Beruflich Dokumente

Kultur Dokumente

Ea 210214-En

Hochgeladen von

Andras AnandOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ea 210214-En

Hochgeladen von

Andras AnandCopyright:

Verfügbare Formate

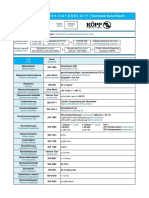

Technical Data Sheet

LOCTITE® EA 210214

Known as Hysol 210214

October-2014

PRODUCT DESCRIPTION TYPICAL PROPERTIES OF CURED MATERIAL

LOCTITE® EA 210214 provides the following product Cured for 30 minutes @ 125 °C.

characteristics: Physical Properties:

Technology Epoxy Coefficient of Thermal Expansion,

ISO 11359-2, K-1:

Chemical Type Epoxy Pre Tg (Alpha 1) 52×10-6

Appearance (uncured) Light grey liquidLMS Post Tg (Alpha 2) 172×10-6

Appearance (cured) Light grey solidLMS Glass Transition Temperature, ASTM E 228, °C 74

Fluorescence Positive under UV light Shore Hardness, ISO 868, Durometer D ≥75LMS

Components One component - Linear Shrinkage, ASTM D 792, % 1.2

requires no mixing Water Absorption, ISO 62, %:

Cure Heat cure 2 hours in boiling water 1.6

Cure Benefit Production - high speed curing 7 days in water @ 22 °C 0.37

Application Assembly of disposable medical Elongation, at break, ISO 527-3, % 1.1

devices. Tensile Strength, ISO 527-3 N/mm² 38

(psi) (5,540)

Key Substrates Stainless steel and Plastics

Tensile Modulus, ISO 527-3 N/mm² 3,902

(psi) (566,000)

LOCTITE® EA 210214 is suitable for a wide range of

applications that require fast cure, excellent environmental

resistance and high adhesion. The product cures rapidly when TYPICAL PERFORMANCE OF CURED MATERIAL

exposed to temperatures as low as 100 °C and achieves Adhesive Properties

excellent adhesion to plastics, metals and glass. LOCTITE® EA Cured for 30 minutes @ 120 °C.

210214 was specifically designed for bonding stainless steel Lap Shear Strength, ISO 4587:

cannulae into hubs, syringes and lancets for needle Aluminum (etched):

assemblies. Suitable for use in the assembly of disposable 0.125 mm gap N/mm² ≥13.8LMS

medical devices. (psi) (≥2,000)

TYPICAL PROPERTIES OF UNCURED MATERIAL Cured for 30 minutes @ 100 °C.

Specific Gravity @ 25 °C 1.38 Needle Pullout Strength:

Flash Point - See SDS Material 22 Gauge Cannula 27 Gauge Cannula:

Viscosity, Brookfield SSA - RVT, 25 °C, mPa·s (cP): ABS N 227 N 142

Spindle 14, speed 20 rpm, 22,000 to 28,000LMS (lb) (51) (lb) (32)

Acrylic N 254 N 147

TYPICAL CURING PERFORMANCE (lb) (57) (lb) (33)

Polycarbonate N 107 N 116

Cure Schedule (lb) (24) (lb) (26)

Typical cure times were estimated as >99% conversion using Polyethylene N 13 N 53

differential scanning calorimetry: (lb) (3) (lb) (12)

@ 100 °C, 25 minutes Polyethylene N 200 N 138

(plasma treated) (lb) (45) (lb) (31)

@ 125 °C, 24 minutes Polypropylene N 27 N 36

@ 150 °C, 17 minutes (lb) (6) (lb) (8)

Polypropylene N 147 N 116

(plasma treated) (lb) (33) (lb) (26)

Polystyrene N 222 N 133

(lb) (50) (lb) (30)

Polyurethane N 196 N 138

(lb) (44) (lb) (31)

TDS LOCTITE® EA 210214, October-2014

Cured for 30 minutes @ 125 °C. Hot Strength

Block Shear Strength, ISO 13445: Cured for 30 minutes @ 125 °C. The bonded specimens were tested

Acrylic N/mm² 4 at the indicated temperature:

(psi) (580) Block Shear Strength, ISO 13445, Polycarbonate

G-10 Epoxy N/mm² 17

(psi) (2,450)

Nylon N/mm² 6 200

(psi) (820)

175

% Strength @ 22 °C

Polybutylene Terephthalate N/mm² 11

(psi) (1,640) 150

Polycarbonate N/mm² 2 125

(psi) (305)

Aluminum (grit blasted) N/mm² 32 100

(psi) (4,580)

75

Steel (grit blasted) N/mm² 45

(psi) (6,590) 50

25

0

TYPICAL ENVIRONMENTAL RESISTANCE 0 40 60 80 100

Temperature, °C

Thermal Stability of Needle Assemblies

Aged @ 60°C and tested @ 22 °C Heat Aging

Needle Pullout Strength, % initial strength retained: Cured for 30 minutes @ 125 °C. The bonded specimens were

Plastic: 4 Weeks 8 Weeks: conditioned as indicated and tested at 22 °C.

Polycarbonate: Block Shear Strength, ISO 13445, Polycarbonate

22 Gauge Cannula 190 190

27 Gauge Cannula 110 110

Polypropylene (plasma treated): % Initial Strength @ 22 °C 200

22 Gauge Cannula 120 150 175

27 Gauge Cannula 105 105 125 °C

150

Polystyrene:

22 Gauge Cannula 100 110 125

100 °C

27 Gauge Cannula 100 100 100

75

Sterilization Resistance of Needle Assemblies 50

Sterilized as indicated and tested @ 22 °C 25

Needle Pullout Strength, % initial strength retained:

0

Plastic Gamma ETO Autoclave 0 250 500 750 1000

30 kGy 1 cycle 1 cycle 5 cycles Time, hours

Polycarbonate:

22 Gauge Cannula 105 100 110 30

Chemical/Solvent Resistance

27 Gauge Cannula 90 80 100 75

Cured for 30 minutes @ 125 °C. The bonded specimens were

Polypropylene (plasma treated): conditioned as indicated and tested at 22 °C.

22 Gauge Cannula 90 100 65 35 Block Shear Strength, ISO 13445, Polycarbonate

27 Gauge Cannula 80 70 110 65

Polystyrene:

22 Gauge Cannula 90 75 N/A N/A % of initial strength

27 Gauge Cannula 75 80 N/A N/A Environment °C 24 h 100 h 500 h 1000 h

95% RH 40 ----- 100 90 135

N/A - Not Applicable. The polystyrene was not compatible

with the autoclave sterilization process. Ambient Water

22 ----- 120 115 165

Submersion

Isopropanol 22 120 ----- ----- -----

Heptane 22 210 ----- ----- -----

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials.

For safe handling information on this product, consult the

Safety Data Sheet (SDS).

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE® EA 210214, October-2014

Directions for use: In case products are delivered by Henkel Colombiana, S.A.S. the following

disclaimer is applicable:

1. Adhesive must be room temperature just prior to use. The information provided in this Technical Data Sheet (TDS) including the

2. Clean and dry surfaces to be bonded. recommendations for use and application of the product are based on our

knowledge and experience of the product as at the date of this TDS. Henkel is,

3. Apply adhesive evenly to both surfaces. therefore, not liable for the suitability of our product for the production processes

4. Assemble parts and allow to cure at 100 °C for 25 minutes and conditions in respect of which you use them, as well as the intended

or until completely firm. applications and results. We strongly recommend that you carry out your own

prior trials to confirm such suitability of our product.

