Beruflich Dokumente

Kultur Dokumente

ID

ID

Hochgeladen von

Igor PopovskiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ID

ID

Hochgeladen von

Igor PopovskiCopyright:

Verfügbare Formate

Text Project no. Document No.

Revision Page

Anslutningar och dimensioner GSS67 K490 60203601 003 1/2

Connections with dimensions GSS67 Status Date Sign. Approved

Anschlüsse mit Dimensionen GSS67 Frisläppt 2017-05-29 ORSV NIKR

Mått till anslutningar se ritning 60202594 & 60202622

Measurement to connections see drawing 60202594 & 60202622

Massangaben zu den Anschlüssen siehe Zeichnung 60202594 & 60202622

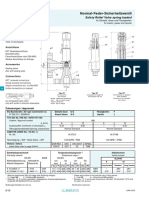

ANSLUTNINGAR DIMENSIONER GSS67 GSS67N

Pos CONNECTIONS DIMENSIONS GSS67 Compatible Use

no ANSCHLÜSSE DIMENSIONEN GSS67 with adapter

1. Ånginlopp vanlig placering DN 25, ISO G1 (S3: TC50)

Steam Inlet Standard Placement DN 25, ISO G1 (S3: TC50) X

Türkisches Einlass Norm - Platzierung DN 25, ISO G1 (S3: TC50)

2. Matar vatten DN 20, ISO G ¾

Feed Water DN 20, ISO G ¾ ¾ NPT

Speisewasser DN 20, ISO G ¾

3. Kallvatteninlopp DN 20, ISO G ¾

Cold Water Inlet DN 20, ISO G ¾ ¾ NPT

Kaltwassereinlass DN 20, ISO G ¾

4. Ånginlopp med alternativ: DN 25, ISO G1 (S3: TC50)

automatisk stängning eller EG-modell kombinerad ånga

Steam Inlet with Option: DN 25, ISO G1 (S3: TC50) X

Automatic close or EC Model Combined steam

Dampf Inlet mit der Wahl: DN 25, ISO G1 (S3: TC50)

Automatische schließen oder EC-Modell Kombi-Dampf

5. Inkommande luften på L-program utan SIP eller WIT DN 15, ISO G-½

(S2, S4)

Incoming air on L program without SIP or WIT (S2, S4) DN 15, ISO G-½ ½ NPT

Zuluft auf L-Programm ohne SIP oder WIT (S2, S4) DN 15, ISO G-½

6. Säkerhetsventil kammare slang DN 25, ISO G1

Safety valve chamber hose DN 25, ISO G1 X

Sicherheitsventil Dreikammerschlauch DN 25, ISO G1

7. Säkerhetsventil Mantel slang DN 25, ISO G1

Safety valve jacket hose DN 25, ISO G1 X

Sicherheitsventil Mantelschlauch DN 25, ISO G1

8. Avlopp DN 65, ISO G 2 ½

Drain DN 65, ISO G 2 ½ X

Ablauf DN 65, ISO G 2 ½

9. Säkerhetsventil ångpanna slang 35 mm EU,AU 1 ¼” JP 1” US (D) 1”US(E) ¾”

Safety valve steam boiler hose 35 mm EU,AU 1 ¼” JP 1” US (D) 1”US(E) ¾”

Sicherheitsventil Dampfkessel Schlauch 35 mm EU,AU 1 ¼” JP 1” US (D) 1”US(E) ¾”

10. Kylvatten inlopp DN 25, ISO G1

Cooling water inlet DN 25, ISO G1 X

Kühlwassereingangsdruck DN 25, ISO G1

11. Retur kylvatten DN 25, ISO G1

Cooling water return DN 25, ISO G1 X

Kühlwasserrücklauf DN 25, ISO G1

12. Kondensat avkastning DN 20, ISO G ¾

Condensate return DN 20, ISO G ¾ ¾ NPT

Kondensatrücklauf DN 20, ISO G ¾

13. Lufttillförsel vanlig placering DN 8, ISO G ¼

Air supply standard placement DN 8, ISO G ¼ X

Luftversorgung Standard Platzierung DN 8, ISO G ¼

60203601 Rev. 003

Text Project no. Document No. Revision Page

Anslutningar och dimensioner GSS67 K490 60203601 003 2/2

Connections with dimensions GSS67 Status Date Sign. Approved

Anschlüsse mit Dimensionen GSS67 Frisläppt 2017-05-29 ORSV NIKR

14a/b 14a&14b Inkommande luft SIP med elskåp placering A DN 15, ISO G ½

(S3)

