Beruflich Dokumente

Kultur Dokumente

04 ASME TT Schweiz

Hochgeladen von

AndreaAlberoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

04 ASME TT Schweiz

Hochgeladen von

AndreaAlberoCopyright:

Verfügbare Formate

Herzlich Willkommen!

ASME Code

und verwandte Regelweke

Dr. Dirk Kölbl,

Inspector & Supervisor

08-13

ASME / AIA / NB

Jurisdiction USA & Kanada

akkreditiert

AIAs

National Board

Gesellschafter &

Geschäftsverteilung

(repair & alteration)

Data Reports (MDR)

Registrierung der

zertifiziert

Authorized

R-Stamp

Inspector

CIS

Consulting Inspection Services

TÜV Thüringen Group

Hersteller

01-2015

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 1

TÜV Thüringen ASME Certificate

ASME Code Symbol Stamps

• Vorgeschrieben ab 01.01.2013:

ASME Certification Mark & Designator

• Konnten verwendet werden bis 31.12.2012:

ASME Code Symbol Stamp

(oder mit Code Case N-822 ASME Section III Div.1, 2, 3 and 5 )

01-13

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 2

ASME Certificate Holders BPV & N‐Type & QSC

4000

3500

3000

2500

2000

USA

International

1500

1000

500

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 3

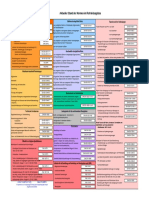

ASME Designators

Section I – Dampfkessel Section X – Faserverbundbehälter

S Dampfkessel RP Druckbehälter aus faserverstärktem Kunstharz

A Montage

E elektrisch beheizte D-Kessel Section XII – Transportbehälter

M Miniaturkessel

T transportatble Druckbehälter

PP Dampfleitungen

TV * Sicherheitsventile

V* Sicherheitsventile

TD * Berstscheiben

Section IV – Heizkessel National Board Inspection Code

H Heizkessel (*gußeiserne Heizkessel)

R Reparaturen und Änderungen

HLW Trinkwasserkessel

VR * Reparaturen von Sicherheitsventilen

HV * Sicherheitsventile

Section VIII, Div. 1 – Druckbehälter * = nicht abnahmepflichtig durch einen Authorized

U unbefeuerte Druckbehälter Inspector, Auditierung durch ASME erforderlich

UM * Miniaturdruckbehälter

UV * Sicherheitsventile

UD * Berstscheiben

Section VIII, Div. 2 – Druckbehälter

U2 Alternative Regeln für Druckbehälter

Section VIII, Div. 3 – Druckbehälter

U3 Hochdruckbehälter

UV3 * Sicherheitsventile für Hochdruckbehälter

01-14

Hierarchie der Regelwerke

• Vorschriften am Aufstellungsort der Anlage

(z.B. South Carolina ‐ USA, North Carolina ‐ USA, Alberta ‐ Canada, Deutschland)

• ASME Boiler and Pressure Vessel Code

CONSTRUCTION CODES

Section I Section III Section IV Section VIII Section X Section XII ASME B31.1 ASME B31.3

Power Boilers Nuclear Comp. Heating Boilers Pressure Vessels Fiber Reinforced Transport Tanks Power Piping Process Piping

Dampfkessel Nuklearanlagen Heizkessel Druckbehälter Faserverst. Beh. Transportbeh. Kesselrohrleit. Prozessrohrleit

.

ASME B31.1 Section II Section V Section IX

REFERENCED Power Piping NDE Welding

Materials

CODES Kesselrohrleit. Werkstoffe ZfP Schweissen

INSERVICE Section VI Section VII Section XI

Maintenance Maintenance Inservice Insp.

CODES Heating Boilers Power Boilers Nuclear

MITGELTENDE ASTM ASME AWS ASNT ISO

STANDARDS

• National Board Inspection Code NBIC

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 4

Hierarchie der Regelwerke

NICHT verwechseln:

ASME Boiler

and Pressure

Vessel Code

( ASME BPVC )

A standard becomes a Code when it has been adopted by

one or more governmental bodies and is enforceable by law,

or when it has been incorporated into a business contract.

