0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen) 446 Ansichten11 SeitenDie Casting PDF

Copyright

© © All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

TOYO�The BD-V4-N shows great versatility covering

pressure - tight castings, super thin- wall castings

and magnesium castings.

V. Super slow laminar flow die-casting

Shot speed setting range

Je U0 ms

Fine speed increment

eal ftitna s

wah eq

GK (bl Mo}

Casting condition in laminar flow die-casting

in the speed range between

= (4 m/s

V. Super high-speed die-casting

‘Max. dry shot speed

° UU m/sec

Low shot speed

Multi-step speed shifting & Parashot

in the speed range up to

SO

ped

Thin-wall products

o// m/sec

‘Quick accleration ability

) misec (11) m/sec

‘Super thin-wall casting

DZ

uminum and Magnesium casting

| Po:0a~[Link]

Geltular phone : 0.7~0.8t�With -throttled shot circuit,

high shot speed is stable

and power is constant.

This suits to wide variety of castings 7

such as strength-required products, Ut

thick products and durable products : -

PCR Ue aod

V. Sharp deceleration before filling Seong]

Completion in high speed shot Lhe Rak ad

‘Deceleration ability (ontionad) SSE Reo ue

Teneo Ree eee

m/sec! |

Post-deceleration

speed can be set.

eRe

ston pump-equipped TOYO

ey

No shot sleeve is necessary on the

Cea an�Defect Rates Reduced

With Any Mold

The Multi Injection System

Each mold has its own character.

The Mult Injection System can cope with any mold

with its super slow laminar flow and super high speed

die casting capabilities.

This system was developed backed by TOYO's

abundant expertise on mold making

as woll as die casting process.

In-throttled High Speed Shot Control

Unlike systems adopted by other machine makers,

the Multi Injection System is provided with a throttle valve

on the head side IN side), so that the melt can be shot

into the cavities at intended speeds boosted by power

that is necessary to maintain the speeds.

Back pressure is applied only at the time of filling end,

As a result, the Multi Injection System can easily handle

wide range of castings such as thin-wall products

and pressure-tight products.

‘Super Slow Shot (SSS) system

(

| | Multi injection System covers:

| | Super fast Shot system

|

|

Super accelerating casting system

poet

See

tend

eee st rn

ees

‘The molt can be shot into cavities

en escent

ie

poets

Tha Fision peed oats

ee arer ene�Features

The Multi Injection System comprises two cylinders;

the injection cylinder and injection intensifying cylinder.

Unlike conventional two-pressure system where only one

cylinder is used, the two-cylinder system can make

sophisticated injection pressure control very easily.

Higher pressure is utilized for quicker acceleration.

independent control can be made for low speed injection,

high speed injection and injection speed deceleration.

Surge pressure is minimized due to the adoption of light

weight intensifying cylinder and a bladder accumulator

optional) for injection intendsifying

TOYO

Pu ey

peer

Ce nc

ii

ee�Machine Design for

One-size Larger Mold

(650-t, 800-t, 900-t)

Ultimate Performance Through

Increased Rigidity�Advanced PLCS-9 Control

System for Higher Precision

and Higher Cycle Casting

Jo ames entered using Ces characters

“stonaticmscanon of periecalchecap screen

‘arm history screen or 200 alarms

gh yee specication as standard

ag recess sped wt igh seed ecrocompter

‘Strengthened producton contra trction�magnesium’

=e

BD—250V4—N

TOYO's high precision magnesium casting System

TOYO's unique magnesium casting system features

a high accuracy automatic ladle, high mobi

high filling rate and highly stable accuracy.

Die Casting

Te Ty

Sail

ig

eo ee RC

Me ee

Prec aU

knowledge on the characteristics

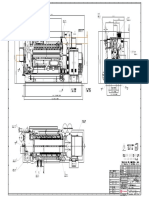

Crea ary��Model BD—125V4—N | BD—200V4—N | BD—250V4—N | BD—350V4—=N | BD—500V4—N

Control system: PLCS—9 PLOS—9 PLCS—9 PLCS—9 PLOS—9

Injection system Mut iecon Syste | Macon Syston | MLE hector Stem jcion Systm) MU ecton Sytem

[g [Clamping force ANI 30 | 1960 2450 sao | 4900

2) Die plate (HW) [nm 700X700 820X820, 850X904 935X1008 | 1070x1070

4§ | Te bar distance (HW) [nn] 46oxaso | 508X590 5eaX>| Motor (hydraulic pump) IKWI 15 15 | 22 22 a

® | Motor (Gio hoight) KWL 02 04 oa 075 15

| Power source capacity IKVA] 22 a 40 40 60

| Vottage [v1 ‘Acezooie0 | Acz00/220 | Acz00/220 | AG200/220 | _AG200/200

| Air pipe connection port (Rel 7 1 1 1 116

4 [Machine size (LXWXH) Ins] | 4670XT570X2107 | AT7EXTBTEXDAHA | 5B16X 1620x2566 | 450% 1800X2600 | 7520X2476X2969

