Beruflich Dokumente

Kultur Dokumente

xz51600000160 - Commissioning Check List

Hochgeladen von

Tưởng VũOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

xz51600000160 - Commissioning Check List

Hochgeladen von

Tưởng VũCopyright:

Verfügbare Formate

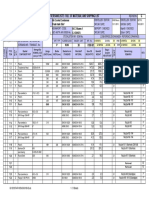

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

Commissioning Pilot Installation Description

Marine Series 2000Mx7

(Report is attachment of ASO cover sheet)

Attach photo to the cover sheet as file

Vessel name: " ”

IMO No (if applicable).:

Engine No. Engine Type:

Are the engines labelled according to EPA regulations (E)? Yes No

Tolerierung/Tolerancing ISO 8015 Masse/Size ISO 14405

Allgemeintoleranzen/General Tolerances ISO 2768-mK Masse/Mass kg Format/Size

Bauart/Type A4

Allgemeine Fertigungsvorschriften nach MMN332 Werkstoff/Material

Ausf. u.Lieferung Tech. Characteristics Production Specification per MMN 332

Oberflaechenschutz Surface Protection

Halbzeug,Modell Gesenk / Semifinished Product Pattern, Die

Oberflaechenangaben nach MTN5033

Verwendbar fuer Typ/Applicable to Model Surface Specification per MTN5033

Fert.Ber.

Projekt-/Auftrags-Nr./Project/Order No. Man.Adv Material-Nr./Material No.

Mont.Ber.

Inst.Adv

Ref.-Nr./ Ref. No. Emission ID XZ51600000160

Alle Rechte aus Schutzrechtsanmeldungen WORD Datum/Date Name Benennung/ Title /

vorbehalten. Weitergabe, Vervielfaeltigung oder

sonstige Verwertung ohne Zustimmung nicht Erstell.

gestattet. Zuwiderhandlungen verpflichten zum Drawn

19.08.2022 obert ulri INBETRIEBNAHME-DOKU

Schadensersatz. Bearb.

19.08.2022 obert ulri

All industrial property rights reserved. Disclosure, Change

reproduction or use for any other purpose is Norm

prohibited unless our express permission has been Std.

19.08.2022 ehrentraut COMMISSIONING DOC.

given. Any infringement results in liability to pay Gepr.

damages. 19.08.2022 ehrentraut

Checked

Blatt/ Sheet

A Rolls-Royce Zeichnungs-Nr./Drawing No. ZNG00049287 1

solution von/of

Beschreibung/Description

Rolls-Royce Solutions GmbH 21

T-468-0107

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

Section 0 – General Vessel data

Please note: Check points marked with (E) are emission relevant and therefore mandatory to be filled out.

Shipyard:

Class:

Length: Width:

Draft: Front: Astern: and add a picture of where measured

Tonnage at seatrial:

Design speed:

Propeller system: Fixed pitch propeller Controllable pitch propeller Number:

Manufacturer:

Type:

Propeller diameter:

Pitch:

Number of blades:

Propeller direction of rotation:

Water jet propulsion:

Manufacturer: Number:

Type:

Direction of rotation:

Fixed/steering

Other:

Object data

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 2

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

Section 1: ICO = Installation Check out

(Visual inspection, no mtu system functions necessary)

Please note: Check points marked with (E) are emission relevant and therefore mandatory to be filled out.

1.1 Equipment data

Fluids and lubricants

Oil type

Coolant type

Fuel type

SCR reducing agent type (if applicable)

In accordance with the current “Fluids and Lubricants Specification”? Yes No

1.2 General arrangement of engines and gearboxes, alternators or pumps

Is there a drawing attached showing position of engines, gearboxes, Yes No

Alternators, pumps in the ship, incl. manufacturer's numbers and

directions of rotation for getting an overview of the engine rooms?

1.3 Documentation & conditions

(Note: Pre-condition of successful commissioning is the implementation of installation ad vises and

requirements of the entire installation instructions, including technical data, drawings, schematics and

other technical documents supplied by the RRS representative)

Are operating manual (delivered with the engine, can also be found on Yes No

the Service page of the business portal) and complete installation

instructions (sent by RRS representative) available in the latest version (E)?

Are all components of the mtu scope of supply and customer interfaces Yes No

undamaged and the requirements regarding cleanliness guaranteed?

Is a test report on the alignment of gearbox and propeller available and Yes No

enclosed as a copy or documented in table 1.5.13 / 1.5.14?

Are all components of the mtu scope of supply (engines, EGAT, pumps, Yes No

couplings, gearboxes, generators,shaft thrust bearing, etc.) documented

– with serial numbers where applicable - in table 1.4?

