Beruflich Dokumente

Kultur Dokumente

Omega Seal

Hochgeladen von

vasantha kumarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Omega Seal

Hochgeladen von

vasantha kumarCopyright:

Verfügbare Formate

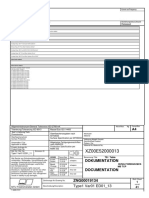

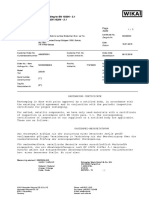

Art Komm.Nr. Baugr. D.Nr. Rev.

Blatt/page

Dokum.Nr.:

document no.: D 46900 907 03 03 Revisionsblatt zu 1

von / of

siehe hierzu

refer to revision cover sheet to 1/3

Art Komm.Nr. Baugr. Z.Nr. Rev.

Dokum.Nr.:

document no.:

S 46900 907 03 03 gemäß

Dokum.Nr.: Z 46900 907 03 03 acc. to

document no.:

Dokum.Nr.:

document no.:

Objekt

Dokum.Nr.:

item

Attachements for

document no.:

Internal Dome RG2

Kunde:

client: ORPIC

Auftrags-Nr.:

P.O. No.:

Orpic document number:

PL-14135-0703-03

Dokumentgenehmigung: Das Dokument wird elektronisch genehmigt und ist im Status "Freigabe"; "Prüfung Kunde/TÜV" und "Endfreigabe" auch ohne Unterschrift gültig!

Document approval: The document is electronically approved and therefore in state "Freigabe"; "Prüfung Kunde/TÜV" and "Endfreigabe" valid without signature!

Datum Ausgef. Geprüft

Ändg. Index Änderungen date by checked

rev. Index revision Status Prüfer Kunde

state Inspector Client

15.04.2016 Schwaighofer --

03 AS-BUILT

Endfreigabe

15.04.2016 Schwaighofer --

02 Radial positions noted

ungültig

26.05.2015 Schöfer --

01 acc. EIL comments, Pos.17 changed

ungültig

Dokument erstellt 08.01.2015 Schöfer --

00

first issued ungültig

MAN Diesel & Turbo SE, Deggendorf

Ausführung nach Z.Format KommNr. Baugr Z.Nr. Rev. Blatt / von

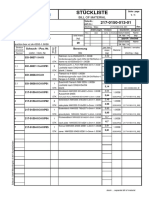

Stückliste: page / of Stückliste zu

fabricate 1 X Stckl.Nr.:

partlist no.: S 46900 907 03 01 1/2 part list to

as per part list

Datum / date Name / name Mit jeder Revision ist das Revisionsblatt aufzugeben Internal Dome Attachements

27.11.14 Schöfer A revision cover sheet shall be issued for each revision Orpic - Oman

Teil/part Beschreibung u. Fertigmaße Stück Zchng. / Norm Material Test / certific. Gewicht Bemerkung

Baugr. description and dimensions no. off drwg. / code material DIN 10204 weight [kg] shop note

