Beruflich Dokumente

Kultur Dokumente

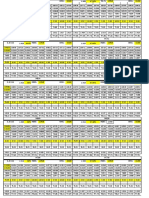

Fail Safe™ On/Off K22Fa Front Air Fan Drives: Assemblies by Part Number

Hochgeladen von

Carlos AnticonaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fail Safe™ On/Off K22Fa Front Air Fan Drives: Assemblies by Part Number

Hochgeladen von

Carlos AnticonaCopyright:

Verfügbare Formate

FAIL SAFE™ On/Off K22FA

Front Air Fan Drives

I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G .

■ Assemblies by Part Number

Fan Drive Assembly Fan Clutch Fan Hub Adapter Kit

1093-05472-01 1090-05261-01 4077-35428-01 4038-35343-01

1093-05607-01 1090-05261-01 None 1096-06547-01

1093-05866-01 1090-05261-01 1077-05827-01 1096-06710-01

1093-05867-01 1090-05262-01 1077-05827-01 1096-06545-01

1093-05868-01 1090-05261-01 1077-05826-01 1096-06699-01

1093-05869-01 1090-05261-01 1077-05826-02 1096-06699-01

1093-05870-01 1090-05262-01 1077-05826-02 1096-06700-01

1093-05911-01 1090-05262-01 4077-37244-01 1096-06700-01

1093-05917-01 1090-05261-01 1077-05849-01 1096-06534-01

1093-05918-01 1090-05262-01 1077-05849-01 1096-06536-01

1093-05956-01 1090-05262-01 1077-05826-04 1096-06538-01

1093-05966-01 1090-05261-01 1077-05826-04 1096-06534-01

1093-05982-01 1090-05262-01 1077-05826-03 1096-06700-01

1093-05985-01 1090-05261-01 1077-05826-01 1096-06534-01

1093-05995-01 1090-05261-01 1077-05826-02 1096-06534-01

1093-05996-01 1090-05261-01 1077-05827-01 1096-06534-01

1093-05997-01 1090-05262-01 1077-05826-02 1096-06535-01

1093-05998-01 1090-05262-01 1077-05827-01 1096-06535-01

1093-05999-01 1090-05261-01 1077-05849-01 1096-06537-01

1093-06001-01 1090-05262-01 1077-05849-01 1096-06538-01

1093-06014-01 1090-05262-01 1077-05826-01 1096-06535-01

1093-06015-01 1090-05262-01 1077-05827-01 1096-06538-01

1093-06016-01 1090-05261-01 1077-05826-01 1096-06539-01

1093-06034-01

1093-06058-01

1090-05262-01

1090-05261-01

1077-05826-02

1077-05849-01

1096-06536-01

1096-06710-01 ■ Fan Drive Assemblies

1093-06059-01 1090-05262-01 1077-05849-01 1096-06545-01

1093-06061-01 1090-05262-01 1077-05827-01 1096-06536-01 The front air fan drive assembly shown here

1093-06062-01 1090-05262-01 1077-05849-01 1096-06549-01

1093-06063-01 1090-05262-01 1077-05826-01 1096-06700-01 consists of a clutch (1090 part number), a hub

1093-06071-01 1090-05261-01 1077-05826-02 1096-06539-01

(1077 part number) and in most cases, an

1093-06072-01 1090-05261-01 1077-05826-01 1096-06537-01

1093-06073-01 1090-05261-01 1077-05826-02 1096-06537-01 adapter kit (1096 part number).

1093-06080-01 1090-05262-01 1077-05826-02 1096-06545-01

1093-06124-01 1090-05262-01 1077-05826-02 1096-06702-01

1093-06128-01 1090-05261-01 1077-05826-01 1096-06533-01

1093-06129-01 1090-05261-01 1077-05826-02 1096-06533-01 Replacement Clutches

1093-06130-01 1090-05261-01 1077-05827-02 1096-06534-01

1093-06162-01

1093-06163-01

1090-05262-01

1090-05262-01

1077-06155-01

1077-06157-01

1096-06538-01

1096-06535-01

The 1090-05000 and 06000 series clutches are obso-

1093-06178-01 1090-05261-01 1077-05826-03 1096-06699-01 lete and service parts are no longer supplied. To

1093-06181-01 1090-05261-01 1077-05849-01 1096-06539-01

1093-06182-01 1090-05261-01 1077-06165-02 1096-06710-01

replace one of them, look up your 1093 drive assem-

1093-06184-01 1090-05261-01 1077-06167-01 1096-06547-01

1093-06187-01 1090-05261-01 1077-06165-01 1096-06534-01

bly in the chart on pages 1-3, determine which clutch

1093-06188-01 1090-05262-01 1077-05849-01 1096-06550-01

was used and select a new one from the table on

1093-06190-01 1090-05261-01 1077-05827-01 1096-06541-01

1093-06192-01 1090-05261-01 1077-05849-01 1096-06543-01 page 4.

1093-06193-01 1090-05261-01 1077-05827-01 1096-06544-01

1093-06194-01 1090-05261-01 1077-05826-01 1096-06547-01

1093-06198-01 1090-05261-01 4077-37791-01 1096-06715-01 Replacement Hubs

1093-06244-01 1090-05261-01 1077-05826-08 1096-06699-01 None of the hubs used in front air 1093 fan drive

1093-06247-01 1090-05261-01 1077-05826-05 1096-06699-01

1093-06253-01 1090-05261-01 1077-06155-01 1096-06710-01 assemblies are in production. The tapered roller bear-

1093-06254-01 1090-05261-01 1077-06157-01 1096-06537-01

1093-06329-01 1090-05261-01 1077-06149-01 1096-06547-01 ing type hub was the most common, and the bearing

1093-06330-01

1093-06331-01

1090-05261-01

1090-05261-01

1077-06127-01

1077-06127-01

1096-06710-01

1096-06537-01

kits for it are still available.

1093-06332-01 1090-05261-01 1077-06201-01 1096-06710-01

1093-06333-01 1090-05261-01 1077-06157-01 1096-06541-01

1093-06397-01 1090-05262-01 1077-05827-01 1096-06630-01

1093-06398-01 1090-05262-01 1077-05849-01 1096-06630-01

1093-06430-01 1090-06060-01 1077-05827-03 1096-06710-01

1093-06514-01 1090-05262-01 1077-05826-02 1096-06700-01

1093-06524-01 1090-06060-01 1077-05826-02 1096-06537-01

1093-06525-01 1090-06060-01 1077-05827-01 1096-06541-01

1093-06526-01 1090-06060-01 1077-05849-02 1096-06541-01

1093-06531-01 1090-06404-01 None None

1093-06553-01 1090-05262-01 4077-36625-01 1096-06722-01

1093-06557-01 1090-05262-01 1077-05826-04 1096-06545-01

1093-06569-01 1090-06060-02 1077-05826-01 1096-06547-01

FAIL SAFE™ On/Off K22FA Front Air Fan Drives I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G

1

Assemblies by Part Number FAIL SAFE™ On/Off K22FA Front Air Fan Drives

■ Assemblies by Part Number continued

Fan Drive Assembly Fan Clutch Fan Hub Adapter Kit Fan Drive Assembly Fan Clutch Fan Hub Adapter Kit

1093-06570-01 1090-06060-02 1077-05827-02 1096-06541-01 1093-06784-01 1090-06620-01 1077-06165-01 1096-06544-01

1093-06571-01 1090-06060-02 1077-05827-01 1096-06533-01 1093-06785-01 1090-06620-01 1077-05826-01 1096-06544-01

1093-06572-01 1090-06060-02 1077-05489-01 1096-06547-01 1093-06786-01 1090-06620-01 1077-05827-02 1096-06534-01

1093-06578-01 1090-05262-01 1077-05849-02 1096-06536-01 1093-06787-01 1090-06620-01 1077-05826-01 1096-06539-01

1093-06598-01 1090-05261-01 1077-05826-04 1096-06537-01 1093-06788-01 1090-06620-01 1077-05849-01 1096-06708-01

1093-06605-01 1090-05262-01 1077-05849-01 1096-06536-01 1093-06789-01 1090-06620-01 1077-05826-01 1096-06534-01

1093-06623-01 1090-06060-02 1077-06521-01 1096-06539-01 1093-06790-01 1090-06620-01 1077-05827-01 1096-06706-01

1093-06634-01 1090-05261-01 1077-05826-02 1096-06547-01 1093-06791-01 1090-06060-02 1077-05826-02 1096-06705-01

1093-06635-01 1090-05262-01 1077-05826-02 1096-06630-01 1093-06792-01 1090-06620-01 1077-05826-02 1096-06707-01

1093-06636-01 1090-06620-01 1077-05826-02 1096-06537-01 1093-06793-01 1090-06620-01 1077-05826-04 1096-06719-01

