Beruflich Dokumente

Kultur Dokumente

P91 T91 Engl PDF

Hochgeladen von

parmodrtkOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

P91 T91 Engl PDF

Hochgeladen von

parmodrtkCopyright:

Verfügbare Formate

ThyssenKruppMaterialsInternational

Page 1 Material data sheet P91/T91 10/2011

Alloysteeltubesforhigh-temperatureservice MaterialDataSheet

Steeldesignation: Name MaterialNo.

91

T91

(X10CrNeVkb9-1)

0k5 es|gnat|en: K91560

K90901

(1.4905)

Scope

Thisdatasheetappliesforseamlesstubes.

Application

ThematerialP91/T91isespeciallysuitedforsteamboiler,boilerparts,boilerdrum,pressurevesselfortheapparatus

engineeringandsimilarpurposes.Itcanbeusedinpermanentoperationwithwalltemperaturesuptoabout650C

1202F.

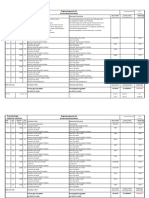

ChemicalcompositionHeatanalysisin%

Name C Si Mn P S Al Cr Mo Ni V N others

P91 0,08-

0,12

0,20-

0,50

0,30-

0,60

0,020 0,010 0,040 8,0-9,50 0,85-

1,05

0,40 0,18-

0,25

0,030-

0,070

Nb0,06-

0,10

T91 0,07-

0,14

0,20-

0,50

0,30-

0,60

0,020 0,010 0,02 8,0-9,5 0,85-

1,05

0,40 0,18-

0,25

0,030-

0,070

Nb0,06-

0,10

X10CrMoV

Nb9-1

0,08-

0,12

0,20-

0,50

0,30-

0,60

0,020 0,010 0,040 8,0-9,5 0,85-

1,05

0,40 0,18-

0,25

0,030-

0,070

Nb0,06-

0,10

Cu0,30

Mechanicalpropertiesatroomtemperature

Material Usual

1

Delivery

condition

Yield/proof

strength

R

p0,2

Tensilestrength

Elongation

A

Impactenergy

KV

N/mm

min.

R

m

N/mm

%

min.

Temperature

C

J

min.

