Beruflich Dokumente

Kultur Dokumente

Jay 3

Hochgeladen von

nmpurchasesOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Jay 3

Hochgeladen von

nmpurchasesCopyright:

Verfügbare Formate

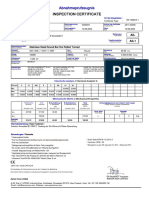

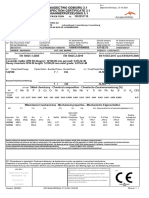

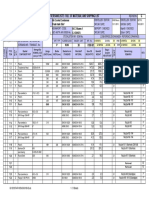

TEST CERTIFICATE ACCORDING TO EN 10204(2005) 3.

1 N 0000634663

BIS NO: CM/L - 4100028364 .1NDIAN STANDARDS NO: 6911:2017

NAME OF THE LICENSES WITH FACTORY : APERAM STAINLESS OY

ABNAHMEPRÜFZEUGNIS - CERTIFICA T D'ESSAIS - CERTIFICATO DI COLLAUDO Pag. 1di 1

Longitudinally laser welded tubes/Laser längsnahtgeschweisste rohre/Tubes soudes longitudinalement laser/Tubi saldati longitudinalmente laser

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------

Chemical analysis acc.to: ASTM A240/ EN 10088-2/EN 10028-7 Last Edition Schmelzanalyse/Chimique analvse/Analisi chimica

Steel making process :E/AOD Erschmelzungsart/Procéde d'elaboration/Proce imento di elaborazione acciaio

Item Manufacturer HEAT NO %C % Si %S %P % Mn % Cr % Ni % Mo % Ti %co %cu %N

Pos Hersteller/Fabricant/Produttore Schmelze/Couléé/COlata

NO

A 78 749106 0.022 0.214 0.022 0.034 1.370 18.13 8.10 0.073

Item HEAT HOMOLOG. TEST SPECIMEN SIZE YIELD STRENGTH TENSILE ELONGAT.

N̊̊̊̊̊̊̊̊̊̊̊ ̊ Zulassung Probe Abmessung Probestab Streck-Dehngrenze STRENGTH Bruchdehnung

Schmelze Omologation Eprouvette Dime. Eprouvette Limite d'élasticité Zugfestigkeit Allongament

Coulée Omologazione Provino Dimensione provetta Limite di snervamento Résistance traction Allungamento

Colata no mm. N/mm2 1% Limite di rottura

N/mm2

REQUIREMENT Anforderun en/Exi ences/Re uisiti >=180 >=215 470 -670 40.0

Mechanical test acc. to tab.: 6-7 EN 10217-7 Mechanische Prüfungen/Essais mécaniques/Caratteristiche meccaniche

A 78 749106 01 L ------------------------------- 20 x 1.00 401 458 653

30.5

TEST RESULTS Ergebnisse der prufungen/RésuItat des essais/Risultati delle prove

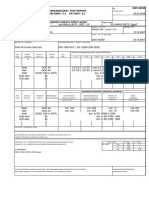

Customer: “Gazki” LTD UIC/ PIC 205957654

Besteller/Client/Cliente : BULGARIA CITY OF BOURGAS 8000 Italy

Customer Order N̊̊ ̊:S/358000587/2305/2023 Mill's lita Inox NO: 04110720665 - - 000042 #042107908 - 000050

Bestellung/Commande Client/Ordine Cliente WerksN0/N0 référence Interne/Conferma ordine

Specifications: EN 10217-7:2020 TCI //EN 10357: 2020 Tolerances: EN 10357 TAB.2 SERIES B

Anforderungen/SpecificatiO pecifiche / / CC Toleranzen/T01érances/T011eranze

Manufacturer's mark: Herstellerzeichen/Maraue du fabricant/ Marchio del produtto Markin : According to EN 10357

Inspector's Stamp: A.C. Stempel des Sachverständigen/Poingon de l'inspecteur/Punzone dell'ispettore Kenzeic nung/Marquage/Marcatura

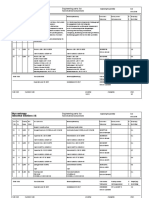

Item DIMENSIONS PIECES METERS GRADE STANDARD CODE EXECUTION

WEIGHT (kg)

Pos. Abmessungen Stückzahl Meter Gewicht/poids Werkstoff/Nuance Normbezeichnung A usführung

No Dimensions/Dimensioni Piéces/Pe Métres/Metri Peso Materiale Designation/Designazione Execution/Esecuzione