Have the loose supplied safety pictograms been attached close to the Yes No

engines as per the relevant instruction?

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 3

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

1.4 mtu scope of supply (beyond cover sheet), e.g. gearbox, pumps, couplings, etc.

Type Serial / Part no. Comment Installed between Installed between

engine - gearbox gearbox – propeller

engine - alternator engine - pump

Table 1.4 – mtu scope of supply

For specific components (e.g. gearboxes, etc.), separate commissioning documents may apply and shall

be attached to this report.

1.5 Accessibility of Maintenance Points

1.5.1 Components

Is the documentation “Removal spaces & weights” available? Yes No

Is minimum clearance around engine and SCR system as well as Yes No

minimum distance between installations given as per the

documentation?

Can the following components be removed and replaced without restrictions?

Coolant pump Yes No, Restriction:

Seawater pump Yes No, Restriction:

Fuel HP pump Yes No, Restriction:

Fuel filter Yes No, Restriction:

Battery-charging generator Yes No, Restriction:

Starter Yes No, Restriction:

Plate-core heat exchanger Yes No, Restriction:

Intercooler Yes No, Restriction:

Oil heat exchanger Yes No, Restriction:

Oil separator Yes No, Restriction:

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 4

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

Oil filter Yes No, Restriction:

Air filter Yes No, Restriction:

Exhaust turbocharger Yes No, Restriction:

Oil dipstick Yes No, Restriction:

Oil pan Yes No, Restriction:

Cylinder head / cover Yes No, Restriction:

Cylinder liner Yes No, Restriction:

Injector Yes No, Restriction:

Conrod and piston Yes No, Restriction:

Camshaft Yes No, Restriction:

Vibration damper Yes No, Restriction:

Flywheel Yes No, Restriction:

Exhaust manifold Yes No, Restriction:

EGAT isolation Yes No, Restriction:

EGAT substrates Yes No, Restriction:

EGAT dosing unit Yes No, Restriction:

EGAT sensors Yes No, Restriction:

1.5.2 Maintenance work

Is the maintenance schedule available? (E) Yes No

Can the following jobs be carried out without restriction?

Valve clearance adjustment Yes No, Restriction:

Oil change - engine Yes No, Restriction:

Oil change - gearbox Yes No, Restriction:

Coolant change Yes No, Restriction:

EGAT substrate change Yes No, Restriction:

EGAT lifting in accordance with Yes No, Restriction:

the respective documents and drawings (incl. overhead suspension to enable engine repair work)

Access to crankcase insp. port Yes No, Restriction:

Clearance for lowering oil pan cm

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 5

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

1.5.3 Remarks regarding Accessibility & Maintenance work

1.6 Systems & Components

1.6.1.1 Starting System – Electric Starter (if applicable)

Electric starter correctly installed and wired? Yes No

Type / Voltage / Current

Batteries installed:

Total number: Type:

Total capacity: Voltage: Charged by:

1.6.1.2 Starting System – Air Starter (if applicable)

Air starter correctly installed, operating pressure of the system Yes No

documented and set to required pressure range (min. / max.)?

1.6.2 Lube Oil System

Is the lube oil system set-up as described in the respective diagram? Yes No

Is the oil refill pump (if applicable) connected and the oil tank filled? Yes No

1.6.3 Fuel System

Is the fuel system set-up as described in the respective diagram? Yes No

Is the fuel supply and return line to the filters connected correctly, Yes No

incl. elastically mounted hose lines?

Nominal size of the hose lines designed according to diagram? Yes No

Is the prefilter correctly installed and has a drainage? Yes No

Is the differential pressure potential of the prefilter as per the drawing? Yes No

Is the ship's fuel system clean? Yes No

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 6

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

1.6.4 Coolant System

Is the coolant system set-up as described in the respective diagram? Yes No

Are the seawater suction lines installed constantly rising and Yes No

mounted vibration-free?

Is the seawater pump prefilled? Yes No

Is the pressure loss of the seawater circuit according to TEN data? Yes No

Does the mesh size of the seawater filter correspond to the mtu spec? Yes No

Is there a decoupling of the connections? Yes No

Is the pressure relief valve on the expansion tank according to TEN data? Yes No

Are the required venting points connected to the expansion tank? Yes No

Is the venting pipe connected to the highest point of the seawater pipe (on Yes No

the pressure side), installed constantly rising and directed overboard above

waterline without back pressure?

Are the vent lines designed without shut-off device? Yes No

Is engine coolant preheating available, connected according to Yes No

drawing and fully functional?