ASME

STANDARDS

( KEIN Boiler and

Pressure Vessel Code )

A Standard can be defined as a set of technical definitions

and guidelines that function as instructions for designers,

manufacturers, operators, or users of equipment.

Und wohin exportieren Sie heute?

Bitte beachten Sie:

‐ Kundenforderungen

(Users Design Specification; Kundenbestellung; Technische

Lieferspezifikationen etc.)

‐ Gesetze und Verordnungen am Aufstellungsort

‐ Code of Federal Regulations ( 10CFR50 ; 10CFR21 )

‐ Bundesstaatliche Anforderungen?

Wo gibt es Informationen zu den Anforderungen? z.B. bei:

=> BSI International Survey (www.BSIgroup.com)

=> NB‐370 Synopsis (www.nationalboard.org)

=> FDBR, Düsseldorf Karte: Wikipedia

=> VDMA, Frankfurt

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 5

Synopsis NB-370 - DELAWARE

STATE DEPARTMENT

David Small, Secretary

John J. Esch, Chief Inspector

Department of Natural Resources and Environmental Control

DNREC, Boiler Safety

655 S. Bay Rd., Suite 5N

Dover, DE 19901

Telephone — 302.744.2735 Email — John.Esch@state.de.us

Fax — 302.739.2526

EMPOWERMENT

Boiler Safety Program empowered to make, alter, and amend rules and regulations.

Boiler Board: Yes. (Contact above official for more information.)

DATE OF LAW PASSAGE: 1919

Date of latest amendment to law: July 2011.

Date rules and regulations implemented: 1925.

Date of latest amendment to rules and regulations: 2013, Fees are expected to change in 2015.

State statute: Delaware Code, Title 7 Conservation Chapter 74B.

Department of Natural Resources and Environmental Control, Section 7401B Boiler Safety Program.

RULES FOR CONSTRUCTION AND STAMPING

Construction:

1. ASME Code (Current Edition), Sections I, II, III (Divisions 1, 2), IV, V, VIII (Divisions 1, 2, 3), IX, X, XI, and code cases.

2. ASME CSD‐1 (Current Edition).

3. ASME B31.1 (Current Edition).

4. ASME PVHO‐1 (Current Edition).

5. A copy of the Manufacturer’s Data Report must be filed with the program on ASME forms through the National Board before boilers or pressure

vessels are shipped into Delaware

6. National Board Inspection Code (Current Edition).

7. National Board registration required for boilers, (except Cast Iron & Cast Aluminum) and pressure vessels.

8. Special design or construction requires approval by Chief Inspector.

Stamping:

Where appropriate, the following National Board stamps or ASME Code symbol stamps are required:

1. National Board: NR, R, VR.

2. ASME Code: all.

All boilers and pressure vessels shall be assigned a Delaware state number at the time of first inspection.

02 / 2015

Synopsis NB-370 - SOUTH CAROLINA

STATE DEPARTMENT

Adrienne Youmans, Director

Michael S. Anderson, Administrator

Ronald W. Spiker, Chief Boiler Inspector

S.C. Department of Labor, Licensing, and Regulation

Boiler Safety Program

300 Windsor Drive

Shelby, NC 28150‐6057

Telephone —803.896.5171 Email — rspiker@carolina.rr.com

Fax — 803.896.4814

Express mail only:

110 Centerview Drive

Columbia, SC 29210

EMPOWERMENT

Boiler Board: No.

DATE OF LAW PASSAGE: 2005

Date rules implemented: May 2005; regulations implemented: January 2006

State Statute: South Carolina Code of Laws, Title 41. Labor and Employment, Chapter 14. Boiler Safety Act,

Sections 41‐14‐10 through 41‐14‐150.

