument2 SeitenFabric care symbols explainedmonicajudgeNoch keine Bewertungen

- Shield CreteDokument2 SeitenShield Cretechris77779Noch keine Bewertungen

- Categrafica Bookletv2 Melissa AmayaDokument4 SeitenCategrafica Bookletv2 Melissa AmayaMelissa AmayaNoch keine Bewertungen

- Aerated Lagoon: Types of Aerated Lagoons or BasinsDokument4 SeitenAerated Lagoon: Types of Aerated Lagoons or BasinsRaajiv MenonNoch keine Bewertungen

- Chemical CompositionDokument6 SeitenChemical CompositionAkbar DarmawansyahNoch keine Bewertungen

- Surface Preparation and Painting Procedure Rev 01 PDFDokument23 SeitenSurface Preparation and Painting Procedure Rev 01 PDFNaceur Turki100% (3)

- Clarification Secrets for Maximizing CPO QualityDokument15 SeitenClarification Secrets for Maximizing CPO QualityMohd Rahimi Mohmad TanuriNoch keine Bewertungen

- 11 Cad Cam CNC Programming MVVDokument37 Seiten11 Cad Cam CNC Programming MVVbassem smatiNoch keine Bewertungen

- SUNANDA - Epoxy BrochureDokument8 SeitenSUNANDA - Epoxy BrochureGuru PrasathNoch keine Bewertungen

- Specification For General Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and StripDokument28 SeitenSpecification For General Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and StripAid Farhan Maarof100% (1)

- Spot Weld Growth On 304L Austenitic Stainless Steel For Equal and Unequal ThicknessesDokument9 SeitenSpot Weld Growth On 304L Austenitic Stainless Steel For Equal and Unequal ThicknessesAmin MojiriNoch keine Bewertungen

- Vertical Roller Mill IntroductionDokument2 SeitenVertical Roller Mill Introductionemad sabriNoch keine Bewertungen

- Pfi Es-47Dokument10 SeitenPfi Es-47Ecruz Cruz LNoch keine Bewertungen

- ASTM A47 A47M Spec For Ferritic Malleable Iron Castings PDFDokument5 SeitenASTM A47 A47M Spec For Ferritic Malleable Iron Castings PDFMuhammad Umer DrazNoch keine Bewertungen

- Ukl 4040Dokument11 SeitenUkl 4040prabal rayNoch keine Bewertungen

- Avantec Catalog 2021 En-1Dokument156 SeitenAvantec Catalog 2021 En-1TodorNoch keine Bewertungen

- McKissick Overhaul BallsDokument1 SeiteMcKissick Overhaul BallsYADAGIRI REDDYNoch keine Bewertungen

- Slip Resistant Coating (R12) : Ferfa Type 2 SystemDokument2 SeitenSlip Resistant Coating (R12) : Ferfa Type 2 SystemAlex BocicaNoch keine Bewertungen

- AISI 1020 Low Carbon/Low Tensile Steel: Topics CoveredDokument5 SeitenAISI 1020 Low Carbon/Low Tensile Steel: Topics CoveredGuntur Aji SubiaktoNoch keine Bewertungen

- Machine LatheDokument4 SeitenMachine LatheKirubel MulugetaNoch keine Bewertungen

- X-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteDokument2 SeitenX-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteAmr RagabNoch keine Bewertungen

- Brazing BookDokument109 SeitenBrazing BooksutrimoNoch keine Bewertungen

- Bamboo Spoon, Fork, Knife Making ProjectsDokument23 SeitenBamboo Spoon, Fork, Knife Making ProjectsLloyd Ki'sNoch keine Bewertungen

- Casting Processes: ME 4210: Manufacturing Processes and Engineering Prof. J.S. Colton © GIT 2006Dokument56 SeitenCasting Processes: ME 4210: Manufacturing Processes and Engineering Prof. J.S. Colton © GIT 2006anand_lmlNoch keine Bewertungen

- Sludge Management: Treatment and Disposal of SludgeDokument108 SeitenSludge Management: Treatment and Disposal of SludgeRishu RajNoch keine Bewertungen