Manufacturer / Type

1.6.5 Combustion air System

Is the combustion air system set-up as described in the respective diagram? Yes No

Is there adequate security against penetration of water and other material Yes No

into the system?

Is an engine room ventilation installed to secure adequate air supply Yes No

under all operating conditions?

1.6.6 Exhaust System

Is the exhaust system set-up as described in the respective diagram? Yes No

Is the insulation of the compensator to the engine correctly installed ? Yes No

Are the compensators installed before and after the EGAT system as per Yes No

the drawing?

Is the ship-side exhaust piping supported directly at the compensators? Yes No

Is there adequate security against penetration of water into the system? Yes No

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 7

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

1.6.7 Exhaust Gas After-treatment System (EGAT) (if applicable, e.g. M87/97)

Engine EGAT (Aftertreatment System)

Model Serial No. Location (e.g. Type Part No. Serial No.

(e.g.16V2000M97) port, starboard)

Table 1.6.7 – SCR matching (E)

Have components of the EGAT system (incl. wiring harness) been Yes No

mechanically damaged during installation?

Are all EGAT components (as identified in the BOM and delivery note) Yes No

correctly installed and documented in table 1.6.7? (E)

Does the installation position of the exhaust aftertreatment system comply Yes No

with the installation instruction? (E)

Is the EGAT system correctly mounted to the respective frame and Yes No

fixed with the tightening torque as per drawing?

Is the insulation of the EGAT fully attached? Yes No

Are there any changes made to the insulation that influences its function? Yes No

Are hydraulic components (such as pumps) positioned correctly? Yes No

Is the measuring flange installed directly before and after EGAT? (E) Yes No

Are port / starboard / etc. components hydraulically and in terms of Yes No

exhaust gas flow correctly connected to the dosing cabinet?

Are the cross-sections between tank and cabinet observed as specified in Yes No

the reducing agent (RA) diagram?

Is a shipyard supplied RA prefilter (incl. pressure gauge) installed? Yes No

Does the mesh size of the RA prefilter correspond to the resp. drawing? Yes No

Is a RA shut-off valve (flow and return) available? Yes No

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 8

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

1.6.8 Engine mounting

Are the control dimensions recorded according to the sketch and are Yes No

deviations documented?

Have the required tightening torques been applied to the screws on the Yes No

mounts according to the drawing?

1.6.8.1 Checking the engine mounting S2000 and alignment

Tightening torque of shipyard supplied mounting

screw (to ship foundation) as per respective

drawing? Yes No

Engine Mount type Mount location Specified Actual value Changed to

location (engine) value (mm) (mm) (mm)

A- Driving end

side Free end

B- Driving end

side Driving end

Specified Actual value Changed to

Mount location (gear)

(e.g. port, (e.g. RD…B - value (mm) (mm) (mm)

starboard, etc.) 11MN60) A- Driving end

side Free end

B- Driving end

side Driving end

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 9

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

Engine Mount type Mount location Specified Actual value Changed to

location (engine) value (mm) (mm) (mm)

A- Driving end

side Free end

B- Driving end

side Driving end

Specified Actual value Changed to

(e.g. port, (e.g. RD…B - Mount location (gear) value (mm) (mm) (mm)

starboard, etc.) 11MN60) Driving end

A-

side Free end

B- Driving end

side Driving end

Engine Mount type Mount location Specified Actual value Changed to

location (engine) value (mm) (mm) (mm)

A- Driving end

side Free end

B- Driving end

side Driving end

Specified Actual value Changed to

Mount location (gear)

(e.g. port, (e.g. RD…B - value (mm) (mm) (mm)

starboard, etc.) 11MN60) A- Driving end

side Free end

B- Driving end

side Driving end

Engine Mount type Mount location Specified Actual value Changed to

location (engine) value (mm) (mm) (mm)

A- Driving end

side Free end

B- Driving end

side Driving end

Specified Actual value Changed to

Mount location (gear)

(e.g. port, (e.g. RD…B - value (mm) (mm) (mm)

starboard, etc.) 11MN60) A- Driving end

side Free end

B- Driving end

side Driving end

Table 1.6.8.1 – engine mounting

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 10

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

1.6.9 Engine, gearbox, alternator and pump mounting, shaft thrust bearing

Engine mounting: Rigid Elastic

Gearbox mounting: Rigid Elastic

Alternator mounting: Rigid Elastic

Pump mounting: Rigid Elastic

Shaft thrust bearing: Separate in gearbox

1.6.10 Power Transmission / Coupling

Are all couplings (main power transmission and - if used - Yes No

at free-end) mounted correctly and covered as per the safety advices?