RULES FOR CONSTRUCTION AND STAMPING

Construction:

1. ASME Code (Current Edition, Current Addendum), Sections I and IV.

2. ASME CSD‐1 (2001 Edition).

3. National Board Inspection Code (2004 Edition, 2004 Addendum).

4. National Board registration required for boilers.

5. NFPA 85.

Stamping:

Where appropriate, the following National Board stamps or ASME Code symbol stamps are required:

1. National Board: R

2. ASME Code: S

02 / 2015

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 6

Laws and Regulations – USA (NB-370)

http://www.nationalboard.org

http://www.nationalboard.org/

SiteDocuments/NB‐370.pdf

Anforderungen in

Kanada

Karte: Wikipedia

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 7

Hierarchie der Regelwerke

• Requirements at the place of installation

(e.g.. South Carolina ‐ USA, North Carolina ‐ USA, Alberta ‐ Canada, Germany)

Provinces:

‐ Alberta

‐ British Columbia

‐ Manitoba

‐ New Brunswick

Jurisdictional requirements: PROVINCIAL ACT ‐ Newfoundland and Labrador

‐ Northwest Territories

‐ Nova Scotia

‐ Nunavut Territory

‐ Ontario

‐ Prince Edward Island

‐ Quebec

‐ Saskatchewan

Codes and Standards CSA B51 ‐ Yukon Territory

ASME BPV ASME Piping Other

Code Codes Codes

‐ Boilers

‐ Pressure Vessels

Canadian Registration [ CRN ] required for: ‐ Piping

‐ Fittings

CSA B51

CSA B51

PART 1:

contains requirements for

boilers, pressure vessels, pressure piping,

and fittings.

PART 2:

contains requirements for

high‐pressure cylinders for the on‐board

storage of natural gas,

Blends of natural gas and hydrogen

(hydrogen blends), and

hydrogen as fuels for automotive vehicles.

PART 3:

contains requirements for compressed

natural gas and hydrogen refuelling

station pressure piping systems and

ground storage vessels.

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 8

CSA B51

CSA B51 is applicable for registration of:

Definitions of CSA B51:

Boiler — a vessel as defined in the Act.

Boilers

Pressure vessel — a closed vessel for containing, storing,

Pressure Vessels distributing, transferring, distilling, processing,

or otherwise handling a gas, vapour, or liquid.

Piping — pipes or piping as defined in the Act.

Piping

Fitting — an appurtenance attached to a boiler, pressure vessel,

or piping, including such items as valves, gauges, and controlling

Fittings devices. It can include other pressure‐retaining components

installed in a piping system within the scope of the Act.

Fired‐heater pressure coil — the total fluid‐retaining piping

Fired Heater Pressure Coils system within the internally insulated enclosure and header

boxes of a petroleum or chemical plant fired heater, including

tubes, return bends, crossover piping, inlet and outlet headers,

and manifolds.

CSA B51

CSA B51 – DESIGN registration

4 General requirements

4.1 Registration of designs

4.1.1

The calculations, drawings, and specifications pertaining to the designs of boilers, pressure vessels, fittings as

specified in Clause 4.2, fired‐heater pressure coils, and piping shall be submitted to the regulatory authority in

the province where the item is intended to be used. The submission shall identify the substance for which the

item is intended. It shall be the responsibility of the users or an agent they designate to determine whether the

substance is lethal. Figures 1(a), (b), and (c) shall be used to determine whether items are to be registered as

pressure vessels or Category H fittings (see Table 1). The name of the authorized inspection agency to be

employed when a boiler or pressure vessel is to be manufactured outside Canada shall also be submitted when

required by the regulatory authority. Acceptance and registration shall be obtained before construction begins.

Manufacturers who commence construction prior to receiving design registration shall rectify any design

deficiencies that are identified in the design registration process.

4.1.2

Any number of boilers, pressure vessels, fittings, fired‐heater pressure coils, and piping systems may be

constructed from a registered design until a change in the applicable Act, Codes, or Standards invalidates the

design, in which case the design shall be obsolete and no further construction to the design shall be made after

the effective date of the change as established by the Act. When the Act does not specify an effective date of

change, the effective date shall be the date specified in the changed document or six months from the

published date of the change, whichever comes first.