14a&14b Incoming air SIP with electrical cabinet DN 15, ISO G ½ ½ NPT

placement A (S3)

14a&14b Zuluft SIP mit Schaltschrank Platzierung A DN 15, ISO G ½

(S3)

15a/b 15a&15b Inkommande luft WIT (S3) DN 15, ISO G ½

15a&15b Incoming air WIT (S3) DN 15, ISO G ½ ½ NPT

15a&15b Zuluft WIT (S3) DN 15, ISO G ½

16a/b 16a&16b Inkommande luft med EFF WIT alternativet DN 15, ISO G ½

(S2, S4)

16a&16b Incoming air with EFF WIT option (S2, S4) DN 15, ISO G ½ ½ NPT

16a&16b Zuluft mit EFF WIT Wahl (S2, S4) DN 15, ISO G ½

17. Inkommande högtrycksånga SSG DN 20, ISO G ¾

Incoming high pressure steam SSG DN 20, ISO G ¾ ¾ NPT

Eingehende Hochdruckdampfes SSG DN 20, ISO G ¾

18a/b 18a&18b Elkraft box anslutning

18a&18b Electrical power box connection

18a&18b Stromkasten Verbindung

19. Avloppsbrunn Ø200 mm

Draining gutter Ø200 mm

instructionEingehende Bodenablauf Ø200 mm

20. Ventilationsstosar, ansluts till ventilationssystem. ∅ 50,8 mm

Ventilation connections shall be connected to ∅ 50,8 mm

ventilation system.

Entlüftungsrohr soll an das Ventilationssystem ∅ 50,8 mm

angeschlossen werden.SSG

21. Internet-anslutning (SIEMENS OR A&B) - Alternativ RJ45 CAT Cable

Internet connection (SIEMENS OR A&B) - Option RJ45 CAT Cable

Internet-Anschluss (SIEMENS OR A&B) – Wahl RJ45 CAT Cable

(a) Internet-anslutning (B&R) - Ovanför kammaren RJ45 CAT Cable

Internet connection (B&R) – Above the Chamber RJ45 CAT Cable

Internet-Anschluss (B&R) - Über der Kammer RJ45 CAT Cable

(b) Internet-anslutning (B&R) - Bredvid kammar RJ45 CAT Cable

Internet connection (B&R) - Beside the Chamber RJ45 CAT Cable

Internet-Anschluss (B&R) - Neben der Kammer RJ45 CAT Cable

22. Vakuumrör DN 40, ISO G 1 ½

Vacuum pipe DN 40, ISO G 1 ½ X

Vakuumrohr DN 40, ISO G 1 ½

23. Kylning ångkondensat DN 20, ISO G ¾

Cooling steam condensate DN 20, ISO G ¾ ¾ NPT

Kühldampfkondensat DN 20, ISO G ¾

60203601 Rev. 003

Revision History Page 3

Rev. By Date Description

1 JCN 2015-12-21 First issue of Page 3

2 RA 2016-08-30 Electrical Data, required supply fuse for Integral Electrical Steam Generator modified

3 JCN 2016-09-08 Added info "Drying is not included" to Note 2.

Electrical Data, required supply fuse9 modified according to R11408. Corrected

4 NZ 2016-11-14 product name. Deleted [G....] and added [XZMM0000..] No

5 BST 2018-12-19 Updated references to EN 285 and update air pressure range

Consumption/cycle 2 Supply

67F10 67F13

Ref1 Connection E 1/2 1/1 E 1/2 1/1 Peak/h Condition Size

1 Steam (kg) 6 9,5 12 6,5 11,5 15,5 80 2,5-4,5 bar 12, 13 1 1/4" DN32

3 Potable Water (l) 112 160 185 131 188 228 2000 3-6 bar,<20°C 3/4" DN20

13 Compressed Air (nm³) 0,2 0,2 0,2 0,2 0,2 0,2 4 5-8 bar 1/4" DN8

8 Drain (l) 118 170 197 138 200 244 3000 <70°C 1 1/2" DN40

Option Condensate Return [XZMM000015]