5. Refer to cure schedule for alternate cure information. Any liability in respect of the information in the Technical Data Sheet or any other

written or oral recommendation(s) regarding the concerned product is excluded,

Loctite Material SpecificationLMS except if otherwise explicitly agreed and except in relation to death or personal

LMS dated August-09, 2002. Test reports for each batch are injury caused by our negligence and any liability under any applicable mandatory

product liability law.

available for the indicated properties. LMS test reports include

selected QC test parameters considered appropriate to In case products are delivered by Henkel Corporation, Resin Technology

specifications for customer use. Additionally, comprehensive Group, Inc., or Henkel Canada Corporation, the following disclaimer is

controls are in place to assure product quality and applicable:

The data contained herein are furnished for information only and are believed to

consistency. Special customer specification requirements may be reliable. We cannot assume responsibility for the results obtained by others

be coordinated through Henkel Quality. over whose methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production methods mentioned

Storage herein and to adopt such precautions as may be advisable for the protection of

Store product in the unopened container in a dry location. property and of persons against any hazards that may be involved in the handling

and use thereof. In light of the foregoing, Henkel Corporation specifically

Storage information may be indicated on the product container disclaims all warranties expressed or implied, including warranties of

labeling. merchantability or fitness for a particular purpose, arising from sale or use

Optimal Storage: 2 °C to 8 °C. Storage below 2 °C or of Henkel Corporation’s products. Henkel Corporation specifically

disclaims any liability for consequential or incidental damages of any kind,

greater than 8 °C can adversely affect product properties. including lost profits. The discussion herein of various processes or

Material removed from containers may be contaminated during compositions is not to be interpreted as representation that they are free from

use. Do not return product to the original container. Henkel domination of patents owned by others or as a license under any Henkel

Corporation cannot assume responsibility for product which Corporation patents that may cover such processes or compositions. We

recommend that each prospective user test his proposed application before

has been contaminated or stored under conditions other than repetitive use, using this data as a guide. This product may be covered by one or

those previously indicated. If additional information is required, more United States or foreign patents or patent applications.

please contact your local Technical Service Center or

Trademark usage

Customer Service Representative.

Except as otherwise noted, all trademarks in this document are trademarks of

Conversions Henkel Corporation in the U.S. and elsewhere. ® denotes a trademark

(°C x 1.8) + 32 = °F registered in the U.S. Patent and Trademark Office.

kV/mm x 25.4 = V/mil

mm / 25.4 = inches

µm / 25.4 = mil Reference 0.1

N x 0.225 = lb

N/mm x 5.71 = lb/in

N/mm² x 145 = psi

MPa x 145 = psi

N·m x 8.851 = lb·in

N·m x 0.738 = lb·ft

N·mm x 0.142 = oz·in

mPa·s = cP

Note:

The information provided in this Technical Data Sheet (TDS) including the

recommendations for use and application of the product are based on our

knowledge and experience of the product as at the date of this TDS. The product

can have a variety of different applications as well as differing application and

working conditions in your environment that are beyond our control. Henkel is,

therefore, not liable for the suitability of our product for the production processes

and conditions in respect of which you use them, as well as the intended

applications and results. We strongly recommend that you carry out your own

prior trials to confirm such suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or any other

written or oral recommendation(s) regarding the concerned product is excluded,

except if otherwise explicitly agreed and except in relation to death or personal

injury caused by our negligence and any liability under any applicable mandatory

product liability law.

In case products are delivered by Henkel Belgium NV, Henkel Electronic

Materials NV, Henkel Nederland BV, Henkel Technologies France SAS and

Henkel France SA please additionally note the following:

In case Henkel would be nevertheless held liable, on whatever legal ground,

Henkel’s liability will in no event exceed the amount of the concerned delivery.

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

Das könnte Ihnen auch gefallen

- MIG-Schweißen von Aluminiumwerkstoffen im FahrzeugbauVon EverandMIG-Schweißen von Aluminiumwerkstoffen im FahrzeugbauNoch keine Bewertungen

- Technologie der Messwandler: Strom- und Spannungsmessung und IsolationssystemeVon EverandTechnologie der Messwandler: Strom- und Spannungsmessung und IsolationssystemeNoch keine Bewertungen

- RESISTAL A90 MX Umwelt Energie ISO ENDokument2 SeitenRESISTAL A90 MX Umwelt Energie ISO ENmonica.alvarezNoch keine Bewertungen

- DOW TrichloroethyleneDokument2 SeitenDOW TrichloroethyleneherrharoNoch keine Bewertungen

- Degacryl® HS 4322 E-EnDokument2 SeitenDegacryl® HS 4322 E-EnLU CHUNHUINoch keine Bewertungen