Coupling Type / Manufacturer Serial / part no. Installation location

Description

Table 1.6.10 – couplings

1.6.11 Engine Management / Electronics

Is the wire cross-section of the power supply (EIM) correct? Yes No

Has the Central Database (CDB) been checked for software / dataset Yes No

updates for ECU, EMU, EIM, etc.?

Has latest MPS data set been sent back to CDB? Yes No

Is the engine & electronics correctly grounded? Yes No

Visual inspection: are connecting cables correctly routed (without Yes No

abrasion points, distance to hot components, correct cable length, etc.)?

Are the tension relief clamps correctly attached to the control units? Yes No

1.6.12 Automation separate IPAS order no.?

Remote Control System (RCS): mtu, Type 3rd party, Type

Monitoring & Control System (MCS): mtu, Type 3rd party, Type

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 11

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

1.6.13 Engine / gearbox alignment (direct propulsion, free-standing gearbox)

Note: - All connections on the engine free-end not connected

- Ship is in water without contact with the bottom

- Blocking of the engine mounting free-end has settled adequately

Alignment performed by: Date:

Alignment tested by: Date:

Values measured with: (e.g. dial gauge, laser device, feeler gauge)

Dial gauge attached to: (e.g. gearbox/engine flange, coupling)

Dial gauge measures on: (e.g. internal contour, external contour)

Status of the system: (e.g. engine at operating temperature)

X and D in mm; dial gauge values in mm/100

0= 0=

System: 9= 3= 9= X= 3=

Engine high 6= 6= D=

low

System: 0= 0=

Engine high 9= 3= 9= X= 3=

low 6= 6= D=

System: 0= 0=

Engine high 9= 3= 9= X= 3=

low 6= 6= D=

System: 0= 0=

Enginse high 9= 3= 9= X= 3=

low 6= 6= D=

Table 1.6.13 - Engine / gearbox alignment

1.6.14 Gearbox / propeller (water jet) drive shaft alignment

Alignment performed by: Date:

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 12

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

Alignment tested by: Date:

Values measured with: (e.g. dial gauge, laser device, feeler gauge)

Dial gauge attached to: (e.g. gearbox/shaft flange)

Dial gauge measures on: (e.g. internal contour, external contour)

Status of the system: (e.g. engine at operating temperature)

X and D in mm; dial gauge values in mm/100

System: 0= 0=

Gearbox high 9= 3= 9= X= 3=

low 6= 6= D=

System: 0= 0=

Gearbox high 9= 3= 9= X= 3=

low 6= 6= D=

System: 0= 0=

Gearbox high 9= 3= 9= X= 3=

low 6= 6= D=

System: 0= 0=

Gearbox high 9= 3= 9= X= 3=

low 6= 6= D=

Table 1.6.14 - Gearbox / propeller (water jet) drive shaft alignment

Section 2: HAT = Harbour Acceptance Tests

(Tests that require a function of the mtu system but do not load the drive system)

Please note: Check points marked with (E) are emission relevant and therefore mandatory to be filled out.

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 13

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

2.1 Systems & Components

2.1.1 Starting System – Electric Starter (if applicable)

Starter motor(s) connected correctly and the engine can be started ? Yes No

2.1.2 Starting System – Air Starter (if applicable)

Is the safety valve and pressure reducing valve preset according to the Yes No

relevant drawing?

2.2 Lube Oil System

Is the pre-lube pump connected and operational? Yes No

Is the direction of rotation correct? Yes No

2.3 Fuel System

Engine not running: Have the pressures and losses for the individual areas Yes No

(between prefilter and engine feed) been observed as per diagram / TEN?

Engine running: pressure of the system before LP pump according to TEN? Yes No

2.4 Coolant System

Is intake air temperature (at nominal load) and the seawater temperature Yes No

(open sea) measured and documented?

2.5 Hydraulic Pumps at Gearbox or Engine

If customer supplied hydraulic pumps are installed on engine and/ or Yes No

Have this pump been vented before being put in operation? (venting to be done by shipyard)

2.6 Exhaust Gas After-treatment System (EGAT) (if applicable, e.g. M87/97)

Is a separate emergency stop switch for the EGAT available and functional? Yes No

Is the system correctly filled and the return flow quantity disposed of ? Yes No

Are the RA lines tight (after filling)? Yes No

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 14

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

Is the RA volume flow and pressure at customer interface as per TEN? Yes No

Has the RA tank level curve been parameterized in the LOP? Yes No

Is the RA tank curve correctly determined? Yes No

Has the RA minimum quantity for circulatory cooling been determined? Yes No

Is the tank level sensor installed according to drawing? Yes No

2.7 Engine Management / Electronics

Do EMI-number and label match? (E) Yes No

Are emergency stop switches available? Yes No

Do they work correctly? Yes No

2.8 Automation

Does the actual software version correspond to the scope of delivery? (E) Yes No

Does the actual material number match the one of the scope of delivery? (E) Yes No

For EGAT system: Is a valid RA tank level value displayed at the LOP? Yes No

Are all triggered alarms (as per the relevant alarm & limit value list)

- correctly displayed and (if required) acoustically signaled? Yes No

- producing the described reaction (e.g. shutdown) Yes No

of the engine?