A 78 20 x4.1 x 6350 558 3486.00 TP.304S1 X2 CrNI 18-9 W2 b

A 78 28 x 4.1 x 6450 592 3850.00 TP.304S1 X2 CrNi 18-9 W2 b

Heat treatment: Wärmebehandlungmaitement termiqueffrattamento termico

Tecnological test : ====== / ===== / EN ISO 8492: OK Technologische prüfung/Examen technologique,prove tecnologiche

Residual Corrosion Test acc.to : =============== Korrosionsfördernde Rückståden/Essai residues corrosif/Prova residui corrosivi

Intergranular Corrosion Test acc.to: EN ISO 3651-2/A : OK 1K Beständigkeit/Essai corr.intergr./Prova di corrosione intergranulare

Non Destructive Test acc. to: EN ISO 10893-2/EIH: 0K

Leak Test/Hydrostatic test to: EN ISO 10893-1: 0K Zerstörungsfreie prüfung/Contröle non destructif/Contr0110 non distruttivo

Uncorrect Material Test: carried out 100% no remarks Dichtheitsprüfung/Essai d'étanchéité/Pro va di tenuta

Visual and gauging control: no remarks Verwechlungsprüfung/Essai P.M.L/Prova antimiscuglio

Besichtigung und Ausmessung/Contröle visuel et dimensionel/Controllo visivo e dimensionale

Notes:

Material fully conform to type 1.4301/304S1 ROUGHNESS ON BASIC MATERIAL Ra Max.0,8 micron. ROUGHNESS ON WELDING ZONE Ra Max. 1,6 micron. -

Statement of conformity acc. to pressure equipment directive 2014/68/EU (PED) annex I, paragraph 4.3 - Statement No 11/2002/MUC - notified body REG. No 0036. The

welding procedure prescribed by the standard EN 15614-1/EN 15614-11 and the qualification of welder according to EN ISO 14732:2013 are homologated by Lloyd's

Register EMEA. The personnel in charge of the NDT tests fulfill the EN 10217-7 requirements. -

28/10/2022

Inspector / Der

Das könnte Ihnen auch gefallen

- Cde 10264-Cert-Matiere-R18-316L-517151Dokument1 SeiteCde 10264-Cert-Matiere-R18-316L-517151alainNoch keine Bewertungen

- 1.so 8-150 RF - 9B5770Dokument1 Seite1.so 8-150 RF - 9B5770Yosses Sang NahkodaNoch keine Bewertungen

- 17 Pre3321 3388 711022Dokument2 Seiten17 Pre3321 3388 711022Puđa TomicaNoch keine Bewertungen

- Inspection Document / Prüfbescheinigung No. / Nr. 2 056 20/16Dokument1 SeiteInspection Document / Prüfbescheinigung No. / Nr. 2 056 20/16Arumugam RajNoch keine Bewertungen

- Inspection Document / Prüfbescheinigung No. / Nr. 2 056 20/16Dokument2 SeitenInspection Document / Prüfbescheinigung No. / Nr. 2 056 20/16Arumugam RajNoch keine Bewertungen

- Round D85mm 304LDokument1 SeiteRound D85mm 304LAgoritsaNoch keine Bewertungen

- Flange 4-300LBDokument1 SeiteFlange 4-300LBsaul dussanNoch keine Bewertungen

- 1-Brida Slipon 3-4x150 Bebitz A7270-21Dokument1 Seite1-Brida Slipon 3-4x150 Bebitz A7270-21rodrigo guerreroNoch keine Bewertungen

- F53 Sample MTCDokument1 SeiteF53 Sample MTCMuzammil100% (1)

- Certtificado de Molino 122598Dokument1 SeiteCerttificado de Molino 122598bm.morales2tNoch keine Bewertungen

- FISA TEHNICA DX51D - No. 113178 - 04.12.2017Dokument1 SeiteFISA TEHNICA DX51D - No. 113178 - 04.12.2017Florin ȘandruNoch keine Bewertungen

- Imp 3159 - Brida Slip On 2X150 - 166525 - 111214 - 158116Dokument4 SeitenImp 3159 - Brida Slip On 2X150 - 166525 - 111214 - 158116Sergio GuacanemeNoch keine Bewertungen

- Imp 3159 - Brida Slip On 3X150 - 201164Dokument1 SeiteImp 3159 - Brida Slip On 3X150 - 201164Sergio GuacanemeNoch keine Bewertungen

- Thyssenkrupp Industrial Solutions AG: Engineering Parts List KonstruktionsstücklisteDokument3 SeitenThyssenkrupp Industrial Solutions AG: Engineering Parts List Konstruktionsstücklistelidio reyesNoch keine Bewertungen