1093-06637-01 1090-06060-02 1077-05826-02 1096-06541-01 1093-06794-01 1090-06060-01 1077-05826-04 1096-06537-01

1093-06638-01 1090-06620-01 1077-05826-01 1096-06534-01 1093-06795-01 1090-06620-01 1077-05826-02 1096-06719-01

1093-06647-01 1090-05262-01 1077-05826-01 4038-35086-31 1093-06796-01 1090-06060-01 1077-05826-02 1096-06719-01

1093-06650-01 1090-06060-02 1077-06157-01 1096-06719-01 1093-06797-01 1090-06060-01 1077-05849-01 1096-06539-01

1093-06651-01 1090-05262-01 1077-06157-01 1096-06538-01 1093-06828-01 1090-05261-01 1077-05849-02 1096-06909-01

1093-06652-01 1090-06060-02 1077-06127-01 1096-06539-01 1093-06829-01 1090-05262-01 1077-05826-02 NONE

1093-06653-01 1090-06060-02 1077-06155-01 1096-06705-01 1093-06831-01 1090-06620-01 1077-05849-01 1096-06534-01

1093-06654-01 1090-06060-02 1077-06149-01 1096-06534-01 1093-06851-01 1090-05261-01 1077-05826-02 1096-06719-01

1093-06658-01 1090-06620-01 1077-05826-02 1096-06544-01 1093-06852-01 1090-05261-01 1077-05827-01 1096-06537-01

1093-06686-01 1090-05261-01 1077-05849-01 1096-06547-01 1093-06862-01 1090-05261-01 1077-05827-01 1096-06706-01

1093-06689-01 1090-05261-01 1077-06201-01 1096-06539-01 1093-06863-01 1090-06060-02 1077-06167-01 1096-06537-01

1093-06690-01 1090-05261-01 1077-06165-01 1096-06544-01 1093-06876-01 1090-06620-01 1077-05826-05 1096-06547-01

1093-06691-01 1090-05261-01 1077-05827-01 1096-06719-01 1093-06878-01 1090-06620-01 1077-06877-01 1096-06719-01

1093-06692-01 1090-05262-01 1077-05827-02 1096-06729-01 1093-06883-01 1090-06620-01 1077-05849-02 1096-07245-01

1093-06730-01 1090-06060-02 1077-06127-01 1096-06710-01 1093-06884-01 1090-06620-01 1077-05849-01 1096-06539-01

1093-06731-01 1090-05261-01 1077-05849-02 1096-06544-01 1093-06885-01 1090-06620-01 1077-05849-02 1096-06544-01

1093-06732-01 1090-05262-01 1077-06149-01 1096-06549-01 1093-06887-01 1090-06060-02 1077-06167-01 1096-06547-01

1093-06733-01 1090-06620-01 1077-05827-01 1096-06541-01 1093-06891-01 1090-06620-01 1077-06565-02 1096-06914-01

1093-06734-01 1090-06620-01 1077-05849-02 1096-06541-01 1093-06892-01 1090-06620-01 1077-06565-01 1096-06908-01

1093-06739-01 1090-05162-01 1077-05826-02 1096-06549-01 1093-06893-01 1090-06060-02 1077-05826-02 1096-06547-01

1093-06740-01 1090-05262-01 1077-05826-02 1096-06729-01 1093-06895-01 1090-06620-01 1077-05826-02 1096-06541-01

1093-06741-01 1090-06060-02 1077-05826-02 1096-06534-01 1093-06896-01 1090-06620-01 1077-05826-04 1096-06541-01

1093-06742-01 1090-06060-02 1077-05827-01 1096-06909-01 1093-06897-01 1090-06620-01 1077-05849-02 1096-06543-01

1093-06743-01 1090-05261-01 1077-05849-02 1096-06719-01 1093-06898-01 1090-06620-01 1077-05849-02 1096-06909-01

1093-06746-01 1090-06620-01 1077-05849-01 1096-06547-01 1093-06903-01 1090-06060-02 1077-05826-02 1096-06699-01

1093-06747-01 1090-06620-01 1077-06127-01 1096-06547-01 1093-06911-01 1090-06060-02 1077-05826-01 1096-06719-01

1093-06748-01 1090-06620-01 1077-06127-01 1096-06539-01 1093-06912-01 1090-06620-01 1077-05827-02 1096-06544-01

1093-06749-01 1090-06620-01 1077-06149-01 1096-06534-01 1093-06915-01 1090-06060-02 1077-05849-02 1096-06544-01

1093-06750-01 1090-06620-01 1077-06155-01 1096-06547-01 1093-06919-01 1090-06060-02 1077-06165-01 1096-06547-01

1093-06751-01 1090-06620-01 1077-06201-01 1096-06534-01 1093-06936-01 1090-06060-02 1077-05827-01 1096-07245-01

1093-06752-01 1090-06620-01 1077-06157-01 1096-06539-01 1093-06950-01 1090-06620-01 1077-05826-03 1096-06547-01

1093-06753-01 1090-06060-02 1077-05849-01 1096-06544-01 1093-06989-01 1090-06060-02 1077-05849-02 1096-06539-01

1093-06754-01 1090-06060-02 1077-05827-01 1096-06534-01 1093-06999-01 1090-06060-02 1077-05826-02 1096-06539-01

1093-06755-01 1090-06060-02 1077-05827-01 1096-06539-01 1093-07001-01 1090-06060-02 1077-05826-02 1096-06537-01

1093-06756-01 1090-06620-01 1077-05826-02 1096-06539-01 1093-07003-01 1090-06060-02 1077-05849-02 1096-06719-01

1093-06759-01 1090-06620-01 1077-05849-01 1096-06707-01 1093-07008-01 1090-06060-02 1077-058-02-02 1096-06699-01

1093-06760-01 1090-06060-02 1077-05849-01 1096-06710-01 1093-07021-01 1090-06060-02 1077-061-01-01 1096-06543-01

1093-06761-01 1090-06060-02 1077-05827-01 1096-06547-01 1093-07023-01 1090-06060-02 1077-058-04-04 1096-06547-01

1093-06762-01 1090-06060-02 1077-05827-01 1096-06534-01 1093-07024-01 1090-06620-01 1077-058-01-01 1096-07245-01

1093-06763-01 1090-06620-01 1077-05826-01 1096-06547-01 1093-07025-01 1090-06060-02 1077-058-02-02 1096-06544-01

1093-06764-01 1090-06060-02 1077-05826-01 1096-06539-01 1093-07042-01 1090-06060-02 1077-06149-02 1096-06534-01

1093-06765-01 1090-06060-02 1077-05849-01 1096-06537-01 1093-07043-01 1090-06060-02 1077-05827-01 1096-06544-01

1093-06766-01 1090-06620-01 1077-05826-01 1096-06699-01 1093-07044-01 1090-06060-02 1077-05826-02 1096-06706-01

1093-06767-01 1090-06620-01 1077-05826-02 1096-06699-01 1093-07056-01 1090-06060-02 1077-06127-02 1096-06539-01

1093-06768-01 1090-06060-02 1077-05826-02 1096-06539-01 1093-07079-01 1090-05262-01 1077-05849-02 1096-06729-01

1093-06769-01 1090-06060-02 1077-05826-02 1096-06537-01 1093-07082-01 1090-06060-02 1077-05849-02 1096-06541-01

1093-06770-01 1090-06620-01 1077-05827-01 1096-06710-01 1093-07099-01 1090-05262-01 1077-05826-02 1096-06550-01

1093-06771-01 1090-06060-02 1077-05827-01 1096-06710-01 1093-07100-01 1090-06620-01 1077-06877-01 1096-06909-01

1093-06772-01 1090-06060-01 1077-05849-01 1096-06544-01 1093-07101-01 1090-07050-01 1077-06521-01 1096-06547-01

1093-06773-01 1090-06060-02 1077-05849-01 1096-06534-01 1093-07102-01 1090-05262-01 1077-05849-02 4038-35086-34

1093-06774-01 1090-06620-01 1077-05826-05 1096-06537-01 1093-07105-01 1090-05262-01 1077-05849-02 4038-35086-34

1093-06775-01 1090-06620-01 1077-05849-01 1096-06537-01 1093-07109-01 1090-06620-01 1077-NEW 1096-06547-01

1093-06776-01 1090-06620-01 1077-05827-02 1096-06719-01 1093-07123-01 1090-06620-01 1077-05849-02 1096-06539-01

1093-06777-01 1090-06620-01 1077-05827-01 1096-06544-01 1093-07124-01 1090-06060-03 1077-05826-02 1096-06534-01