12 Condensate Return (l) 0,5 0,6 0,7 0,7 0,85 0,95 110 max lift 5m 3/4" DN20

Option Chilled Water Recirculation [XZMM000020]

3 Potable Water (l) 10 10 10 10 10 10 2000 3-6 bar,<20°C 3/4" DN20

10 Chilled Water5 (l) - - - - - - 5000 Δp>0,5bar 1" DN25

Cooling Energy to Chilled Water

System (kWh) 6 9 10 6,5 10 12 200 Δp>0,5bar 1" DN25

Option Integral Electrical Steam Generator

1 Steam (kg) 0 0 0 0 0 0 0 N/A N/A

2 Feed Water (l) 6 9,5 12 6,5 11,5 15,5 600 3-6 bar,<20°C 3/4" DN20

Option Integral Steam to Steam Generator

1 Steam (kg) 0 0 0 0 0 0 0 N/A N/A

17 Steam (kg) 7 11 14 7 14 17,5 100 6-8 bar 3/4" DN20

2 Feed Water (l) 6 9,5 12 6,5 11,5 15,5 600 3-6 bar,<20°C 3/4" DN20

Performance and Dimensions

Process Time, metal load 2,4 (h:mm) 0:20 0:25 0:27 0:23 0:29 0:32

Process Time, textile load 3,4 (h:mm) - - 0:33 - - 0:37

Usable Space (WxHxL) (mm) 660x611x1000 660x611x1300

Chamber Capacity (STU) 6 8

Weight (kg) 880 960

Sound Power Level LwA 6 (dBA) 80 80

EN 285:2015 and ISO 3746:2010

Sound Pressure Level LpA 6 (dBA) <70 <70

Heat Generation 7 (kW) 2,4 2,7

Option Integrated Electrical Steam Generator, Option Integrated Steam to Steam Generator

Weight 8 (kg) 970 1050

Heat Generation 7 (kW) 3,3 3,6

Option Air Detector [XZMM000022]

(mbar/ 10

Air Detector Leak min) 35-40 35-40

Test Probe insertion (mm) 120 120

Electrical Data, required supply fuse 9

Central Steam Supply as standard or Integrated Steam-to-Steam converter

3x200V 50/60 Hz 20A 20A

3x208V 50 Hz 20A 20A

3x208V 60 Hz 20A 20A

3x220V 50 Hz 20A 20A

3x220V 60 Hz 20A 20A

3x380V 50 Hz 16A 16A

3x380V 60 Hz 16A 16A

3x400V 50 Hz 16A 16A

TN-S system;

3x400V 60 Hz 16A 16A

3 phases + protective earth (PE)

3x415V 50 Hz 16A 16A

3x415V 60 Hz 16A 16A

3x440V 60 Hz 16A 16A

3x460V 60 Hz 16A 16A

3x480V 60 Hz 16A 16A

3x600V 60 Hz 10A 10A

Power(kWh) 10 0,5 0,53 0,55 0,6 0,7 0,75

Peak(kW) 3,5 3,5

Integrated Electrical Steam Generator or Combined Central Steam/Integrated Electrical Steam Generator

3x200V 50/60 Hz 160A 160A

3x208V 50 Hz 200A 200A

3x208V 60 Hz 200A 200A

3x220V 50 Hz 160A 160A

3x220V 60 Hz 160A 160A

3x380V 50 Hz 80A 80A

3x380V 60 Hz 100A 100A

3x400V 50 Hz 100A 100A

TN-S system;

3x400V 60 Hz 100A 100A

3 phases + protective earth (PE)

3x415V 50 Hz 100A 100A

3x415V 60 Hz 100A 100A

3x440V 60 Hz 80A 80A

3x460V 60 Hz 80A 80A

3x480V 60 Hz 80A 80A

3x600V 60 Hz 80A 80A

Power(kWh) 10 3,6 6,6 8,3 4,7 8,8 10,9

Peak(kW) 57 57

Notes

1

Reference to typical installation drawing

2

Metal load according to EN285-23.5, vacuum level 85 mbar; E-Empty chamber, no load; 1/2-Half load; 1/1-Full load. 15 kg/STU. P1 program. Drying is

not included.

