Beruflich Dokumente

Kultur Dokumente

3M - Ranger 245 - Service Manual

3M - Ranger 245 - Service Manual

Hochgeladen von

Colleen WalkerOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3M - Ranger 245 - Service Manual

3M - Ranger 245 - Service Manual

Hochgeladen von

Colleen WalkerCopyright:

Verfügbare Formate

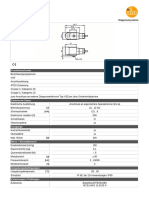

GERÄTEEIGENSCHAFTEN

ERWÄRMUNGSEINHEIT

ELEKTRISCHE EIGENSCHAFTEN TEMPERATUR‑ UND

GENAUIGKEITSEIGENSCHAFTEN 3M™ Ranger™

Blood/Fluid

Höhe 11 cm x Breite 19 cm x Länge 25 cm, Gewicht: 3,4 kg

GERÄTETYP SOLLTEMPERATUR

ZERTIFIZIERUNGEN 100-120 V AC, 50/60 Hz 41 °C [±1 °C]

Warming System

IEC/EN 60601-1; CAN/CSA-C22.2, Nr. 601.1

220-240 V AC, 50/60 Hz

KLASSIFIZIERUNG

MAXIMALE HEIZLEISTUNG ÜBERTEMPERATURALARM

MEDIZINTECHNIK – ALLGEMEINE MEDIZINISCHE

AUSRÜSTUNG NUR IM HINBLICK AUF STROMSCHLAG,

FEUER UND MECHANISCHE GEFAHREN IN EINKLANG MIT

900 W Modell 245:

43 °C [+3/-2 °C] Model 245 – For I.V. Use

UL 60601‑1; CAN/CSA‑C22.2, Nr. 601.1; ANSI/AAMI Modell 247: Service Manual

ES60601‑1:2005 CSA‑C22.2 Nr. 60601‑1:08; 48 °C [±2 °C]

Kontrollnr. 4HZ8

SICHERUNG UNTERTEMPERATURALARM

Das Produkt erfüllt die Anforderungen der Richtlinien: EN60601-1:

2 x T10A-H (250 V) für 33 °C [±2 °C]

3M™ Ranger™

2006 + CORR: 2010 (Medizinische elektrische Geräte – Teil 1:

Allgemeine Festlegungen für die Sicherheit einschließlich der 100-120 V AC

wesentlichen Leistungsmerkmale) CAN/CSA-C22.2 Nr. 60601-1 (2008) 2 x T6.3A-H (250 V) für

(Medizinische elektrische Geräte – Teil 1: Allgemeine Festlegungen

für die Sicherheit einschließlich der wesentlichen Leistungsmerkmale)

(einschließlich länderspezifischer Abweichungen für Kanada) ANSI/AAMI

220-240 V AC

SICHERUNGSTYP AUTOMATISCHE Irrigation Fluid

Warming System

UNTERBRECHUNG

ES60601-1 (2005 + C1:09 + A2:10) (Medizinische elektrische Geräte – Teil 1: Verzögert, Hochleistung

BEI ÜBERHITZUNG

Allgemeine Festlegungen für die Sicherheit einschließlich der wesentlichen

Leistungsmerkmale) (einschließlich länderspezifischer Abweichungen für Modell 245:

die USA.)

Das Modell 245 ist klassifiziert als Gerät der Klasse IIb

44 °C [±2 °C] (Erwärmungseinheiten

Rev N und neuer)

Model 247 – Not for I.V. Use

gemäß Medizingeräte-Richtlinie. 46 °C [±2 °C] (Erwärmungseinheiten

Service Manual

Rev A bis M)

Modell 247:

1 Model 245 1 Model 247

50 °C [±2 °C] • 3M™ Ranger™ Blood/Fluid Warming System • 3M™ Ranger™ Irrigation Fluid Warming System

LECKSTROM • For I.V. Use • Not for I.V. Use

Erfüllt die Anforderungen für Leckströme gemäß UL/IEC 60601-1.

2 Modèle 245 2 Modèle 247

Umgebungsbedingungen • Système de réchauffement de sang/liquide • Système de réchauffement pour liquide

BETRIEBSTEMPERATURBEREICH Ranger ™ de 3M™ d'irrigation Ranger™ de 3M™

15 °C bis 40 °C • Pour perfusion I.V • Ne pas utiliser pour une perfusion I.V

LAGERUNGSTEMPERATURBEREICH

3 Modell 245 3 Modell 247

-20 °C bis 45 °C

• 3M™ Ranger™ Blut- und Infusionswärmesystem • 3M™ Ranger™ Spülflüssigkeitserwärmungssystem

BETRIEBSFEUCHTIGKEIT • für intravenöse Anwendungen • Nicht für intravenöse Anwendungen

10 bis 85 % rel. Luftfeuchtigkeit, nicht kondensierend

BEREICH DES ATMOSPHÄRISCHEN DRUCKS

50 kPa bis 106 kPa

1 English......................................................1

2 Français ................................................ 19

3 Deutsch ............................................... 39

3M Deutschland GmbH

Health Care Business

Made in the USA by Carl-Schurz-Str. 1

41453 Neuss

3M Health Care Germany

2510 Conway Ave.

St. Paul, MN 55144

1-800-228-3957

www.rangerfluidwarming.com

3M, RANGER and BAIR HUGGER

are trademarks of 3M.

Used under license in Canada.

Issue Date: 2016-08

© 2016, 3M. All rights reserved.

34-8719-2503-7

4420684 2

Description: 3M TM Ranger™ Item Spec#: 34-8719-2503-7

Blood/Fluid Warming Unit

Service Manual 08.31.16 New Build Jer/k

Supersedes#:

09.13.16 Copy edits per proof report & Final release. DJ

Base File Name:

Structure#:

PA: 34871925037.indd

GA: Cat/Product#:Model 245 & 247

Software: InDesign CC 2014 - BOOK

SGS Contact: Reference:

Email:

Requester: Frank Boeshart/Debra Staack

Printer:

Printer Location: Die # / Doc. Size: 8.5" x 11"

Supplier:

PROCESS PMS

BLACK 280

PDF Scaled at 75.0%

1 Table of Contents

TECHNICAL SUPPORT AND ORDER PLACEMENT ........................................................................................................... 3

IN‑WARRANTY REPAIR AND EXCHANGE ........................................................................................................................... 3

WHEN YOU CALL FOR TECHNICAL SUPPORT .................................................................................................................. 3

INITIAL EQUIPMENT CHECK................................................................................................................................................... 3

INTRODUCTION.......................................................................................................................................................................... 3

MODEL 245 BLOOD/FLUID WARMING SYSTEM............................................................................................................... 3

MODEL 247 IRRIGATION FLUID WARMING SYSTEM....................................................................................................... 3

INDICATIONS FOR USE............................................................................................................................................................. 3

DEFINITION OF SYMBOLS ....................................................................................................................................................... 3

EXPLANATION OF SIGNAL WORD CONSEQUENCES ..................................................................................................... 4

WARNINGS AND CAUTIONS................................................................................................................................................... 4

BEFORE SERVICING EQUIPMENT .......................................................................................................................................... 5

PRODUCT DESCRIPTION ......................................................................................................................................................... 5

RANGER WARMING UNIT ........................................................................................................................................................ 6

RANGER MODELS 245 AND 247 ............................................................................................................................................ 6

MAINTENANCE AND STORAGE..............................................................................................................................................7

BLOOD/FLUID WARMING SYSTEM PREVENTATIVE MAINTENANCE CHECKLIST..................................................7

RANGER BLOOD/FLUID WARMING UNIT, MODEL 245 MAINTENANCE LOG ......................................................... 9

RANGER IRRIGATION FLUID WARMING SYSTEM, MODEL 247 PREVENTATIVE

MAINTENANCE CHECKLIST ..................................................................................................................................................10

RANGER IRRIGATION FLUID WARMING, MODEL 247 MAINTENANCE LOG ...........................................................11

REPLACING THE POWER FUSE...............................................................................................................................................11

TROUBLESHOOTING ................................................................................................................................................................12

SPECIFICATIONS .......................................................................................................................................................................13

ENVIRONMENTAL CONDITIONS.......................................................................................................................................... 17

1

GB / 34-8719-2503-7

PDF Scaled at 75.0%

1 Ranger™ Blood/Fluid Warming System Model 245 ‑ For I.V. Use

Ranger™ Irrigation Fluid Warming System Model 247 ‑ Not for I.V. Use

SERVICE MANUAL The Ranger irrigation disposable fluid warming set is sterile, latex-free, and

is designed to be used with the Ranger irrigation fluid warming unit. Do not

Technical Support and Order Placement use other warming sets with the Model 247, including those designed for

USA the Model 245 blood/fluid warming unit.