Profil Ring SA 240 3.1 5tlg., gebogen

1 100 x 50 x 10 …26641lg. 1 Tp304 296 Mat. 1025709

907 continous Ring / 1.4301

e

Profil Ring SA 240 3.1 5tlg., gebogen

L1 2 100 x 50 x 10 ….27646lg. 1 Tp304 307 Mat. 1025709

907 continous Ring / 1.4301

e

Halteblech SA 240 Fl. 50x10

(L1) 3 55 x 50 x 10 90 Tp304H 20 Mat. 1025688

907 support clip

e

Rohr 3 ½“ Sch. 10S, gebogen R4320 SA 240

L2 4 ø101,6 x 3,6 …27144lg. 1 Tp321 241 Mat. 1025722

907 5tlg., 72°-Segmente

Expansion Element pipe e

L/ 6kt. Schraube SA 193

L1 5 ½” x 2” (50,8lg.) 120 B8 Cl.1 6 Mat. 1025916

907 Heavy Hex Screw

e

L/ Mutter SA 194

L1 6 ½“-UNC 120 Gr. 8A 4 Mat. 1025917

907 Heavy Hex Nut

(f. Transport auf Pos.5 montiert!) e

Scheibe SA 194

L1 7 50x50 s=10 120 Gr. 8A 24 Mat.1026108

907 Washer

(f. Transport auf Pos.5 montiert!) e

Expansionselement UOP 309SS

L 8 27444lg. 1 980237- Ceramic Fibr. 50 Mat. 1026197

907 Knitted wire mash+fiber blanket insulation 327-43-A1 Silica

e

Haltering (36°-Segmente) SA 240

L 9 R4400 / R4506 s=10 10 Tp304H 237 Mat.1025445

120 support Ring

e

Übergangsblech SA 240

L 10 sblech

900 x 50 x 10 2 Tp304H 3 Mat.1026110

907 Splice Plate

e

Rohr 3“ XS SA 240

L2 11 ø88,9 x 5,5…230lg. 5 Tp304H 5 Mat.1004724

907 Sleeve Pipe

e

Abdeckblech Typ A SA 240

L3 12 R 4120 / R4470 s=20 18 Tp304H 755 Mat. 1025443

907 Seal Plate Type A

e

Abdeckblech Typ B SA 240

L3 13 R 4120 / R4470 s=20 18 Tp304H 755 Mat. 1025443

907 Seal Plate Type B

e

Flachstahl, zu Typ B SA 240

L3 14 20 x 75 …350lg. 36 Tp304H 152 Mat. 1025682

110 flat bar f. type B

e

MAN Diesel & Turbo SE Gesamtgewicht [kg]:

5015 S-46900-907-

Deggendorf total weight 03_Attachements.docx

Ausführung nach Z.Format KommNr. Baugr Z.Nr. Rev. Blatt / von

Stückliste: page / of Stückliste zu

fabricate 1 X Stckl.Nr.:

partlist no.: S 46900 907 03 01 2/2 part list to

as per part list

Datum / date Name / name Mit jeder Revision ist das Revisionsblatt aufzugeben Internal Dome Attachements

27.11.14 Schöfer A revision cover sheet shall be issued for each revision Orpic - Oman

Teil/part Beschreibung u. Fertigmaße Stück Zchng. / Norm Material Test / certific. Gewicht Bemerkung

Baugr. description and dimensions no. off drwg. / code material DIN 10204 weight [kg] shop note

Haltegriffe SA 240

L3 15 ø13 ….318lg. 72 Tp304H 25 Mat. 1025690

907 Handle

e

Auflager-Ring, 22,5° Segmente SA 240

L 16 R 4412 / R4732 s=20 16 Tp304H 1470 Mat. 1025443

907 Outer support Ring (f. seal plates)

e

Versteifungsrippe SA 240

L 17 296 x 124 x 20 96 Tp304H 187 Mat. 1025443

907 Plate Stiffener

e

18

19

Air gap braided hose Tp304H /

L 20 ø150 (before installation) ….26374lg. 1 Ceramic Fibr. 478 Mat. 1026196

907 (64kg/m³)

e

Isolierung ~3m³

L 21 150kg/m³ =450kg

907 lower ceramic fiber blanket insulation

Isolierung ~5m³

L 22 150kg/m³ =750kg

907 upper ceramic fiber blanket insulation

23

24

25

26

27

28

MAN Diesel & Turbo SE Gesamtgewicht [kg]:

5015 S-46900-907-

Deggendorf total weight 03_Attachements.docx

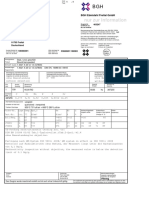

50 A1 901563 327

B C D E F G H I J

100 100

REGENERATOR COMBUSTION

RISER

0.01"-.015" THICK

95 DETAIL B50 95

(TYPE 309 SS)