1093-06778-01 1090-06620-01 1077-06165-02 1096-06534-01 1093-07125-01 1090-06060-03 1077-05849-02 1096-06544-01

1093-06779-01 1090-06620-01 1077-06165-02 1096-06539-01 1093-07126-01 1090-06060-03 1077-05849-01 1096-06544-01

1093-06780-01 1090-06620-01 1077-06167-01 1096-06534-01 1093-07131-01 1090-06060-02 1077-07091-01 1096-06908-01

1093-06781-01 1090-06620-01 1077-06166-01 1096-06537-01 1093-07132-01 1090-06060-02 1077-07091-02 1096-06908-01

1093-06782-01 1090-06620-01 1077-06165-01 1096-06534-01 1093-07133-01 1090-06060-02 1077-07091-03 1096-07259-01

1093-06783-01 1090-06620-01 1077-05827-01 1096-06719-01 1093-07157-01 1090-06620-01 1077-07156-03 1096-06547-01

2 I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G FAIL SAFE™ On/Off K22FA Front Air Fan Drives

FAIL SAFE™ On/Off K22FA Front Air Fan Drives Assemblies by

■ Assemblies by Part Number continued

Fan Drive Assembly Fan Clutch Fan Hub Adapter Kit Fan Drive Assembly Fan Clutch Fan Hub Adapter Kit

1093-07181-01 1090-07050-01 1077-05826-10 1096-06710-01 1093-07523-01 1090-06060-02 1077-05826-02 1096-06719-01

1093-07189-01 1090-07050-01 1077-05849-01 1096-06537-01 1093-07546-01 1090-07050-01 1077-07438-03 1096-37101-03

1093-07190-01 1090-07050-01 1077-06165-02 1096-06537-01 1093-07547-01 1090-08000-01 1077-05827-01 1096-05915-01

1093-07191-01 1090-07050-01 1077-05827-02 1096-06547-01 1093-07556-01 1090-08000-01 1077-05826-02 1096-06539-01

1093-07192-01 1090-07050-01 1077-06167-01 1096-06539-01 1093-07557-01 1090-08000-01 1077-05849-01 1096-05364-01

1093-07193-01 1090-07050-01 1077-06166-01 1096-06539-01

1093-07194-01 1090-07050-01 1077-06565-01 1096-07259-01 1093-07558-01 1090-08000-01 1077-05826-02 1096-05874-01

1093-07195-01 1090-07050-01 1077-06165-01 1096-06539-01 1093-07559-01 1090-08000-01 1077-05826-02 1096-05915-01

1093-07197-01 1090-07050-01 1077-06565-02 1096-07259-01 1093-07561-01 1090-08000-01 1077-05826-02 1096-05364-01

1093-07200-01 1090-07050-01 1077-05849-02 1096-06537-01 1093-07562-01 1090-08000-01 1077-05849-02 1096-06539-01

1093-07563-01 1090-08000-01 1077-05849-02 1096-06719-01

1093-07201-01 1090-07050-01 1077-05827-01 1096-06534-01

1093-07213-01 1090-06060-02 1077-06877-01 1096-06706-01 1093-07564-01 1090-08000-01 1077-05826-02 1096-05902-01

1093-07218-01 1090-06060-02 1077-07070-01 1096-06710-01 1093-07565-01 1090-08000-01 1077-07070-01 1096-07244-01

1093-07219-01 1090-06060-02 1077-07070-02 1096-06710-01 1093-07566-01 1090-08000-01 1077-07070-02 1096-07244-01

1093-07220-01 1090-07050-01 1077-05826-02 1096-06547-01 1093-07566-02 1090-08000-01 1077-07070-03 1096-06710-01

1093-07571-01 1090-08000-01 1077-05826-02 1096-06539-01

1093-07221-01 1090-06060-02 1077-05826-01 1096-06544-01 1093-07572-01 1090-08000-01 1077-06925-02 1096-06710-01

1093-07222-01 1090-06060-02 1077-05826-01 1096-06534-01 1093-07573-01 1090-08000-01 1077-05826-02 1096-05378-01

1093-07224-01 1090-07050-01 1077-06565-01 None 1093-07574-01 1090-08000-01 1077-05826-02 1096-06706-01

1093-07225-01 1090-07050-01 1077-06565-02 None 1093-07575-01 1090-08000-01 1077-07156-02 1096-05876-01

1093-07227-01 1090-07050-01 1077-06565-01 1096-06695-01 1093-07576-01 1090-08000-01 1077-07156-01 1096-06541-01

1093-07228-01 1090-06060-02 1077-05849-01 1096-06533-01 1093-07577-01 1090-08000-01 1077-07156-02 1096-06544-01

1093-07230-01 1090-07050-01 1077-05827-01 1096-07245-01 1093-07578-01 1090-07050-01 1077-05826-02 1096-06705-01

1093-07233-01 1090-06060-02 1077-07253-01 1096-06710-01 1093-07582-01 1090-08000-01 1077-07253-01 1096-06710-01

1093-07234-01 1090-07050-01 1077-05826-01 1096-06699-01 1093-07582-02 1090-08000-01 1077-07253-02 1096-06710-01

1093-07235-01 1090-07050-01 1077-05849-01 1096-06534-01 1093-07584-01 1090-08000-01 1077-05827-01 1096-07245-01

1093-07236-01 1090-06060-02 1077-05849-02 1096-06533-01 1093-07585-01 1090-08000-01 1077-05827-01 1096-05364-01

1093-07237-01 1090-06060-02 1077-05827-01 New 1093-07586-01 1090-08000-01 1077-06165-01 1096-06543-01

1093-07240-01 1090-06060-02 1077-07156-02 1096-06534-01 1093-07587-01 1090-08000-01 1077-05827-01 1096-06729-01

1093-07241-01 1090-07050-01 1077-05849-02 1096-06909-01 1093-07588-01 1090-08000-01 1077-05827-02 1096-05365-01

1093-07243-01 1090-07050-01 1077-06565-03 None 1093-07589-01 1090-08000-01 1077-05826-02 1096-06710-01

1093-07254-01 1090-07050-01 1077-06565-01 4038-37101-15 1093-07590-01 1090-08000-01 1077-05849-01 1096-06539-01

1093-07256-01 1090-06060-02 1077-06565-04 None 1093-07591-01 1090-08000-01 1077-06521-01 1096-06539-01

1093-07269-01 1090-07050-01 1077-06925-02 1096-06710-01 1093-07592-01 1090-08000-01 1077-05826-02 1096-06544-01

1093-07300-01 1090-07050-01 1077-07156-08 1096-06710-01 1093-07593-01 1090-08000-01 1077-05849-02 1096-06541-01

1093-07311-01 1090-05262-01 1077-07156-02 1096-06630-01 1093-07594-01 1090-08000-01 1077-05827-01 1096-06539-01

1093-07312-01 1090-06060-03 1077-07156-02 1096-06534-01 1093-07600-01 1090-08000-01 1077-06149-02 1096-06534-01

1093-07316-01 1090-06060-03 1077-07156-02 1096-06706-01 1093-07601-01 1090-08000-01 1077-05826-02 1966-06719-01

1093-07345-01 1090-06060-02 1077-07156-02 1096-06544-01 1093-07604-01 1090-08000-01 1077-05849-04 1096-06544-01

1093-07357-01 1090-07050-01 1077-05826-02 1096-06534-01 1093-07630-01 1090-07050-01 1077-05827-01 1096-06539-01

1093-07358-01 1090-07050-01 1077-05826-02 1096-06541-01 1093-07637-01 1090-08000-01 1077-05827-03 1096-06534-01

1093-07359-01 1090-06060-02 1077-06925-02 1096-06914-01 1093-07638-01 1090-08000-01 1077-06165-03 1096-06534-01

1093-07424-01 1090-07050-01 1077-05826-02 1096-06539-01 1093-07641-01 1090-07050-01 1077-06165-01 1096-06534-01

1093-07463-01 1090-08000-01 1077-07156-07 1096-06719-01 1093-07671-01 1090-08000-01 1077-07438-02 4038-37101-03

1093-07466-01 1090-08000-01 1077-06565-01 1096-37101-08 1093-07672-01 1090-07050-01 1077-05849-04 1096-06710-01

1093-07466-02 1090-08000-01 1077-06565-02 1096-06703-01 1093-07673-01 1090-07050-01 1077-05849-04 1096-06544-01

1093-07467-01 1090-08000-01 1077-05849-03 1096-06909-01 1093-07674-01 1090-08000-01 1077-05827-01 1096-06543-01

1093-07467-02 1090-08000-01 1077-05849-04 1096-06544-01 1093-07693-01 1090-08000-01 1077-06925-02 1096-06710-01

1093-07468-01 1090-08000-01 1077-07439-05 1096-06534-01 1093-07731-01 1090-08000-01 1077-05826-07 1096-06537-01

