Beruflich Dokumente

Kultur Dokumente

Din 316

Hochgeladen von

tobster990 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

703 Ansichten4 SeitenWing Screws.

Originaltitel

DIN 316

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenWing Screws.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

703 Ansichten4 SeitenDin 316

Hochgeladen von

tobster99Wing Screws.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

UDC 621.882.218.1 June 1983

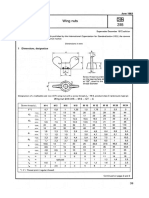

Wing screws

Fldgelschrauben Supersedes November 1970 edition

As itis current practice in standards published by the Intemational Organization for Standardization (1SO), the comma

hnas been used throughout 352 decimal marker.

Dimensions in mm

1. Dimensions, designation

Fiat point or oval point

in accordance with DIN 78

(at manufacturer's discretion)

Designation of» malleable cast iron (GT) wing serew witha serew thread d = M6

‘and @ length 1= 20 mm, of product class C (previously type 3}

Wing screw DIN 316 ~ M6 x 20-GT—C

Continued on pages 2to 4

23

Poge2 DINSI6

Serew thread dy ma | ms | me | ms | mio | maz | mis | mzo | 2s

PY o7 | oa | 1 | ta | ts | ws] 2 | 25

ome 2a | 3 | 4 4s | 53 | 6 | 75

~~ nun [3 |w | | | ao |» | 4

ff et |e che wv jo [2 [a2 | a |

_ ~={7]e | ws | 195 | 2 | 2 | 375°

nn | 55 | 75 ws | i7s | a | a | 3

m= 20 | 26

© mm |e | 20

me] 19 | 23

salinese oy EE ER

wm | 23 [ 28

=m | 17 | 23 | 2

nome | os [fe

Range

of commercially available

3

36.2

412

lengths

512

615

*) P= Theead pitch (regular thread)

24

DIN316 Pages

2_ Technical delivery conditions

i Malleable cast iron Stee! ‘Copper tine alloys

in ‘s iGuznl

‘General reauirements in accordance with DIN 267 Part 1

Tolerance 6a (product class 8); 8 (oroductclss G)

Serewtneess Sancard DIN 13 Pare 13

fe ] ‘St see

Mechanical joperty cass | GT =GTS3510 | min.tenslestergtn | Cuzn= G-CuZnd0 Fe

Properties eee 2400 Nimm2

Standard [ow 1602 IN 17 100 IN 1709

Permissible dimen. Product class 8 (previously ma) "Yi: © (previ =

sional deviations Standard | DIN 150 4759 Part 1

| ‘5 manufactured

Surface [As regards galvanic surface protection, DIN 267 Part 9 shall aly

Other kinds of surface protection subject to agreement

‘Acceptance test DIN 267 Part 5) shal apply to the acceptance test

=) At prevent at the stage of draft

+) Bearing face machined

2) Bearing face unmachined

Wing serews complying with this standard may be made from two separate pieces. The joint between these pieces shal be

0 designed a¢ not to impaie the mechanical and functional properties of the screws, compared to screws made of one

piece only.

Standards referred to

DIN 19Part 13 ISO metric sere threads; review of screw threads for bolts and nuts from 1 to 62 mm screw

thread ciamet

on 78 “Thread ends, lengths of projection of thread ends for ISO metric erew threads according to DIN 13

DIN 267 Part Fasteners: technical delivery conditions, general requirements

DIN 267PartS (at present atthe stage of draft) Fasteners; technical delivery conditions, acceptance test

DIN 267Part9 Fasteners; technical delivery conditions, components with electroplated coatings

DIN 1682 Malleable cast ivon; terminology, properties

DIN 1709 Copper-zine casting alloy (cast brats and special cast bras) castings

IN 17 100 Steels for general structural purposes; quality standard

DIN 1S0.4758 Part 1 Fasteners; tolerances for bolts and nuts with screw thread diameters from 1,6 to 150mm:

product classes A, B and ©

Previous editions

DIN 316: 10.20, 04.25, 10.43, 01.86, 11.70

Amendments

‘The following amendments have been made in comparizon with the November 1970 edition

4) The dimensions ofthe wing screws have been altered in some respects

) Limiting sizes have been adopted.

©) Sizes M 2 to M 3,5 have been deleted

4) The technical delivery conditions have been complemented.

©) The contents of the standard have been revised editorially,

25

Page 4 DIN 316

Explanatory notes

In June 1975, drafts of the planned new editions of DIN 315 (wing nuts) and of DIN 316 (wing screws) were published;

they made a distinction between Part 1 “heavy duty type” and Part 2 "light duty type”. This dstinetion did not how:

ever meet with general approval, because it did not reflect the real situation in practice.

Consequently, new dratt standards were published in December 1980, which no longer made ths distinction. In

thereof, the constructionel dimensions of the wing nuts and wing screws have been selected in such a way, also from the

tolerance aspect, thatthe most common production series are covered thereby, without having to worry about any impait-

‘ment of the proper functioning of the components due to the revised dimensions and tolerances,

‘These draft standards led to the revised editions of DIN 315 and DIN 316, which manage to preserve the relatively wide

latitude forthe various shapes and types. Sizes M 2 to M 3,5 have been deleted because no requirement for these sizes,

worthy oftheir inclusion in the standard could be ascertained,

‘Specifications with regard to the weight of wing nuts and wing screws have been dropped from the standards because the

‘wide ranges of tolerance of the individual dimensions do not permit the specification of weights which would give any

useful information.

‘The data relating to technical delivery conditions have been modified and complemented. In this connection, no property

classes in accordance with DIN ISO 898 Part 1 (previously DIN 267 Part 3) have been selected for wing screws made of

Steel, because the requirements and tests associated with these property clases in the standard concerned are not appli

cable, or ae only applicable toa limited extent 10 wing screws. As far a¢ wing nuts made of stool are concerned, recourse

Was had to DIN ISO 898 Part 2, and in the ease of components made of malleable eat iron or of eopper-zine alloys, the

appropriate materials have been specified.

‘The previous mg and g types in accordance with DIN 267 Patt 2 have been replaced by product classes A and B in accord:

anee with DIN 180.4759 Part 1, and the latter will shortly be complemented by the planned new edition of DIN 267 Part 2

‘These revised designations have not resulted in any fundamental chenges however. These two product classes, apart from

the screw thread tolerances, only differ in practice from each other in respect of their bearing faces (machined v. unrna

{chined), which fact ean however only be deduced with reservations trom DIN ISO 4759 Part 1 or from DIN 267 Part 2.

Consequently, appropriate notes to this effect have been incorporated

In deference to established practice, the manufacture of wing screws made from two separate pieces has been authorized

{85 previously, on condition thatthe joint between the two pieces is properly designed, and thatthe Use ofthe wing screws

is inno way impaired thereby

International Patent Classification

F 166 25.00

26