P91

5

+NT 415 585 20

24

13

4

- -

T91

5

+NT 415 585 20

24

13

4

-

X10CrMoVNb9-1 +NT 450 620-850 19

2

17

3

+20 40

2

27

3

1

NT:normalizingandtempered

2

Longitudinaltestpiece

3

Transversetestpiece

4

Forwallthicknesses8mmthevaluesofthetransversetestpieceapply

5

Hardnessmax.25HRC

MinimumvaluesoftheproofstrengthR

p0,2

atelevatedtemperatures

Name

0,2%-ProofstrengthatthetemperatureFinKsi

300 400 500 600 700 800 900 1000 1100 1200

P91

ASMEB31.3

a

28,3 28,2 28,1 27,7 26,7 24,9 22,3 18,0 10,3 4,3

ThyssenKruppMaterialsInternational

Page 2 Material data sheet P91/T91 10/2011

Name

0,2%-ProofstrengthatthetemperatureFinKsi

-20bis

100

200 300 400 500 600 700 800 900 1000 1100 1200

P91/T91

ASMEB31.1

b

24,3 24,3 24,3 24,2 24,1 23,7 22,9 21,3 19,1 16,3 9,6 4,3

a

ASME31.3-ProcessPiping

b

ASME31.1-PowerPiping

ConversionKsiinN/mmMPa:ValueinKsix6,895

ConversionFahrenheitinCelsius:C=Temp.inF-32x5/9

Name

0,2%-ProofstrengthatthetemperaturerCinN/mmMPa

100 150 200 250 300 350 400 450 500 550 600

X10CrMoVNb9-1 410 395 380 370 360 350 340 320 300 270 215

Referencedataforsomephysicalproperties

Densityat

20C

Modulusofelasticity

kN/mmat

Thermalconductivity

at20C

spec.thermal

capacityat20C

spec.electrical

resistivityat20C

kg/dm 20C 300C 400C 500C W/mK J/kgK

mm/m

7,76 210 185 175 165 33 622 0,24

Linearcoefficient10

6

K

-1

ofthermalexpansionbetween20Cand

300C 400C 500C 600C

12,9 13,5 13,9 14,1

Hotforming/Heattreatment

Hotforming Heattreatmentquenchedandtempered,microstructure

TemperatureC Typeofcooling Austenitization

Annealing

1

Microstructure

1100-950 Air 920-980C 680-760C bainitic/ferritic

1

Whenannealingthementionedtemperatureshavetobeholdafterachievingoverthewholecross-sectionforminimum30minutes.

Stressrelievinganneal:600-650C.Holdingtime1-2minutespermmplatethickness,minimum30minutes

Processing/Welding

Standardweldingprocessesforthesesteelgradesare:

TIG-welding ArcweldingE

MAG-weldingmassivewire SubmergedarcweldingSAW

MAG-weldingcoredwire

Dependingontheweldingpositionandtheplatethickness,maybeotherfillermetalshavetobeapplied,whichcanbe

inquiredatthemanufacturerincaseofneed.

Forthesesteelgradesasfillermetalthefollowingelectrodesandweldingwiresarerecommended:

Process Fillermetal

TIG UnionICrMo910

MAGmassivewire UnionICrMo910

MAGcoredwire UnionMVCrMo-M21

ArcweldingE PhoenixSHChromium2KS

ThyssenKruppMaterialsInternational

Page 3 Material data sheet P91/T91 10/2011

SAW UnionS1CrMo2/UV420TTR

Thesesteelscanbeweldedwithinallthicknessrangesaccordingtotheaforementionedweldingprocesses.Preheating

upto200Cispermittedforworkpieceswiththicknesses>10mm.

Afterweldingforworkpieces,whicharesubjecttothetechnicalregulationsforsteamboilerplants,aheattreatmenthas

tobedefinedinparticular.Inallcasesstressrelievingannealhastobeperformed.

Whenflamecuttingoflargerwallthicknessesisperformedthecuttingareahastobepreheatedupto200C.

Remark

Thematerialismagnetizable.

Editor

THYSSENKRUPPMATERIALSINTERNATIONALGMBH

TechnicalSales/QualityManagement

AmThyssenhaus1

45128Essen

References

ASME/ASTMA106:2010 ASTMInternational,100BarrHarborDrive,POBoxC700,

ASTMA213:2011-02 WestConshohocken,PA19428-2959

ASTMA335:2009-03

ASME31.3:2010 TheAmericanSocietyofMechanicalEngineers,ThreeParkAvenue,

ASME31.1:2010 NewYork,NY10016-5990

DINEN10216-2:2007-10 BeuthVerlagGmbH,Postfach,D-10772Berlin

BhlerSchweitechnikDeutschlandGmbH,Hamm

ImportantHint

Informationgiveninthisdatasheetaboutpropertyorapplicabilityofmaterialsrespectiveproductsareno

assuranceofcharacteristicsbutservefordescription.

Information,withwhichweliketoadviseyou,relatetotheexperienceoftheproducersandourown.

Warrantyfortheresultsofthetreatmentandapplicationoftheproductscannotbegranted.

Das könnte Ihnen auch gefallen

- Stahlerzeugung: Integrierte Hüttenwerks- und GasreinigungsanlagenVon EverandStahlerzeugung: Integrierte Hüttenwerks- und GasreinigungsanlagenNoch keine Bewertungen

- Die vierte Generation der Kernreaktoren: Grundlagen, Typen und Nutzen verständlich erklärtVon EverandDie vierte Generation der Kernreaktoren: Grundlagen, Typen und Nutzen verständlich erklärtNoch keine Bewertungen

- Neuartige PDFDokument16 SeitenNeuartige PDFCabra VolklingenNoch keine Bewertungen

- SZ Kraftwerk DDokument20 SeitenSZ Kraftwerk DBorn ToSinNoch keine Bewertungen

- K110DE - Aisi D2Dokument16 SeitenK110DE - Aisi D2italangeloNoch keine Bewertungen