1093-07468-02 1090-08000-01 1077-07439-02 1096-06539-01 1093-07762-01 1090-08000-01 1077-05827-03 1096-06909-01

1093-07468-03 1090-08000-01 1077-07439-02 1096-06544-01 1093-07794-01 1090-08000-01 1077-07757-03 1096-06710-01

1093-07506-01 1090-08000-01 1077-07438-02 1096-05364-01 1093-07794-02 1090-08000-01 1077-07757-04 1096-06710-01

1093-07509-01 1090-08000-01 1077-06925-02 1096-06914-01 1093-07813-01 1090-07050-01 1077-07773-01 1096-06710-01

1093-07510-01 1090-07050-01 1077-05849-02 1096-06719-01 1093-07813-02 1090-08000-01 1077-07773-01 1096-06710-01

1093-07519-01 1090-07050-01 1077-07438-03 1096-06908-01 1093-07959-01 1090-08000-01 1077-07958-01 1096-06710-01

1093-07521-01 1090-08000-01 1077-05826-02 1096-06719-01 1093-08172-01 1090-08000-01 1077-08171-01 3042-01223-16

FAIL SAFE™ On/Off K22FA Front Air Fan Drives I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G 3

Fan Clutches - Description, ID, Replacement FAIL SAFE™ On/Off K22FA Front Air Fan Drives

■ Fan Clutches - Description And Availability

The Quik-Kool front air fan clutch is available in two Finally, these clutches have an idle speed. When the

current production models: the 8 horsepower 1090- vehicle is stopped, engine running, fan clutch disen-

07050-XX and the 22 horsepower 1090-08000-XX. gaged, the fan will turn at approximately 100-300 rpm.

Both clutches are spring engaged, air pressure disen- This is a design feature and is normal. It cannot be

gaged designs, requiring a minimum of 90 psi (6.12 eliminated. Clutches that are fully warmed up will idle

BAR) to achieve a clean disengagement. slower than cold clutches. Older clutches will idle

slower than new clutches. Front-to-rear play at the fan

Quik-Kool fan drives are modular in design, that is, in

blade tip with the clutch disengaged is normal and not

most applications it is possible to remove the fan

a cause for concern.

clutch from the hub without removing any other part of

the vehicle, which can reduce vehicle down time for

repairs.

■ Fan Clutches - Identification And Replacements

Obsolete Fan Clutches

No longer sold or produced and service parts & procedures have been discontinued.

Old Part# Diameter Length Descriptive Notes Replace With

1090-05261-01 6.8 inches 4.6 inches Lining retaining plate is a 1090-07050-01

1090-05261-02 one-piece ring; Piston is copper 1090-07050-03

1090-05261-04 colored and cup shaped; 3 equal 1090-07050-02

sized O-rings on piston rod. (May require

adapter kit

1096-06914-01

to keep clutch from

hitting pulley.)

1090-05262-01 8.2 inches 5 inches Lining retaining plate is a 1090-08000-01

1090-05262-03 one-piece ring; Piston is copper 1090-08000-02

colored and cup shaped; 3 equal (Requires adapter

sized O-rings on piston rod. ring 4038-42430-01)

1090-06620-01 6.8 inches 3.9 inches Lining retaining plate 1090-07050-01

1090-06620-02 is a one-piece ring; 1 large and 1090-07050-03

1090-06620-03 1 small O-ring on piston rod. 1090-07050-02

1090-06060-02 8.2 inches 3.9 inches Lining retaining plate is a 1090-08000-01

1090-06060-03 one-piece ring; 1 large and 1090-08000-01

1090-06060-04 1 small O-ring on piston rod. 1090-08000-02

Current Production Fan Clutches

Old Part# Diameter Length Descriptive Notes

1090-07050-XX 6.8 inches 4.1 inches Outer housing is die cast aluminum. Access holes on front

are oval in shape. Lining plate (one piece) is retained by

screws and nuts.

1090-08000-XX 7.9 inches 4 inches Lining retention is with 3 separate plates

4 I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G FAIL SAFE™ On/Off K22FA Front Air Fan Drives

FAIL SAFE™ On/Off K22FA Front Air Fan Drives Fan Clutches

■ Fan Clutches - Identification And Replacements continued

Fan B.C./Bolt DIA. Hub B.C./Hole DIA. Hub Pilot

Clutch (3.500 and 3/8-24 Fan Pilot (3.50 B.C. and .406 (2.001 unless

studs unless noted) (2.560 unless noted) holes unless noted) noted)

1090-05261-01

1090-05261-02 2.563

1090-05261-04 3.25 B.C./ 5/16-24 THDS requires adapter

kit #1097-09115-01*

1090-06262-01 1.377

1090-05626-03 3.875 B.C./.343 DIA. 1.377

1090-06060-02

1090-06060-03

1090-06060-04 3.875 B.C.

1090-06620-01

1090-06620-02 2.563

1090-06620-03 3.25 B.C./ 5/16-24 THDS requires adapter

kit #1097-09115-01*

1090-07050-01

1090-07050-02 3.25 B.C./ 5/16-24 THDS requires adapter

kit # 1097-09115-01*

1090-07050-03 2.563

1090-07050-04 (obsolete) 3.307 B.C./.343 DIA.

1090-08000-01

1090-08000-02 3.875 B.C.

1090-08000-03 3.25 B.C./ 5/16-24 THDS requires adapter

kit # 1097-09115-01*

1090-08000-04 3.25 B.C./ 5/16-24 THDS requires adapter

kit # 1097-09115-01* 3.781 B.C./.50 DIA.

1090-08000-05 2.563

*see page 10

FAIL SAFE™ On/Off K22FA Front Air Fan Drives I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G 5

Hubs - ID, Service, Parts & Repair FAIL SAFE™ On/Off K22FA Front Air Fan Drives

■ Fan Hubs - Identification, Service Parts & Repair

Once you have identified your fan hub from the chart on pages 1-3, determine if a bearing kit is available.

Bearing kits are available for the following series hub models:

Use Bearing Kit

1033-06554-01 for

1077-06127 hub series

SEAL

3018-01321-01

SHIMS

3058-01531-XX

SPACER

4038-36917-XX

ROLLER BEARING(2)

3003-01427-01 CUP

FLATWASHER 3003-01428-01 CONE

LOCKNUT 3058-01316-01

3029-01317-01

SERIES

1077-05826

1077-06901

1077-07156

Use bearing kit

1077-07253

DE

LS 1033-07707-05 for the

1077-07773

E MO following hub series

1077-07958 AT

RN

LTE

A ER BEARING RETAINER 1077-05826 1077-06901

TE TH

NO L O IES 4038-36989-01

A L

R 1077-07156 1077-07253

SE CAPSCREW

3042-01323-20

1077-07773 1077-07958

Note: Includes bearings, seal, spacers and shims.

Use Bearing Kit

1033-07707-04 for

1077-06565 hub series

Note: Includes bearings, seal, spacers and shims.

6 I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G FAIL SAFE™ On/Off K22FA Front Air Fan Drives

FAIL SAFE™ On/Off K22FA Front Air Fan Drives Overhaul Notes

■ Tapered Roller Bearing Design

The Quik-Kool Hub should be overhauled during a major engine overhaul.

Disassemble the Hub and replace the seal and two bearings using the

service kit.

1

Important Overhaul Notes

2 1. Remove and discard the factory installed bearing spacer.

2. When removing old bearing cups, do not strike the snap rings that locate

them. Pack bearings with a high temperature wheel bearing grease with EP

additives, preferably a synthetic. Do not use chassis grease - it will melt.

(See page 10)

3 3. During reassembly, use the service spacer and shims provided in the overhaul

kit to set endplay between .001-.005”.

4. Reassemble using pulley retaining hardware torques:

• Locknut and washer type: 170 lbs.-ft.

• Single socket head capscrew type: 80 lbs.-ft.

• Double socket head capscrew type: 44 lbs.-ft.

4

5. Make a final endplay check. Allowable endplay is .001- .005”. Remove or add

shims as necessary to obtain this.

6. After final assembly, use a grease gun to lubricate with a high temperature

wheel bearing grease only.

FAIL SAFE™ On/Off K22FA Front Air Fan Drives I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G 7

Idler Pulleys - ID, Service Parts & Repair FAIL SAFE™ On/Off K22FA Front Air Fan Drives

■ Idler Pulleys - Identification, Service Parts And Repair

Bearing kits for tapered roller bearing type idler pulleys are also available. Note that these idlers are also

currently available under a new part number. (Sealed ball bearing type.)