3

Textile load according to EN285-23.4, vacuum level 85 mbar; E-Empty chamber, no load; 1/2-Half load; 1/1-Full load. 7,5 kg/STU. P1 program.

4

Reference measurement point is located 95 mm below bottom of the chamber, position of controlling temperature sensor

5

Chilled water @ΔT=40°C

6

Maximum impulsive noise index for 67F10-67F13 : 5,0

7

Total heat thermal power released from sterilizer with empty chamber and 2 doors both closed at an ambient temp of 23°C ± 2°C. Thermal power

released through the front is 0,65 kW/side with closed door and 1,74 kW/side with open door.

8

Total weight of sterilizer including steam generator

9

Tolerances acc to EN61010-1-1.4.1

10

@400V 50Hz

11

Maximum pressure change rate is less than 10bar/min as required by EN285.

12

Steam supply with pressure in range 3,5-4,5 bar(g) requires jacket safety valve which is optional for EU and CN

13

Steam supply above 3,5 bar(g) is not allowed for Japan

Das könnte Ihnen auch gefallen

- MRT 2150 Service ManualDokument527 SeitenMRT 2150 Service ManualHeavy Equipment Parts Expert100% (14)

- M015200 40EOperational Manual8 12V183TE93Dokument340 SeitenM015200 40EOperational Manual8 12V183TE93wilmer0% (1)

- Din 74 2 PDFDokument5 SeitenDin 74 2 PDFIng Kovács Levente-KálmánNoch keine Bewertungen

- AD2000 Vs EN13445Dokument23 SeitenAD2000 Vs EN13445rodrigoperezsimoneNoch keine Bewertungen

- Savage Worlds - Gentlemen's Edition RevisedDokument233 SeitenSavage Worlds - Gentlemen's Edition RevisedMax Klostermann100% (2)

- Din 24193-2 PDFDokument4 SeitenDin 24193-2 PDFJamie BallNoch keine Bewertungen

- Beton - Herstellung nach Norm: Arbeitshilfe für die Ausbildung, Planung und BaupraxisVon EverandBeton - Herstellung nach Norm: Arbeitshilfe für die Ausbildung, Planung und BaupraxisNoch keine Bewertungen

- 506710D KotikaDokument2 Seiten506710D KotikaRafael Wellington MacedoNoch keine Bewertungen

- Rubrik 7Dokument23 SeitenRubrik 7DAMIR SARAVANJANoch keine Bewertungen

- Hidrant Prezentare KrammmerDokument12 SeitenHidrant Prezentare Krammmeriza66bellNoch keine Bewertungen

- DIN / ISO - Normen Für SD-PART SolutionsDokument19 SeitenDIN / ISO - Normen Für SD-PART SolutionsPeterDonerNoch keine Bewertungen

- Gruppe 2Dokument52 SeitenGruppe 2externalprovided719Noch keine Bewertungen

- Data Sheet Tanque LINDEDokument14 SeitenData Sheet Tanque LINDEM Betzabe MoraNoch keine Bewertungen

- KDG AbsperrklappeDokument7 SeitenKDG AbsperrklappeKemal GokovicNoch keine Bewertungen

- Equipment List - 20090403Dokument42 SeitenEquipment List - 20090403Muneeb QayyumNoch keine Bewertungen

- 437 LeserDokument3 Seiten437 LeserIndra GabeNoch keine Bewertungen

- DIN 43772 Bei-2 2008-03Dokument19 SeitenDIN 43772 Bei-2 2008-03teonesalazarNoch keine Bewertungen

- GOETZE - Safety Valves 852F Product Catalogue10-11Dokument3 SeitenGOETZE - Safety Valves 852F Product Catalogue10-11SAINoch keine Bewertungen