8590 DIA KNITTED WIRE MESH

0.05"-.075" THICK (2-LAYERS)

SILICA FABRIC CLOTH

TACKWELD (TYP)

F50

90 90

TYP 10 RAD (TYP)

6

10 x 50 x 50 WASHER

WITH 14 DIA HOLE

DETAIL C50 RADIUS CORNERS AS SHOWN

DETAIL D50 (TYPICAL EXCEPT AT SPLICE) 2-LAYERS OF 13

85 DETAIL E50 F50 CERAMIC FIBER

85

1/2 " DIA HEAVY HEX NUT (TYP) BLANKET INSULATION

SPLICE 1/2 " DIA HEX BOLT x 50 LONG

(TYP) 0.01"-.015" THICK

WITH HEX NUT AND WASHER

(TYPE 309 SS)

BOLTS TO BE LOCATED BETWEEN SUPPORT

80 KNITTED WIRE MESH 80

3 1/2 " SCH 10S PIPE

CLIPS ON APPROXIMATELY 450 CENTERS

(2-LAYERS)

A50 A50

DETAIL B50

25

EXPANSION ELEMENT

IA 10

100

75 D 75

25

90

85 TYP

65

6

10

INSTALL SECOND LAYER OF

70 KNITTED WIRE MESH OVER 70

SPLICE IF NECESSARY TO

C SPLICE STITCH ENDS OF KNITTED

COMPLETELY COVER CERAMIC

10 x 100 x 50 50 x 10 x 55 PLATE WIRE MESH TOGETHER ALL

FIBER BLANKET INSULATION

FABRICATED ANGLE SUPPORT CLIP AROUND OUTER SURFACE

COMBUSTOR

CONTINUOUS RING LOCATE ON WITH TYPE 309 SS WIRE

RISER CONE

600 CENTERS

65 65

(STAGGER WITH

OPPOSITE SUPPORT WIRE MESH

(TYP)

55 CLIP)

50 110 (COLD POSITION) 50 CERAMIC FIBER

60 55 (HOT POSITION) BLANKET AND 60

FABRIC CLOTH

PLAN

PIPE

55 CONTRACTOR/SUPPLIER TO DETERMINE REQUIRED 55

150

NUMBER AND LOCATION OF SPLICES SECTION A50-A50

300 OVERLAP

50 50

SPLICE END OF EXPANSION ELEMENT

SECTION F50-F50

13

TO BE SHIPPED OPEN TO TYPICAL AT SPLICE

ALLOW OVERLAP AT SPLICE

45 45

CUT EXPANSION

ELEMENT AT LEAST

SUPPORT

150 LONG

CLIP

40 40

NOTE: THE INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND THE PROPERTY OF UOP LLC AND MUST NOT BE DISCLOSED TO

0

G5

TYP SUPPORT

35 35

CLIP

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PURPOSE WHATSOEVER WITHOUT ITS WRITTEN PERMISSION.

WASHER

SUPPORT C SPLICE

C SPLICE

CLIP

3" SCH 10S PIPE OVERLAP

30 30

SLEEVE x 230 LONG EXPANSION

TOP SECTION OF PIPE

ELEMENT

AS ACCESSIBLE ONE SPLICE PLATE

3

SIDE OF SPLICE ONLY INSTALL LAST

25

DETAIL C50 P

25 GA 25

TYPICAL AT SPLICE END

0

SUPPORT

G5

CLIP

FOR DESIGN DATA AND ADDITIONAL NOTES SEE

20 WASHER SUPPORT 20

UOP DRAWING 901563-327-30-A1

C SPLICE

CLIP

300

(TYP) END OF EXPANSION RADIUS

ELEMENT (TYP) CORNERS FOLD BACK EXPANSION REV DFTR CKR APVD DATE REV DFTR CKR APVD DATE

ELEMENT AS REQUIRED

15 UOP LLC 15

FOR WELD ACCESS (BOTH ENDS)