é ‘Machine weight [1] 45 63 ea | 2

Hydraulic ol tank capacity [el 310 310. 310 400 | 600

Combination of die casting machine and peripheral equipment

TON | Avomatelade [Auomate spray | Alma [Adoraiceradon’ Trnifa | ARRTE [vacuum unt

125 | KOT=15Mz—N | SO2—15Me-N | TDSL—16MiB—N | TOSL—16Ms-N | TRI—5C

200_[ KOI=S5Me=N | SO2—G5W.—N | TDSL=S5MEBN | TDSL—ASMO=N | TRI— IOC

250_| KDI—S5Me—N | S02—35Me—N | TOSL—36MeB=N | TDSL—A5M:—N | TRI—10CM

250_| KOF=AGME=N"[ SOE=26NK=N [TORLMSBHEBN | TDeLmaeis=N [TRI=TocM | |

'500_| KDI=65Me-N | SD2—65M,B—N | TOSL—6SMGB—N | TD6L—E5Mo—N | TRI—15RO

650 | KDI—65M/—N | SD2—65M.8=N | TOSL—65MB—N | TOSL—ESME-N | TRI—15RO

1800 | KOI—EoMe—N | SD2—e0M.—N | TOSL—BOMKB=N | TOGL—eOML—N | TRI—20RO

900 | KD1=80M»—N | SD2—80M.—N | TDSL—80MB—N | | TRI—20RO |�Standard and optional specifications * ox:

BD—650V4—N | BD—B00V4—N | BD—S00V4—N] [Model (TON) 125 [200 |e sn 500 [s00] 00 [ano

7 Pics—9 pics=9 | _PLCS=9 Auiomatcgeasngdevce @[@ @/eleelele

Thi rection Syste [Mut ncn Syste | Mu con Sion ‘Automatic damp force seuo |@[@ @lelelelele

6370 7840 ‘3826 ‘Automatic ajustment of amptorce | @|@ @|@ e\elele

"2a0x1200 | 14o0xt400__| _rao0xs400_| | ,,[Clamptoree monitor elelelelelelele

Sea axed ERSTE E [Doielioadmeter(ipc) |e [eleleleleleie

= a oe 3 | Teserpacn onesin cpwatrese|—|—|O|O 0 ole le

ae a was | | Cheon ted in brag bar eeceee

a fas Sic plate over de plates ofolofolc

tas | | Mantaciaatsaey orien [@ [ele le lelelele

Fence on rear side efor

[aa Toggle side covers rontandreat) | @ | @ | @

oe {oe Core eee

=a15O) | = 2750) ae ole

8065+) 36100 | a0 9 (O)110129 Ge ear on stator dep) | — | —

354 a7 $ [Coe spocdadustnent | @ ee

342 a2 > (Core pressure reducing valve | O] 0] C

0~125 o~ 125 [Pug socket C220 eee

3x2 B4x2 etal Plug Socket ofolo

—aax2 | 34x2 | J |Standardsieeve length __|215 [257] 257

Hx 2c) Ux2 B4x2 Tp joint system ole

Ta We ae gg Mutiecion sytem jeee

aE Par ae 3 | injection intensiying ccuruaor| — | —| 00/0 [0

7 : 3 [ick deceleration uncton | —|—[O fo To}o

; - : Tip lubrication device eec5cee

et xt aa Tiptereantming stem TOTO TOTO TOTO

[sexs x15 Huis —— Stee eet

, es - 2* | Hicrauie ol rieraDcompatbie | @ | @ | @ @ @|@

iz 3 | Ollceaner wih alarm eeccecee

5980 7o=180_ | 70150 | | 8foitemporauroaim |e |e [e[e[e |e

7 rs) = 5 | Water oniot vaio foro coos | @ | @|@ @ 0 @

(4s 22 22 5 [Temperature nication max) | O [0] OO] O|0

80 70 70 = [Ono valveiorde cooing [O|o|0}0|o]o

czooiaz | ACa00/@20 | AO200/200 | | =| Squeeze pin motion ofolololo[olole

1% 14 1 S | Vacuum casing system (ves)] 0) O | o [< IIE

| Lee oe

2 a #2 PG software or uaity contol] © | O | «

fe e00. 750 750 Inemalmeray frSedessups| @|@ |e |e @

al rjcton postions avaiable as opton or | | emenicardior izede sets | @ | @/ @|@ | @

‘Spada con patonswalale aston |e eneonmetuncion ['@[@T@ [6 ©

‘#Optenal Monitor function forsS tems | @ /@|@ ele

[3 [Automatic corecion(Titems)| @ [@ | @|@ | @

[8 | Galulation of st condtion eevee

"Detect signal ouput ofofofe

Spay inser tompeauraoortal| © | © | OO |O

Aarmhisioy indeaton | @/@|@lele

A\Note Peviodie-checkup indication [@/@|@/@|@

‘Specicatons are subject to change High ele specication | @|@|elele@

eae eget st ial purging funcon eccee

inbek wh ob raters ogipmat | C

Das könnte Ihnen auch gefallen