Old Idle Pulleys: New Idle Pulleys:

Use kit Use kit 1033-07783-01

1033-07781-01 (sealed bearing)

CUP

1077-07238-01 1077-07756-02

CONE 1077-07226-01 1077-07756-01

Important Overhaul Notes:

1. During reassembly, use the service spacer and

shims provided in the overhaul kit to set endplay

between .001- .005”. (figure 3)

2. Torque idler pulley low head socket head cap-

screws to 25 lbs.-ft.

3. Make a final endplay check. Allowable endplay is

.001-.005”.

4. There is no grease fitting for idler pulleys, there-

fore pack grease cavity and bearings 50% - 60%

full prior to assembly. Take caution not to over

pack with grease. Use only high temperature

wheel bearing grease. (See page 10)

8 I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G FAIL SAFE™ On/Off K22FA Front Air Fan Drives

FAIL SAFE™ On/Off K22FA Front Air Fan Drives Installation - All Clutches

■ Installation - All clutches

FAN CLEARANCES WARNING LABEL AIR FITTING

SEE #3

SEE

#4

ABOVE

FIGURE 1 FIGURE 2 FIGURE 3 FIGURE 4

1. Before putting the fan clutch into position, the fan the air line to the radiator core. Using the clamp,

may have to be put onto the front of the clutch or place enough tension on the air line to assure that

set into the shroud. Do not permanently mount front to rear or side to side play does not exceed

the fan to the clutch until the clutch is mounted 1/2”. See figure 5.

to the hub.

8. The air line should not be angled forward anymore

2. To mount the fan clutch to the hub, use self-locking than 15 degrees and should exit the fan shroud in

3/8” - 16 socket head cap screws that are 1” longer the upper right hand quadrant when viewed from

than the adapter for proper thread engagement. the rear. See figure 5.

Torque these screws to 45 lbs/ft. Do not use wash-

9. Important: be sure to recheck the 1” front and back

ers of any kind.

and the 3/4” fan tip clearances.

3. Attach the fan allowing for 1” clearances, front and

back, and 3/4” tip clearance. See figure 1. It’s the

installer’s responsibility to prevent contact

between the fan and other parts of the vehicle.

4. Attach the WARNING label in a prominent and

easily seen place at eye level, on the fan shroud

as shown in figure 3.

5. Install the air fitting into the cylinder of the fan

clutch so that the inlet is angled approximately 10

degrees forward. See figure 4.

6. Use installation kit 1097-05348-01 to install the air

supply to the fan clutch. Use of any other hard-

ware may result in damage to the fan, fan

clutch and or radiator.

7. Run the air line and its protective cover through a

1/2” hole drilled in the fan shroud and attach to the

FIGURE 5

front of the clutch at the cylinder inlet. Do not tie

FAIL SAFE™ On/Off K22FA Front Air Fan Drives I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G 9

Installation & Preventative Maintenance FAIL SAFE™ On/Off K22FA Front Air Fan Drives

Cross Torque fan mounting ■ Installation - Crankshaft

screws to 15 lbs/ft

Repeat process to 25 lbs/ft

& Isolation Mount Clutches

Note: Written engineering approval is required for all crank-

shaft applications.

Fan mounting screw torque pattern

for both isolation or crankshaft

mount.

■ Preventative Maintenance

Fan Hubs AeroShell 5 or Chevron SRI-2. Do not use ordinary

Grease at every PM using a high quality, high temper- chassis grease. It will melt under the temperatures

ature bearing grease with EP additives such as generated by fan drives.

Fan Clutches (Every PM)

What to do How to do it

Check operations Turn on key or jumper control system so that 120 psi air gets to clutch. It should

disengage and turn freely. Turn off key. clutch should lock up and be difficult to

turn by hand.

Check for air leaks Turn on key or jumper control system so that 120 psi air get to clutch. Feel front

and cylinder problems of clutch (cylinder) for air leaks. Turn cylinder back and forth to limit of air line. It

should not bind or catch. (Remove clutch to repair if either problem is found.)

Check that air line has some tension and cannot get into fan. (See installation

instructions. )

Lining wear check 1090-07050. When clutch has no air pressure, fan should be very difficult to

turn. It it seems easy, remove clutch and replace lining or rebuild as described in

repair section.

1090-08000. See use of lining wear gauge. (See page 11)

10 I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G FAIL SAFE™ On/Off K22FA Front Air Fan Drives

FAIL SAFE™ On/Off K22FA Front Air Fan Drives Fan Clutch Lining Maintenance

■ Fan Clutch Lining Maintenance

This fan clutch requires 90-120 PSI air • The clutch in the top image has a brand new lining.

pressure to DISENGAGE (6.2-8.2 bar). The Notice how the tool sits down in the pocket, below

air pressure is vented to ENGAGE the fan. the surface of the lining retention plate.

Any interruption of the air supply will allow • The clutch in the bottom image has a lining that is

the fan to run, keeping it in fail-safe mode. worn to the point where it should be replaced. Note

how the tool protrudes above surface of the lining

plate.

Fan clutch maintenance should be performed at every

"A" PM schedule, at every oil drain, or every 25,000 2. Order a new lining when the tool is exactly flush

miles (40,225 KM), which ever comes first. with the plate, and change it at the next scheduled

service. Instructions for changing the lining are

1. Verify clutch operation. Turn key or jump the control

included in the lining kit, part# 1033-08250-01.

system so that 90-120 psi air is supplied to the

(See page 12)

clutch. It should disengage and turn freely. Remove

air supply. Clutch should lock up and be difficult to

turn by hand.

2. Check electrical and air connections at solenoid.

3. Examine wire and airline routing for damage and

chafing. Repair as required.

4. Check exhaust port on solenoid for restrictions and

debris. Remove any obstructions to insure positive

engagement.

Clutch Lining Maintenance

It is very important to check fan clutch lining condition

on a regular basis.

First Check 100,000 miles

(160,930KM)

Subsequent Checks Every 50,000 miles

(80,465KM)

System Alert Tool

Note: Rapid lining wear indicates a problem in the fan

This tool is a “go/no-go” gauge that will indicate

drive control system. See page 18 and 19 for control

whether the lining is close to wearing out and needs

system specifications and types. Call Technical

replacing.

Service for troubleshooting assistance, 800-927-7811.

1. Start with the fan clutch engaged. (No air to the

clutch.) If necessary, disconnect the air line from

the fan clutch.

FAIL SAFE™ On/Off K22FA Front Air Fan Drives I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G 11

Lining Replacement / Lockup Procedures FAIL SAFE™ On/Off K22FA Front Air Fan Drives

■ Replacing the Lining (1090-08000 only)

The Fan Drive is easy to reline without removing it from the vehicle.

Tools & Parts Required

• Inch pound or Newton Meter torque wrench

Step 1

• 1/4” drive ratchet

• 1/4” drive 5/16” socket

• Clutch lining kit #1033-08250-01

Caution: The fan clutch must have air pressure

(90-120 psi; 6.2-8.2 bar) during this procedure

Step 2

1. Remove the six lining plate screws and the three lining retainer plates.

2. Remove the old lining. If the lining sticks, use a hammer and a screwdriver

to free it by tapping on the dividing cut in the lining.

3. Inspect clutch shaft. If lining residue is present or if surface appears glazed

over (non-metallic), temporarily release air pressure from the clutch to get

a little more room, and use crocus cloth or sandpaper to break the glaze.

4. Re-apply air pressure to the clutch, and install the new lining as shown.

Step 3 Some applications may be too tight to spread the lining and slip over

the pulley. If necessary the lining can be cut in half with a hacksaw for

installation.

5. Replace the plates and screws using the new screws supplied in the

kit and toque screws to 30lbs-in. (3.4 Newton Meters).

Step 4

■ Emergency Lockup Procedures

If the lining wears to the point where

the fan clutch will not engage, the fan

clutch can be locked up by doing the

following:

1. Remove the air supply from the fan clutch.

(Usually disconnecting solenoid valve

Step 5 electric plug will work)

2. Remove the lock nut and cylinder from

the front of the clutch. The clutch will

remain engaged.

12 I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G FAIL SAFE™ On/Off K22FA Front Air Fan Drives

FAIL SAFE™ On/Off K22FA Front Air Fan Drives Troubleshooting

■ Troubleshooting

Note that lining and seal life is dependent on a clean, dry air supply and proper control of clutch engagement. If

liner of seal life is less than expected and inspection of the air supply and control system does not reveal any

problems, contact Technical Service for assistance.

Problem Cause Solution Reference

Front air leaks Dirty or worn seals Rebuild or replace clutch pgs 4, 14-17

Air leak in clutch Internal O-ring damaged Rebuild or replace clutch pgs 4, 14-17

Clutch will not Worn out lining or dust Rebuild the clutch pgs 14-17

engage when air seal hanging up on

pressure is removed cylinder wall

Lining worn Over cycled caused by 1090-8000 only: pg 12

bad temperature or Supply air pressure to

A/C switch clutch and remove

and replace lining. Clean

out back of clutch.