Function test “emergency stop” via emergency stop button Yes No

(LOP and/or external) successfully performed?

Function “emergency stop” triggers horn and/or strobe light? Yes No

Function “test overspeed ECU / EMU emergency stop (standstill)” Yes No

successfully performed?

Has an overspeed test been performed, is the "engine overspeed" alarm Yes No

correctly displayed and does the engine reaction correspond to the alarm

and limit value list?

If Datalogger is used:

Is datalogger commissioning performed in GO! Manage? Yes No

Section 3: SAT = Sea Acceptance Tests

Please note: Check points marked with (E) are emission relevant and therefore mandatory to be filled out.

3.1 Systems & Components

3.1.1 General measurement log sheet with operational values

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 15

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

Has a measurement log sheet of the sea trial with operational values Yes No

been filled out as per example in Annex I (or equivalent), filed with this

report and a copy been left on board?

Are all operating parameters within the specified limits and the systems Yes No

are operating as expected?

Has a crash stop maneuver been successfully effected with the systems Yes No

still operating within the specified limits?

3.1.2 Fuel System

Is the pressure loss of the prefilter up to the LP pump documented and Yes No

the pressure loss reserve sufficient for prefilter loading?

Is the pressure at fuel return line within the specified values? Yes No

3.1.3 Coolant System

Is the seawater inlet pressure and the shipside pressure loss within Yes No

the specified values?

3.1.4 Combustion air System

Has the check of intake air depression indicator been carried out after trial? Yes No

3.1.5 Exhaust System

Is the exhaust backpressure within the specified values? Yes No

Measured values rpm 550 800 1000 1200 1400 1600 1800 2000 2250 2450

Exh. backpressure after EGAT mbar

If above- / under-water exhaust is used: is the exhaust backpressure of the Yes No

shifting point measured and within the specified values?

If exhaust spray ring is used: is the distance between injected water and Yes No

NOx sensors at SCR outlet documented (reason: avoid damage to the sensors)?

3.1.6 Exhaust Gas After-treatment System (EGAT) (if applicable)

Is the "SCR Quick Check" measurement successful? (E) Yes No

In case of switchability: is the dosing check carried out using the Yes No

corresponding parameters for both switch positions

Has the strainer on the PFM been cleaned after SAT? Yes No

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 16

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

3.1.7 Engine Management / Electronics

Is the electronic components’ temperature (measure side at LOP) Yes No

less than 60°C under realistic engine room temperatures?

3.1.8 Automation

Is the automation document "Commissioning report for mtu scopes of Yes No

supply" completely filled out and signed?

Are there any errors in the error log? Yes No

In case of EPA label: has an EPA alarm report been attached to the report? Yes No

Has a data retrieval been created with the service tool and uploaded to the Yes No

FTP server?

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 17

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

Section 4: General& Signatures

Please note: Check points marked with (E) are emission relevant and therefore mandatory to be filled out.

4.1 Type of Check

mtu system for Main propulsion On-board power Other:

Installation check was carried out as follows:

Time / Date:

Location:

RRS representative:

Engine model:

Reference order number:

Participants

Name: Company:

4.2 Documentation of the Installation check

Has the commissioning cover sheet been filled out with all necessary Yes No

data and the document signed by all necessary persons?

Are all serial and / or material numbers of engines, EGAT, bypass (if Yes No

applied), cabinet (if applied) and LOP documented? (E)

Is the assignment of EGATs to the engines clearly documented? (E) Yes No

Has a copy of the complete report (incl. measured values) been handed Yes No

over to the shipyard’s representative?

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 18

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

Have all installation guidelines been satisfactorily met? Yes No

4.3 Remarks regarding deviations from installation guidelines

Are all deviations documented? Yes No

Was notification about the deviations given to the shipyard? Yes No

If no deviations have been detected, the engine and related systems are installed correctly and shall work

without malfunctions.

If deviations have been detected, the shipyard is obliged to fix all deviations and report the

corrective actions to the RRS Representative.

