Beruflich Dokumente

Kultur Dokumente

xr44ch PDF

Hochgeladen von

roby72Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

xr44ch PDF

Hochgeladen von

roby72Copyright:

Verfügbare Formate

Digital controller with defrost and fan management 3.2.

1 Sequence activation

With 2CC = SEq the second compressor is activated after a delay counter AC1 ( parameter ). Both

XR44CH compressor are switched off when the temperature set point is reached.

1. GENERAL WARNING __________________________________________________________1 3.2.2 Dual band activation

2. GENERAL DESCRIPTION ______________________________________________________1 With 2CC = HAF the regulation is

3. CONTROLLING LOADS ________________________________________________________1 changed as follows.

4. FRONT PANEL COMMANDS ____________________________________________________2

5. MAX & MIN TEMPERATURE MEMORIZATION _____________________________________2 a. Activation of

6. DUAL TEMPERATURE FUNCTION _______________________________________________2 compressors

7. MAIN FUNCTIONS ____________________________________________________________2 The activation threshold of the first

8. PARAMETERS _______________________________________________________________3 compressor is (where T is

9. DIGITAL INPUTS _____________________________________________________________4 temperature):

10. TTL SERIAL LINE – FOR MONITORING SYSTEMS _________________________________4 T> SET + Hy

11. INSTALLATION AND MOUNTING ________________________________________________4 The activation threshold of the

12. ELECTRICAL CONNECTIONS___________________________________________________4 second compressor is (where T is

13. USE THE HOT KEY ___________________________________________________________4 temperature) :

14. ALARM SIGNALS _____________________________________________________________5 T>SET+Hy+Hy2

15. TECHNICAL DATA ____________________________________________________________5

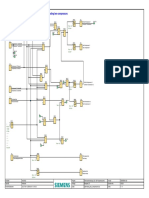

16. CONNECTIONS ______________________________________________________________5

17. DEFAULT SETTING VALUES ___________________________________________________5 The second compressor is activated in any case only if the AC1 timer has already expired, where AC1

is the delay between the activation of two compressors

1. GENERAL WARNING b. Deactivation of compressors

The second compressor is switched off when the temperature drops below

T <SET + Hy

1.1 PLEASE READ BEFORE USING THIS MANUAL

The first compressor is turned off when:

This manual is part of the product and should be kept near the instrument for easy and quick T<SET

reference.

The instrument shall not be used for purposes different from those described hereunder. It ROTATION

cannot be used as a safety device. Once both the compressors are switched off, the activation order of the 2 compressors is reversed in

Check the application limits before proceeding. order to balance the working hours.

Dixell Srl reserves the right to change the composition of its products, even without notice, A cycle is considered as completed even if only one compressor is switched on and off: that is, when

ensuring the same and unchanged functionality. the temperature exceeds the first activation threshold, (SET + HY) and then latter returns below the

value of the set point (SET).

1.2 SAFETY PRECAUTIONS

STALL PREVENTION

Check the supply voltage is correct before connecting the instrument.

The Mon parameter defines the maximum time a single compressor can run continuously. When the

Do not expose to water or moisture: use the controller only within the operating limits avoiding

Mon timer expires the other compressor is activated, to increase capacity and therefore to reduce the

sudden temperature changes with high atmospheric humidity to prevent formation of

temperature, both the compressors are switched off at the same time when the SET point is reached

condensation

Warning: disconnect all electrical connections before any kind of maintenance.

Fit the probe where it is not accessible by the End User. The instrument must not be opened. 3.3 DEFROST

In case of failure or faulty operation send the instrument back to the distributor or to “Dixell S.r.l.”

(see address) with a detailed description of the fault. 3.3.1 THE PRE-DEFROST CYCLE

Consider the maximum current which can be applied to each relay (see Technical Data). A pre-defrost cycle, to cool deeper the goods before the defrost can be managed.

Ensure that the wires for probes, loads and the power supply are separated and far enough from If it is enabled the temperature set point (SET) becomes: SET+Hd1 for Ht1 mins, then the defrost

each other, without crossing or intertwining. starts.

In case of applications in industrial environments, the use of mains filters (our mod. FT1) in The pre-defrost cycle cannot be performed if the defrost is started manually by keyboard.

parallel with inductive loads could be useful. 3.3.2 THE POST- DEFROST CYCLE

After defrost and dripping time, a post defrost cycle can be managed.

2. GENERAL DESCRIPTION If it is enabled the temperature set point (SET) becomes: SET+Hd2 for Ht2 mins, then the standard

Model XR44CH, format 32 x 74 mm, is microprocessor based controller, suitable for applications on regulation starts..

low temperature refrigerating units. It has four relay outputs to control compressor 1 and 2, defrost 1 If enabled, the post defrost cycle si always done.

and 2, which can be either electrical or reverse cycle (hot gas). It is also provided with up to three NTC 3.3.3 DEFROST MODES

or PTC probe inputs, the first one for temperature control, the second and third one, to be located onto Two defrost modes are available through the tdF parameter: defrost through electrical heater

the evaporator, to control the defrost termination temperature on the evaporator 1 and 2. (tdF=EL) and hot gas defrost (tdF=in). In this case by the parameter StC (0÷15min) the compressor

It allows to program the controller by means the HOT KEY programming keyboard. can be stopped before the defrost. The compressor is stopped after the pre-defrost cycle.

3. CONTROLLING LOADS Other parameters are used to control the interval between defrost cycles (idF), its maximum length

(MdF) and two defrost modes: timed or controlled by the evaporator’s probe (P2P).

3.1 COMPRESSOR At the end of defrost dripping time is started, its length is set in the Fdt parameter. With Fdt=0 the

dripping time is disabled.

The regulation is performed according to Temper.

the temperature measured by the

thermostat probe with a positive 3.3.4 SECOND EVAPORATOR CONTROL AND EVAPORATORS CYCLING WITH HOT GAS

SET DEFROST

differential from the set point: if the

temperature increases and reaches set With tdF = ALt a hot gas defrost with double evaporator is managed. The 2 evaporators are

point plus differential the compressor is

Time alternated according to the following indications:

started and then turned off when the Compr. a. After IdF the COMP+DEF1 are activated

temperature reaches the set point value ON b. After IdF the COMP+DEF2 are activated

again. c. After IdF the COMP+DEF1 are activated

In case of fault in the thermostat probe the start and stop of the compressor are timed through

parameters Con and CoF. 3.4 CONTROL OF EVAPORATOR FANS

3.2 SECOND COMPRESSOR MANAGEMENT The fan control mode is selected by means of the FnC parameter:

The relay of the second compressor is activated according to the settings of the following parameters. FnC=C_n, fans will switch ON and OFF with the compressor and not run during defrost.

The 2CC (SEq; HAF), defines how the second compressor is activated. FnC=o_n, fans will run even if the compressor is off, and not run during defrost.

After defrost, there is a timed fan delay allowing for drip time, set by means of the Fnd parameter.

FnC=C_Y, fans will switch ON and OFF with the compressor and run during defrost.

FnC=o_Y, fans will run continuously also during defrost.

An additional parameter FSt provides the setting of temperature, detected by the evaporator probe,

above which the fans are always OFF. This is used to make sure circulation of air only if his

temperature is lower than set in FSt.