1090-07050 only: pgs 14-15

remove to repair

Both clutches: Replace pgs 18-19

switches if necessary.

Air line leaks check for leaks in pgs 9, 12

air line and fittings.

Replace lining

Stationary vehicle or PTO Install an override pgs 12,

over cycling the fan clutch device. Replace lining 18-19

Insufficient air pressure Air pressure 90-120psi. pgs 12

or debris in solenoid Check air supply.

valve restricting airflow Replace lining and pgs 18-19

solenoid valve if

necessary.

Clutch will not Over cycling caused by bad 1090-08000 only: Supply pg 12

disengage temperature or A/C switch air pressure to clutch

or clutch lining rusted to and remove and replace

shaft. lining. clean out back of

clutch.

1090-07050 only: pgs 14-15

Remove to repair

Both clutches: Replace pgs 18-19

switches if necessary

FAIL SAFE™ On/Off K22FA Front Air Fan Drives I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G 13

Fan Clutch Removal, Service, Parts & Repair FAIL SAFE™ On/Off K22FA Front Air Fan Drives

■ Fan Clutch Removal CORRECT

Pressurize clutch to disengage so that holes can be lined up with 3/8” allen

screws. If clutch will not disengage, put fan back on studs and manually rotate

clutch to line up holes.

■ Repair

Tools Required

1. Two carriage bolts with wing nuts and washers. These must be about 4”

long, as shown. Install them and compress the clutch slightly while loosen- INCORRECT

ing the cylinder nut (item 2) and the lining plate screws and nuts (items 17

and 18) then back them off evenly to allow the clutch halves to separate.

During reassembly, tighten the carriage bolts evenly to compress the clutch

before you install and tighten the cylinder nut and the lining plate nuts and

screws.

2. Inch pound torque wrench with 5/16” and 1/2” sockets, 5/16” box wrench

3. LocTite® 640

4. Internal snap ring pliers

Parts Required

Product # Repair Kit Cylinder Assy Piston Rod

1090-07050 0133-05434-02 4043-40639-01 4079-40642-01

1090-08000 0133-05435-02 4043-41130-01 4079-41133-01

Cylinder Installation

The photo indicates the correct tab washer (item 3) position

in relation to the cylinder.

Key Description

1 Cylinder Assy

Part#

4043-40639-01

■ 7000 Series

2 Cylinder Nut 3029-01371-01

3 Tab Washer 3058-01264-02

“D-8” Series Design 1090-07050-XX

4 “O” Ring 9002-00781-68

5 Dust Seal 3018-01453-01

6 Housing Assy 4040-40640 (-01,-03,-04)

7 Grease Seal 3018-01334-01

8 Fan Nut 3030-00364-01

9 Lock Washer 3059-00870-06

10 Flat Washer 3058-00843-07

11 Spring 4088-39197-01

12 Shaft Assy 4079-40641(-01,-02)

4079-40641-02 (-03 only)

4079-40641-03 (-04 only)

13 “O” Ring 1 of 9002-00561-58

14 Piston Rod Assy 4079-40642-01

15 Snap Ring 3038-01268-01

16 1 Pc. Lining 4026-35868-01

17 Retaining Plate 1 of 4073-35867-01

18 Screw 3042-01282-12

19 Nut 3029-01516-01

20 Spring End Cap 4038-41098-01

21 Wear Plate 4073-39008-01

22 Spring Carrier Included w/item 14

Grease Packet 2035-01353-01

Repair Kit* 1033-05435-02

* Items in gray areas are included in the repair kit.

14 I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G FAIL SAFE™ On/Off K22FA Front Air Fan Drives

FAIL SAFE™ On/Off K22FA Front Air Fan Drives Rebuild Procedures

■ 7000 Series times until there are no signs of excess grease. The

Rebuild Procedures goal is to have a layer of grease from front to rear,

even with the needles and with plenty of grease

1. Compress clutch about 1/16”. Remove lining plate

worked in behind the needles, without excess. Make

screws and nuts, lining plate, lining and wear plate.

sure no grease is on the outside of the grease seal

Discard lining.

where it could get slung into the lining.

2. Remove the 1/2” nut from the cylinder. Release pres-

4. Use sandpaper, crocus cloth or Scotch Brite on a

sure from clutch so that it comes all the way up.

grinder to break the glaze on the inside of the war

3. Remove cylinder and cylinder tab washer and discard.

plate (item 21) where the lining touches. Use Brake

Separate the shaft assembly (inner part) from the

Clean to clean afterwards.

bearing housing (outer part). Remove front spring cap

5. Apply ample amounts of grease around the shoulder

and spring. Discard spring. Remove large O-ring from

on the inside of the cylinder and lubricate the cylinder

outside of piston and discard. Remove small O-ring

dust seal.

from inside of piston and discard.

Shaft Assembly Service

4. Inspect needle bearing inner race on shaft (item A in

previous diagram). It may be discolored and 1. Wash shaft and lining plate with Brake Clean and dry.

streaked,but as long as you can feel no damage with a Use crocus cloth, sandpaper or Scotch Brite on a

finger nail, it’s OK. It may be cleaned with a Scotch grinder to break the glaze on the shaft and plate

Brite pad to make inspection easier. If damaged, dis- where the lining touches. Use only Scotch Brite by

card clutch. Inspect the fan studs on the bearing hous- hand to clean the needle bearing inner race on the

ing (outer part). If any are loose or missing, discard shaft. Rewash.

clutch. If any are damaged and cannot be repaired 2. Place rear spring cap (small) onto the piston rod.

with a thread die, discard clutch. Inspect piston bear- Place new spring on piston rod. Liberally lubricate

ing by rotating piston (brass). If bearing feels rough or inside rear of front spring cap and place on the piston

spins freely, discard clutch. If needle bearing inner rod. Use Brake Clean to remove any grease or finger-

race, studs and piston bearing are OK, proceed with prints from shaft where lining touches.

rebuild. Final Assembly

Bearing Housing & Cylinder Service 1. Insert shaft assembly into bearing housing. Lay wear

1. Pry out the grease seal with a very large screwdriver. plate into back of housing. Place new lining into pock-

Use a rag wet with Brake Clean to thoroughly clean et. Lay lining plate on top of lining. Compress clutch

needle bearings and bearing housing. Do not let Brake slowly while pushing down on plate. Stop when plate

Clean get into piston Bearing. Do not use safety sol- becomes flush with outer edge of clutch. Tighten

vent. screws and nuts until they bottom out, but do not

2. Press the grease seal in, lip down. Press until flush torque.

with edge of hole. Lubricate large piston O-ring with 2. Place new tab washer into cylinder cavity. align tab

grease and install in groove on outside of piston. and keyway in piston rod and push cylinder onto

Liberally smear grease around outside of O-ring after clutch. Start the nut.

installation. Lubricate small piston O-ring with grease 3. Slowly compress clutch until it disengages and can be

and install into inner piston groove. turned. Restrain cylinder from turning and torque the

3. Apply grease from kit to the needle bearings and pack cylinder nut to 84 lbs/inch.

the groove in front of the needle bearings (down in the 4. Pressurize clutch to 90 psi several times to test free

bottom near the snap ring) and the groove between movement and to center wear plate and lining in hous-

the needle bearing and the seal. Push the cleaned ing. While clutch is pressurized, torque lining plate

shaft (inner part) into the housing. Turn it a few times screws and nuts to 30 lbs/inch. Check for leaks. while

to work the grease into the needles. Remove it and clutch is pressurized, line up access holes in front with

wipe off any grease on the front. If no excess grease bolt holes in rear.

came out, you didn’t have enough. Do this a couple

FAIL SAFE™ On/Off K22FA Front Air Fan Drives I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G 15

8000 Series Rebuild Procedures FAIL SAFE™ On/Off K22FA Front Air Fan Drives

Key Description

1 Cylinder Assy

Part#

4043-41130-01

■ 8000 Series

2 Cylinder Nut 3029-01371-01

3 Tab Washer 3058-01264-02

“K22” Front Air 1090-08000-XX

4 O-Ring 9002-00491-68

5 Dust Seal O-Ring 3018-01703-01

6 Housing Assy 4040-40640-01 (-02,-05)

4040-41131-02 (-03,-04)

7 Grease Seal 3018-01507-01

8 Fan Nut 3030-00364-01

9 Lock Washer 3059-00870-06

10 Flat Washer 3058-00843-07

11 Spring 4088-40615-01

12 Shaft Assy 4079-41132-01 (-03)

4079-41132-02 (-02 only)

4079-41132-04 (-04 only)

4079-41132-05 (-05 only)

13 O-Ring 9002-00741-58

14 Piston Rod Assy 4079-41133-01

15 Snap Ring 3038-01510-01

16 1 Pc. Lining 4026-36900-01

17 Retaining Plate 3 of 4073-38444-01

18 Screw 3042-01684-01

19 Spring End Cap 4001-340690-01

20 Spring Carrier* 4001-340691-01

21 Dust Seal 3018-01702-01

Grease Packet 2035-01353-01

Repair Kits 1033-05435-02

* Included in Piston Rod Assembly

Items in gray areas are included in the repair kit.