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 9

CSA B51

CSA B51 – CRN numbers

4.3 Canadian Registration Numbers (CRNs)

4.3.1

Designs and specifications that are accepted and registered by the regulatory authority shall be

assigned a Canadian Registration Number. The province in which a design is registered shall be

indicated by a digit or letter following a decimal point (see Clause 4.3.2).

4.3.2

When a design that is registered in a province is subsequently registered in other provinces,

additional digits or letters identifying those provinces shall be added after the digit or letter

representing the original registering province. The following identifications shall be used:

1 British Columbia 6 Québec T Northwest Territories

2 Alberta 7 New Brunswick Y Yukon

3 Saskatchewan 8 Nova Scotia N Nunavut

4 Manitoba 9 Prince Edward Island

5 Ontario 0 Newfoundland and Labrador

Notes:

(1) For example, a design registered in Ontario and allotted the registration number K4567 will be registered as CRN K4567.5. If this

design is subsequently registered in Alberta, the CRN will be K4567.52; and if afterwards registered in Manitoba, the CRN will be

K4567.524.

(2) If a design is registered in all provinces and territories, the CRN stamped on the nameplate and marked on the data report may be

shortened to include the designation of first registration plus the letter “C”, e.g., K4567.5C.

(3) If a design is registered in all provinces and territories that require registration but not in provinces and territories that do not

require registration, the CRN may be shortened to include the designation of first registration plus the letters “CL”, e.g., K4567.5CL.

(The “L” means limited.)

CSA B51

Table 1

Categories of FITTINGS

Category Type of fitting

A Pipe fittings, including couplings, tees, elbows, wyes, plugs, unions, nipples, pipe caps,

and reducers

B All flanges

C All line valves

D All types of expansion joints, flexible connections, and hose assemblies

E Strainers, filters, separators, and steam traps

F Measuring devices, including pressure gauges, level gauges, sight glasses, levels,

and pressure transmitters

G Certified capacity‐rated pressure‐relief devices acceptable as primary overpressure

protection on boilers, pressure vessels and pressure piping, and fusible plugs

H Pressure‐retaining components that do not fall into Categories A to G

Notes:

(1) These categories do not take into account size, materials, end connections, ratings, schedules, and methods of fabrication.

(2) Category H can include

(a) small pressure vessels registered and inspected as specified in Figure 1(a), (b), or (c). Such ( . . . . )

(b) an assembly of components (including piping components), provided that the diameter of any component does not

exceed 152 mm (6 in) and the total volume of the fitting does not exceed 42.5 L (1.5 ft3). Such an assembly ( . . . . )

(c) condenser coils and evaporator coils as defined in CSA B52 and air heater coils, provided ( . . . . )

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 10

ASME Code Section VIII

Pressure Vessels

Karte: Wikipedia

ASME Code – Section VIII

Pressure Vessels Pressure Vessels Pressure Vessels

VIII Div.1 U

VIII Div.2 U2

VIII Div.3 U3

up to 20 MPa ( 3000 psi ) No pressure limit No pressure limit

Scope

[ For higher pressures additional [ Above 68,95 MPa ( 10000 psi ) [ intended for use above

design principles and construction additional design principles and 70 MPa ( 10000 psi ) ]

practices shall be applied ] construction practices may be neccessary.

Section VIII Div. 3 should be considered ]

‐ Simple Design Calculations ‐ Owner must specify Design criteria in ‐ Owner must specify Design criteria in

‐ No Stress Analysis required a USERS DESIGN SPECIFICATION certified a USERS DESIGN SPECIFICATION certified

by an Registered Professional Engineer [ RPE ] by an Registered Professional Engineer s[ RPE ]

‐ Manuafcturer shall prepare a DESIGN ‐ Manuafcturer shall prepare a DESIGN

REPORT certified by an Registered Professional REPORT certified by an Registered

Engineer [ RPE ] Professional Engineers [ RPE ]

‐ Design by Rule (Part 4) and / or ‐ Design by Stress Analysis is mandatory

Design

Design by Analysis (Part 5) and includes Fatigue or

‐ Highest stress values of the Code Fracture mechanics,

[ UTS/2.4 at roomtemperature and ‐ Alternatives to an RPE given in

2/ S at designtemperature ]

3 y KG‐311.15 and KG‐324.1.