TEL: 1-800-733-7775

Indications for Use

OUTSIDE OF THE USA

Contact your local 3M representative.

BLOOD/FLUID WARMING SYSTEM

The Ranger blood/fluid warming system is intended to warm blood, blood

In‑warranty Repair and Exchange products, and liquids.

To return a device to 3M for service, first obtain a Return Authorization (RA) IRRIGATION FLUID WARMING SYSTEM

number from a customer service representative. Please use the (RA) number The Ranger irrigation fluid warming system is intended to warm

on all correspondence when returning a device for service. A shipping irrigation fluids.

carton will be delivered to you at no charge, if needed. Call your local

supplier or sales representative to inquire about a loaner device while your Definition of Symbols

device is being serviced.

When You Call for Technical Support ON

Remember, we will need to know the serial number of your unit when you

call us. The serial number label is located on the bottom of the warming unit.

Initial Equipment Check OFF

• Make sure the 3M™ Ranger™ warming unit’s power cord is plugged

into the unit.

• When checking for grounding, clamp to the screw threads on the

Fuse

unit’s I.V. pole clamp or the equipotential stud on the rear of the unit.

Clamp should be tightened securely.

• Sometime during shipping, this unit may have been exposed to

extreme temperatures. The unit may need a period of 20 minutes or CAUTION

more to return to normal operating temperature. Store the Ranger

warming unit at room temperature, allowing it to equilibrate, before

using or testing the unit.

Introduction Type BF Applied Part

The Ranger warming system includes a warming unit and a disposable

warming set. The Ranger warming unit is designed to be mounted to an I.V.

pole. A handle located on the top of the unit makes transport easy. When

mounted to the I.V. pole, the unit fits easily above the 3M™ Bair Hugger™ Voltage, Alternating Current (AC)

500 or 700 series warming unit. For additional information on Ranger

warming sets visit us online at rangerfluidwarming.com.

Model 245 Blood/Fluid Warming System An equipotentiality plug (grounded) conductor

The Ranger blood/fluid warming system is designed to warm blood, blood other than a protective earth conductor or a neutral

products, and liquids and deliver these at flow rates from KVO to 500 mL/ conductor, providing a direct connection between

min. At these flow rates, the device maintains fluid output temperatures electrical equipment and the potential equalization

ranging from 33°C to 41°C (Note: This is for room temperature fluids only). busbar of the electrical installation. Please consult IEC

It takes less than two minutes to warm up to the 41°C [±1°C] set point 60601-1; 2005 for requirements.

temperature. The alert points on the Model 245 are 43°C [±1°C] and 46°C

[+3, -2°C].

Disposable warming sets are available for standard flow, high flow, and

pediatric applications. Warming sets are sterile, latex-free, single-use-only This system is subject to European WEEE

items and are designed to be used with the reusable warming unit. Do not Directive 2002/96/EC. This product contains

use other warming sets with the Model 245, including those designed for electrical and electronic components and must not be

the Model 247 irrigation fluid warming system. disposed of using standard refuse collection. Please

consult local directives for disposal of electrical and

Model 247 Irrigation Fluid Warming System electronic equipment.

The Ranger irrigation fluid warming system is designed to warm irrigation

fluids and deliver these at flow rates from 0 to 870 mL/min when the bag

is hung 100 cm above the scope. At these flow rates, the device maintains

fluid output temperatures ranging from 33°C to 41°C (Note: This is for room Protective earth ground

temperature fluids only). It takes less than two minutes to warm up to the

41°C [±1] set point temperature. The alert points on the Model 247 are 48°C

[±2] and 50°C [±2].

Consult instructions for use

3

GB / 34-8719-2503-7

PDF Scaled at 75.0%

1 Ranger™ Blood/Fluid Warming System Model 245 ‑ For I.V. Use

Ranger™ Irrigation Fluid Warming System Model 247 ‑ Not for I.V. Use

SERVICE MANUAL The Ranger irrigation disposable fluid warming set is sterile, latex-free, and

is designed to be used with the Ranger irrigation fluid warming unit. Do not

Technical Support and Order Placement use other warming sets with the Model 247, including those designed for

USA the Model 245 blood/fluid warming unit.

TEL: 1-800-733-7775

Indications for Use

OUTSIDE OF THE USA

Contact your local 3M representative.

BLOOD/FLUID WARMING SYSTEM

The Ranger blood/fluid warming system is intended to warm blood, blood

In‑warranty Repair and Exchange products, and liquids.

To return a device to 3M for service, first obtain a Return Authorization (RA) IRRIGATION FLUID WARMING SYSTEM

number from a customer service representative. Please use the (RA) number The Ranger irrigation fluid warming system is intended to warm

on all correspondence when returning a device for service. A shipping irrigation fluids.

carton will be delivered to you at no charge, if needed. Call your local

supplier or sales representative to inquire about a loaner device while your Definition of Symbols

device is being serviced.

When You Call for Technical Support ON

Remember, we will need to know the serial number of your unit when you

call us. The serial number label is located on the bottom of the warming unit.

Initial Equipment Check OFF

• Make sure the 3M™ Ranger™ warming unit’s power cord is plugged

into the unit.

• When checking for grounding, clamp to the screw threads on the

Fuse

unit’s I.V. pole clamp or the equipotential stud on the rear of the unit.

Clamp should be tightened securely.

• Sometime during shipping, this unit may have been exposed to

extreme temperatures. The unit may need a period of 20 minutes or CAUTION

more to return to normal operating temperature. Store the Ranger

warming unit at room temperature, allowing it to equilibrate, before

using or testing the unit.

Introduction Type BF Applied Part

The Ranger warming system includes a warming unit and a disposable

warming set. The Ranger warming unit is designed to be mounted to an I.V.

pole. A handle located on the top of the unit makes transport easy. When

mounted to the I.V. pole, the unit fits easily above the 3M™ Bair Hugger™ Voltage, Alternating Current (AC)

500 or 700 series warming unit. For additional information on Ranger

warming sets visit us online at rangerfluidwarming.com.

Model 245 Blood/Fluid Warming System An equipotentiality plug (grounded) conductor

The Ranger blood/fluid warming system is designed to warm blood, blood other than a protective earth conductor or a neutral

products, and liquids and deliver these at flow rates from KVO to 500 mL/ conductor, providing a direct connection between

min. At these flow rates, the device maintains fluid output temperatures electrical equipment and the potential equalization

ranging from 33°C to 41°C (Note: This is for room temperature fluids only). busbar of the electrical installation. Please consult IEC

It takes less than two minutes to warm up to the 41°C [±1°C] set point 60601-1; 2005 for requirements.

temperature. The alert points on the Model 245 are 43°C [±1°C] and 46°C

[+3, -2°C].

Disposable warming sets are available for standard flow, high flow, and

pediatric applications. Warming sets are sterile, latex-free, single-use-only This system is subject to European WEEE

items and are designed to be used with the reusable warming unit. Do not Directive 2002/96/EC. This product contains

use other warming sets with the Model 245, including those designed for electrical and electronic components and must not be

the Model 247 irrigation fluid warming system. disposed of using standard refuse collection. Please

consult local directives for disposal of electrical and

Model 247 Irrigation Fluid Warming System electronic equipment.

The Ranger irrigation fluid warming system is designed to warm irrigation

fluids and deliver these at flow rates from 0 to 870 mL/min when the bag

is hung 100 cm above the scope. At these flow rates, the device maintains

fluid output temperatures ranging from 33°C to 41°C (Note: This is for room Protective earth ground

temperature fluids only). It takes less than two minutes to warm up to the

41°C [±1] set point temperature. The alert points on the Model 247 are 48°C

[±2] and 50°C [±2].

Consult instructions for use

3

GB / 34-8719-2503-7

PDF Scaled at 75.0%

Warnings and Cautions 4. Do not use the Ranger blood/fluid warming system Model 245 for • Do not immerse the warming unit in cleaning or sterilizing

Follow instructions for use direct cardiac application. When using the Model 245 with a central solutions. The unit is not liquid proof.

! WARNINGS: venous catheter (CVC), ensure that the catheter tip does not have

• Do not insert metallic instruments in the warming unit.

1. To reduce the risks associated with hazardous voltage and fire and direct contact with the heart and ensure that all electrical devices

thermal energy hazards: connected to or near the patient have an appropriate leakage • Do not use abrasive materials or solutions to clean the

Recycle to avoid environmental contamination. This current rating for the application. If a CVC tip is found to be in direct heater plates.

product contains recyclable parts. For information • Do not substitute other devices (i.e. Model 245) for the Ranger contact with a patient’s heart, the Model 245 should be immediately

• Do not allow spills to dry inside the unit, as this may make it more

on recycling - please contact 3M technical support irrigation fluid warming unit or Ranger irrigation warming sets. disconnected from the CVC until the CVC is safely repositioned.

difficult to clean the unit.

for advice. • Do not substitute other devices (i.e. Model 247) for the Ranger Failure to follow these precautions may cause cardiac disturbance

blood/fluid warming unit or Ranger blood/fluid warming sets. and/or patient injury. 3. The Ranger blood/fluid warming unit and irrigation fluid warming unit

meet medical electronic interference requirements. If radio frequency

• Do not continue use of the unit if the over-temperature alert 5. Follow the AABB Guidelines for the use of blood warming device

interference with other equipment should occur, connect the unit to a

continues to sound and the temperature does not return to the set which caution against warming when administering platelets,

different power source.