3.4.1 Forced activation of fans

This function managed by the FCt parameter is designed to avoid short cycles of fans, that could

happen when the controller is switched on or after a defrost, when the room air warms the evaporator.

How it works: if the temperature difference between evaporator probe and room probe is higher than

the FCt parameter value, fans will be switched on. With FCt=0 the function is disabled.

1598040181 XR44CH ISA GB r16.8 27.04.2017 XR44CH 1/6

3.4.2 Cyclical activation of the fans with compressor off. LED MODE FUNCTION

When FnC=C-n or C-Y (fans working in parallel with the compressor), by means of the Fon and FoF Flashing Fans delay after defrost in progress.

parameters the fans can carry out on and off cycles even if the compressor is switched off. When the ECO ON Energy saving enabled

compressor is stopped the fans go on working for the Fon time. With Fon=0 the fans remain always AUX ON AUX relay on

off, also when the compressor is off. Flashing Fan stopped by key

3.4.3 Forced activation of fans

This function managed by the Fct parameter is designed to avoid short cycles of fans, that could

happen when the controller is switched on or after a defrost, when the room air warms the evaporator. 5. MAX & MIN TEMPERATURE MEMORIZATION

Functioning: if the difference of temperature between the evaporator and the room probes is more

than the value of the Fct parameter, the fans are switched on. With Fct=0 the function is disabled. 5.1 HOW TO: SEE THE MIN TEMPERATURE

3.4.4 Double humidity function

By means of the parameter FSU is possible to set different actions of the fan.

1. Press and release the DOWN key.

With FSU = Std the fan operates according to Fnc parameter 2. The “Lo” message will be displayed followed by the minimum temperature recorded.

3. By pressing the DOWN key again or by waiting 5 sec the normal display will be restored.

With FSU = Fon, FNC = C-n or C-Y and i1F = FAn or by UP key pushed for 3s is possible to perform 5.2 HOW TO: SEE THE MAX TEMPERATURE

a double humidity action: when the digital input is activated, it keeps evaporator fan continuously

working, when d.i. is disable the fan works with compressor. 1. Press and release the UP key.

2. The “Hi” message will be displayed followed by the maximum temperature recorded.

NOTE2: With this function enabled the LED flashes.

3. By pressing the UP key again or by waiting 5 sec the normal display will be restored.

With FSU = FoF and i1F = FAn or by UP key pushed for 3s when the digital input is activated, it stops 5.3 HOW TO: RESET THE MAX AND MIN TEMPERATURE RECORDED

the fan, when d.i. is disable the fan works according to the FnC parameter. 1. Keep the SET key pressed more than 3 sec, while the max or min temperature is displayed.

(“rSt” message will be displayed)

NOTE2: With this function enabled the LED flashes. 2. To confirm the operation the “rSt” message will start blinking and the normal temperature will be

displayed.

3.5 DRIPPING HEATERS 6. DUAL TEMPERATURE FUNCTION

With oAx=HEt, the relay will work as dripping heater to eliminate the humidity/water after a defrost. 6.1.1 How to see which temperature function is used

The relay is on during Stc time and for hot gas defrost during defrost and dripping time.

Push and release the key, controller will display:

4. FRONT PANEL COMMANDS - Pt: positive temperature

- Lt: negative temperature

6.1.2 How to switch from LT to PT and vice versa

To modifiy the operating temperature, keep pushed for 5s the key within the first minute after

start up: controller will move from negative temperature (LT) to positive temperature (Pt) and vice

versa.

NB: after switching the temperature the controller is switched off and on to load the new configuration.

7. MAIN FUNCTIONS

7.1 HOW TO: SEE THE SET POINT

1. Push and immediately release the SET key: the display will show the Set

point value.

To display target set point; in programming mode it selects a parameter or confirm 2. Push and immediately release the SET key or wait for 5 sec to display

an operation. the probe value again.

Dual temperature function

Pushed for 5s within the first min after power on, it switches from negative 7.2 HOW TO CHANGE THE SET POINT

temperature (Lt) to positive temperature (Pt) 1. Push the SET key more than 2 sec to change the Set point value.

(UP/Dual Humidity)In programming mode it browses the parameter codes or 2. The value of the set point will be displayed and the “°C” or “°F” LED will start blinking.

increases the displayed value. 3. To change the Set value push the UP or DOWN arrows within 10 sec.

Hold pushed for 5s enable/disabled the fan according to the setting. 4. To save the new set point value, push the SET key again or wait for 10 sec.

(DOWN) In programming mode it browses the parameter codes or decreases the 7.3 HOW TO START A MANUAL DEFROST

displayed value.

Hold pushed for 5s to start a manual defrost

Hold pushed for 5s to switch the instrument on and off (when onF=oFF). Push the key for more than 2 sec and a manual defrost will start.

7.4 HOW TO: CHANGE A PARAMETER VALUE

To switch on and off the light output (if present).

To change a parameter value, operate as follows:

1. Enter the Programming mode by pressing the SET+DOWN buttons for 3s (the °C or °F LED will

start blinking).

KEY COMBINATIONS:

2. Select the required parameter. Press the SET button to display its actual value.

3. Use UP or DOWN buttons to change its value.

To lock & unlock the keyboard. 4. Press SET button to store the new value and move to the following parameter.

+

To exit: Press SET + UP buttons or waiting for 15s without pressing any key.

To enter in programming mode.

+ NOTE: the set value is stored even when the procedure is exited by waiting for the time-out to expire.

7.5 THE HIDDEN MENU

To return to the room temperature display.

+ The hidden menu includes all the parameters of the instrument.

7.5.1 HOW TO: ENTER THE HIDDEN MENU

4.1 USE OF LEDS

1. Enter the Programming mode by pressing the SET+DOWN buttons for 3 sec (the °C or °F LED will

Each LED function is described in the following table. start blinking).

2. Released the buttons and then push again the SET+DOWN buttons for more than 7s. The Pr2

LED MODE FUNCTION label will be displayed immediately followed from the HY parameter.

ON Compressor enabled Now it is possible to browse the hidden menu.

Flashing Anti-short cycle delay enabled 3. Select the required parameter.

ON Defrost enabled 4. Press the SET button to display its value.

Flashing Drip time in progress 5. Use UP or DOWN to change its value.

ON An alarm is occurring 6. Press SET to store the new value and move to the following parameter.

ON Continuous cycle is running

To exit: Press SET+DOWN or wait 15 sec without pressing a key.

ON Measurement unit

°C/°F

Flashing Programming phase NOTE1: if no parameter is present in Pr1 menu, after 3 sec the “noP” message will be displayed.

ON Fans enabled Keep the buttons pushed till the Pr2 message will be displayed.

1598040181 XR44CH ISA GB r16.8 27.04.2017 XR44CH 2/6

DISPLAY

NOTE2: the set value is stored even when the procedure is exited by waiting for the time-out to expire

CF Temperature measurement unit: (°C; °F) °C = Celsius; °F = Fahrenheit.

WARNING: When the measurement unit is changed the SET point and the values of the

7.5.2 HOW TO: MOVE A PARAMETER FROM THE HIDDEN MENU TO THE FIRST LEVEL AND

parameters HY, LS, US, ot, ALU and ALL have to be checked and modified (if

VICEVERSA.

necessary).