‐ Includes methods for Stress Analysis,

Fatigue, Fracture mechanics,

secondary stresses, cyclic loading

‐ Alternatives to an RPE given in 2‐A.2.2

and 2‐B.2.2.

Most common used Code worldwide ‐ Higher fabrication requirements ‐ Highest fabrication requirements

Others

for Pressure Vessels ‐ Higher NDE requirements ‐ Highest NDE requirements

‐ Lower wall thicknesses can reduce costs ‐ Limited no. of allowable materials

05-2013

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 11

ASME Construction Codes

ASME Code Section VIII is a CONSTRUCTION Code !

Construction Codes are including requirements for:

• Manufacturer Certification (Herstellerzulassung)

• Quality System (Qualitätssicherung) Certified by

• Material (Material) Pressure Vessels Ltd.

• Design (Auslegung) (Name of Manufacturer)

• Fabrication (Fertigung, Schweissen) U

• Examination (Prüfen) W

MAWP 120 bar at 280 °C

(Max. allow. working pressure)

• Inspection (Abnahme) RT‐1 MDMT -35 °C at 120 bar

• Testing (Druckprobe) HT (Min. design metal temperature)

12345

• Certification (Konformitätserklärung) (Manufacturer‘s serial number)

• Assembly (Zusammenbau, Montage) 2013

(Year built)

• Documentation (Dokumentation)

• Pressure Relief (Überdruckschutz)

A Construction Code does NOT include requirements for:

Inservice Inspections, Repairs, Alterations.

( Wiederkehrende Prüfungen, Reparaturen, Änderungen )

ASME Section VIII Div.1 - Scope

Paragraph U‐1 ‐‐ Scope

For internal or external pressures with:

MAWP: > 100 kPa ( 15 psi )

[ For pressures above 20 MPa (3000 psi) additional design

principles and construction practices shall be applied ]

Pressure => Section VIII Div.2

Pressure

Vessel

Vessel Inside Diameter: > 152 mm ( 6 in )

INCLUDED are: NOT INCLUDED are:

‐ Heat Exchangers ‐ Piping and Piping Components

‐ Evaporators ‐ Rotating or reciprocating mechanical devices, such as

‐ Steam generators without direct firing pumps, compressors, turbines, generators, engines

‐ Fired pressure vessels ‐ Steam generators with direct firing

‐ Gas fired jacketed steam kettles with jacket operating ‐ Vessels containing Water

pressures < 50 psi (345 kPa) < 2 Mpa (300 psi) and < 99 °C (210 °F)

‐ Hot Water Supply Storage tanks

< 58,6 KW (200000 Btu/hr) and

< 99 °C (210 °F) and

< 450 L (120 gal)

‐ Pressure vessels for human occupancy => PVHO

05-2013

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 12

ASME Section VIII – required certificates

ASME Code Section VIII requires ASME Certificates of Authorization for:

Engineering Organizations

( Planung und Auslegung von Druckbehältern) ‐‐‐

Shop/Field Fabrication ( Div.1 ; Div.2 ; Div.3 )

( Fertigung von Druckbehältern im Werk / Baustelle ) U ; U2 ; U3

Welding on Pressure Parts ( Div.1 ; Div.2 ; Div.3 )

( Schweissen von Druckteilen ) U ; U2 ; U3

Field Assembly of Pressure Vessels ( Div.1 ; Div.2 ; Div.3 )

( Baustellenmontage von Druckbehältern )

U ; U2 ; U3

Manufacturing of Safety Relief Valves ; Rupture Discs

( Herstellung von Sicherheitsventilen / Berstscheiben )

UV ; UD

Manufacturing of Safety Relief Valves for Div.3 UV3

( Herstellung von Sicherheitsventilen für Div.3)

05-2013

ASME Section I – required certificates

ASME Code Section I requires ASME Certificates of Authorization for:

Engineering Contractor

( Planung und Auslegung von Dampfkesseln ) S

Shop/Field Fabrication

( Fertigung von Dampfkesseln im Werk / Baustelle ) S

Welding on Pressure Parts S

( Schweissen von Druckteilen )