Date Shipyard representative RRS representative Form completed by

(Name & Signature) (Name & Signature) (Name & Signature)

4.4 Distribution instruction

Report to be sent to asodb-pwm@ps.rolls-royce.com

Are the engines labelled according to EPA regulations (E)? Yes No

If labelled according to EPA regulations, please note:

Report to be sent within 5 days from date of commissioning!

RRS is obliged to report any deviations relating to the emission certified configuration within 15 days

of detection to the EPA.

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 19

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

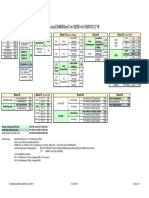

Annex I: Example Measurement log sheet of sea trial with operational values

Suitable Template to document measurements during sea trial can be found in „Diasys” as follows:

„ECU-9 Diesel / MST_S2000_M07_V1“ (or variations thereof)

Please attach the file to this report.

Please also provide data in a format as per following example:

Trial date Trial location

Ambient temp. Seawater temp.

Sea conditions Weather conditions

Vessel name / no. Vessel load (full, half, ..)

Engine model Serial no.

Installation position Runtime (h) end of trial

Engine inclination Runtime (h) at Vmax

Coolant type Coolant mix

Oil type Propulsion system

Customer rep. RRS rep.

Speed range rpm 550 800 1000 1200 1400 1600 1800 2000 2250 2450

Power

Engine speed demand (ECU) rpm

Engine speed (ECU) rpm

Engine power kW

Requested torque Nm

Max. requested torque Nm

Act. torque in relation to DBR %

Temperatures

Sea water bef ore engine HE °C

Seawater af ter engine HE °C

Seawater af ter gearbox HE °C

Gear box oil temp. °C

Engine room temp. front °C

Engine room temp. rear °C

T-Intake Air °C

T-Charge Air °C

T-Exhaust A °C

T-Exhaust B °C

T-Exhaust before EGAT °C

T-Exhaust af ter EGAT °C

T-Coolant °C

T-Lube Oil °C

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 20

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Aenderungsbeschreibung/Description of Revision Kommt vor/Frequency

Buchst./Rev.Ltr. Erh-Antrags-Nr. / Promotion request No. Aenderungs-Nr./Revision Notice No. Bearbeitungsstatus/Lifecycle

-.3 PR101471 Released

T-Fuel °C

T-ECU °C

Speed range rpm 550 800 1000 1200 1400 1600 1800 2000 2250 2450

Pressures

Fuel depression before pump bar

P-Fuel bar

Fuel return bar

Intake depression sea water bar

Seawater af ter pump bar

Seawater af ter engine HE bar

Seawater af ter gearbox cooler bar

P-Lube oil after filter bar

P-Charge air bef ore cylinder bar

P-Exhaust after cylinder bar

P-HD (Common Rail) bar

Ex. backpressure before EGAT mbar

Ex. backpressure after EGAT mbar

Engine room bar

Others

ETC 1 Speed krpm

Vessel Speed knots

Actual Fuel Consumption l/h

Actual HWL Consumption l/h

Specific Fuel Consumption g/kWh

Specific HWL Consumption g/kWh

NOx bef ore EGAT g/kWh

NOx af ter EGAT g/kWh

HC3 af ter EGAT g/kWh

ECU Power Supply Voltage V

Blatt/ Sheet

A Rolls-Royce

Zeichnungs-Nr./Drawing No. ZNG00049287 21

solution von/of

Rolls-Royce Solutions GmbH

Material-Nr./Material No. XZ51600000160 21

Alle Rechte aus Schutzrechtsanmeldungen vorbehalten. Weitergabe, Vervielfältigung oder sonstige Verwertung ohne Zustimmung nicht gestattet. Zuwiderhandlungen

verpflichten zum Schadensersatz.

All industrial property rights reserved. Disclosure, reproduction or use for any other purpose is prohibited unless our express permission has been given. Any

infringement results in liability to pay damages.

Das könnte Ihnen auch gefallen

- Din 743Dokument85 SeitenDin 743qxyz123Noch keine Bewertungen

- Etl 23ab 2257900 00 00 00Dokument305 SeitenEtl 23ab 2257900 00 00 00Ivica Šućur100% (1)

- Propellerhandbuch For KS-F2Dokument6 SeitenPropellerhandbuch For KS-F2mario bulgheriniNoch keine Bewertungen

- Teilegutachten: NR.: TÜH-TB 2005-126.02Dokument18 SeitenTeilegutachten: NR.: TÜH-TB 2005-126.02Sam Van NieuwenhovenNoch keine Bewertungen

- Catalogo Peças Acabadora 1300Dokument341 SeitenCatalogo Peças Acabadora 1300José Marques100% (1)