25 East Algonquin Road

Des Plaines, Illinois 60017-5017, USA

PROTECT EXPANSION ELEMENT

FROM WELD SPATTER WITH

SUITABLE BLANKET REGENERATOR EXPANSION ELEMENT

10 10

50

REACTOR REGENERATOR ASSEMBLY

UOP FLUID CATALYTIC CRACKING PROCESS UNIT

DETAIL D50 DETAIL E50 (RFCC)

TYPICAL SPLICE TYPICAL SPLICE WITH SPLICE PLATE INSTALLED OMAN REFINERY COMPANY L.L.C.

5 5

10 SPLICE PLATE 14 DIA x 20 LONG SOHAR REFINERY PROJECT

VERTICAL FLANGE OF ANGLE OMITTED FOR CLARITY

SLOTTED HOLE SOHAR, SULTANATE OF OMAN

(TYP)

DFTR CKR APVD DATE PROJECT TYPE DWG NO REV

SECTION G50-G50 01APR

MBP AM DRJ

09 901563 327 50 A1 0

0 0

A B C D E F G H I J

Das könnte Ihnen auch gefallen

- Leitfaden für Bausachverständige: Rechtsgrundlagen – Gutachten – HaftungVon EverandLeitfaden für Bausachverständige: Rechtsgrundlagen – Gutachten – HaftungNoch keine Bewertungen

- Deckblatt/Active Sheet RecordDokument7 SeitenDeckblatt/Active Sheet RecordMyFullNoch keine Bewertungen

- Deckblatt/Active Sheet RecordDokument3 SeitenDeckblatt/Active Sheet RecordJuan RiveraNoch keine Bewertungen

- Deckblatt/Active Sheet RecordDokument1 SeiteDeckblatt/Active Sheet RecordSavindu NanayakkaraNoch keine Bewertungen

- Mtu Xz00e50205750 DWGDokument2 SeitenMtu Xz00e50205750 DWGAldrine Dela CruzNoch keine Bewertungen

- 002 CaP2Dokument1 Seite002 CaP2inspecaodaqualidadeNoch keine Bewertungen

- SM LOP - Motor (Mit Starter)Dokument16 SeitenSM LOP - Motor (Mit Starter)legiond85Noch keine Bewertungen

- 001 CaP2Dokument3 Seiten001 CaP2inspecaodaqualidadeNoch keine Bewertungen

- 100se0080 01 2011Dokument9 Seiten100se0080 01 2011Abdallah MansouriNoch keine Bewertungen

- 8D-Report Für Lieferanten // 8D-Report For Suppliers: Formblatt / FormDokument6 Seiten8D-Report Für Lieferanten // 8D-Report For Suppliers: Formblatt / FormSuljo MesicNoch keine Bewertungen

- O18-03550 - 40 - ALDUR 700QL - WZ - Q463260Dokument6 SeitenO18-03550 - 40 - ALDUR 700QL - WZ - Q463260Peter TvardzíkNoch keine Bewertungen

- O19-00164 - 40,70 - ALDUR 700QL+S690QL - WZ - Q464247 PDFDokument8 SeitenO19-00164 - 40,70 - ALDUR 700QL+S690QL - WZ - Q464247 PDFPeter Tvardzík100% (1)

- Din-Dvgw 4510 W DDokument2 SeitenDin-Dvgw 4510 W DRicardo BarrosNoch keine Bewertungen

- Thyssenkrupp Steel Europe: Universal Eisen Und StahlDokument3 SeitenThyssenkrupp Steel Europe: Universal Eisen Und StahlIsaac LopbenNoch keine Bewertungen

- MTC - S 690 QL1Dokument5 SeitenMTC - S 690 QL1wajdiNoch keine Bewertungen

- Brazing Notes (Induction Brazing)Dokument2 SeitenBrazing Notes (Induction Brazing)Emir MumicNoch keine Bewertungen