- Thyssen KrupDokument44 SeitenThyssen Krupreleone11100% (1)

- M2TK8 SillDokument1 SeiteM2TK8 SillkędzierzawyNoch keine Bewertungen

- Gasturbinenkenndaten 01Dokument28 SeitenGasturbinenkenndaten 01bastechNoch keine Bewertungen

- Cladding Material Thyssen KruppDokument40 SeitenCladding Material Thyssen KruppumeshNoch keine Bewertungen

- Titan - Und TitanlegierungenDokument11 SeitenTitan - Und TitanlegierungenBobNoch keine Bewertungen

- ROTH - Axial Expansion JointDokument56 SeitenROTH - Axial Expansion Jointandmar2011Noch keine Bewertungen

- Katalog2 2005 10 PDFDokument34 SeitenKatalog2 2005 10 PDFmasatusNoch keine Bewertungen

- 20160226042521-1191 1201 C45e C45RDokument2 Seiten20160226042521-1191 1201 C45e C45RGianfranco BolliNoch keine Bewertungen

- Werkstoffdatenblatt 1 - 4541Dokument1 SeiteWerkstoffdatenblatt 1 - 4541weshazwanNoch keine Bewertungen

- Meh Svojstva-Podjela CelikaDokument3 SeitenMeh Svojstva-Podjela CelikaAminaNoch keine Bewertungen

- 20160129032849-8159 51CrV4Dokument1 Seite20160129032849-8159 51CrV4Kokić MirzaNoch keine Bewertungen

- Kaltzaehe StaehleDokument69 SeitenKaltzaehe Staehle9914102Noch keine Bewertungen

- IMT ValvesDokument76 SeitenIMT Valvesebbys89Noch keine Bewertungen

- 42 Crmo 4Dokument16 Seiten42 Crmo 4motolisaNoch keine Bewertungen

- 6511 36CrNiMo4Dokument1 Seite6511 36CrNiMo4Miorita_13Noch keine Bewertungen

- Bauregelliste 2015 (100-193)Dokument94 SeitenBauregelliste 2015 (100-193)Tyson TyNoch keine Bewertungen

- Especificación Técnica: Se Revisionan Pag. 2-3-13-27-40-50-60-70-75, Se Agregan Pag. 79 A 87Dokument170 SeitenEspecificación Técnica: Se Revisionan Pag. 2-3-13-27-40-50-60-70-75, Se Agregan Pag. 79 A 87DestructorDeDiosesNoch keine Bewertungen

- 30CrMoV9 WerkstoffeDokument6 Seiten30CrMoV9 WerkstoffeAntonioNoch keine Bewertungen

- AnwendungstabelleDokument11 SeitenAnwendungstabelleSkrastincsNoch keine Bewertungen

- Material DataDokument2 SeitenMaterial Datakaushik65Noch keine Bewertungen

- Cert 1Dokument3 SeitenCert 1Gaston LooNoch keine Bewertungen

- 20130116015740AVI Technische ProduktinformationDokument48 Seiten20130116015740AVI Technische ProduktinformationPiulitza88100% (1)

- Technisches Datenblatt Loctite 243Dokument4 SeitenTechnisches Datenblatt Loctite 243Chris HaNoch keine Bewertungen

- Bauart 240 Pneumatische Stellventile Typ 3241-1 Und Typ 3241-7 Durchgangsventil Typ 3241Dokument12 SeitenBauart 240 Pneumatische Stellventile Typ 3241-1 Und Typ 3241-7 Durchgangsventil Typ 3241mlachenal5237Noch keine Bewertungen

- Ritag ValveDokument0 SeitenRitag Valvekingathur26681Noch keine Bewertungen

- BENSON HRSG Reference List PDFDokument1 SeiteBENSON HRSG Reference List PDFbagastcNoch keine Bewertungen

- Imp 3159 - Brida Slip On 3X150 - 201164Dokument1 SeiteImp 3159 - Brida Slip On 3X150 - 201164Sergio GuacanemeNoch keine Bewertungen