- Xz00e52000013 Modbus TCP Release 080 ModifiedDokument41 SeitenXz00e52000013 Modbus TCP Release 080 ModifiedVu TuongNoch keine Bewertungen

- Tuv H&RDokument7 SeitenTuv H&RsmokefieldNoch keine Bewertungen

- Teilegutachten: Nr. 112XT0226-04Dokument8 SeitenTeilegutachten: Nr. 112XT0226-04Frieden für die ganze Welt. Ohne AusnahmenNoch keine Bewertungen

- XG3041700064 - SilenciadorDokument1 SeiteXG3041700064 - SilenciadorTheo Pozo JNoch keine Bewertungen

- AtestDokument7 SeitenAtestAdelinaShalaNoch keine Bewertungen

- RSS-37-827Dokument6 SeitenRSS-37-827maxbeckerbruningNoch keine Bewertungen

- 05EUTG015Dokument11 Seiten05EUTG015alkoNoch keine Bewertungen

- 17 Pre3321 3388 711022Dokument2 Seiten17 Pre3321 3388 711022Puđa TomicaNoch keine Bewertungen

- Certificado TÜVDokument10 SeitenCertificado TÜVSr TonechoNoch keine Bewertungen

- Teilegutachten: Nr. 42TG0341E-04Dokument7 SeitenTeilegutachten: Nr. 42TG0341E-04jassko cizzmicNoch keine Bewertungen

- EG - Genehmigung / EC Type-Approval-Certificate Frontschutzsystem / Frontal Protection System Für / For Mitsubishi Pajero V80 AlleDokument8 SeitenEG - Genehmigung / EC Type-Approval-Certificate Frontschutzsystem / Frontal Protection System Für / For Mitsubishi Pajero V80 AlleDega VaraždinNoch keine Bewertungen

- IrmscherDokument7 SeitenIrmscherTanasescu Bogdan-emilNoch keine Bewertungen

- Uebersicht Overview - TM DG 1000Dokument11 SeitenUebersicht Overview - TM DG 1000Mallikarjun ReddyNoch keine Bewertungen

- Deckblatt/Active Sheet RecordDokument7 SeitenDeckblatt/Active Sheet RecordMyFullNoch keine Bewertungen

- Teilegutachten: 0. Hinweise Für Den FahrzeughalterDokument8 SeitenTeilegutachten: 0. Hinweise Für Den FahrzeughalterPaulNoch keine Bewertungen

- Yss 001 PDFDokument51 SeitenYss 001 PDFmarinoNoch keine Bewertungen

- 03 SIN656 5x114,3 ET38 MO1 67,1 ECE 2aDokument4 Seiten03 SIN656 5x114,3 ET38 MO1 67,1 ECE 2aScenic777Noch keine Bewertungen

- Homologation Form Number 5295 Group ADokument67 SeitenHomologation Form Number 5295 Group ASebastian CastroNoch keine Bewertungen

- Kuisioner AndritzDokument6 SeitenKuisioner AndritzTumbal PogoNoch keine Bewertungen

- Deckblatt/Active Sheet RecordDokument3 SeitenDeckblatt/Active Sheet RecordJuan RiveraNoch keine Bewertungen

- 703 GutachtenDokument16 Seiten703 GutachtenWimzjok SeirgasNoch keine Bewertungen

- PS-2.0017 - HV Bushing TestingDokument13 SeitenPS-2.0017 - HV Bushing TestingSuresh RamanujaluNoch keine Bewertungen

- Thyssenkrupp Industrial Solutions AG: Engineering Parts List KonstruktionsstücklisteDokument3 SeitenThyssenkrupp Industrial Solutions AG: Engineering Parts List Konstruktionsstücklistelidio reyesNoch keine Bewertungen

- Deckblatt/Active Sheet RecordDokument17 SeitenDeckblatt/Active Sheet RecordHandoko HandNoch keine Bewertungen

- Installation Manual Rev 200303 A CDokument49 SeitenInstallation Manual Rev 200303 A CInsan AzizNoch keine Bewertungen

- Jay 3Dokument1 SeiteJay 3nmpurchasesNoch keine Bewertungen

- Telescope Loader 4107 Spare PartsDokument20 SeitenTelescope Loader 4107 Spare Partsrobert100% (53)

- Horsch Cultro CatalogDokument118 SeitenHorsch Cultro CatalogVitaliy TrotsenkoNoch keine Bewertungen

- Super 1800-1 2006Dokument557 SeitenSuper 1800-1 2006rmax54386Noch keine Bewertungen

- Atu778 Abe BMW 525Dokument12 SeitenAtu778 Abe BMW 525Dervis Fakir Nur BabalriNoch keine Bewertungen