Each parameter present in the hidden menu (Pr2) can be moved into the user level (Pr1) by pressing rES Resolution (for °C): (in=1°C; dE=0.1°C) allows decimal point display.

SET+DOWN buttons. If a parameter is part of the user level, when showed in the hidden menu the Lod Instrument display: (P1; P2, P3, P4, SET, dtr) it selects which probe is displayed by the

decimal point will be lit. instrument. P1 = Thermostat probe; P2 = Evaporator probe; P3 = Third probe (only for

model with this option enabled); P4 = Fourth probe, SET = set point; dtr = percentage of

7.6 HOW TO: LOCK THE KEYBOARD

visualization.

1. Keep both UP and DOWN buttons pressed for more than 3 sec. rEd X- REP display (optional): (P1; P2, P3, P4, SET, dtr): it selects which probe is

2. The “PoF” message will be displayed and the keyboard will be locked. At this point it will be displayed by X- REP: P1 = Thermostat probe; P2 = Evaporator probe; P3 = Third

possible only to see the set point or the MAX o Min temperature stored probe(only for model with this option enabled); P4 = Fourth probe, SET = set point; dtr =

3. If a button is pressed more than 3 sec the “PoF” message will be displayed percentage of visualization.

dLy Display delay: (0 ÷20.0m; risul. 10s) when the temperature increases, the display is

7.7 HOW TO: UNLOCK THE KEYBOARD updated of 1 °C/1°F after this time.

dtr Percentage of the third and first probe for visualization when Lod = dtr (0÷100; 100

Keep pressed together for more than 3 sec the UP and DOWN keys till the “Pon” message will be

= P1, 0 = P3 ): if Lod = dtr it allows to set the visualization according to the percentage

displayed.

of the first and third probe, as for the following formula (dtr(P1-P3)/100 + P3).

7.8 THE CONTINUOUS CYCLE DEFROST

When defrost is not in progress, it can be activated by holding the UP key pressed for about 3 sec.

tdF Defrost type: (EL; in) EL = electrical heater; in = hot gas.

The compressor operates to maintain the CCS set point for the time set through the CCt parameter.

dFP Probe selection for first defrost termination: (nP; P1; P2; P3; P4) nP = no probe;

The cycle can be terminated before the end of the set time using the same activation key UP for 3 sec.

P1 =thermostat probe; P2 = second probe; P3 =configurable probe; P4 = Fourth probe.

7.9 THE ON/OFF FUNCTION dSP Probe selection for second defrost termination: (nP; P1; P2; P3; P4) nP = no probe;

P1 =thermostat probe; P2 = second probe; P3 =configurable probe; P4 = Fourth probe.

With “onF = oFF”, pushing the ON/OFF key, the instrument is switched off. The “OFF” dtE First defrost termination temperature: (-55 to 50°C; -67 to 122°F) (enabled only when

message is displayed. In this configuration, the regulation is disabled. EdF=Pb) sets the temperature measured by the evaporator probe, which causes the end

To switch the instrument on, push again the ON/OFF key. of defrost.

WARNING: Loads connected to the normally closed contacts of the relays are always supplied

dtS Second defrost termination temperature: (-55 to 50°C; -67 to 122°F) (enabled only

and under voltage, even if the instrument is in stand by mode.

when EdF=Pb) sets the temperature measured by the evaporator probe, which causes

7.10 SECOND DIGITAL INPUT OR PROBE 4. the end of defrost.

idF Interval between defrost cycles: (0 to 120 hours) determines the interval of time

The input normally used as fourth probe can be used as second digital input according to the setting of between two defrost cycles.

the parameter P4C. MdF (Maximum) length for first defrost: (0 to 255 min) when P2P=n, (not evaporator probe:

With P4C = Pb the input works as probe. timed defrost) it sets the defrost duration. When P2P=Y (defrost end based on

With P4C = i2F the input works as second digital input (par. i2F) temperature) it sets the maximum length for defrost.

MdS (Maximum) length for second defrost: (0 to 255 min) when P2P=n, (not evaporator

8. PARAMETERS probe: timed defrost) it sets the defrost duration. When P2P=Y (defrost end based on

temperature) it sets the maximum length for defrost.

REGULATION dSd Start defrost delay: (0 to 99 min) this is useful when different defrost start times are

HY Differential: (0.1 to 25.5°C; 1 to 45°F) intervention differential for set point. Compressor necessary to avoid overloading the plant.

Cut IN is Set Point + differential (HY). Compressor Cut OUT is when the temperature Compressor stop before defrost: (da 0 a 30 min) with hot gas defrost it sets

StC

reaches the set point. compressor stop vefore defrost.

Hy2 Second compressor differential (0.1°C to 25.5°C; 0 to 45°F): intervention differential dFd Temperature displayed during defrost: (rt; it; SEt; dEF) rt = real temperature;

for second compressor. Hy2 is added to SET+Hy: second compressor is ON when the it = temperature at defrost start; SEt = set point; dEF = “dEF” label.

temperature reaches set+Hy+Hy2 and second compressor is OFF when the dAd MAX display delay after defrost: (0 to 255 min) sets the maximum time between the

temperature returns to the set point value (2CC = SEQ) or SET+Hy (2CC = HAF). end of defrost and the restarting of the real room temperature display.

LS Minimum set point: (-100°C to SET; -148°F to SET) sets the minimum value for the Fdt Drip time: (0 to 120 min) time interval between reaching defrost termination temperature

set point. and the restoring of the control’s normal operation. This time allows the evaporator to

US Maximum set point: (SET to 150°C; SET to 302°F) set the maximum value for set eliminate water drops that might have formed due to defrost.

point. dPo First defrost after start-up: (n; Y) n = after the idF time, Y = immediately.

ot Thermostat probe calibration: (-12.0 to 12.0°C; -21 to 21°F) allows to adjust possible Hd1 Pre-defrost cycle differential (-12.0÷12.0°C/-24÷24°F)

offset of the thermostat probe. Ht1 Pre-defrost cycle duration (0÷120min)

P2P First evaporator probe presence: (n; Y) n = not present, the defrost stops by time; Hd2 Post-defrost cycle differential (-12.0÷12.0°C/-24÷24°F)

Y = present, the defrost stops by temperature. Ht2 Post-defrost cycle duration (0÷120min)

oE First evaporator probe calibration: (-12.0 to 12.0°C; -21 to 21°F) allows to adjust dAF Defrost delay after continuous cycle: (0.0 to 24h00min, res. 10min) time interval

possible offset of the evaporator probe. between the end of the fast freezing cycle and the following defrost related to it.

P3P Second evaporator probe presence (P3): (n; Y) n = not present, the terminals operate

FANS

as digital input; Y = present, the terminals operate as third probe.

o3 Second evaporator probe calibration (P3): (-12.0 to 12.0°C; -21 to 21°F) allows to FnC Fans operating mode: (C-n; o-n; C-Y; o-Y) C-n = runs with the compressor, OFF during

adjust possible offset of the third probe. defrost; o-n = continuous mode, OFF during defrost; C-Y = runs with the compressor,

P4P Fourth probe presence (P4): (n; Y) n = not present, Y = present ON during defrost; o-Y = continuous mode, ON during defrost.