Date of manufacture point temperature. Have the warming unit tested by a biomedical cryoprecipitates, or granulocyte suspensions.

technician or call 3M technical support. 6. The 3M Ranger blood/fluid warming system has been tested to Before Servicing Equipment

be resistant to both electromagnetic fields (EMI) and electrostatic All repair, calibration, and servicing of this equipment must be performed

2. To reduce the risks associated with hazardous voltage and fire:

discharge (ESD). To reduce the risk associated with EMI due to by 3M or an authorized service technician. 3M assumes no responsibility for

Manufacturer • Do not modify this device. portable and mobile RF communications equipment: the reliability, performance, or safety of the equipment if:

• Connect power cord to receptacles marked “Hospital Only,” • Install and put into service the 3M Ranger blood/fluid warming

• Modifications or repairs are performed by unauthorized personnel.

“Hospital Grade,” or a reliably grounded outlet. system according to the EMC information provided In the

Guidance and Manufacturer’s Declaration. • The equipment is used in a manner other than that described in the

• Use only the power cord specified for the product and certified

Sterile, ethylene oxide operator’s manual.

for the country of use. • Should interference occur move away from the portable or mobile

RF communications equipment. • The equipment is installed in an environment that does not meet the

• Do not allow the power cord to get wet.

appropriate electrical and grounding requirements.

• Do not use the warming unit when it appears the Ranger warming NOTICE:

• Do not modify this equipment without authorization of

Store at room temperature unit, power cord, or warming set is damaged. Use only 3M 1. Federal law (USA) restricts this device to sale by or on the order of a the manufacturer.

specified replacement parts.

!

licensed healthcare professional.

WARNING:

• Keep power cord visible and accessible at all times. The plug on

2. To avoid device damage: • To reduce the risk associated with exposure to biohazards always

the power cord serves as the disconnect device. The wall socket

Container quantity outlet shall be as close as practical and shall be easily accessible. • Do not clean the warming unit with solvents. Damage to the case, perform the Cleaning the Ranger warming unit procedure on page

label, and internal components may result. 10 prior to beginning service procedures, returning the warming

• Do not use with a multiple socket outlet or extension cord.

unit for service, and prior to disposal.

• Do not use this equipment adjacent to, stacked with or in

Do not reuse combination with other equipment without verifying that the total Product Description

leakage current from the combined equipment does not exceed The Ranger blood/fluid, and irrigation fluid warming systems consist of a warming unit and a sterile disposable fluid warming set.

the safety limits for Type BF equipment and to assure normal

operation in the configuration in which it will be used.

Not made with natural rubber latex 3. To reduce the risks associated with air embolism and incorrect routing

ALERT

INDICATOR

LIGHT

MODEL 247 ALERT

INDICATOR

LIGHT

MODEL 245

SLOT FOR

of fluids: WARMING

CASSETTE I.V. POLE CLAMP SLOT FOR

• Never infuse fluids if air bubbles are present in fluid line. WARMING

CASSETTE

Keep dry • Ensure all luer connections are tightened. I.V. POLE CLAMP

4. Do not mount the Ranger blood/fluid warming system higher than

patient level during infusion, as air embolism may result.

5. To reduce the risks associated with potential blood loss, do not use in

Temperature limits

combination with an extracorporeal circuit.

! CAUTION:

POWER

BUBBLE TRAP HOLDER

POWER SWITCH

ALPHANUMERIC ALPHANUMERIC

1. To reduce the risks associated with cross-contamination: DISPLAY

SWITCH

Explanation of Signal Word Consequences DISPLAY

• The cleaning tool provides only superficial cleaning, it does not

! WARNING: disinfect or sterilize the interior of the unit. FIGURE 1: RANGER MODELS 247 AND 245 FLUID WARMING UNITS

Indicates a hazardous situation which, if not avoided, could result in death

2. To reduce the risks associated with impact and facility medical

or serious injury.

device damage:

! CAUTION: • Clamp the Ranger warming unit to an I.V. pole with a minimum 14”

(35.6 cm) radius wheelbase and at a height no higher than 44”

Indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury. (112 cm).

3. To reduce the risks associated with environmental contamination:

NOTICE:

• Follow applicable regulations when disposing of this device or any

Indicates a situation which, if not avoided, could result in property

of its electronic components.

damage only.

CONTRAINDICATIONS:

None

4 5

3M™ Ranger™ Blood/Fluid Warming System - Model 245/ 3M™ Ranger™ Irrigation Fluid Warming System - Model 247 – Service Manual GB / 34-8719-2503-7

PDF Scaled at 75.0%

Warnings and Cautions 4. Do not use the Ranger blood/fluid warming system Model 245 for • Do not immerse the warming unit in cleaning or sterilizing

Follow instructions for use direct cardiac application. When using the Model 245 with a central solutions. The unit is not liquid proof.

! WARNINGS: venous catheter (CVC), ensure that the catheter tip does not have

• Do not insert metallic instruments in the warming unit.

1. To reduce the risks associated with hazardous voltage and fire and direct contact with the heart and ensure that all electrical devices

thermal energy hazards: connected to or near the patient have an appropriate leakage • Do not use abrasive materials or solutions to clean the

Recycle to avoid environmental contamination. This current rating for the application. If a CVC tip is found to be in direct heater plates.

product contains recyclable parts. For information • Do not substitute other devices (i.e. Model 245) for the Ranger contact with a patient’s heart, the Model 245 should be immediately

• Do not allow spills to dry inside the unit, as this may make it more

on recycling - please contact 3M technical support irrigation fluid warming unit or Ranger irrigation warming sets. disconnected from the CVC until the CVC is safely repositioned.

difficult to clean the unit.

for advice. • Do not substitute other devices (i.e. Model 247) for the Ranger Failure to follow these precautions may cause cardiac disturbance

blood/fluid warming unit or Ranger blood/fluid warming sets. and/or patient injury. 3. The Ranger blood/fluid warming unit and irrigation fluid warming unit

meet medical electronic interference requirements. If radio frequency

• Do not continue use of the unit if the over-temperature alert 5. Follow the AABB Guidelines for the use of blood warming device

interference with other equipment should occur, connect the unit to a

continues to sound and the temperature does not return to the set which caution against warming when administering platelets,

different power source.

Date of manufacture point temperature. Have the warming unit tested by a biomedical cryoprecipitates, or granulocyte suspensions.

technician or call 3M technical support. 6. The 3M Ranger blood/fluid warming system has been tested to Before Servicing Equipment

be resistant to both electromagnetic fields (EMI) and electrostatic All repair, calibration, and servicing of this equipment must be performed

2. To reduce the risks associated with hazardous voltage and fire:

discharge (ESD). To reduce the risk associated with EMI due to by 3M or an authorized service technician. 3M assumes no responsibility for

Manufacturer • Do not modify this device. portable and mobile RF communications equipment: the reliability, performance, or safety of the equipment if:

• Connect power cord to receptacles marked “Hospital Only,” • Install and put into service the 3M Ranger blood/fluid warming

• Modifications or repairs are performed by unauthorized personnel.

“Hospital Grade,” or a reliably grounded outlet. system according to the EMC information provided In the

Guidance and Manufacturer’s Declaration. • The equipment is used in a manner other than that described in the

• Use only the power cord specified for the product and certified

Sterile, ethylene oxide operator’s manual.

for the country of use. • Should interference occur move away from the portable or mobile

RF communications equipment. • The equipment is installed in an environment that does not meet the

• Do not allow the power cord to get wet.

appropriate electrical and grounding requirements.

• Do not use the warming unit when it appears the Ranger warming NOTICE:

• Do not modify this equipment without authorization of

Store at room temperature unit, power cord, or warming set is damaged. Use only 3M 1. Federal law (USA) restricts this device to sale by or on the order of a the manufacturer.

specified replacement parts.

!

licensed healthcare professional.

WARNING:

• Keep power cord visible and accessible at all times. The plug on

2. To avoid device damage: • To reduce the risk associated with exposure to biohazards always

the power cord serves as the disconnect device. The wall socket

Container quantity outlet shall be as close as practical and shall be easily accessible. • Do not clean the warming unit with solvents. Damage to the case, perform the Cleaning the Ranger warming unit procedure on page

label, and internal components may result. 10 prior to beginning service procedures, returning the warming

• Do not use with a multiple socket outlet or extension cord.

unit for service, and prior to disposal.