- 4 X 1500 X Coil H.# 512333-3Dokument2 Seiten4 X 1500 X Coil H.# 512333-3Ashok TiwariNoch keine Bewertungen

- Thyssenkrupp Industrial Solutions AG: Engineering Parts List KonstruktionsstücklisteDokument3 SeitenThyssenkrupp Industrial Solutions AG: Engineering Parts List Konstruktionsstücklistelidio reyesNoch keine Bewertungen

- Ram Bottom ValveDokument45 SeitenRam Bottom ValveIhsan AhmedNoch keine Bewertungen

- Cert 1Dokument3 SeitenCert 1Gaston LooNoch keine Bewertungen

- ID 3 05 02 A1055 - Datenblatt - 6082 PDFDokument3 SeitenID 3 05 02 A1055 - Datenblatt - 6082 PDFPeterNoch keine Bewertungen

- G3Si1 - Lot 120080112 - 420MPa (20201007) PDFDokument1 SeiteG3Si1 - Lot 120080112 - 420MPa (20201007) PDFPeter TvardzíkNoch keine Bewertungen

- Werkszeugnis Leser 17 1 12Dokument1 SeiteWerkszeugnis Leser 17 1 12Erik RochaNoch keine Bewertungen

- Techno LiftDokument2 SeitenTechno LiftANTON NEAGUNoch keine Bewertungen

- Pipes - Erndtebrücker Eisenwerk GMBHDokument1 SeitePipes - Erndtebrücker Eisenwerk GMBHMETAL EngNoch keine Bewertungen

- 00 Stück-Und Versandliste / Bill of Material and Shipping ListDokument3 Seiten00 Stück-Und Versandliste / Bill of Material and Shipping ListJibin Reji KoshyNoch keine Bewertungen

- Scope W0 - Valbruna 2014 PDFDokument3 SeitenScope W0 - Valbruna 2014 PDFSatish ShewaleNoch keine Bewertungen

- Werkszeugnis / Test Report DIN 50049 / 2.2. EN 10204 / 2.2. 2007-40259Dokument1 SeiteWerkszeugnis / Test Report DIN 50049 / 2.2. EN 10204 / 2.2. 2007-40259sdsds-54Noch keine Bewertungen

- 05EUTG015Dokument11 Seiten05EUTG015alkoNoch keine Bewertungen

- 1010-5565 Schrauben 1.7218 KG - 09Dokument9 Seiten1010-5565 Schrauben 1.7218 KG - 09bkatsamsonNoch keine Bewertungen

- GK 3171 Serti̇fi̇kaDokument1 SeiteGK 3171 Serti̇fi̇kanedim cılızNoch keine Bewertungen

- Prüfprotokoll / Test Report: Ritz Instrument Transformers GMBHDokument2 SeitenPrüfprotokoll / Test Report: Ritz Instrument Transformers GMBHAlejandro MárquezNoch keine Bewertungen

- Hilti Certificate 22 333153 58 HAS-E-F M16X125 38 Inspection Document ASSET DOC 1709775Dokument2 SeitenHilti Certificate 22 333153 58 HAS-E-F M16X125 38 Inspection Document ASSET DOC 1709775nikas672Noch keine Bewertungen

- ESP PF 13 Rev. 0 ET Cama de AsientoDokument3 SeitenESP PF 13 Rev. 0 ET Cama de AsientoMatias SegoviaNoch keine Bewertungen

- G-1301074-P-KON-30-0100-001 (Rev-G)Dokument3 SeitenG-1301074-P-KON-30-0100-001 (Rev-G)Jibin Reji KoshyNoch keine Bewertungen

- Atest 855 MPL 2023Dokument2 SeitenAtest 855 MPL 2023Josip ArambasicNoch keine Bewertungen

- 1.0045 S355JRDokument2 Seiten1.0045 S355JRgenuesslichwohlriechendersteinbockNoch keine Bewertungen

- Mill Certificate Bs en 10204/3.1 Certificat de Reception NF en 10204/3.1 Abnahmepruefzeugnis Din en 10204/3.1Dokument1 SeiteMill Certificate Bs en 10204/3.1 Certificat de Reception NF en 10204/3.1 Abnahmepruefzeugnis Din en 10204/3.1CRISTIAN SILVIU IANUCNoch keine Bewertungen

- Qualitaetszertifikat 3.1 EN 10204: Allgemeine DatenDokument2 SeitenQualitaetszertifikat 3.1 EN 10204: Allgemeine DatenzzzaNoch keine Bewertungen