- MAG-Schweißen Hochfester FeinkornbaustähleDokument25 SeitenMAG-Schweißen Hochfester FeinkornbaustählesusanwebNoch keine Bewertungen

- 1.1191 C45E - Baustahl - Datenblatt - TK - 1191 - 1201Dokument3 Seiten1.1191 C45E - Baustahl - Datenblatt - TK - 1191 - 1201genuesslichwohlriechendersteinbockNoch keine Bewertungen

- Linde Criogenic Tanks LITS - F2Dokument18 SeitenLinde Criogenic Tanks LITS - F2Georgi KalchevNoch keine Bewertungen

- Bohler K990DEDokument12 SeitenBohler K990DEDeysi CardenasNoch keine Bewertungen

- Eltra Consumables - de - enDokument13 SeitenEltra Consumables - de - enBasNoch keine Bewertungen

- 1.7223 deDokument6 Seiten1.7223 devoldemortsNoch keine Bewertungen

- Volvomotor B230F LH2 2Dokument50 SeitenVolvomotor B230F LH2 2Achim Maximilian Naumann d'Alnoncourt100% (1)

- Technische Kera MikDokument0 SeitenTechnische Kera MikhoscriNoch keine Bewertungen

- AD2000 Vs EN13445Dokument23 SeitenAD2000 Vs EN13445rodrigoperezsimoneNoch keine Bewertungen

- Benson HRSG Reference ListDokument1 SeiteBenson HRSG Reference List55312714Noch keine Bewertungen

- B57540G0103F000Dokument36 SeitenB57540G0103F000ThisNoch keine Bewertungen

- Din en 15860 2008-09 PDFDokument49 SeitenDin en 15860 2008-09 PDFAhmed AlzubaidiNoch keine Bewertungen

- PTFE SlidingPadsDokument32 SeitenPTFE SlidingPadsBhoopendra SinghNoch keine Bewertungen

- ISFO 02 Isolierfolien FlammhemmendDokument2 SeitenISFO 02 Isolierfolien FlammhemmendRameez Ali FaridiNoch keine Bewertungen

- 1 4571Dokument4 Seiten1 4571wilian_coelho3309Noch keine Bewertungen

- Im4 Povistemp 12 PDFDokument86 SeitenIm4 Povistemp 12 PDFgrgur5Noch keine Bewertungen

- Voith Turbo 422 TVGDokument11 SeitenVoith Turbo 422 TVGAlireza TakrimiNoch keine Bewertungen

- Engineering Parts List Konstruktionsstückliste Thyssenkrupp Industrial SolutionsDokument10 SeitenEngineering Parts List Konstruktionsstückliste Thyssenkrupp Industrial SolutionsluischicoNoch keine Bewertungen

- TD BrazeTec S94 DEDokument1 SeiteTD BrazeTec S94 DEkmNoch keine Bewertungen

- Datenblatt-100Cr6 2Dokument2 SeitenDatenblatt-100Cr6 2peterNoch keine Bewertungen

- TSP 231 20241Dokument8 SeitenTSP 231 20241ruben dario guerra chirinosNoch keine Bewertungen

- Strebel Preisliste - 2014 PDFDokument84 SeitenStrebel Preisliste - 2014 PDFzvonkomihajlovic4891Noch keine Bewertungen

- RESISTAL A90 MX Umwelt Energie ISO ENDokument2 SeitenRESISTAL A90 MX Umwelt Energie ISO ENmonica.alvarezNoch keine Bewertungen

- 015 POTMPH IGF18297 AbschlussDokument2 Seiten015 POTMPH IGF18297 Abschlussmanjumv27Noch keine Bewertungen

- WW-2010154 Sorg BP1023703 WannenkühlungDokument2 SeitenWW-2010154 Sorg BP1023703 WannenkühlungranishNoch keine Bewertungen

- Ancon TT MBTDokument16 SeitenAncon TT MBTUmpahPah75Noch keine Bewertungen

- Metallurgy and Processing of High-Integrity Light Metal Pressure CastingsVon EverandMetallurgy and Processing of High-Integrity Light Metal Pressure CastingsNoch keine Bewertungen