• Do not use this equipment adjacent to, stacked with or in

Do not reuse combination with other equipment without verifying that the total Product Description

leakage current from the combined equipment does not exceed The Ranger blood/fluid, and irrigation fluid warming systems consist of a warming unit and a sterile disposable fluid warming set.

the safety limits for Type BF equipment and to assure normal

operation in the configuration in which it will be used.

Not made with natural rubber latex 3. To reduce the risks associated with air embolism and incorrect routing

ALERT

INDICATOR

LIGHT

MODEL 247 ALERT

INDICATOR

LIGHT

MODEL 245

SLOT FOR

of fluids: WARMING

CASSETTE I.V. POLE CLAMP SLOT FOR

• Never infuse fluids if air bubbles are present in fluid line. WARMING

CASSETTE

Keep dry • Ensure all luer connections are tightened. I.V. POLE CLAMP

4. Do not mount the Ranger blood/fluid warming system higher than

patient level during infusion, as air embolism may result.

5. To reduce the risks associated with potential blood loss, do not use in

Temperature limits

combination with an extracorporeal circuit.

! CAUTION:

POWER

BUBBLE TRAP HOLDER

POWER SWITCH

ALPHANUMERIC ALPHANUMERIC

1. To reduce the risks associated with cross-contamination: DISPLAY

SWITCH

Explanation of Signal Word Consequences DISPLAY

• The cleaning tool provides only superficial cleaning, it does not

! WARNING: disinfect or sterilize the interior of the unit. FIGURE 1: RANGER MODELS 247 AND 245 FLUID WARMING UNITS

Indicates a hazardous situation which, if not avoided, could result in death

2. To reduce the risks associated with impact and facility medical

or serious injury.

device damage:

! CAUTION: • Clamp the Ranger warming unit to an I.V. pole with a minimum 14”

(35.6 cm) radius wheelbase and at a height no higher than 44”

Indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury. (112 cm).

3. To reduce the risks associated with environmental contamination:

NOTICE:

• Follow applicable regulations when disposing of this device or any

Indicates a situation which, if not avoided, could result in property

of its electronic components.

damage only.

CONTRAINDICATIONS:

None

4 5

3M™ Ranger™ Blood/Fluid Warming System - Model 245/ 3M™ Ranger™ Irrigation Fluid Warming System - Model 247 – Service Manual GB / 34-8719-2503-7

PDF Scaled at 75.0%

Ranger Warming Unit Maintenance and Storage METHOD

The warming unit is a compact, lightweight, liquid-resistant device with a clamp located on the side for attachment to an I.V. pole. A carrying handle on the CLEANING THE RANGER WARMING UNIT 1. Unplug the warming unit.

top of the unit makes it easy to transport (see Figure 1). Clean the Ranger warming unit on an as-needed basis.

2. Unfold the cleaning tool. Wet the foam pads with a nonabrasive

Located on the front panel you will find:

• Alphanumeric display that indicates the heater temperature during normal operation. In an over-temperature condition, the display alternately flashes

! CAUTION solution, such as Alconox™* brand detergent.

1. To reduce the risks associated with cross-contamination: 3. Insert the tool from the back of the unit and pull the tool all the way

a temperature of 43°C for the Model 245 (48°C for the Model 247) or higher and the word “HI.” An audible alert also sounds. In an under-temperature out from the front (See Figure 3.).

condition, the display alternately flashes a temperature of 33°C or lower and the word “LO.” • The cleaning tool provides only superficial cleaning, it does not

disinfect or sterilize the interior of the unit. 4. Rinse the tool with water and repeat 3 times. Discard the tool

• Alert indicator light that comes on when either an over- or under-temperature condition occurs. according to institutional protocol.

NOTICE

Ranger Models 245 and 247 5. Wipe off the unit to remove excess fluid.

18. 2. To avoid device damage:

TO CLEAN RESISTANT, DRIED‑ON FLUIDS:

• Do not immerse the warming unit in cleaning or sterilizing

1. solutions. The unit is not liquid proof. 1. Spray a nonabrasive solution inside the slot of the warming unit and

let sit for 15-20 minutes.

• Do not clean the warming unit with solvents. Damage to the case,

label, and internal components may result. 2. Clean the unit by using the cleaning tool.

• Do not insert metallic instruments in the warming unit. NOTE: You may use a nonmetal instrument, such as a cotton swab, to clean

3. the upper channels. If you are unable to adequately clean the unit, call 3M

17.

• Do not use abrasive materials or solutions to clean the technical support.

heater plates.

STORAGE

• Do not allow spills to dry inside the unit, as this may make it more Store all components in a cool, dry place when not in use.

7. difficult to clean the unit.

5. Call 3M technical support at 800‑228‑3957 for service information.

TO CLEAN THE EXTERIOR OF THE WARMING UNIT: * Alconox is a trademark of Alconox, Inc.

1. Disconnect the Ranger warming unit from the power source.

11. Blood/Fluid Warming System Preventative

2. Wipe the outside of the unit with warm, soapy water, nonabrasive Maintenance Checklist

8. cleaning solutions, dilute bleach, or cold sterilants. Do not use

abrasive materials. CAUTION

6.

Temperature adjustments cannot be made to the Ranger warming unit. If

19. 3. Wipe with a dry, soft cloth. the test shows the temperature is out of specification, please contact 3M

13. TO CLEAN THE HEATING PLATES: technical support.

The Ranger warming unit cleaning tool is intended to clean both heating

TOOLS AND EQUIPMENT

9. plates of the warming unit. It is not necessary to disassemble the warming

4. unit to use the tool. • Thermocouple: 0.005” lead or smaller (part #90020)

• Calibrated thermocouple temperature monitor

10.

• Aluminum tape

• Ranger standard flow blood/fluid warming set

• Phillips screwdriver

20. • Saline/water

INLET TUBE

12.

16. 14.

21. 15.

before priming.

Insert cassette

2.

Blood/Fluid Warming System

from cassette to remove.

Drain 2mL or more

FIGURE 2: RANGER FLUID WARMING UNIT ASSEMBLY DIAGRAM

1. Upper Enclosure 8. Thermistor Sensor 15. Microswitch

FIGURE 3: RANGER FLUID WARMING UNIT CLEANING

2. Lower Enclosure 9. Pole Clamp 16. Alarm Board

ALUMINUM TAPE

3. Upper Heater 10. Pole Clamp Knob 17. Controller

4. Lower Heater 11. Bubble Trap Holder (Model 245) 18. Handle 0.75" THERMOCOUPLE

1.80"

5. Upper Heater Plate 12. Power Entry Module 19. Cable Clamp

FIGURE 4: RANGER STANDARD FLOW BLOOD/FLUID WARMING CASSETTE

6. Lower Heater Plate 13. Cord Retainer 20. Ground Plane

1. Use aluminum tape to affix a thermocouple to the top surface of the

7. RTD Sensor 14. Solid State Relay 21. Heat Sink Ranger blood/fluid warming cassette as shown in Figure 4.

2. Slide the cassette into the slot of the Ranger warming unit.

6 7

3M™ Ranger™ Blood/Fluid Warming System - Model 245/ 3M™ Ranger™ Irrigation Fluid Warming System - Model 247 – Service Manual GB / 34-8719-2503-7

PDF Scaled at 75.0%

Ranger Warming Unit Maintenance and Storage METHOD

The warming unit is a compact, lightweight, liquid-resistant device with a clamp located on the side for attachment to an I.V. pole. A carrying handle on the CLEANING THE RANGER WARMING UNIT 1. Unplug the warming unit.

top of the unit makes it easy to transport (see Figure 1). Clean the Ranger warming unit on an as-needed basis.

2. Unfold the cleaning tool. Wet the foam pads with a nonabrasive

Located on the front panel you will find:

• Alphanumeric display that indicates the heater temperature during normal operation. In an over-temperature condition, the display alternately flashes

! CAUTION solution, such as Alconox™* brand detergent.

1. To reduce the risks associated with cross-contamination: 3. Insert the tool from the back of the unit and pull the tool all the way

a temperature of 43°C for the Model 245 (48°C for the Model 247) or higher and the word “HI.” An audible alert also sounds. In an under-temperature out from the front (See Figure 3.).

condition, the display alternately flashes a temperature of 33°C or lower and the word “LO.” • The cleaning tool provides only superficial cleaning, it does not

disinfect or sterilize the interior of the unit. 4. Rinse the tool with water and repeat 3 times. Discard the tool

• Alert indicator light that comes on when either an over- or under-temperature condition occurs. according to institutional protocol.

NOTICE

Ranger Models 245 and 247 5. Wipe off the unit to remove excess fluid.