- 7452N Ag190 0.28mm 膜片Dokument1 Seite7452N Ag190 0.28mm 膜片deppre ZNoch keine Bewertungen

- 6 MMDokument1 Seite6 MMCRISTIAN SILVIU IANUCNoch keine Bewertungen

- Qualitaetszertifikat 3.1 EN 10204: Allgemeine DatenDokument2 SeitenQualitaetszertifikat 3.1 EN 10204: Allgemeine DatenzzzaNoch keine Bewertungen

- MTC For MaterialDokument4 SeitenMTC For Materialbhct1987Noch keine Bewertungen

- Rohrfedermanometer, Kupferlegierung Einbauausführung Typen 111.16 Und 111.26Dokument5 SeitenRohrfedermanometer, Kupferlegierung Einbauausführung Typen 111.16 Und 111.26behnamdaftary2Noch keine Bewertungen

- DuroplastDokument2 SeitenDuroplastANTON NEAGUNoch keine Bewertungen

- 6SL2065 LJFDokument3 Seiten6SL2065 LJFaviexltdNoch keine Bewertungen

- Teilegutachten: Nr. 02TG0576-02Dokument10 SeitenTeilegutachten: Nr. 02TG0576-02PaulNoch keine Bewertungen

- Unidad Succión (Llave)Dokument1 SeiteUnidad Succión (Llave)Miguel UllóNoch keine Bewertungen

- EKL Medium DEDokument2 SeitenEKL Medium DEMichael BaumgartnerNoch keine Bewertungen

- PF SDS 5.5x25 MTCDokument1 SeitePF SDS 5.5x25 MTCSajathNoch keine Bewertungen

- Mill Certificate Bs en 10204/3.1 Certificat de Reception NF en 10204/3.1 Abnahmepruefzeugnis Din en 10204/3.1Dokument1 SeiteMill Certificate Bs en 10204/3.1 Certificat de Reception NF en 10204/3.1 Abnahmepruefzeugnis Din en 10204/3.1CRISTIAN SILVIU IANUCNoch keine Bewertungen

- Qualitaetszertifikat 3.1 EN 10204: Allgemeine DatenDokument2 SeitenQualitaetszertifikat 3.1 EN 10204: Allgemeine DatenzzzaNoch keine Bewertungen

- 1le0142 2BB86 4aa4 Z PDFDokument1 Seite1le0142 2BB86 4aa4 Z PDFCady StantonNoch keine Bewertungen

- xz51600000160 - Commissioning Check ListDokument21 Seitenxz51600000160 - Commissioning Check ListTưởng VũNoch keine Bewertungen

- Superplast 8Dokument2 SeitenSuperplast 8ANTON NEAGUNoch keine Bewertungen

- G-1301074-P-KON-31-0101-001 (Rev-E)Dokument2 SeitenG-1301074-P-KON-31-0101-001 (Rev-E)Jibin Reji KoshyNoch keine Bewertungen

- 2018 - 006 - Protokoll Taiho Surfcom 480A AllDokument7 Seiten2018 - 006 - Protokoll Taiho Surfcom 480A AllÁdám KovácsNoch keine Bewertungen

- Messtechnik und Prüfstände für Verbrennungsmotoren: Messungen am Motor, Abgasanalytik, Prüfstände und MedienversorgungVon EverandMesstechnik und Prüfstände für Verbrennungsmotoren: Messungen am Motor, Abgasanalytik, Prüfstände und MedienversorgungNoch keine Bewertungen

- Fahrwiderstände des Kraftfahrzeugs: Luft- und Rollwiderstandsermittlung im FahrversuchVon EverandFahrwiderstände des Kraftfahrzeugs: Luft- und Rollwiderstandsermittlung im FahrversuchNoch keine Bewertungen

- Triebwerksdynamik und Konstruktionselemente des VerbrennungsmotorsVon EverandTriebwerksdynamik und Konstruktionselemente des VerbrennungsmotorsNoch keine Bewertungen

- Wie misst man mit dem Oszilloskop?: Technik, Geräte, Messpraxis mit über 150 MessbeispielenVon EverandWie misst man mit dem Oszilloskop?: Technik, Geräte, Messpraxis mit über 150 MessbeispielenNoch keine Bewertungen

- MIG-Schweißen von Aluminiumwerkstoffen im FahrzeugbauVon EverandMIG-Schweißen von Aluminiumwerkstoffen im FahrzeugbauNoch keine Bewertungen