■ 8000 Series Bearing Housing & Cylinder Service

Rebuild Procedures 1. Remove O-ring from piston and discard. Remove dust

seal from front groove of bearing housing. It may be

1. Compress clutch about 1/16”. Remove lining plate

the steel type, which has to be spiraled out like a pis-

screws and nuts, lining plate, lining and wear plate.

ton ring. It may be the white Teflon type which is cut

Discard lining.

and comes out easily. It may be the two piece, O-ring

2. Remove the 1/2” nut from the cylinder. Release pres-

and square cut seal type which are removed one at a

sure from clutch so that it comes all the way up.

time. Discard the dust seal.

3. Remove cylinder and cylinder tab washer and discard.

2. Pry out the grease seal with a very large screwdriver.

Separate the shaft assembly (inner part) from the

Use a rag wet with Brake Clean to thoroughly clean

bearing housing (outer part). Remove front spring

needle bearings and bearing housing. Do not let Brake

cap and spring. Inspect front of spring cap for signs

Clean get into piston Bearing. Do not use safety

of rubbing (it will be shiny). If found, stop and replace

solvent.

fan clutch.

3. Using specified grease, lubricate the two piece dust

4. Inspect needle bearing inner race on shaft (item A in

seal. (Black O-ring and blue square-cut seal). Being

previous diagram). It may be discolored and

careful not to stretch, first install the O-ring into the

streaked,but as long as you can feel no damage with a

front groove on the stud side of the bearing housing

fingernail, it’s OK. It may be cleaned with a Scotch

then the blue seal on top of it. Make sure the blue seal

Brite pad to make inspection easier. If damaged, dis-

sits down in the groove squarely and does not get

card clutch. Inspect the fan studs on the bearing hous-

rolled over. (It will be necessary to first work each

ing (outer part). If any are loose or missing, discard

piece of the seal into the piston (brass) groove then

clutch. If any are damaged and cannot be repaired

out into the second groove. Blue seal may be warmed

with a thread die, discard clutch. Inspect piston bear-

with a hair dryer to ease installation.)

ing by rotating piston (brass). If bearing feels rough or

4. Use a flat plate to press the grease seal in, lip down.

spins freely, discard clutch. If needle bearing inner

Press until flush with edge of hole.

race, studs and piston bearing are OK, proceed with

rebuild. 5. Liberally lubricate the piston O-ring, the blue dust seal

16 I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G FAIL SAFE™ On/Off K22FA Front Air Fan Drives

FAIL SAFE™ On/Off K22FA Front Air Fan Drives Rebuild Procedures/Torque Specs

■ 8000 Series Rebuild Procedures continued

and the nose of the clutch. Apply grease from the kit to 2. Place rear spring cap (small) onto the piston rod.

the needle bearings and pack the groove in front of Place spring on piston rod. Liberally lubricate inside

the needle bearings (down in the bottom near the rear of front spring cap and place on the piston rod.

snap ring) and the groove between the needle bear- Use Brake Clean to remove any grease or fingerprints

ings and the seal. Push the cleaned shaft (inner part) from shaft where lining touches.

into the housing. Turn it a few times to work the grease Final Assembly

into the needles. Remove it and wipe off any grease 1. Insert shaft assembly into bearing housing. Place new

on the front. If no excess grease came out, you didn’t lining into pocket. Compress clutch slowly while push-

have enough. Do this a couple times until there are no ing down on lining. Stop when lining becomes flush

signs of excess grease. The goal is to have a layer of with outer edge of clutch. Install lining plates, sharp

grease from front to rear, even with the needles and edge down. Tighten screws to 30 lbs-inch.

with plenty of grease worked in behind the needles,

2. Use grease from kit to hold small O-ring in place on

without excess. Make sure no grease is on the outside

shoulder on rear inside of cylinder. Lubricate the rest

of the grease seal where it could get slung into the

of the shoulder in front of the O-ring. Place new tab

lining.

washer into cylinder cavity. Align tab and keyway in

6. Use Brake Clean to clean any grease or fingerprints piston rod and push cylinder onto clutch. Start the nut.

from inside of bearing housing where lining touches.

3. Restrain cylinder from turning and torque the cylinder

Make suer no grease is on the outside of the grease

nut to 84 lbs/inch. Turn cylinder. It may have a slight

seal where it could get slung into the lining.

gritty feel due to the additives in the grease but if it

7. Set bearing housing aside. feels real notchy or turns hard, you most likely lost the

Shaft Assembly Service small O-ring. If this is the case, disassemble and cor-

1. Wash shaft and lining plate with Brake Clean and dry. rect.

Use crocus cloth, sandpaper or Scotch Brite on a 4. Pressurize clutch to 90 psi several times to test free

grinder to break the glaze on the shaft and plate movement. Check for leaks. While clutch is disen-

where the lining touches. Use only Scotch Brite by gaged, line up access holes in front with bolt holes in

hand to clean the needle bearing inner race on the rear.

shaft. Rewash.

■ Control System Requirements

1. As a minimum, control systems must be thermal 4. If the vehicle is a sleeper cab and the engine is fast

switches controlling solenoid valves. Mechanical ther- idled with the AC on, a timed AC override circuit must

mal valves such as the old Shutterstat® are not per- be provided so the fan clutch will not be over cycled.

mitted. (The Medallion TTM® system is an example of a timed

2. Air conditioning override pressure switches must have control system.

a built in hysteresis of 50 psi (3.4 bar) minimum. 5. The preferred system is engine ECM Control. Contact

3. If the vehicle is used in any kind of stationary opera- the engine distributor for assistance.

tion involving a PTO or turbo unloader, there must be

a provision in the control system to automatically lock Torque Specs

the fan clutch on whenever the PTO or unloader is Clutch to Hub 45lbs-ft (61 Newton Meters)

being operated. Failure to provide this will void all war- Fan to Clutch 26lbs-ft (35.3 Newton Meters)

ranties.

Front Piston Nut 84lbs-in (9.5 Newton Meters)

Lining Plate Screws 30lbs-in (3.4 Newton Meters)

FAIL SAFE™ On/Off K22FA Front Air Fan Drives I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G 17

Control Circuit Diagrams FAIL SAFE™ On/Off K22FA Front Air Fan Drives

■ Normally Closed Fan Clutch Control Circuit

■ Normally Closed System with 3-Minute Timer (Ford Trucks)

18 I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G FAIL SAFE™ On/Off K22FA Front Air Fan Drives

FAIL SAFE™ On/Off K22FA Front Air Fan Drives Control System Diagrams

■ TTM® Timed Control System

Note

PTO/Turbo Unloader Switch: Use a pressure switch in the control circuit

that will open the pink wire when the PTO or Unloader is engaged.

If required by engine manufacturer, install a normally closed charge air

temperature override Alarmstat® 1002-04880-22.

■ Typical Electronic Engine Control System

FAIL SAFE™ On/Off K22FA Front Air Fan Drives I N S TA L L AT I O N | S E RV I C E | T RO U B L E S H O OT I N G 19

Contact Quik-Kool FAIL SAFE™ On/Off K22FA Front Air Fan Drives

www.quik-kool.com

Quik-Kool Cooling System Components

1100 Wright Street

Cadillac, MI 49601

231-779-7500 phone

231-775-5749 fax

800-927-7811 Customer Service

231-779-7528 Tech Service & Troubleshooting

LIT# 21109

6/02

Das könnte Ihnen auch gefallen

- LUHMANN, Niklas - Soziologische Aufklarung 1 PDFDokument268 SeitenLUHMANN, Niklas - Soziologische Aufklarung 1 PDFMatheus Figueiredo SouzaNoch keine Bewertungen

- Oem Numbers Total - Kaeser - Ast - 07 - 08Dokument382 SeitenOem Numbers Total - Kaeser - Ast - 07 - 08Dragoslav DzolicNoch keine Bewertungen

- FiltrosDokument368 SeitenFiltrosJaime Adolfo Mejia LeónNoch keine Bewertungen

- 787-9 RSPL Rev 1Dokument2.156 Seiten787-9 RSPL Rev 1Aviation Documents ManualsNoch keine Bewertungen