18. 2. To avoid device damage:

TO CLEAN RESISTANT, DRIED‑ON FLUIDS:

• Do not immerse the warming unit in cleaning or sterilizing

1. solutions. The unit is not liquid proof. 1. Spray a nonabrasive solution inside the slot of the warming unit and

let sit for 15-20 minutes.

• Do not clean the warming unit with solvents. Damage to the case,

label, and internal components may result. 2. Clean the unit by using the cleaning tool.

• Do not insert metallic instruments in the warming unit. NOTE: You may use a nonmetal instrument, such as a cotton swab, to clean

3. the upper channels. If you are unable to adequately clean the unit, call 3M

17.

• Do not use abrasive materials or solutions to clean the technical support.

heater plates.

STORAGE

• Do not allow spills to dry inside the unit, as this may make it more Store all components in a cool, dry place when not in use.

7. difficult to clean the unit.

5. Call 3M technical support at 800‑228‑3957 for service information.

TO CLEAN THE EXTERIOR OF THE WARMING UNIT: * Alconox is a trademark of Alconox, Inc.

1. Disconnect the Ranger warming unit from the power source.

11. Blood/Fluid Warming System Preventative

2. Wipe the outside of the unit with warm, soapy water, nonabrasive Maintenance Checklist

8. cleaning solutions, dilute bleach, or cold sterilants. Do not use

abrasive materials. CAUTION

6.

Temperature adjustments cannot be made to the Ranger warming unit. If

19. 3. Wipe with a dry, soft cloth. the test shows the temperature is out of specification, please contact 3M

13. TO CLEAN THE HEATING PLATES: technical support.

The Ranger warming unit cleaning tool is intended to clean both heating

TOOLS AND EQUIPMENT

9. plates of the warming unit. It is not necessary to disassemble the warming

4. unit to use the tool. • Thermocouple: 0.005” lead or smaller (part #90020)

• Calibrated thermocouple temperature monitor

10.

• Aluminum tape

• Ranger standard flow blood/fluid warming set

• Phillips screwdriver

20. • Saline/water

INLET TUBE

12.

16. 14.

21. 15.

before priming.

Insert cassette

2.

Blood/Fluid Warming System

from cassette to remove.

Drain 2mL or more

FIGURE 2: RANGER FLUID WARMING UNIT ASSEMBLY DIAGRAM

1. Upper Enclosure 8. Thermistor Sensor 15. Microswitch

FIGURE 3: RANGER FLUID WARMING UNIT CLEANING

2. Lower Enclosure 9. Pole Clamp 16. Alarm Board

ALUMINUM TAPE

3. Upper Heater 10. Pole Clamp Knob 17. Controller

4. Lower Heater 11. Bubble Trap Holder (Model 245) 18. Handle 0.75" THERMOCOUPLE

1.80"

5. Upper Heater Plate 12. Power Entry Module 19. Cable Clamp

FIGURE 4: RANGER STANDARD FLOW BLOOD/FLUID WARMING CASSETTE

6. Lower Heater Plate 13. Cord Retainer 20. Ground Plane

1. Use aluminum tape to affix a thermocouple to the top surface of the

7. RTD Sensor 14. Solid State Relay 21. Heat Sink Ranger blood/fluid warming cassette as shown in Figure 4.

2. Slide the cassette into the slot of the Ranger warming unit.

6 7

3M™ Ranger™ Blood/Fluid Warming System - Model 245/ 3M™ Ranger™ Irrigation Fluid Warming System - Model 247 – Service Manual GB / 34-8719-2503-7

PDF Scaled at 75.0%

3. Using room temperature saline/water, prime the cassette per TESTING THE OVER‑TEMPERATURE ALERT POINTS (43°C Ranger Blood/Fluid Warming Unit, Model 245 Maintenance Log

instructions included with it. [±1°C] AND 46°C [+3, ‑2°C]) The operating temperature and alerts should be tested at least every 6 months or according to institutional protocol.

NOTE: To achieve correct results, fluids must be administered into the inlet The over-temperature alert test causes the Ranger warming unit to go into

tube, NOT into the outlet tube. an over-temperature test mode by manually overriding the primary control MAINTENANCE ACTION PERFORMED

system and engaging the heaters. The Ranger warming system is very

4. Close patient line with white clamp to stop flow (See Figure 5.). responsive to heater input; therefore the test procedures are technique MODEL ____________ SN____________

5. Turn the Ranger warming unit ON and allow it to warm up for sensitive. Read instructions thoroughly before beginning these tests.

5 minutes. The first alert point at 43°C [±1°C] notifies user to the rise in temperature

Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

6. The Ranger warming unit display should read 41°C [±1°C]. Note (see step 7). At the 46°C [+3, -2°C] secondary alert set point, the unit cuts

the temperature on the thermocouple temperature monitor. If the power to the heaters (see step 8). Please note that due to the heaters’ Over‑temperature alert points:

temperature reading is not 41°C [±1°C], contact 3M technical support. rapid response, you may see temperature readings drift within the range Audible (43°C [±1°C] on Ranger unit display) ______°C

NOTE: Most handheld temperature meters have a ±1°C tolerance. of 44-49°C.

Secondary (46°C [+3, -2°C]) ______°C

CASSETTE Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

OVER‑TEMPERATURE

SCREW

Over‑temperature alert points:

Audible (43°C [±1°C] on Ranger unit display) ______°C

Secondary (46°C [+3, -2°C]) ______°C

BLUE Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

CLAMP FIGURE 6: RANGER WARMING UNIT OVER‑TEMPERATURE SCREW

Over‑temperature alert points:

INLET OUTLET

TUBE TUBE 7. Loosen the over-temperature screw on the bottom of the Ranger Audible (43°C [±1°C] on Ranger unit display) ______°C

warming unit (see Figure 6.). Listen for a slight click as the

Secondary (46°C [+3, -2°C]) ______°C

FLUID

microswitch opens. Loosen 1/2 turn more. This unit is now in

SOURCE EXIT over-temperature test mode, and the temperature output of the unit

should begin to rise. When the Ranger display reads 43°C, verify that

BUBBLE

TRAP an audible alert sounds, the alert light illuminates, and the display Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

alternately flashes “HI” and the plate temperature.

WHITE Over‑temperature alert points:

CLAMP 8. Listen for the power relay to click at 46°C [+3, -2°C] (you can feel

the click when holding the lower left corner of the unit as you Audible (43°C [±1°C] on Ranger unit display) ______°C

face the front display). The click signifies the secondary alert trip Secondary (46°C [+3, -2°C]) ______°C

point and signals that power to the heaters has been shut off. The

over-temperature alert sounds, the alarm light illuminates, and the

ROLLER alphanumeric display alternately reads “HI” and the plate temperature.

CLAMP

Watch the thermocouple temperature monitor to determine the Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

unit’s peak temperature output (less than 1 minute). The temperature Over‑temperature alert points:

reading on the monitor should peak at 46°C [+3, -2°C].

Audible (43°C [±1°C] on Ranger unit display) ______°C

NOTE:

FIGURE 5: RANGER STANDARD FLOW BLOOD/FLUID WARMING SET Secondary (46°C [+3, -2°C]) ______°C

If the temperature displayed on the thermocouple monitor exceeds 49°C

during the test, tighten the over-temperature test screw on the bottom

of the Ranger warming unit, unplug it, and run cold fluids through the

cassette. This returns the unit to normal operating temperature. Contact 3M Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

technical support.

Over‑temperature alert points:

9. The secondary alert is designed to latch. Verify this feature by Audible (43°C [±1°C] on Ranger unit display) ______°C

momentarily turning off the power switch, then turning it on again.

The Ranger warming unit should continue alerting throughout Secondary (46°C [+3, -2°C]) ______°C

this sequence.

10. Securely tighten the over-temperature screw, turn off the Ranger

warming unit, and unplug the unit. Once power is cut to the Ranger Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

warming unit, the alert will cease. The unit is ready to return to

service after it cools to normal operating temperature (approximately

Over‑temperature alert points:

20-30 minutes). Audible (43°C [±1°C] on Ranger unit display) ______°C

Secondary (46°C [+3, -2°C]) ______°C

8 9

3M™ Ranger™ Blood/Fluid Warming System - Model 245/ 3M™ Ranger™ Irrigation Fluid Warming System - Model 247 – Service Manual GB / 34-8719-2503-7

PDF Scaled at 75.0%

3. Using room temperature saline/water, prime the cassette per TESTING THE OVER‑TEMPERATURE ALERT POINTS (43°C Ranger Blood/Fluid Warming Unit, Model 245 Maintenance Log

instructions included with it. [±1°C] AND 46°C [+3, ‑2°C]) The operating temperature and alerts should be tested at least every 6 months or according to institutional protocol.