- 001 CaP1Dokument3 Seiten001 CaP1inspecaodaqualidadeNoch keine Bewertungen

- Deutsche Edelstahlwerke: DIN EN 10204 3.1/01.05 DIN EN 10204 3.1B/08.95Dokument3 SeitenDeutsche Edelstahlwerke: DIN EN 10204 3.1/01.05 DIN EN 10204 3.1B/08.95Dedika MulyanaNoch keine Bewertungen

- 05.032 - BOM - Suction Box - 217-0150-013-01Dokument1 Seite05.032 - BOM - Suction Box - 217-0150-013-01Juan P. EscuderoNoch keine Bewertungen

- DE303-000-QC-FQP-00002 FIELD QUALITY PLAN For EARTHWORKSDokument12 SeitenDE303-000-QC-FQP-00002 FIELD QUALITY PLAN For EARTHWORKSBarbaros GülşahNoch keine Bewertungen

- 4 X 1500 X Coil H.# 512333-3Dokument2 Seiten4 X 1500 X Coil H.# 512333-3Ashok TiwariNoch keine Bewertungen

- Thyssenkrupp Steel Europe: Universal Eisen Und StahlDokument4 SeitenThyssenkrupp Steel Europe: Universal Eisen Und StahlIsaac LopbenNoch keine Bewertungen

- AA-0224 Edge Corrosion of E-CoatDokument13 SeitenAA-0224 Edge Corrosion of E-CoatEmre OtenkusNoch keine Bewertungen

- Jobrpt Z BL CC EMAIL ZLOG4 6819000000002Dokument2 SeitenJobrpt Z BL CC EMAIL ZLOG4 6819000000002Martin GoyardNoch keine Bewertungen

- 17 Pre3321 3388 711022Dokument2 Seiten17 Pre3321 3388 711022Puđa TomicaNoch keine Bewertungen

- 820234-03-151-2 DS V-2301 PDFDokument1 Seite820234-03-151-2 DS V-2301 PDFrantonio mz smgNoch keine Bewertungen

- Xz00e52000013 Modbus TCP Release 080 ModifiedDokument41 SeitenXz00e52000013 Modbus TCP Release 080 ModifiedVu TuongNoch keine Bewertungen

- PS-2.0017 - HV Bushing TestingDokument13 SeitenPS-2.0017 - HV Bushing TestingSuresh RamanujaluNoch keine Bewertungen

- Z 403247Dokument1 SeiteZ 403247vijayabhaskarsarmaNoch keine Bewertungen

- F-04.07.08.12 Bauabweichungsantrag Deviation RequestDokument1 SeiteF-04.07.08.12 Bauabweichungsantrag Deviation RequestOTNoch keine Bewertungen

- KBK Anlage PDFDokument5 SeitenKBK Anlage PDFPato PuruncajasNoch keine Bewertungen

- Таблица Nea с Уплотнит КольцамиDokument1 SeiteТаблица Nea с Уплотнит КольцамиТатьяна ВасильеваNoch keine Bewertungen

- Hilti Certificate 22 333153 58 HAS-E-F M16X125 38 Inspection Document ASSET DOC 1709775Dokument2 SeitenHilti Certificate 22 333153 58 HAS-E-F M16X125 38 Inspection Document ASSET DOC 1709775nikas672Noch keine Bewertungen

- Inspection Certificate 0000347796 / 1 / 2: Outokumpu Stainless USA, LLCDokument2 SeitenInspection Certificate 0000347796 / 1 / 2: Outokumpu Stainless USA, LLCEmigdio MartinezNoch keine Bewertungen

- 001 04012427Dokument10 Seiten001 04012427ferhat kahveciNoch keine Bewertungen

- Export ASMEDokument278 SeitenExport ASMElizet11Noch keine Bewertungen

- 6 MMDokument1 Seite6 MMCRISTIAN SILVIU IANUCNoch keine Bewertungen

- 1039S41729 Äas 0281016409 03l906018an 6779Dokument6 Seiten1039S41729 Äas 0281016409 03l906018an 6779Dylan PerezNoch keine Bewertungen