- Cross ReferenceDokument152 SeitenCross ReferenceAndreas H100% (1)

- Udd FDD Formula KtilDokument105 SeitenUdd FDD Formula KtilEr Dnyaneshwar PatilNoch keine Bewertungen

- Part-Ii 2021Dokument15 SeitenPart-Ii 2021ahmer joyoNoch keine Bewertungen

- Stok Gudang Sep22Dokument213 SeitenStok Gudang Sep22Monkey d LuffyNoch keine Bewertungen

- Tugas 2metode NomerikDokument2 SeitenTugas 2metode NomerikVeashopNoch keine Bewertungen

- Data Shu Kopkar PT Rapp Per Desember 2022Dokument119 SeitenData Shu Kopkar PT Rapp Per Desember 2022Gidion AdiNoch keine Bewertungen

- Método Analítico Euler Explícito Euler Implícito Runge-Kutta 2 OrdemDokument8 SeitenMétodo Analítico Euler Explícito Euler Implícito Runge-Kutta 2 Ordemmelissa longenNoch keine Bewertungen

- 4000 PertaliteDokument3.872 Seiten4000 Pertalitedon corleoneNoch keine Bewertungen

- LPU Lab Emgotel Atualizado 2017Dokument69 SeitenLPU Lab Emgotel Atualizado 2017Anderson SouzaNoch keine Bewertungen

- Motors NMA Katalog2011 12 deDokument208 SeitenMotors NMA Katalog2011 12 deTotaram Sital Gopal DasNoch keine Bewertungen

- Custos Dos Serviços - Outubro 2021Dokument422 SeitenCustos Dos Serviços - Outubro 2021LinNoch keine Bewertungen

- 0932-4089 A000319 Esm2Dokument5 Seiten0932-4089 A000319 Esm2qzt77498Noch keine Bewertungen

- BisectionDokument1 SeiteBisectionLovely SinghNoch keine Bewertungen

- Copie de ME2J-007-18-08-2022Dokument8 SeitenCopie de ME2J-007-18-08-2022souhail jalalNoch keine Bewertungen

- SKROTNINGDokument42 SeitenSKROTNINGRodejongNoch keine Bewertungen

- Calculo de CortesDokument7 SeitenCalculo de Corteskenny98989Noch keine Bewertungen

- Dane PKMiS SNDokument76 SeitenDane PKMiS SNbrpiotrwojtowiczNoch keine Bewertungen

- Einachser HONDA F800Dokument50 SeitenEinachser HONDA F800Anonymous aigwY0jgzpNoch keine Bewertungen

- Armare Grinzi BynDokument5 SeitenArmare Grinzi BynralucaNoch keine Bewertungen

- Oferta AircooledpartsDokument170 SeitenOferta Aircooledpartsdan dinescuNoch keine Bewertungen

- 2.1 ResDokument108 Seiten2.1 ResOli PortalNoch keine Bewertungen

- Noe Fact Du 2023-0109 - 12pgDokument5 SeitenNoe Fact Du 2023-0109 - 12pgChristian AcousticNoch keine Bewertungen

- Cuadro Clasificacion Documental 2018Dokument153 SeitenCuadro Clasificacion Documental 2018Camilo EspinelNoch keine Bewertungen

- Tarea 3-Van Der WalzDokument3 SeitenTarea 3-Van Der WalzKarol CamachoNoch keine Bewertungen

- Data For BetaDokument28 SeitenData For BetaShreyash TiwariNoch keine Bewertungen

- Data Peserta Un 1718 SMK Widya DirgantaraDokument16 SeitenData Peserta Un 1718 SMK Widya Dirgantaraarsandi doankNoch keine Bewertungen

- Mutasi Harga OktDokument34 SeitenMutasi Harga OktAlviani FellaNoch keine Bewertungen

- From CTS - Tính Khoảng CáchDokument43 SeitenFrom CTS - Tính Khoảng CáchnoName314Noch keine Bewertungen

- KoordinatDokument516 SeitenKoordinattriboediNoch keine Bewertungen

- EMG 4 ArregladoDokument295 SeitenEMG 4 ArregladoFernanda ZentellaNoch keine Bewertungen

- Adx300 370-01Dokument8 SeitenAdx300 370-01JOSEALBERICHNoch keine Bewertungen

- Turbo Spare Parts Catalogue 02 2015 NP JRONEDokument66 SeitenTurbo Spare Parts Catalogue 02 2015 NP JRONEJavier TurbopowerNoch keine Bewertungen

- Puntos ArmandoDokument4 SeitenPuntos ArmandoArmando Aukgapuri HuitoccolloNoch keine Bewertungen

- Lemdvhhh PDF 1476231902Dokument148 SeitenLemdvhhh PDF 1476231902Tony WongNoch keine Bewertungen

- Parametros ManDokument71 SeitenParametros ManHector JacoboNoch keine Bewertungen

- Final 11111Dokument278 SeitenFinal 11111aylokolloNoch keine Bewertungen

- Naca 63812 AnsysDokument4 SeitenNaca 63812 AnsysAlex Mtz FloresNoch keine Bewertungen

- Bordes PavimentoDokument8 SeitenBordes Pavimentowilmer mena abadiaNoch keine Bewertungen

- Nuevo Reporte de Inventario 21-10-2021Dokument96 SeitenNuevo Reporte de Inventario 21-10-2021Ernesto SalazarNoch keine Bewertungen

- Custos Dos Serviços - Outubro 2022Dokument408 SeitenCustos Dos Serviços - Outubro 2022Flávia de AlvarengaNoch keine Bewertungen

- Argamassa RefDokument204 SeitenArgamassa RefCLAUDIA YANARA MEIRA DA COSTANoch keine Bewertungen

- UL2 CódigosDokument8 SeitenUL2 CódigosGabo Benavides CampoverdeNoch keine Bewertungen

- DUE TO LIVE LOADSsssssssssDokument12 SeitenDUE TO LIVE LOADSsssssssssMarvin BermidoNoch keine Bewertungen

- Caudal 1Dokument589 SeitenCaudal 1ronal ramirezNoch keine Bewertungen

- Sindangbarang 1 X 1 NewDokument4 SeitenSindangbarang 1 X 1 NewaditNoch keine Bewertungen

- DESPIECES KOSLAN V 1 2.xlsmDokument124 SeitenDESPIECES KOSLAN V 1 2.xlsmCristobalNoch keine Bewertungen

- Custos Dos Serviços - Fevereiro 2020 PDFDokument434 SeitenCustos Dos Serviços - Fevereiro 2020 PDFviniciusltNoch keine Bewertungen

- Balance HidiricoDokument4.898 SeitenBalance HidiricoMilagros Maria Portal RiveraNoch keine Bewertungen

- Density of GlycerineDokument1 SeiteDensity of Glycerinevanhung680% (1)

- Método de Cross H-W HANDY UGARTEDokument1 SeiteMétodo de Cross H-W HANDY UGARTEhandyNoch keine Bewertungen

- Naca 2412Dokument1 SeiteNaca 2412paplubpNoch keine Bewertungen

- Lager - Lista 07 08 2023Dokument1.280 SeitenLager - Lista 07 08 2023Dalibor1981Noch keine Bewertungen

- Tablas de DistribucionesDokument20 SeitenTablas de Distribucionesandres sanchesNoch keine Bewertungen

- Prad 1001 B Resu PP MDokument945 SeitenPrad 1001 B Resu PP MRidha AbdallahNoch keine Bewertungen

- Tablas EstadisticasDokument2 SeitenTablas Estadisticasstefanny martinezzNoch keine Bewertungen

- Towns in EthiopiaDokument10 SeitenTowns in EthiopiaThe Ethiopian AffairNoch keine Bewertungen

- L1 B2.1 Kapiteltests K03Dokument3 SeitenL1 B2.1 Kapiteltests K03akuNoch keine Bewertungen

- Grundig L6B PDFDokument75 SeitenGrundig L6B PDFFloricica Victor VasileNoch keine Bewertungen

- Molekulargewichtsbestimmung Von PolymerenDokument3 SeitenMolekulargewichtsbestimmung Von PolymerenLana VeselinovicNoch keine Bewertungen

- 25.3 Pflege Von Menschen Mit DrainagenDokument1 Seite25.3 Pflege Von Menschen Mit DrainagenbordeiiulianNoch keine Bewertungen

- Bachelor-Thesis Patientenedukation Im Wundmanagement WieseDokument98 SeitenBachelor-Thesis Patientenedukation Im Wundmanagement WieseValcan OvidiuNoch keine Bewertungen

- VW Media IN KompatabilitaetslisteDokument15 SeitenVW Media IN KompatabilitaetslisteSlMrtsNoch keine Bewertungen