O4 Fourth probe calibration (P4): (-12.0 to 12.0°C; -21 to 21°F) allows to adjust possible Fnd Fans delay after defrost: (0 to 255min) interval between end of defrost and evaporator

offset of the fourth probe. fans start.

P4C Probe 4 setting (Pb = temperature probe: id4 = second digital input) FCt Temperature differential to avoid fan short cycles: (0 to 59°C; 0 to 90°F) (N.B.: if

odS Outputs activation delay at start up: (0 to 255min) this function is enabled at the initial FCt=0 function disabled) if the difference of temperature between the evaporator and the

start-up of the instrument and inhibits any output activation for the period of time set in room probes is higher than FCt value, the fans will be switched on.

the parameter. FSt Fans stop temperature: (-55 to 50°C; -67 to 122°F) setting of temperature, detected by

AC Anti-short cycle delay for first compressor: (0 to 50 min) minimum interval between evaporator probe, above which fans are always OFF.

the compressor stop and the following restart. Fon Fan ON time: (0÷15 min) with Fnc = C_n or C_y, (fan activated in parallel with

AC1 Anti-short cycle delay for second compressor: (0 to 50 min) minimum interval compressor). it sets the evaporator fan ON cycling time when the compressor is off.

between the compressor stop and the following restart. With Fon =0 and FoF ≠ 0 the fan are always off, with Fon=0 and FoF =0 the fan are

Mon Maximum time single compressor on: (0÷255min; with 0 function not enabled). When always off.

Mon is expired the second compressor is activated. FoF Fan OFF time: (0÷15 min) with Fnc = C_n or C_y, (fan activated in parallel with

2CC Dual compressor management: SEq = sequence – HAF= Dual band compressor). it sets the evaporator fan off cycling time when the compressor is off. With

rtr Percentage of the third and first probe for regulation (0÷100; 100 = P1, 0 = P3 ): it Fon =0 and FoF ≠ 0 the fan are always off, with Fon=0 and FoF =0 the fan are always

allows to set the regulation according to the percentage of the first and third probe, as off.

for the following formula (rtr(P1-P3)/100 + P3) FSU Kind of action of fan:

CCt Compressor ON time during continuous cycle: (0.0 to 24h00min, res. 10 min) allows Std = standard, according to the Fnc parameter

to set the length of the continuous cycle. Compressor stays on without interruption Fon = with i1F = FAn and Fnc = Cn or C-y, by means of digital input the fan works

during CCt time. This is useful, for instance, when the room is filled with new products. according to the Fnc parameter or are always on.

CCS Set point for continuous cycle: (-55 to 150°C; -67 to 302°F) it sets the set point used FoF = with i1F = FAn by means of digital input the fan are enabled or switched off.

during the continuous cycle. ALARMS

Con Compressor ON time with faulty probe: (0 to 255min) time during which the

compressor is active in case of faulty thermostat probe. With Con=0 compressor is ALU MAXIMUM temperature alarm:

always OFF. If ALC=Ab: [ALL to 150.0°C or ALL to 302°F]

CoF Compressor OFF time with faulty probe: (0 to 255min) time during which the If ALC=rE: [0.0 to 50.0°C or 0 to 90°F]

compressor is OFF in case of faulty thermostat probe. With CoF=0 compressor is when this temperature is reached the alarm is enabled, after the ALd delay time.

always active.

1598040181 XR44CH ISA GB r16.8 27.04.2017 XR44CH 3/6

ALL Minimum temperature alarm: 9.2 SERIOUS ALARM MODE (i1F or i2F = BAL)

If ALC=Ab: [-100°C to ALU; -148 to ALU]

If ALC=rE: [0.0 to 50.0°C or 0 to 90°F] When the digital input is activated, the unit will wait for did delay before signalling the CA alarm

when this temperature is reached the alarm is enabled, after the ALd delay time. message. The relay outputs are switched OFF. The alarm will stop as soon as the digital input is de-

AFH Differential for temperature alarm recovery: (0.1 to 25.5°C; 1 to 45°F) intervention activated.

differential for recovery of temperature alarm. 9.3 PRESSURE SWITCH (i1F or i2F = PAL)

ALd Temperature alarm delay: (0 to 255 min) time interval between the detection of an

alarm condition and alarm signalling. If during the interval time set by did parameter, the pressure switch has reached the number of

dAo Exclusion of temperature alarm at start-up: (0.0 to 24h00min, res. 10min) time activation of the nPS parameter; the CA pressure alarm message will be displayed. The compressor

interval between the detection of the temperature alarm condition after instrument power and the regulation are stopped. When the digital input is ON the compressor is always OFF. If the

on and alarm signalling. nPS activation in the did time is reached, switch off and on the instrument to restart normal

regulation.

OUTPUT RELAYS

9.4 DOOR SWITCH INPUT (i1F or i2F = dor)

oA1 First relay configuration AUX1: (dEF; FAn; ALr; LiG; AUS; onF; db; CP2; dEF2) dEF =

defrost; FAn = fans; ALr = alarm; LiG = light; AUS = Auxiliary relay; onF = always on It signals the door status and the corresponding relay output status through the odC parameter:

when instrument on; CP2 = second compressor; dF2 = second defrost, HES= energy no = normal (any change); FAn = Fan OFF; CPr = Compressor OFF; F_C = Compressor and fan

saving. OFF. Since the door is opened, after the delay time set through parameter doA, the door alarm is

oA2 Second relay configuration AUX2: (dEF; FAn; ALr; LiG; AUS; onF; db; CP2; dEF2) enabled, the display shows the message dA and the regulation restarts is rtr=YES. The alarm stops

dEF = defrost; FAn = fans; ALr = alarm; LiG = light; AUS = Auxiliary relay; onF = as soon as the external digital input is disabled again. With the door open, the high and low

always on when instrument on; CP2 = second compressor; dEF2 = second defrost, temperature alarms are disabled.

HES= energy saving.

9.5 START DEFROST (i1F or i2F = dFr)

oA3 Third relay configuration AUX3: (dEF; FAn; ALr; LiG; AUS; onF; db; CP2; dEF2) dEF

= defrost; FAn = fans; ALr = alarm; LiG = light; AUS = Auxiliary relay; onF = always on It starts a defrost if there are the right conditions. After the defrost is finished, the normal regulation will

when instrument on; CP2 = second compressor; dEF2 = second defrost, HES= energy restart only if the digital input is disabled otherwise the instrument will wait until the “MdF” safety time

saving. is expired.

DIGITAL INPUTS 9.6 SWITCH THE AUXILIARY RELAY (i1F or i2F = AUS)

i1P Digital input polarity: (oP; CL) oP = the digital input is activated by opening the contact; With oAx = AUS the digital input activate the auxiliary relay.