- HTWT600013 eDokument2 SeitenHTWT600013 eMarcoNoch keine Bewertungen

- Baainbw: Technische LieferbedingungenDokument78 SeitenBaainbw: Technische LieferbedingungenG_ASantosNoch keine Bewertungen

- Strass: Werk 9Dokument4 SeitenStrass: Werk 9mayank dixitNoch keine Bewertungen

- 0160066.0.340.7900 - 02 - Pipe SpecDokument103 Seiten0160066.0.340.7900 - 02 - Pipe SpecBola AdelNoch keine Bewertungen

- HTWT600008 ADokument1 SeiteHTWT600008 AMarcoNoch keine Bewertungen

- Spezifikationen Werkzeuge deDokument82 SeitenSpezifikationen Werkzeuge deMarcosNoch keine Bewertungen

- DAkkS Muster TempKaliDokument5 SeitenDAkkS Muster TempKaliZafar H RehmanNoch keine Bewertungen

- A-746820-11 Typical Anchoring For Machinery & EquipmentDokument13 SeitenA-746820-11 Typical Anchoring For Machinery & Equipmentrantonio mz smgNoch keine Bewertungen

- Brenner Basistunnel: Galleria Di Base Del BrenneroDokument41 SeitenBrenner Basistunnel: Galleria Di Base Del BrenneroserafiniNoch keine Bewertungen

- MTC Item 1 PDFDokument39 SeitenMTC Item 1 PDFGuddu YadavNoch keine Bewertungen

- DV-8612CP0567 2022Dokument8 SeitenDV-8612CP0567 2022Sanel TucakovicNoch keine Bewertungen

- 1.so 8-150 RF - 9B5770Dokument1 Seite1.so 8-150 RF - 9B5770Yosses Sang NahkodaNoch keine Bewertungen

- DR 10.01 Protokoll RT S1Dokument1 SeiteDR 10.01 Protokoll RT S1Sasa ZivkovicNoch keine Bewertungen

- Din-Dvgw 451 W DDokument2 SeitenDin-Dvgw 451 W DRicardo BarrosNoch keine Bewertungen

- Mill Certificate Bs en 10204/3.1 Certificat de Reception NF en 10204/3.1 Abnahmepruefzeugnis Din en 10204/3.1Dokument1 SeiteMill Certificate Bs en 10204/3.1 Certificat de Reception NF en 10204/3.1 Abnahmepruefzeugnis Din en 10204/3.1CRISTIAN SILVIU IANUCNoch keine Bewertungen

- Spezifikationen Werkzeuge deDokument79 SeitenSpezifikationen Werkzeuge deeduardo_umNoch keine Bewertungen

- BFP 10071-9-V9b-Muss-00059Dokument62 SeitenBFP 10071-9-V9b-Muss-00059mohamed abourayaNoch keine Bewertungen

- Gfps-Certificate-Butterfly-Valves-Types-038 - 039-DeDokument2 SeitenGfps-Certificate-Butterfly-Valves-Types-038 - 039-DeAlejandro VnNoch keine Bewertungen

- Dynapac pl2000lsDokument24 SeitenDynapac pl2000lslapan111Noch keine Bewertungen

- Siegenia Favorit (Germania)Dokument4 SeitenSiegenia Favorit (Germania)GuzicNikaNoch keine Bewertungen

- 74890A 561 LOC Rev01 CKEDokument5 Seiten74890A 561 LOC Rev01 CKEMammad54Noch keine Bewertungen

- Sungrow SG10KTL-M-V15 - VDE AR N 4105 - DEDokument67 SeitenSungrow SG10KTL-M-V15 - VDE AR N 4105 - DEmarkylloNoch keine Bewertungen