- Tectyl Turbine 46 PDS ENDokument1 SeiteTectyl Turbine 46 PDS ENtaufksNoch keine Bewertungen

- Clariant Flyer Antifrogen Universelle Waermetraegerfluessigkei 201410 DEDokument2 SeitenClariant Flyer Antifrogen Universelle Waermetraegerfluessigkei 201410 DEDonny IrawanNoch keine Bewertungen

- ISFO 02 Isolierfolien FlammhemmendDokument2 SeitenISFO 02 Isolierfolien FlammhemmendRameez Ali FaridiNoch keine Bewertungen

- B57540G0103F000Dokument36 SeitenB57540G0103F000ThisNoch keine Bewertungen

- WEROMID PA 6 Typ B40SK W1Dokument1 SeiteWEROMID PA 6 Typ B40SK W1muamerNoch keine Bewertungen

- TYFOCOR-L de TIDokument11 SeitenTYFOCOR-L de TIReinerNoch keine Bewertungen

- Transition 32 X 1Dokument1 SeiteTransition 32 X 1Jhon merino rodriguezNoch keine Bewertungen

- K110DE - Aisi D2Dokument16 SeitenK110DE - Aisi D2italangeloNoch keine Bewertungen

- Norseal2520 deDokument2 SeitenNorseal2520 deaNoch keine Bewertungen

- NP155F D 5 2012Dokument3 SeitenNP155F D 5 2012MihaiNoch keine Bewertungen

- K-Pe35fr 12.2021Dokument2 SeitenK-Pe35fr 12.2021venkatramanNoch keine Bewertungen

- Prepreg - ET445 Epoxy Matrix Prepreg - BNS.01.01.14Dokument7 SeitenPrepreg - ET445 Epoxy Matrix Prepreg - BNS.01.01.14Namelezz ShadowwNoch keine Bewertungen

- Belimo Umschaltventil R3..BLDokument5 SeitenBelimo Umschaltventil R3..BLWolfgangNoch keine Bewertungen

- 1.1191 C45E - Baustahl - Datenblatt - TK - 1191 - 1201Dokument3 Seiten1.1191 C45E - Baustahl - Datenblatt - TK - 1191 - 1201genuesslichwohlriechendersteinbockNoch keine Bewertungen

- Datenblatt Polystone P Copolymer DEDokument1 SeiteDatenblatt Polystone P Copolymer DEAndreArmaniniNoch keine Bewertungen

- IBC PolySol 250 - 260 VMDokument2 SeitenIBC PolySol 250 - 260 VMKurt LeënNoch keine Bewertungen

- FUCHS Renolit CX FO 20 2008-09Dokument2 SeitenFUCHS Renolit CX FO 20 2008-09karthik venkatachalamNoch keine Bewertungen

- 8.036 Stellatex HC-VE - deDokument5 Seiten8.036 Stellatex HC-VE - decoved.servicesNoch keine Bewertungen

- DD450020 CPsingle CPdouble 01Dokument7 SeitenDD450020 CPsingle CPdouble 01seve1Noch keine Bewertungen

- Rear - K-LED 2.0Dokument2 SeitenRear - K-LED 2.0Chin Wei SteNoch keine Bewertungen

- Hikra Sol Hikra Sol1500v En50618Dokument5 SeitenHikra Sol Hikra Sol1500v En50618BorisNoch keine Bewertungen

- Bohler K990DEDokument12 SeitenBohler K990DEDeysi CardenasNoch keine Bewertungen

- Eurotec Limit Switch Box Eae ExDokument3 SeitenEurotec Limit Switch Box Eae ExJulio Vega AngelesNoch keine Bewertungen

- 2 BNZ 21 en - 2bnz21en PDFDokument6 Seiten2 BNZ 21 en - 2bnz21en PDFMuhammad RidwanNoch keine Bewertungen

- MetaglasDokument1 SeiteMetaglascristiano mosqueiraNoch keine Bewertungen

- 1003D SchwimmermagnetschalterDokument36 Seiten1003D SchwimmermagnetschalterSaroNoch keine Bewertungen