- Katalog 4 Hydraulikkupplungen ТралDokument59 SeitenKatalog 4 Hydraulikkupplungen ТралOlegNoch keine Bewertungen

- GOETZE - Safety Valves 852tF Product CatalogueDokument3 SeitenGOETZE - Safety Valves 852tF Product CatalogueSAINoch keine Bewertungen

- Schottverschraubung PDFDokument1 SeiteSchottverschraubung PDFtica75Noch keine Bewertungen

- Wenn Markierung Dann,: Darstellung Ist EinbaulageDokument1 SeiteWenn Markierung Dann,: Darstellung Ist EinbaulageMario BarbarićNoch keine Bewertungen

- Sicherheitsventil 813Dokument3 SeitenSicherheitsventil 813Armağan AlıcıNoch keine Bewertungen

- Doppelrohr PDFDokument45 SeitenDoppelrohr PDFAdnan ŠkuljNoch keine Bewertungen

- Kat de DP-1Dokument20 SeitenKat de DP-1Sergio Vela GarciaNoch keine Bewertungen

- (DIN 802-3 - 2008-11) - Nach DIN EN ISO 228-1 Tolerancije RP I G Navoja DIN EN 10Dokument11 Seiten(DIN 802-3 - 2008-11) - Nach DIN EN ISO 228-1 Tolerancije RP I G Navoja DIN EN 10zvezdan bilanovicNoch keine Bewertungen

- FRIATEC TK Produktkatalog 2018Dokument168 SeitenFRIATEC TK Produktkatalog 2018BiannaNoch keine Bewertungen

- Ge2 GemelsDokument8 SeitenGe2 GemelsIvan OlivaNoch keine Bewertungen

- Broca WerkoDokument30 SeitenBroca WerkoLuis FelipeNoch keine Bewertungen

- FAMIX Recommended Spare Parts #1713Dokument3 SeitenFAMIX Recommended Spare Parts #1713JerickNoch keine Bewertungen

- Binder Airflex - deDokument18 SeitenBinder Airflex - delacothNoch keine Bewertungen

- Ma-Jic GBDokument2 SeitenMa-Jic GBGeovanny Andres Cabezas SandovalNoch keine Bewertungen

- Guentner CXGDF Data Sheet de enDokument12 SeitenGuentner CXGDF Data Sheet de enRodrigo GonçalvesNoch keine Bewertungen

- Prirubnice Blind FlanscheDokument6 SeitenPrirubnice Blind FlanschemasatusNoch keine Bewertungen

- Hydrocontrol VTR VPR DB 1060103 deDokument10 SeitenHydrocontrol VTR VPR DB 1060103 deIcer_CRONoch keine Bewertungen

- 26 11 15 User Guide GDF0258 0372GDokument56 Seiten26 11 15 User Guide GDF0258 0372GNhân NgọcNoch keine Bewertungen

- Heco Produktblatt 1301 Edelstahl Vorschweissflansche PN 10 Groesser DN 150Dokument6 SeitenHeco Produktblatt 1301 Edelstahl Vorschweissflansche PN 10 Groesser DN 150Martin MoserNoch keine Bewertungen

- Typ 031 TD PDFDokument27 SeitenTyp 031 TD PDFbeneNoch keine Bewertungen

- Bauart 240 Pneumatische Stellventile Typ 3241-1 Und Typ 3241-7 Durchgangsventil Typ 3241Dokument12 SeitenBauart 240 Pneumatische Stellventile Typ 3241-1 Und Typ 3241-7 Durchgangsventil Typ 3241mlachenal5237Noch keine Bewertungen

- Katalog 1 Zylinder 01 PDFDokument60 SeitenKatalog 1 Zylinder 01 PDFWalid AhmedNoch keine Bewertungen

- v71 de File d643 17Dokument103 Seitenv71 de File d643 17sehmediaNoch keine Bewertungen

- 7333-F DE-TIMS-34811 Master-N Stückliste 2023 11 09Dokument12 Seiten7333-F DE-TIMS-34811 Master-N Stückliste 2023 11 09Ilie IvanoviciNoch keine Bewertungen

- Thermo Varioklav 25T - Ersatzteilkatalog PDFDokument26 SeitenThermo Varioklav 25T - Ersatzteilkatalog PDFluisNoch keine Bewertungen