NOTE: To achieve correct results, fluids must be administered into the inlet The over-temperature alert test causes the Ranger warming unit to go into

tube, NOT into the outlet tube. an over-temperature test mode by manually overriding the primary control MAINTENANCE ACTION PERFORMED

system and engaging the heaters. The Ranger warming system is very

4. Close patient line with white clamp to stop flow (See Figure 5.). responsive to heater input; therefore the test procedures are technique MODEL ____________ SN____________

5. Turn the Ranger warming unit ON and allow it to warm up for sensitive. Read instructions thoroughly before beginning these tests.

5 minutes. The first alert point at 43°C [±1°C] notifies user to the rise in temperature

Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

6. The Ranger warming unit display should read 41°C [±1°C]. Note (see step 7). At the 46°C [+3, -2°C] secondary alert set point, the unit cuts

the temperature on the thermocouple temperature monitor. If the power to the heaters (see step 8). Please note that due to the heaters’ Over‑temperature alert points:

temperature reading is not 41°C [±1°C], contact 3M technical support. rapid response, you may see temperature readings drift within the range Audible (43°C [±1°C] on Ranger unit display) ______°C

NOTE: Most handheld temperature meters have a ±1°C tolerance. of 44-49°C.

Secondary (46°C [+3, -2°C]) ______°C

CASSETTE Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

OVER‑TEMPERATURE

SCREW

Over‑temperature alert points:

Audible (43°C [±1°C] on Ranger unit display) ______°C

Secondary (46°C [+3, -2°C]) ______°C

BLUE Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

CLAMP FIGURE 6: RANGER WARMING UNIT OVER‑TEMPERATURE SCREW

Over‑temperature alert points:

INLET OUTLET

TUBE TUBE 7. Loosen the over-temperature screw on the bottom of the Ranger Audible (43°C [±1°C] on Ranger unit display) ______°C

warming unit (see Figure 6.). Listen for a slight click as the

Secondary (46°C [+3, -2°C]) ______°C

FLUID

microswitch opens. Loosen 1/2 turn more. This unit is now in

SOURCE EXIT over-temperature test mode, and the temperature output of the unit

should begin to rise. When the Ranger display reads 43°C, verify that

BUBBLE

TRAP an audible alert sounds, the alert light illuminates, and the display Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

alternately flashes “HI” and the plate temperature.

WHITE Over‑temperature alert points:

CLAMP 8. Listen for the power relay to click at 46°C [+3, -2°C] (you can feel

the click when holding the lower left corner of the unit as you Audible (43°C [±1°C] on Ranger unit display) ______°C

face the front display). The click signifies the secondary alert trip Secondary (46°C [+3, -2°C]) ______°C

point and signals that power to the heaters has been shut off. The

over-temperature alert sounds, the alarm light illuminates, and the

ROLLER alphanumeric display alternately reads “HI” and the plate temperature.

CLAMP

Watch the thermocouple temperature monitor to determine the Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

unit’s peak temperature output (less than 1 minute). The temperature Over‑temperature alert points:

reading on the monitor should peak at 46°C [+3, -2°C].

Audible (43°C [±1°C] on Ranger unit display) ______°C

NOTE:

FIGURE 5: RANGER STANDARD FLOW BLOOD/FLUID WARMING SET Secondary (46°C [+3, -2°C]) ______°C

If the temperature displayed on the thermocouple monitor exceeds 49°C

during the test, tighten the over-temperature test screw on the bottom

of the Ranger warming unit, unplug it, and run cold fluids through the

cassette. This returns the unit to normal operating temperature. Contact 3M Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

technical support.

Over‑temperature alert points:

9. The secondary alert is designed to latch. Verify this feature by Audible (43°C [±1°C] on Ranger unit display) ______°C

momentarily turning off the power switch, then turning it on again.

The Ranger warming unit should continue alerting throughout Secondary (46°C [+3, -2°C]) ______°C

this sequence.

10. Securely tighten the over-temperature screw, turn off the Ranger

warming unit, and unplug the unit. Once power is cut to the Ranger Date ____________ Operating temperature: (Specification = 41°C [±1°C] ______°C

warming unit, the alert will cease. The unit is ready to return to

service after it cools to normal operating temperature (approximately

Over‑temperature alert points:

20-30 minutes). Audible (43°C [±1°C] on Ranger unit display) ______°C

Secondary (46°C [+3, -2°C]) ______°C

8 9

3M™ Ranger™ Blood/Fluid Warming System - Model 245/ 3M™ Ranger™ Irrigation Fluid Warming System - Model 247 – Service Manual GB / 34-8719-2503-7

PDF Scaled at 75.0%

RANGER IRRIGATION FLUID WARMING SYSTEM, 4. Close patient line with white clamp to stop flow (See Figure 8.). Ranger Irrigation Fluid Warming, Model 247 Maintenance Log

MODEL 247 PREVENTATIVE MAINTENANCE CHECKLIST 5. Turn the Ranger irrigation warming unit ON and allow it to warm up THE OPERATING TEMPERATURE AND ALERTS SHOULD BE TESTED AT LEAST EVERY 6 MONTHS OR ACCORDING TO INSTITUTIONAL PROTOCOL.

for 5 minutes.

CAUTION

MAINTENANCE ACTION PERFORMED

Temperature adjustments cannot be made to the Ranger irrigation fluid 6. The Ranger irrigation warming unit display should read 41°C

warming unit. If the test shows the temperature is out of specification, [±1°C]. Note the temperature on the thermocouple temperature MODEL ____________ SN____________

please contact 3M technical support. monitor. If the temperature reading is not 41°C [±1°C], contact 3M

technical support.

INLET TUBE

NOTE: Most handheld temperature meters have a ±1°C tolerance. Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

TESTING THE OVER‑TEMPERATURE ALERT POINTS Over‑temperature alert points:

(48°C [±2°C] AND 50°C [±2°C]) Audible (48°C [±2°C] on Ranger unit display) ______°C

The over-temperature alert test causes the Ranger irrigation warming unit to

Secondary (50°C [±2°C]) ______°C

before priming.

Insert cassette

go into an over-temperature test mode by manually overriding the primary

control system and engaging the heaters. The Ranger irrigation warming

Blood/Fluid Warming System

from cassette to remove.

Drain 2mL or more

system is very responsive to heater input; therefore the test procedures

are technique sensitive. Read instructions thoroughly before beginning Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

these tests.

Over‑temperature alert points:

The first alert point at 48°C [±2°C] notifies user to the rise in temperature

ALUMINUM TAPE (see step 7). At the 50°C [±2°C] secondary alert set point, the unit cuts Audible (48°C [±2°C] on Ranger unit display) ______°C

THERMOCOUPLE power to the heaters (see step 8). Secondary (50°C [±2°C]) ______°C

0.75"

8.50"

FIGURE 7: RANGER IRRIGATION FLUID WARMING CASSETTE

OVER‑TEMPERATURE

SCREW Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

Over‑temperature alert points:

Audible (48°C [±2°C] on Ranger unit display) ______°C

CASSETTE

Secondary (50°C [±2°C]) ______°C

Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

Over‑temperature alert points:

FIG. 9: RANGER IRRIGATION FLUID WARMING UNIT OVER‑TEMPERATURE SCREW

Audible (48°C [±2°C] on Ranger unit display) ______°C

FLUID OVER‑TEMPERATURE SCREW

SOURCE Secondary (50°C [±2°C]) ______°C

7. Loosen the over-temperature screw on the bottom of the Ranger

WHITE irrigation unit (see Figure 9). Listen for a slight click as the microswitch

CLAMP

INLET opens. Loosen 1/2 turn more. This unit is now in over-temperature test

TUBE mode, and the temperature output of the unit should begin to rise.

Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

When the display reads 48°C, verify that an audible alert sounds, the Over‑temperature alert points:

OUTLET TUBE alert light illuminates, and the display alternately flashes “HI” and the

Audible (48°C [±2°C] on Ranger unit display) ______°C

plate temperature.

BLUE CLAMP Secondary (50°C [±2°C]) ______°C

8. Listen for the power relay to click at 50°C [±2°C] (you can feel

the click when holding the lower left corner of the unit as you

EXIT face the front display). The click signifies the secondary alert trip

point and signals that power to the heaters has been shut off. The Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

FIGURE 8: RANGER IRRIGATION FLUID WARMING CASSETTE over-temperature alert sounds, the alert light illuminates, and the

alphanumeric display alternately reads “HI” and the plate temperature. Over‑temperature alert points:

TOOLS AND EQUIPMENT Watch the thermocouple temperature monitor to determine the Audible (48°C [±2°C] on Ranger unit display) ______°C

unit’s peak temperature output (less than 1 minute). The temperature

• Thermocouple: 0.005” lead or smaller (part #90020) reading on the monitor should peak at 50°C [±2°C].