- Technisches Datenblatt PA6-E: Physikalische EingenschaftenDokument1 SeiteTechnisches Datenblatt PA6-E: Physikalische EingenschaftenAlessandro WeissNoch keine Bewertungen

- GFT 2015 ManuskriptDokument11 SeitenGFT 2015 Manuskriptotokar2Noch keine Bewertungen

- CBT - Leaflets - Bảo ôn NeodulDokument2 SeitenCBT - Leaflets - Bảo ôn NeodulNguyễn Long ThịnhNoch keine Bewertungen

- H2021 - Teil B L"sungDokument5 SeitenH2021 - Teil B L"sungSebastian VoigtNoch keine Bewertungen

- Sikaflex 252Dokument2 SeitenSikaflex 252pmNoch keine Bewertungen

- Dustex 25L - 35L - 20221018Dokument287 SeitenDustex 25L - 35L - 20221018Andres GutierrezNoch keine Bewertungen

- SGL Datenblatt SIGRAFLEX ECONOMY DE PDFDokument4 SeitenSGL Datenblatt SIGRAFLEX ECONOMY DE PDFnarayan46Noch keine Bewertungen

- RAVENOL Motogear SAE 10W30 GL4 0Dokument1 SeiteRAVENOL Motogear SAE 10W30 GL4 0AnimalNoch keine Bewertungen

- RW Ultramid B3S deDokument2 SeitenRW Ultramid B3S demuamerNoch keine Bewertungen

- TDS TS014 Badamid A70Dokument2 SeitenTDS TS014 Badamid A70oberta.andrzejNoch keine Bewertungen

- 08-Bemessung Von Stahlbauteilen Nach Din 18800Dokument5 Seiten08-Bemessung Von Stahlbauteilen Nach Din 18800ceca89Noch keine Bewertungen

- TV 200 Sliding PDFDokument52 SeitenTV 200 Sliding PDFMohamed BadraNoch keine Bewertungen

- Produktdatenblatt Kooltherm K5 PDFDokument2 SeitenProduktdatenblatt Kooltherm K5 PDFLeoNoch keine Bewertungen

- L329DEDokument8 SeitenL329DEMahmoud NasrNoch keine Bewertungen

- Exercise To DistillationDokument14 SeitenExercise To DistillationksdfkslNoch keine Bewertungen

- Handbuch CastolinDokument47 SeitenHandbuch CastolinPeterD100% (1)

- 2007 04 26 Vortrag Zink Nickel Beschichtung Gegenwart Und ZukunftDokument36 Seiten2007 04 26 Vortrag Zink Nickel Beschichtung Gegenwart Und ZukunftalbertoNoch keine Bewertungen

- Nanodur-Compound-5941 2017 1 DDokument4 SeitenNanodur-Compound-5941 2017 1 DjulioNoch keine Bewertungen

- K460de PDFDokument12 SeitenK460de PDFMogos PaulNoch keine Bewertungen

- 506710D KotikaDokument2 Seiten506710D KotikaRafael Wellington MacedoNoch keine Bewertungen

- TV 400 HINGED PDFDokument36 SeitenTV 400 HINGED PDFMohamed BadraNoch keine Bewertungen

- MNF 00001 GeDokument4 SeitenMNF 00001 GeMario BarbarićNoch keine Bewertungen

- Tds Elbeblue Line Sbu 078 2016-09 deDokument1 SeiteTds Elbeblue Line Sbu 078 2016-09 dedobleNoch keine Bewertungen

- 6SL2065 LJFDokument3 Seiten6SL2065 LJFaviexltdNoch keine Bewertungen

- Eupen LV Cable - N2XH-B2caDokument3 SeitenEupen LV Cable - N2XH-B2caTadala MaluwaNoch keine Bewertungen

- Mat Chem Comp deDokument50 SeitenMat Chem Comp deNicolas AguilarNoch keine Bewertungen

- Technisches Datenblatt Loctite 243Dokument4 SeitenTechnisches Datenblatt Loctite 243Chris HaNoch keine Bewertungen

- EC0401Dokument3 SeitenEC0401Marcos González FernándezNoch keine Bewertungen