CL = the digital input is activated by closing the contact.

i1F Digital input configuration: (EAL; bAL; PAL; dor; dEF; AUS; Htr; FAn; ES) EAL = 9.7 INVERSION OF THE KIND OF ACTION: HEATING-COOLING (i1F or i2F = Htr)

external alarm: “EA” message is displayed; bAL = serious alarm “CA” message is This function allows to invert the regulation of the controller: from cooling to heating and viceversa.

displayed; PAL = pressure switch alarm, “CA” message is displayed; dor = door switch

function; dEF = activation of a defrost cycle; AUS = auxiliary relay activation with 9.8 ENERGY SAVING (i1F or i2F = ES)

oAx=AUS; Htr = type of inverting action (cooling or heating); FAn = fan; ES = energy

saving. The HES parameter is added to the working set; nt = to set from low temperature The Energy Saving function allows to change the set point value as the result of the SET+ HES

(Lt) to positive temperature (Pt); onF = activation of the stand by mode. CC = activation (parameter) sum. This function is enabled until the digital input is activated.

of the continuous cycle. 9.9 ON OFF FUNCTION (i1F or i2F = ONF)

did Digital input alarm delay: (0 to 255 min) delay between the detection of the external

alarm condition and its signalling. with i1F= EAL or i1F = bAL digital input alarm To switch the controller on and off.

delay: delay between the detection of the external alarm condition and its signalling.

9.10 CONTINUOUS CYCLE FUNCTION (i1F or i2F =CC)

When i1F= PAL, it is the interval of time to calculate the number of pressure switch

activation. To start the continuous cycle. The set point value is CCt during CCS time. This is an alternative to the

i2P Second digital input polarity: (oP; CL) oP = the digital input is activated by opening the key.

contact; CL = the digital input is activated by closing the contact.

i2F Second digital input configuration: (EAL; bAL; PAL; dor; dEF; AUS; Htr; FAn; ES) 9.11 DIGITAL INPUT POLARITY

EAL = external alarm: “EA” message is displayed; bAL = serious alarm “CA” message is The digital input polarity depends on the i1P parameter.

displayed; PAL = pressure switch alarm, “CA” message is displayed; dor = door switch i1P = CL: the input is activated by closing the contact.

function; dEF = activation of a defrost cycle; AUS = auxiliary relay activation with i1P = oP: the input is activated by opening the contact

oAx=AUS; Htr = type of inverting action (cooling or heating); FAn = fan; ES = energy

saving. The HES parameter is added to the working set; nt = to set from low temperature 10. TTL SERIAL LINE – FOR MONITORING SYSTEMS

(Lt) to positive temperature (Pt); onF = activation of the stand by mode. CC = activation

of the continuous cycle. The TTL serial line, available through the HOT KEY connector, allows to connect the instrument to a

d2d Second digital input alarm delay: (0 to 255 min) delay between the detection of the monitoring system ModBUS-RTU compatible such as the XWEB500. The connection needs a special

external alarm condition and its signalling. with i2F= EAL or i2F = bAL digital input TTL/RS485 adapter: the XJ485CX.

alarm delay: delay between the detection of the external alarm condition and its

signalling. When i2F= PAL, it is the interval of time to calculate the number of pressure 11. INSTALLATION AND MOUNTING

switch activation. Instrument XR44CX shall be mounted on vertical panel, in a 29x71

nPS Number of pressure switch activation: (0 to 15) Number of activation, during the did mm hole, and fixed using the special bracket supplied.

or d2d interval, before signalling an alarm event (i1F, i2F=PAL). The temperature range allowed for correct operation is 0 to 60°C.

If the nPS activation during did or d2d time is reached, switch off and on the instrument Avoid places subject to strong vibrations, corrosive gases,

to restart normal regulation. excessive dirt or humidity. The same recommendations apply to

odC Compressor status when open door: (no; FAn; CPr;F_C;) no = normal; probes. Let air circulate by the cooling holes.

FAn = normal; CPr = compressor OFF, F_C = compressor OFF.

rrd Outputs restart after door open alarm: (n; Y) n = outputs follow the odC parameter.

Y = outputs restart with a door open alarm.

OTHER

12. ELECTRICAL CONNECTIONS

HES Temperature increase during the Energy Saving cycle : (-30,0°C30,0°C/-22÷86°F) The instrument is provided with screw terminal block to connect cables with a cross section up to

it sets the increasing value of the set point during the Energy Saving cycle 2.5mm2. Before connecting cables make sure the power supply complies with the instrument’s

o-F Display during stand by: OFF = “OFF”; Lin: “- - -“ requirements. Separate the probe cables from the power supply cables, from the outputs and the

Adr Serial address: (1 to 247) identifies the instrument address when connected to a power connections. Do not exceed the maximum current allowed on each relay, in case of heavier

ModBUS compatible monitoring system. loads use a suitable external relay.

PbC Type of probe: (PtC; ntC) it allows to set the kind of probe used by the instrument:

PtC = PTC probe, ntC = NTC probe. 12.1 PROBE CONNECTION

onF On/Off key enabling: (nU; oFF; ES) nU = disabled; oFF = enabled; ES = not set it. The probes shall be mounted with the bulb upwards to prevent damages due to casual liquid

dP1 Thermostat probe display. infiltration. It is recommended to place the thermostat probe away from air streams to correctly

dP2 Evaporator probe display. measure the average room temperature. Place the defrost termination probe among the evaporator

dP3 Third probe display- optional. fins in the coldest place, where most ice is formed, far from heaters or from the warmest place during

dP4 Fourth probe display- optional. defrost, to prevent premature defrost termination.

rSE Regulation set (SET + HES)

rEL Software release for internal use. 13. USE THE HOT KEY

Ptb Parameter table code: readable only.

13.1 HOW TO: PROGRAM A HOT KEY FROM THE INSTRUMENT (UPLOAD)

9. DIGITAL INPUTS 1. Program one controller with the front keypad.

The free voltage digital input is programmable by the i1F parameter. 2. When the controller is ON, insert the “HOT-KEY” and push UP button; the “uPL” message

appears followed a by a flashing “End” label.

9.1 GENERIC ALARM (i1F or i2F= EAL) 3. Push SET button and the “End” will stop flashing.

As soon as the digital input is activated the unit will wait for did time delay before signalling the EAL 4. Turn OFF the instrument, remove the “HOT-KEY” and then turn it ON again.

alarm message. The outputs statuses don’t change. The alarm stops just after the digital input is de-

activated. NOTE: the “Err” message appears in case of a failed programming operation. In this case push again

button if you want to restart the upload again or remove the “HOT-KEY” to abort the operation.

1598040181 XR44CH ISA GB r16.8 27.04.2017 XR44CH 4/6

13.2 HOW TO: PROGRAM AN INSTRUMENT USING A HOT KEY (DOWNLOAD)

1. Turn OFF the instrument. 17. DEFAULT SETTING VALUES

2. Insert a pre-programmed “HOT-KEY” into the 5-PIN receptacle and then turn the Controller

ON. Label Name Range Nt Pt Liv

3. The parameter list of the “HOT-KEY” will be automatically downloaded into the Controller SEt Set point LS-US -22 2

memory. The “doL” message will blink followed a by a flashing “End” label. HY Differential [0,1°C ÷ 25,5°C] [1°F ÷ 45°F] 2 2 Pr2

4. After 10 seconds the instrument will restart working with the new parameters. Hy2 Second compressor differential [0,1°C ÷ 25,5°C] [1°F ÷ 45°F] 2 2 Pr2