Secondary (50°C [±2°C]) ______°C

• Calibrated thermocouple temperature monitor NOTE: If the temperature displayed on the thermocouple monitor exceeds

52°C during the test, tighten the over-temperature test screw on the bottom

• Aluminum tape

of the Ranger irrigation warming unit, unplug it, and run cold fluids through

• Ranger irrigation fluid warming set the cassette. This returns the unit to normal operating temperature. Call 3M REPLACING THE POWER FUSE

• Phillips screwdriver technical support. The power fuses are located in the power entry module. 5. Remove the blown fuse from the fuse carrier and replace with a new

fuse (as marked).

• Saline/water 9. The secondary alert is designed to latch. Verify this feature by TOOLS AND EQUIPMENT

momentarily turning off the power switch, then turning it on Small slotted screwdriver 6. Place the fuse carrier back into the power entry module.

1. Use aluminum tape to affix a thermocouple to the top surface of the again. The Ranger irrigation warming unit should continue alerting

Ranger irrigation fluid warming cassette as shown in Figure 7. METHOD 7. Reattach the power cord.

throughout this sequence.

1. Disconnect the warming unit from the power source. 8. Reconnect the warming unit to the power source.

2. Slide the warming cassette into the slot of the Ranger irrigation fluid 10. Securely tighten the over-temperature screw, turn off the Ranger

warming unit. irrigation warming unit, and unplug the unit. Once power is cut to the 9. Turn the unit on to verify normal operation.

2. Remove the power cord.

3. Using room temperature saline/water, prime the cassette per Ranger irrigation warming unit, the alert will cease. The unit is ready 10. Record the maintenance action taken.

3. Locate the fuse carrier in the power entry module.

instructions included with it. to return to service after it cools to normal operating temperature

(approximately 20-30 minutes). 4. Use the small screwdriver to remove the fuse carrier from the power

NOTE: To achieve correct results, fluids must be administered into the inlet

entry module.

tube, NOT into the outlet tube.

10 11

3M™ Ranger™ Blood/Fluid Warming System - Model 245/ 3M™ Ranger™ Irrigation Fluid Warming System - Model 247 – Service Manual GB / 34-8719-2503-7

PDF Scaled at 75.0%

RANGER IRRIGATION FLUID WARMING SYSTEM, 4. Close patient line with white clamp to stop flow (See Figure 8.). Ranger Irrigation Fluid Warming, Model 247 Maintenance Log

MODEL 247 PREVENTATIVE MAINTENANCE CHECKLIST 5. Turn the Ranger irrigation warming unit ON and allow it to warm up THE OPERATING TEMPERATURE AND ALERTS SHOULD BE TESTED AT LEAST EVERY 6 MONTHS OR ACCORDING TO INSTITUTIONAL PROTOCOL.

for 5 minutes.

CAUTION

MAINTENANCE ACTION PERFORMED

Temperature adjustments cannot be made to the Ranger irrigation fluid 6. The Ranger irrigation warming unit display should read 41°C

warming unit. If the test shows the temperature is out of specification, [±1°C]. Note the temperature on the thermocouple temperature MODEL ____________ SN____________

please contact 3M technical support. monitor. If the temperature reading is not 41°C [±1°C], contact 3M

technical support.

INLET TUBE

NOTE: Most handheld temperature meters have a ±1°C tolerance. Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

TESTING THE OVER‑TEMPERATURE ALERT POINTS Over‑temperature alert points:

(48°C [±2°C] AND 50°C [±2°C]) Audible (48°C [±2°C] on Ranger unit display) ______°C

The over-temperature alert test causes the Ranger irrigation warming unit to

Secondary (50°C [±2°C]) ______°C

before priming.

Insert cassette

go into an over-temperature test mode by manually overriding the primary

control system and engaging the heaters. The Ranger irrigation warming

Blood/Fluid Warming System

from cassette to remove.

Drain 2mL or more

system is very responsive to heater input; therefore the test procedures

are technique sensitive. Read instructions thoroughly before beginning Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

these tests.

Over‑temperature alert points:

The first alert point at 48°C [±2°C] notifies user to the rise in temperature

ALUMINUM TAPE (see step 7). At the 50°C [±2°C] secondary alert set point, the unit cuts Audible (48°C [±2°C] on Ranger unit display) ______°C

THERMOCOUPLE power to the heaters (see step 8). Secondary (50°C [±2°C]) ______°C

0.75"

8.50"

FIGURE 7: RANGER IRRIGATION FLUID WARMING CASSETTE

OVER‑TEMPERATURE

SCREW Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

Over‑temperature alert points:

Audible (48°C [±2°C] on Ranger unit display) ______°C

CASSETTE

Secondary (50°C [±2°C]) ______°C

Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

Over‑temperature alert points:

FIG. 9: RANGER IRRIGATION FLUID WARMING UNIT OVER‑TEMPERATURE SCREW

Audible (48°C [±2°C] on Ranger unit display) ______°C

FLUID OVER‑TEMPERATURE SCREW

SOURCE Secondary (50°C [±2°C]) ______°C

7. Loosen the over-temperature screw on the bottom of the Ranger

WHITE irrigation unit (see Figure 9). Listen for a slight click as the microswitch

CLAMP

INLET opens. Loosen 1/2 turn more. This unit is now in over-temperature test

TUBE mode, and the temperature output of the unit should begin to rise.

Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

When the display reads 48°C, verify that an audible alert sounds, the Over‑temperature alert points:

OUTLET TUBE alert light illuminates, and the display alternately flashes “HI” and the

Audible (48°C [±2°C] on Ranger unit display) ______°C

plate temperature.

BLUE CLAMP Secondary (50°C [±2°C]) ______°C

8. Listen for the power relay to click at 50°C [±2°C] (you can feel

the click when holding the lower left corner of the unit as you

EXIT face the front display). The click signifies the secondary alert trip

point and signals that power to the heaters has been shut off. The Date ____________ Operating temperature: (Specification = 41°C [±1°C]) ______°C

FIGURE 8: RANGER IRRIGATION FLUID WARMING CASSETTE over-temperature alert sounds, the alert light illuminates, and the

alphanumeric display alternately reads “HI” and the plate temperature. Over‑temperature alert points:

TOOLS AND EQUIPMENT Watch the thermocouple temperature monitor to determine the Audible (48°C [±2°C] on Ranger unit display) ______°C

unit’s peak temperature output (less than 1 minute). The temperature

• Thermocouple: 0.005” lead or smaller (part #90020) reading on the monitor should peak at 50°C [±2°C].

Secondary (50°C [±2°C]) ______°C

• Calibrated thermocouple temperature monitor NOTE: If the temperature displayed on the thermocouple monitor exceeds

52°C during the test, tighten the over-temperature test screw on the bottom

• Aluminum tape

of the Ranger irrigation warming unit, unplug it, and run cold fluids through

• Ranger irrigation fluid warming set the cassette. This returns the unit to normal operating temperature. Call 3M REPLACING THE POWER FUSE

• Phillips screwdriver technical support. The power fuses are located in the power entry module. 5. Remove the blown fuse from the fuse carrier and replace with a new

fuse (as marked).

• Saline/water 9. The secondary alert is designed to latch. Verify this feature by TOOLS AND EQUIPMENT

momentarily turning off the power switch, then turning it on Small slotted screwdriver 6. Place the fuse carrier back into the power entry module.

1. Use aluminum tape to affix a thermocouple to the top surface of the again. The Ranger irrigation warming unit should continue alerting

Ranger irrigation fluid warming cassette as shown in Figure 7. METHOD 7. Reattach the power cord.

throughout this sequence.

1. Disconnect the warming unit from the power source. 8. Reconnect the warming unit to the power source.

2. Slide the warming cassette into the slot of the Ranger irrigation fluid 10. Securely tighten the over-temperature screw, turn off the Ranger

warming unit. irrigation warming unit, and unplug the unit. Once power is cut to the 9. Turn the unit on to verify normal operation.

2. Remove the power cord.

3. Using room temperature saline/water, prime the cassette per Ranger irrigation warming unit, the alert will cease. The unit is ready 10. Record the maintenance action taken.

3. Locate the fuse carrier in the power entry module.

instructions included with it. to return to service after it cools to normal operating temperature

(approximately 20-30 minutes). 4. Use the small screwdriver to remove the fuse carrier from the power

NOTE: To achieve correct results, fluids must be administered into the inlet

entry module.

tube, NOT into the outlet tube.