- Teilegutachten: Nr. 32TG0332-17Dokument5 SeitenTeilegutachten: Nr. 32TG0332-17PaulNoch keine Bewertungen

- Catalogo de Peças HAMMDokument405 SeitenCatalogo de Peças HAMMStefane Julian AquinoNoch keine Bewertungen

- 132XT0084 01Dokument5 Seiten132XT0084 01Binni FeratiNoch keine Bewertungen

- Paver Screed CatalougeDokument477 SeitenPaver Screed Catalougesengottaiyan100% (4)

- 1282 (Super 1800-2)Dokument385 Seiten1282 (Super 1800-2)Paulo RobertoNoch keine Bewertungen

- 00EUTG37Dokument11 Seiten00EUTG37Gerhard SämannNoch keine Bewertungen

- BW100 SB02Dokument5 SeitenBW100 SB02Andi.ElNoch keine Bewertungen

- Abe2020013 PDFDokument16 SeitenAbe2020013 PDFNanuk BosselmannNoch keine Bewertungen

- FQP Turbine PDFDokument32 SeitenFQP Turbine PDFapsNoch keine Bewertungen

- Andy Tagwvw13 50 Tagwvw13Dokument13 SeitenAndy Tagwvw13 50 Tagwvw13andynols320iNoch keine Bewertungen

- Thyssenkrupp Industrial Solutions AG: Engineering Parts List KonstruktionsstücklisteDokument3 SeitenThyssenkrupp Industrial Solutions AG: Engineering Parts List Konstruktionsstücklistelidio reyesNoch keine Bewertungen

- Каталог Unmog MS 32 передний отвалDokument74 SeitenКаталог Unmog MS 32 передний отвалСветлана Гайдай100% (1)

- 配件手册 (福格勒S1800 3)Dokument645 Seiten配件手册 (福格勒S1800 3)caoxinjunNoch keine Bewertungen

- G-1301074-P-KON-30-0100-001 (Rev-G)Dokument3 SeitenG-1301074-P-KON-30-0100-001 (Rev-G)Jibin Reji KoshyNoch keine Bewertungen

- XVS1300A 4YP 4NL 4NK-flachDokument0 SeitenXVS1300A 4YP 4NL 4NK-flachAndi.ElNoch keine Bewertungen

- Leiten - Despiece - Pisón Bomag BT65 PDFDokument150 SeitenLeiten - Despiece - Pisón Bomag BT65 PDFHansel RoblesNoch keine Bewertungen

- Wirtgen MinadoraDokument1.341 SeitenWirtgen MinadoraJose MarquezNoch keine Bewertungen

- Teilegutachten: Nr. 02TG0576-02Dokument10 SeitenTeilegutachten: Nr. 02TG0576-02PaulNoch keine Bewertungen

- CRAMER DOCsDokument124 SeitenCRAMER DOCsNizar SGHIRNoch keine Bewertungen

- TL 9 161 301.6 TL Verstärkungsmaterial Für Leder - ScanDokument45 SeitenTL 9 161 301.6 TL Verstärkungsmaterial Für Leder - ScanOliver SteinrötterNoch keine Bewertungen

- CRAMER DOCsDokument118 SeitenCRAMER DOCsNizar SGHIR100% (1)

- Export ASMEDokument278 SeitenExport ASMElizet11Noch keine Bewertungen

- Homologation Golf Gti Mk3 Form Number 5483 Group ADokument89 SeitenHomologation Golf Gti Mk3 Form Number 5483 Group AJUAN PARADA ALARCONNoch keine Bewertungen

- Triebwerksdynamik und Konstruktionselemente des VerbrennungsmotorsVon EverandTriebwerksdynamik und Konstruktionselemente des VerbrennungsmotorsNoch keine Bewertungen

- Codierliste EA888Gen3 Im MQB - V18Dokument1 SeiteCodierliste EA888Gen3 Im MQB - V18Liu HelloNoch keine Bewertungen

- Still Kalmar r70!60!70 80 Spare Parts Book in GermanDokument20 SeitenStill Kalmar r70!60!70 80 Spare Parts Book in Germanrobert100% (45)

- 1XDiavel Diavel - DEDokument1 Seite1XDiavel Diavel - DEGOGONoch keine Bewertungen

- MASH23 Anfahrt ZarteBandeDokument4 SeitenMASH23 Anfahrt ZarteBandeHochstetter MediaNoch keine Bewertungen

- 7128DEDokument3 Seiten7128DEMUHAMAD AWISSNoch keine Bewertungen

- Rud VLBGDokument8 SeitenRud VLBGmrcNoch keine Bewertungen