5. Remove the “HOT-KEY”. LS Minimum set point [-55,0°C ÷ SET] [-67°F ÷ SET] -30 -10 Pr2

US Maximum set point [SET ÷ 150,0°C] [SET ÷ 302°F] -10 10 Pr2

NOTE: the message “Err” is displayed for failed programming. In this case turn the unit off and then ot Thermostat probe calibration [-12,0°C ÷ 12,0°C] [-21°F ÷ 21°F] 3 3 Pr2

on if you want to restart the download again or remove the “HOT-KEY” to abort the operation. P2P Evaporator probe presence n(0) – Y(1) yes yes Pr2

oE Evaporator probe calibration [-12,0°C ÷ 12,0°C] [-21°F ÷ 21°F] 0.0 0.0 Pr2

14. ALARM SIGNALS P3P Third probe presence n(0) – Y(1) no no Pr2

o3 Third probe calibration [-12,0°C ÷ 12,0°C] [-21°F ÷ 21°F] 0.0 0.0 Pr2

Message Cause Outputs P4P Fourth probe presence n(0) – Y(1) no no Pr2

P1 Room probe failure Compressor output acc. to par. Con and CoF o4 Fourth probe calibration [-12,0°C ÷ 12,0°C] [-21°F ÷ 21°F] 0.0 0.0 Pr2

P2 Evaporator probe failure Defrost end is timed P4C Fourth probe function Pb – id4 Pb Pb Pr2

P3 Third probe failure Outputs unchanged odS Outputs delay at start up 0 ÷ 255 (min.) 0 0 Pr2

P4 Fourth probe failure Outputs unchanged Anti-short cycle delay for first

AC 0 ÷ 50 (min.) 2 2 Pr2

HA Maximum temperature alarm Outputs unchanged. compressor

LA Minimum temperature alarm Outputs unchanged. Anti-short cycle delay for

AC1 0 ÷ 255 (sec.) 120 120 Pr2

dA Door open Compressor and fans restarts second compressor

EA External alarm Output unchanged. Mon Max time compressor 1 on 0 ÷ 255 (min.) 0 0 Pr2

CA Serious external alarm (i2F=bAL) All outputs OFF. 2CC Dual compressor management SEq(0) – HAF (1) Seq Seq Pr2

CA Pressure switch alarm (i2F=PAL) All outputs OFF P1-P3 percentage for

rtr 0 ÷ 100 (100=P1 , 0=P3) 00:00 100 Pr2

regulation

oFF Controller in stand by All outputs OFF

CCt Continuous cycle duration 0 ÷ 24H0(144) 0.0 0.0 Pr2

- -- Controller in stand by All outputs OFF

CCS Set point for continuous cycle [-55.0°C ÷ 150,0°C] [-67°F ÷ 302°F] -22 0.0 Pr2

14.1 ALARM RECOVERY Compressor ON time with Pr2

Con 0 ÷ 255 (min.) 10 10

faulty probe

Probe alarms “P1”, “P2”, “P3” and “P4” start some seconds after the fault in the related probe; they Compressor OFF time with

automatically stop some seconds after the probe restarts normal operation. Check connections before CoF 0 ÷ 255 (min.) 5 5 Pr2

faulty probe

replacing the probe. CH Kind of action CL(0) - Ht(1) CL CL Pr2

Temperature alarms “HA” and “LA” automatically stop as soon as the temperature returns to normal Temperature measurement

values. CF °C(0) - °F(1) °C °C Pr2

unit

Alarms “EA” and “CA” (with i1F=bAL) recover as soon as the digital input is disabled. rES Resolution dE(0) - in(1) in in Pr2

Alarm “CA” (with i1F=PAL) recovers only by switching off and on the instrument. Lod Probe displayed P1(0) - P2(1) - P3(2) - P4(3) - SEt(4) - dtr(5) P1 P1 Pr2

dLy Display temperature delay 0 ÷ 255 (sec) 0 0 Pr2

14.2 OTHER MESSAGES dtr P1-P3 percentage for display 1 ÷ 99 50 50 Pr2

Pon Keyboard unlocked. tdF Defrost type EL(0) - in(1) - ALt(2) in in Pr2

PoF Keyboard locked dFP Probe for first defrost nP(0) - P1(1) - P2(2) - P3(3) - P4(4) P2 P2 Pr2

noP In programming mode: none parameter is present in Pr1 dSP Probe for second defrost nP(0) - P1(1) - P2(2) - P3(3) - P4(4) nP nP Pr2

On the display or in dP2, dP3, dP4: the selected probe is nor enabled First defrost termination

dtE [-55.0°C ÷ 50.0°C] [-67°F ÷ 122°F] 15 15 Pr2

temperature

15. TECHNICAL DATA dtS

Second defrost termination

temperature

[-55.0°C ÷ 50.0°C] [-67°F ÷ 122°F] 6 15 Pr2

Housing: self-extinguishing ABS. idF Interval between defrost cycles 0 ÷ 120 (hours) 8 8 Pr2

Case: frontal 32x74 mm; depth 60mm; (Maximum) length for first

MdF 0 ÷ 255 (min.) 30 45 Pr2

Mounting: panel mounting in a 71x29mm panel cut-out defrost

Protection: IP20; Frontal protection: IP65 (Maximum) length for second

MdS 0 ÷ 255 (min.) 0 0 Pr2

Connections: Screw terminal block 2.5 mm2 wiring defrost

Power supply: 12VAC/DC, ±10% dSd Start defrost delay 0 ÷ 255 (min.) 0 0 Pr2

Power absorption: 3VA max Compressor stop before

Stc rt(0) - it(1) - SEt(2) - dEF(3) 0 0 Pr2

Display: 3 digits, red LED, 14.2 mm high defrost

Inputs: Up to 4 NTC or PTC probes dFd Displaying during defrost rt(0) - it(1) - SEt(2) - dEF(3) it it Pr2

Digital inputs: free voltage contact, maximum distance 10m dAd Display delay after defrost 0 ÷ 255 (min.) 30 30 Pr2

Relay outputs: Fdt Draining time 0 ÷ 255 (min.) 1 1 Pr2

Compressor SPST 16(6) A 250VAC dPo First defrost after start-up n(0) - Y(1) no no Pr2

Defrost: SPDT 16(6) A, 250VAC Differenziale rispetto al set per

Hd1 -12.0÷12.0°C/-24÷24°F 0 0 Pr2

Data storing: on the non-volatile memory (EEPROM) ciclo pre-sbrinamento

Kind of action: 1B Ht1 Durata ciclo pre-sbrinamento 0÷120min 0 0 Pr2

Pollution degree: 2 Differenziale rispetto al set per

Hd2 -12.0÷12.0°C/-24÷24°F 0 0 Pr2

Software class: A ciclo post-sbrinamento

Rated impulsive voltage: 2500V Ht2 Durata ciclo post-sbrinamento 0÷120min 0 0 Pr2

Overvoltage Category: II dAF Defrost delay after fast freezing 0 ÷ 24H0(144) 00:00 00:00 Pr2

Operating temperature: 0 to 60°C; 32 to 140°F FnC Fan operating mode C_n(0) - O_n(1) - C_Y(2) - O_Y(3) O_n O_n Pr2

Storage temperature: -25 to 60°C (-13 to 140°F) Fnd Fan delay after defrost 0 ÷ 255 (min.) 1 1 Pr2