- Thermo Varioklav 25T - ErsatzteilkatalogDokument26 SeitenThermo Varioklav 25T - ErsatzteilkatalogAnthony Casas100% (1)

- Gas Governer VGBFDokument6 SeitenGas Governer VGBFambresh.09Noch keine Bewertungen

- Gfps Datasheet 586 Pressure Retaining Valve deDokument5 SeitenGfps Datasheet 586 Pressure Retaining Valve deKrisNoch keine Bewertungen

- Guntner IsparivaciDokument4 SeitenGuntner IsparivaciSelver SalkicNoch keine Bewertungen

- Brunnbauer-Armaturen: Kugelhahn - 3-Teilig Ball Valve 3-Piece Type 9/011 TYPE 9/013 PN 10 - 250Dokument2 SeitenBrunnbauer-Armaturen: Kugelhahn - 3-Teilig Ball Valve 3-Piece Type 9/011 TYPE 9/013 PN 10 - 250cdiaconuNoch keine Bewertungen

- Armaturen Und ZubehörDokument65 SeitenArmaturen Und ZubehörLeandro ChiodiniNoch keine Bewertungen

- HWZ0002 EngDokument1 SeiteHWZ0002 EngnejibNoch keine Bewertungen

- D SicherungenDokument20 SeitenD SicherungenAli AhmadNoch keine Bewertungen

- MatadorDokument8 SeitenMatadorGuillermo Velasquez AmasNoch keine Bewertungen

- Rohrzubehoer Flansche KatalogDokument51 SeitenRohrzubehoer Flansche KatalogfuffinoNoch keine Bewertungen

- Belimo Umschaltventil R3..BLDokument5 SeitenBelimo Umschaltventil R3..BLWolfgangNoch keine Bewertungen

- MB An Normen Din Iso EsDokument2 SeitenMB An Normen Din Iso EsPacoNoch keine Bewertungen

- Din 74-1 PDFDokument5 SeitenDin 74-1 PDFAndronic Cosmin100% (1)

- Schéma Coté Rapido TDokument32 SeitenSchéma Coté Rapido TleplombierducanalNoch keine Bewertungen

- FAMIX Recommended Spare Parts #1711+1712Dokument3 SeitenFAMIX Recommended Spare Parts #1711+1712JerickNoch keine Bewertungen

- (DIN 2245-1-2008-07) - Geometrische Produktspezifikation (GPS) - Grenzlehrdorne - Teil 1 - Für Bohrungen Von 1 MM Bis 40 MM NenndurchmesserDokument6 Seiten(DIN 2245-1-2008-07) - Geometrische Produktspezifikation (GPS) - Grenzlehrdorne - Teil 1 - Für Bohrungen Von 1 MM Bis 40 MM NenndurchmesserAugusto Maury ToledoNoch keine Bewertungen

- Din 98 2003-10 PDFDokument4 SeitenDin 98 2003-10 PDFSrđan KovačNoch keine Bewertungen

- Din 437722000 Trubki Zashchitnye Metallicheskie I UdlinitelnDokument23 SeitenDin 437722000 Trubki Zashchitnye Metallicheskie I Udlinitelngeorge stanley paceteNoch keine Bewertungen

- HutschieneDokument1 SeiteHutschienebeneNoch keine Bewertungen

- CreditsDokument4 SeitenCreditsTomas CostaNoch keine Bewertungen

- Spare Parts - K813HDokument40 SeitenSpare Parts - K813HSergei KurpishNoch keine Bewertungen

- Splitter Mond CharakterbogenDokument2 SeitenSplitter Mond CharakterbogenRich Ie 196Noch keine Bewertungen

- #146 Lavados - Pokédex - Bisafans - deDokument1 Seite#146 Lavados - Pokédex - Bisafans - dejedfNoch keine Bewertungen

- Splittermond CharakterbogenDokument2 SeitenSplittermond CharakterbogenAzalnubizarNoch keine Bewertungen

- Youtube DatasetDokument1.169 SeitenYoutube DatasetVaijayanthi MalaNoch keine Bewertungen