Welding of Boiler External Piping S or PP

( Schweissen von BEP Rohrleitungen )

Field Assembly of Boilers and Boiler External Piping

( Baustellenmontage von Dampfkesseln und BEP Rohrleitungen )

S or A

Manufacturing of Boiler Safety Valves V

( Herstellung von Dampfkessel‐Sicherheitsventilen )

NOTES (see Section I PG‐104):

(1) Boiler Manufacturer or Manufacturer as used in PG‐104 or other paragraphs referenced to this Note may also be an

Engineering‐Contractor organization with or without fabricating facilities, but having the capability of providing a design

specification that establishes the pressure and temperature conditions for each component of a complete boiler unit and of

assembling the fabricated parts in the field with authorization from the Society to use the Certification Mark with the “S”

Designator in accordance with the Code provisions in PG‐105.3.

05-2013

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 13

ASME Code

und

Druckgeräterichtlinie

Karte: Wikipedia

ASME Code und PED

LAWS AND REGULATIONS PED 97/23/EC

+ Leitlinien

Konformitätsvermutung liegt

CONSTRUCTION CODES Harmonized Standards

bei Einhaltung vor.

or

ASME BPV Code

or

AD 2000 Konformitätsvermutung liegt

NICHT vor.

or

„DELTA“ ermitteln und

British Standard schriftlich bewerten.

. . . .

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 14

ASME Code und PED

PED + ASME Code

Wird der ASME Code zur Auslegung, Herstellung und Prüfung eines Druckgeräts

verwendet, dann sind zum Beispiel folgende Anforderungen ZUSÄTZLICH zu

berücksichtigen um die Anforderungen der PED zu erfüllen:

Benannte Stelle / Unabhängige Prüfstelle

INSPECTION für Druckprüfung, Kennzeichnung und

Abnahme notwendig

Einstufung

Beschreibung Für Schweißverfahren und Schweißer ist

DESIGN Gefahrenanalyse WELDING eine Zulassung durch Benannte Stelle

Modulauswahl oder Unabhängige Prüfstelle notwendig

Antrag an Benannte Stelle

Für NDE Verfahren ist eine Zulassung

durch die Benannte Stelle und für NDE‐

PED konformes Material NDE

MATERIAL Personal durch eine Unabhängige

Ggf. Einzelgutachten

Prüfstelle notwendig

Konformitätserklärung

RECORDS

Betriebsanleitung

05-2013

ASME Code und PED

05-2013

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 15

Haben Sie Fragen?

Wir haben Antworten!

Dr. Dirk Kölbl,

CIS GmbH Consulting Inspection Services

Karolingerstr. 96

45141 Essen, Germany

Tel.: +49 201 747275‐0

Fax: +49 201 747275‐29

www.cis‐inspector.com

Karte: Wikipedia

(c) D. Kölbl, CIS Gmbh ‐ Druckgerätesymposium Schweiz 2015 Page 16

Das könnte Ihnen auch gefallen

- Die Kreiselpumpen: Fiir Fliissigkeiten Und GaseDokument634 SeitenDie Kreiselpumpen: Fiir Fliissigkeiten Und GaseSsheshan Pugazhendhi100% (1)

- Normen RohrleitungsbauDokument1 SeiteNormen RohrleitungsbauAlis MalovicNoch keine Bewertungen

- kb-110-7 BITZERDokument0 Seitenkb-110-7 BITZERBruno MonteiroNoch keine Bewertungen

- HF 40Dokument127 SeitenHF 40ahmat100% (1)

- HM15029DDokument25 SeitenHM15029DYoni EhmNoch keine Bewertungen

- A10VSO rd92711 2021Dokument48 SeitenA10VSO rd92711 2021j uNoch keine Bewertungen

- GHILUXDokument44 SeitenGHILUXMiguel HazaNoch keine Bewertungen

- Price List OlmecDokument12 SeitenPrice List OlmecMuhammad SayyamNoch keine Bewertungen