Relative humidity: 20 to 85% (no condensing) Differential of temperature for

FCt [0°C ÷ 50°C] [0°F ÷ 90°F] 0 0 Pr2

Measuring and regulation range: forced activation of fans

NTC probe: -50 to 150°C (-55 to 302°F) FSt Fan stop temperature [-55.0°C ÷ 50.0°C] [-67°F ÷ 122°F] 50 50 Pr2

PTC probe: -40 to 110°C (-40 to 230°F) Time is ON when compressors

Fon 0÷15 (min.) 0 0 Pr2

Resolution: 0.1°C or 1°F (selectable) oFF

Accuracy (ambient temp. 25°C): ±0.7°C ±1 digit Time is OFF when

FoF 0÷15 (min.) 0 0 Pr2

compressors oFF

16. CONNECTIONS FSU Fan operating type Std(0) - FoF(1) - Fon(2) Std Std Pr2

ALC Temperat. alarms configuration rE(0) - Ab(1) Ab Ab Pr2

°C[0.0° ÷ 50.0° o ALL ÷ 150,0°]

ALU MAXIMUM temperature alarm 50 50 Pr2

°F[0° ÷ 90° o ALL ÷ 302°]

°C[0.0° ÷ 50.0° o -55.0° ÷ ALU]

ALL Minimum temperature alarm -50.0 -50.0 Pr2

°F[0° ÷ 90° o -67.0° ÷ ALU]

Differential for temperat. alarm

AFH [0,1°C ÷ 25,5°C] [1°F ÷ 45°F] 1.0 1.0 Pr2

recovery

ALd Temperature alarm delay 0 ÷ 255 (min.) 10 10 Pr2

Delay of temperature alarm at

dAo 0 ÷ 24H0(144) 01:30 01:30 Pr2

start up

dEF(0) - FAn(1) - ALr(2) - LiG(3) - AUS(4) -

oA1 AUX1 relay configuration CP2 CP2 Pr2

OnF(5) - db(6) - CP2(7) - dF2(8) - HES(9)

dEF(0) - FAn(1) - ALr(2) - LiG(3) - AUS(4) -

oA2 AUX2 configuration dEF dEF Pr2

OnF(5) - db(6) - CP2(7) - dF2(8) - HES(9)

dEF(0) - FAn(1) - ALr(2) - LiG(3) - AUS(4) -

oA3 AUX3 relay configuration LiG LiG Pr2

OnF(5) - db(6) - CP2(7) - dF2(8) - HES(9)

i1P Digital input polarity OP(0) - CL(1) cL cL Pr2

1598040181 XR44CH ISA GB r16.8 27.04.2017 XR44CH 5/6

Label Name Range Nt Pt Liv

EAL(0) - bAL(1) - PAL(2) - dor(3) - dEF(4) -

i1F Digital input configuration AUS(5) - Htr(6) - FAn(7) - ES(8) - nt(9) - BAL BAL Pr2

onF(10) - CC(11)

did Digital input alarm delay 0 ÷ 255 (min.) 0 0 Pr2

i2P Second digital input polarity OP(0) - CL(1) CL CL Pr2

EAL(0) - bAL(1) - PAL(2) - dor(3) - dEF(4) -

i2F Second digital input function AUS(5) - Htr(6) - FAn(7) - ES(8) - nt(9) - EAL EAL Pr2

onF(10) - CC(11)

Alarm delay of configurable

d2d digital input 0 ÷ 255 (min.) 0 0 Pr2

Number of activations of

nPS 0 ÷ 15 5 5 Pr2

pressure switch

Compress and fan status when

odC no(0) - FAn(1) - CPr(2) - F-C(3) no no Pr2

open door

Regulation restart with door

rrd n(0) - Y(1) yes yes Pr2

open alarm

HES Differential for Energy Saving [-30°C ÷ 30°C] [-54°F ÷ 54°F] 0 0 Pr2

o-F Visualization on stand-by n(0) - Y(1) OFF OFF Pr2

Adr Serial address 0 ÷ 247 1 1 Pr2

PbC Kind of probe PtC(0) - ntC(1) ntC ntC Pr2

dP1 Room probe display probe value - - Pr1

dP2 Evaporator probe display probe value - - Pr1

dP3 Third probe display probe value - - Pr1

dP4 Fourth probe display probe value - - Pr1

Visualization of regulation set

rSE Read only - - Pr2

(SET + ES + SETd)

rEL Software release read only 16.8 16.8 Pr2

Ptb Map code read only 1 1 Pr2

1598040181 XR44CH ISA GB r16.8 27.04.2017 XR44CH 6/6

Das könnte Ihnen auch gefallen

- Danfoss ECL9300Dokument12 SeitenDanfoss ECL9300Nikola Lordan50% (2)

- ViperTouch Big Dutchman PDFDokument20 SeitenViperTouch Big Dutchman PDFSachin AmbhoreNoch keine Bewertungen

- 01 - PR6201 Instruction Manual EDokument22 Seiten01 - PR6201 Instruction Manual ETreeNoch keine Bewertungen

- GRUNDING C7 C8 ChassisDokument62 SeitenGRUNDING C7 C8 ChassisMoaath AltousiNoch keine Bewertungen

- Circuit Diagram P001423 - 180909 PDFDokument806 SeitenCircuit Diagram P001423 - 180909 PDFНеша Даца АндрићNoch keine Bewertungen

- Lae At2 5Dokument6 SeitenLae At2 5Samuel Wilson100% (1)

- BSL Tool 42 0410 0631 PDFDokument33 SeitenBSL Tool 42 0410 0631 PDFex-2156Noch keine Bewertungen

- Manual Completo Bomba WittDokument42 SeitenManual Completo Bomba WittDick Robert Grández Fasanando100% (3)

- Mettler Toledo ps7 ManualDokument162 SeitenMettler Toledo ps7 ManualceleronvalleyNoch keine Bewertungen

- Bitzer Se-170-2Dokument28 SeitenBitzer Se-170-2GingubaNoch keine Bewertungen

- BedienungsanleitungDokument12 SeitenBedienungsanleitungRakhmatulla MambetberdievNoch keine Bewertungen

- Computherm: Programmierbarer, Kabelloser (Funkfrequenz) Digital-RaumthermostatDokument56 SeitenComputherm: Programmierbarer, Kabelloser (Funkfrequenz) Digital-RaumthermostatUwe FiluschNoch keine Bewertungen

- Regloplas 90S RT61 ManualDokument40 SeitenRegloplas 90S RT61 ManualJoão Cavaco100% (2)

- Bedienungsanleitung Heizkörperthermostat Von KomforthausDokument53 SeitenBedienungsanleitung Heizkörperthermostat Von KomforthausmodastNoch keine Bewertungen

- Thermovalve - CC RT O CNL W R5 2 - EQ - UM - GEFD - InstallationDokument112 SeitenThermovalve - CC RT O CNL W R5 2 - EQ - UM - GEFD - Installationbruno.reggNoch keine Bewertungen

- SolarLog Manual Solar Log PRO380 CT ENDokument2 SeitenSolarLog Manual Solar Log PRO380 CT ENEDUARDO DIAZNoch keine Bewertungen

- Betriebsanleitung Elektronisches RegelgerätDokument46 SeitenBetriebsanleitung Elektronisches Regelgerät4301395Noch keine Bewertungen