10 11

3M™ Ranger™ Blood/Fluid Warming System - Model 245/ 3M™ Ranger™ Irrigation Fluid Warming System - Model 247 – Service Manual GB / 34-8719-2503-7

PDF Scaled at 75.0%

Troubleshooting Specifications

Guidance and manufacturer’s declaration – electromagnetic emissions

CONDITION CAUSE SOLUTION

The model 245 is intended for use in the electromagnetic environment specified below. The customer or the user of the model 245 should assure that it

Nothing illuminates on the warming unit panel. • Unit is not turned on, plugged in, • Turn unit on. Make sure the power cord is plugged

is used in such an environment.

or power cord is not plugged into into the power entry module of the warming unit.

an appropriate outlet. Make sure the warming unit is plugged into a properly Emissions Compliance Electromagnetic

grounded outlet. test environment ‑ guidance

• Unit failure. • Check fuses. RF emissions Group 1 The model 245 uses RF energy only for its internal function. Therefore, its RF emissions are

very low and are not likely to cause any interference in nearby electronic equipment.

• Contact 3M technical support. CISPR 11

CONDITION CAUSE SOLUTION RF emissions Class B The model 245 is suitable for use in all establishments, including domestic establishments

and those directly connected to the public low-voltage power supply network that supplies

Alert indicator illuminates and alert sounds, Temporary over-temperature • Open flow to reduce temperature. Alerts will stop when CISPR 11

buildings used for domestic purposes.

alphanumeric display alternately flashes a condition because: the display reads 41°C. The unit is ready to use.

Harmonic emissions Class A

temperature of 43˚C for the Model 245 (48°C for

the Model 247) or higher and the word “HI.” • An extreme change in flow rates IEC 61000-3-2

occurred (e.g., from 500 mL/min

Voltage fluctuations/ Complies

to stop flow).

Flicker emissions

• Unit was turned on and reached • Alerts will stop when the display reads 41°C. The unit is

set point temperature before ready to use. IEC 61000-3-3

cassette was inserted.

Guidance and manufacturer’s declaration – electromagnetic immunity

• Fluids were prewarmed to above • Turn off unit. Discontinue infusion of fluids. Do not

42°C before being run through warm fluids before infusing them through the Ranger The model 245 is intended for use in the electromagnetic environment specified below. The customer or the user of the model 245 should assure that it

the warming unit. warming unit. is used in such an environment.

CONDITION CAUSE SOLUTION Immunity IEC 60601 Compliance Electromagnetic

Test test level level environment ‑ guidance

Alert sounds, alphanumeric display and alert Primary controller failure. Unit will no Power to heating plates will shut off if temperature rises

indicator light go dark. longer operate. to 44°C for the Model 245 (50°C for the Model 247). Turn Electrostatic discharge (ESD) ±6 kV contact ±6 kV contact Floors should be wood, concrete or ceramic tile. If floors are covered

unit off and unplug it. Discontinue use of unit. Discard with synthetic material, the relative humidity should be at least 30%.

IEC 61000-4-2 ±8 kV air ±8 kV air

warming set. Alert will continue to sound if you do not

unplug unit. Contact 3M technical support. Electrical fast transient/burst ±2 kV power lines ±2 kV power lines Mains power quality should be that of a typical commercial or

hospital environment.

CONDITION CAUSE SOLUTION IEC 61000-4-4

• Unit alerts soon after plugging it in (unit does not Over-temperature screw on bottom Make sure over-temperature screw is completely Surge ±1 kV line to line ±1 kV line to line Mains power quality should be that of a typical commercial or

have to be turned on for this condition to occur). of unit is loose or missing. tightened. If it is missing, turn unit off and unplug it. hospital environment.

IEC 61000-4-5 ±2 kV line to gnd ±2 kV line to gnd

Contact 3M technical support.

Voltage dips, short <5% UT <5% UT Mains power quality should be that of a typical commercial or

• Heater temperature rises to 44°C for Model interruptions and voltage (>95% dip in UT) (>95% dip in UT) hospital environment. If the user of the model 245 requires continued

245 (50°C for Model 247) and unit shuts down variations on power supply for 0,5 cycle for 0,5 cycle operation during power mains interruptions, it is recommended that

soon after plugging it in (unit does not have to be input lines the model 245 be powered from an uninterruptible power supply or

turned on for this condition to occur). 40% UT 40% UT

a battery.

IEC 61000-4-11 (60% dip in UT) (60% dip in UT)

CONDITION CAUSE SOLUTION for 6 cycles for 6 cycles

Alert sounds but unit has been turned off. • Independent backup safety • Unplug unit. Contact 3M technical support. 70% UT 70% UT

system has been activated. (30% dip in UT) (30% dip in UT)

• Over-temperature screw loose. • Make sure over-temperature screw is completely for 30 cycles for 30 cycles

tightened. If it is missing, turn unit off and unplug it. <5% UT <5% UT

Contact 3M technical support. (>95% dip in UT) (>95% dip in UT)

CONDITION CAUSE SOLUTION for 5 sec for 5 sec

Cannot remove cassette from unit. • Cassette is too full, fluids are still • Make sure fluid is drained from cassette before sliding Power frequency (50/60 Hz) 3 A/m 3 A/m Power frequency magnetic fields should be at levels characteristic of

being infused, or clamp is open out the cassette, that fluids are no longer infusing, and magnetic field a typical location in a typical commercial or hospital environment.

proximal to the cassette. that clamp is closed proximal to the warming cassette. IEC 61000-4-8

• Warming unit is below patient • Raise unit above patient level. NOTE UT is the a.c. mains voltage prior to application of the test level.

level, creating excessive back

pressure.

CONDITION CAUSE SOLUTION

Alert indicator light illuminates and alert sounds, Under-temperature condition caused Alert should stop when temperature rises above 33°C. If

alphanumeric display alternately flashes a by very high flow using very cold alert continues, turn off unit, unplug unit and discontinue

temperature of 33°C or below and the word “LO.” fluid, or defective heater/relay. use. Contact 3M technical support.

CONDITION CAUSE SOLUTION

Alphanumeric display reads “Er 4” or “Open.” Open wire on temperature sensor. Do not use unit. Contact 3M technical support.

CONDITION CAUSE SOLUTION

Alphanumeric display reads “Er 5” or “Open.” Electrical interference. Remove the unit. Refer to biomedical technician or contact

3M technical support.

12 13

3M™ Ranger™ Blood/Fluid Warming System - Model 245/ 3M™ Ranger™ Irrigation Fluid Warming System - Model 247 – Service Manual GB / 34-8719-2503-7

PDF Scaled at 75.0%

Troubleshooting Specifications

Guidance and manufacturer’s declaration – electromagnetic emissions

CONDITION CAUSE SOLUTION

The model 245 is intended for use in the electromagnetic environment specified below. The customer or the user of the model 245 should assure that it

Nothing illuminates on the warming unit panel. • Unit is not turned on, plugged in, • Turn unit on. Make sure the power cord is plugged

is used in such an environment.

or power cord is not plugged into into the power entry module of the warming unit.

an appropriate outlet. Make sure the warming unit is plugged into a properly Emissions Compliance Electromagnetic

grounded outlet. test environment ‑ guidance

• Unit failure. • Check fuses. RF emissions Group 1 The model 245 uses RF energy only for its internal function. Therefore, its RF emissions are

very low and are not likely to cause any interference in nearby electronic equipment.

• Contact 3M technical support. CISPR 11

CONDITION CAUSE SOLUTION RF emissions Class B The model 245 is suitable for use in all establishments, including domestic establishments

and those directly connected to the public low-voltage power supply network that supplies

Alert indicator illuminates and alert sounds, Temporary over-temperature • Open flow to reduce temperature. Alerts will stop when CISPR 11

buildings used for domestic purposes.

alphanumeric display alternately flashes a condition because: the display reads 41°C. The unit is ready to use.

Harmonic emissions Class A

temperature of 43˚C for the Model 245 (48°C for

the Model 247) or higher and the word “HI.” • An extreme change in flow rates IEC 61000-3-2

occurred (e.g., from 500 mL/min

Voltage fluctuations/ Complies

to stop flow).

Flicker emissions

• Unit was turned on and reached • Alerts will stop when the display reads 41°C. The unit is

set point temperature before ready to use. IEC 61000-3-3

cassette was inserted.

Guidance and manufacturer’s declaration – electromagnetic immunity

• Fluids were prewarmed to above • Turn off unit. Discontinue infusion of fluids. Do not

42°C before being run through warm fluids before infusing them through the Ranger The model 245 is intended for use in the electromagnetic environment specified below. The customer or the user of the model 245 should assure that it

the warming unit. warming unit. is used in such an environment.

CONDITION CAUSE SOLUTION Immunity IEC 60601 Compliance Electromagnetic

Test test level level environment ‑ guidance

Alert sounds, alphanumeric display and alert Primary controller failure. Unit will no Power to heating plates will shut off if temperature rises

indicator light go dark. longer operate. to 44°C for the Model 245 (50°C for the Model 247). Turn Electrostatic discharge (ESD) ±6 kV contact ±6 kV contact Floors should be wood, concrete or ceramic tile. If floors are covered