- Waermepumpe Elesta-V5Dokument56 SeitenWaermepumpe Elesta-V5Roland KroißNoch keine Bewertungen

- Solar Differenzregler SD1 PTDokument20 SeitenSolar Differenzregler SD1 PTvinzf2Noch keine Bewertungen

- 12 Klimageraet deDokument62 Seiten12 Klimageraet dem_925Noch keine Bewertungen

- TermostatDokument16 SeitenTermostatFinias CostanNoch keine Bewertungen

- RennertronicDokument85 SeitenRennertronicVijačni kompresori- Prodaja i servis100% (1)

- Tom584tf DDokument11 SeitenTom584tf DhaseNoch keine Bewertungen

- Suntec Klimatronic Dynamic 9.0 PlusDokument13 SeitenSuntec Klimatronic Dynamic 9.0 PlusAlexandr DontuNoch keine Bewertungen

- Bedienungsanleitung Digital Kontaktmanometer TST PM82Dokument3 SeitenBedienungsanleitung Digital Kontaktmanometer TST PM82dawitNoch keine Bewertungen

- Alternating Two Compressors PDFDokument9 SeitenAlternating Two Compressors PDFMrBob KmpsNoch keine Bewertungen

- Signa Excite 1.5T Preinstallation Manual - PIM - 2223170 - 13Dokument261 SeitenSigna Excite 1.5T Preinstallation Manual - PIM - 2223170 - 13Ian Bruno Rodriguez CenturionNoch keine Bewertungen

- Weishaupt WRDDokument36 SeitenWeishaupt WRDZimson0% (2)

- 72-95972081 B PDFDokument68 Seiten72-95972081 B PDFTRIQUERENoch keine Bewertungen

- Diagnose HandbuchDokument24 SeitenDiagnose HandbuchHolger HausmannNoch keine Bewertungen

- Control Solutions: Atlas CopcoDokument30 SeitenControl Solutions: Atlas CopcoВладислав СередаNoch keine Bewertungen

- 616036-An-01-Ml-Dual Zeitschaltuhr DX 2 de en NLDokument14 Seiten616036-An-01-Ml-Dual Zeitschaltuhr DX 2 de en NLjpbarrio0% (1)

- Termostat PDFDokument16 SeitenTermostat PDFPodariu CosminNoch keine Bewertungen

- Manual pm82Dokument3 SeitenManual pm82dawitNoch keine Bewertungen

- Brennenstuhl PM 231 e Energiemeter Handleiding ManualDokument104 SeitenBrennenstuhl PM 231 e Energiemeter Handleiding ManualJacquie HuibertsNoch keine Bewertungen

- DD DiematicM Delta-Schaltfeld K-Schaltfeld Vario Platine Für SBK14 SBK18 Kolli DU8 Und DU9 Anleitung Elektro Inbetrieb Bedienung 8387-4055B de PDFDokument52 SeitenDD DiematicM Delta-Schaltfeld K-Schaltfeld Vario Platine Für SBK14 SBK18 Kolli DU8 Und DU9 Anleitung Elektro Inbetrieb Bedienung 8387-4055B de PDFmishu35Noch keine Bewertungen

- Heizkörperthermostat Model N EQ-3 deDokument2 SeitenHeizkörperthermostat Model N EQ-3 decybtrashNoch keine Bewertungen

- FD8409 FernbedWPMDokument5 SeitenFD8409 FernbedWPMIvanNoch keine Bewertungen

- Energiekostenmessgeraet Neu UmDokument8 SeitenEnergiekostenmessgeraet Neu UmAntheaLouloudiNoch keine Bewertungen

- SSP271-Der Phaeton-Heizung Und KlimaanlageDokument76 SeitenSSP271-Der Phaeton-Heizung Und KlimaanlageMarkus SichelschmidtNoch keine Bewertungen

- C67 DanfossDokument43 SeitenC67 DanfossgreemansNoch keine Bewertungen

- REPAIR - MANUAL - GENESIS - 1100 - 1500 - TLH-GB (2018 - 05 - 01 10 - 20 - 49 UTC) .En - deDokument43 SeitenREPAIR - MANUAL - GENESIS - 1100 - 1500 - TLH-GB (2018 - 05 - 01 10 - 20 - 49 UTC) .En - dejoNoch keine Bewertungen

- Ceramill Therm INTDokument80 SeitenCeramill Therm INTAhmedMahirNoch keine Bewertungen

- TRITEC TRI KA Manual v2.2 de en Es FR ItDokument242 SeitenTRITEC TRI KA Manual v2.2 de en Es FR ItMatias Alejandro Colon RojasNoch keine Bewertungen

- Bedienungsanleitung OKU SuncontrolDokument4 SeitenBedienungsanleitung OKU SuncontrolDieter StNoch keine Bewertungen

- PSD02 Controller PDFDokument96 SeitenPSD02 Controller PDFFredrik0% (1)

- Bedienerhandbuch: Gültig Für Die 50-Hz-TrocknerDokument16 SeitenBedienerhandbuch: Gültig Für Die 50-Hz-TrocknerMarcelo OlivaresNoch keine Bewertungen

- Sanyo Sap-Ftr129e GermanDokument12 SeitenSanyo Sap-Ftr129e GermanwaterspiegelNoch keine Bewertungen

- Manual de Ussuario Aquamedic Twin ControllerDokument24 SeitenManual de Ussuario Aquamedic Twin Controllerf.castrejonNoch keine Bewertungen

- Bestellnummer: 900320.118: Datenblatt ST122-KI1KAR.112Dokument24 SeitenBestellnummer: 900320.118: Datenblatt ST122-KI1KAR.112Юрій КобцевNoch keine Bewertungen

- Manual Multi 300792Dokument40 SeitenManual Multi 300792Jean Christophe DangladesNoch keine Bewertungen

- DL-140TH Operation Manual V3 0409 MDokument4 SeitenDL-140TH Operation Manual V3 0409 MwwwengNoch keine Bewertungen

- PeakTech 9035 03 2016Dokument45 SeitenPeakTech 9035 03 2016marcNoch keine Bewertungen

- MA Mehrausstattung DE D24123Dokument17 SeitenMA Mehrausstattung DE D24123SiddarthNoch keine Bewertungen

- Truma Heating CP Plus Installation Operating de en FR ItDokument96 SeitenTruma Heating CP Plus Installation Operating de en FR ItPascal BaudinNoch keine Bewertungen

- Gebruikershandleiding ComDokument13 SeitenGebruikershandleiding ComAlexandr DontuNoch keine Bewertungen

- SilverCrest RT2000 ThermostatDokument44 SeitenSilverCrest RT2000 ThermostatArabella Francesca ZadicNoch keine Bewertungen

- 9040120B OI-II Telestart T99 - DEDokument18 Seiten9040120B OI-II Telestart T99 - DELukas DiederichNoch keine Bewertungen

- Nji-281bx Eh-150 Manual deDokument541 SeitenNji-281bx Eh-150 Manual dericardo-sutterNoch keine Bewertungen

- Einführung in die Simulation von Kraftwerken mit EBSILON®Professional Version 15Von EverandEinführung in die Simulation von Kraftwerken mit EBSILON®Professional Version 15Noch keine Bewertungen