Beruflich Dokumente

Kultur Dokumente

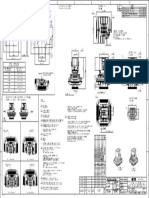

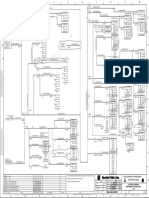

159 210 S84 Q4 012R4

Hochgeladen von

Yahya AteeniOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

159 210 S84 Q4 012R4

Hochgeladen von

Yahya AteeniCopyright:

Verfügbare Formate

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

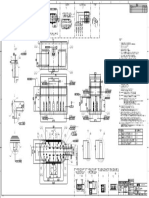

THIS DRAWING AND DESIGN, INCLUDING ANY PATENTED OR GENERAL TOLERANCES YLEISTOLERANSSIT Values in millimetres

PATENTABLE FEATURES, EMBODIES CONFIDENTIAL INFORMATION OF ISO 2768-1 EN ISO 13920 EN ISO 9013 DIN 6935 Arvot mm

OUTOTEC OYJ AND ITS USE IS CONDITIONED UPON THE USER'S Basic size range Nimellismitta-alue

AGREEMENT NOT TO REPRODUCE THE DRAWING OR DESIGN, LINEAR

IN WHOLE OR IN PART, NOR THE MATERIAL DESCRIBED THEREON, 19 24 25 31 14 24 DIMENSIONS

PITUUSMITAT > 0,5

≤3

>3

≤6

>6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

> 4000 > 8000 > 12 000 > 16 000 > 20 000

≤ 8000 ≤ 12 000 ≤ 16 000 ≤ 20 000

NOR TO USE THE DRAWING OR DESIGN FOR ANY PURPOSE OTHER

THAN SPECIFICALLY PERMITTED IN WRITING BY OUTOTEC OYJ. Machining ISO 2768-m Koneistus

25

± 0,1 ± 0,1 ± 0,2 ± 0,3 ± 0,5 ± 0,8 ± 1,2 ±2

24 Chamfers and external radii Viisteet ja ulkop. säteet ± 0,2 ± 0,5 ±1

B

A Welding ISO 13920-B Hitsaus ± 1 (Range 2-30) ±2 ±2 ±3 ±4 ±6 ±8 ± 10 ± 12 ± 14 ± 16 A

25 19 31 7 19 Thermal cutting ISO 9013-2 Terminen leikkaus ≥ 3 < 10 ≥ 10 < 35 ≥ 35 < 125 ≥ 125 < 315 ≥ 315 < 1000 ≥ 1000 < 2000 ≥ 2000 < 4000

Quality of cut surface

A

3,15 < t ≤ 6,3 ± 0,7 ± 0,8 ± 0,9 ± 1,1 ± 1,2 ± 1,3 ± 1,3

Leikatun pinnan laatu

36 24 ? 24 36 24 24 6,3 < t ≤ 10 ±1 ± 1,1 ± 1,3 ± 1,4 ± 1,5 ± 1,6 ± 1,7

ISO 9013-44

22 ANGULAR

10 < t ≤ 50 ± 1,8

Shorter side

± 1,8

Lyhyempi sivu

± 1,8 ± 1,9 ± 2,3 ±3 ± 4,2

34 4 25 2 2 25 3 35 25 25 2 13 DIMENSIONS KULMAMITAT ≤ 10 > 10 ≤ 50 > 50 ≤ 120 > 120 ≤ 400 > 400 ≤ 1000 > 1000

18 Machining ISO 2768-m Koneistus ± 1° ± 0°30' ± 0°20' ± 0°10' ± 0°5'

26 13 17 9 23 8 19 19 10 23 20 12 28 31 6 22 19 Welding ISO 13920-B Hitsaus ± 13 mm/m ± 9 mm/m ± 6 mm/m

Bending Taivutus SEE DIN 6935 KS. DIN 6935

6 GEOMETRICAL TOLERANCES GEOMETRISET TOLERANSSIT Machining

Koneistus ISO 2768-K

Welding

Hitsaus ISO 13920-F

25 GENERAL GEOMETRICAL TOLERANCES GEOMETRISET YLEISTOLERANSSIT Values in millimetres

41 ISO 2768-2 EN ISO 13920 Arvot mm

24 Basic size range Nimellismitta-alue

B GOOSE NECK PIPING SUPPORT

MACHINING KONEISTUS B

7

> 300 > 1000

22

> 100 > 10 > 30 > 100 > 300 > 1000

ISO 2768-K ≤ 100 ≤ 300 ≤ 1000 ≤ 3000 ≤ 10 ≤ 30 ≤ 100 ≤ 300 ≤ 1000 ≤ 3000

Perpendicularity Kohtisuoruus 0,4 0,6 0,8 1

5 Symmetry Symmetrisyys 0,6 0,6 0,8 1

2524,5

2482

Straightness and flatness Suoruus ja tasomaisuus 0,05 0,1 0,2 0,4 0,6 0,8

18

2286

2257

Circular run-out Heitto 0,2

2151

Basic size range Nimellismitta-alue

WELDING HITSAUS

5 14 ISO 13920-F

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

> 4000

≤ 8000

> 8000

≤ 12 000

> 12 000

≤ 16 000

> 16 000

≤ 20 000

> 20 000

21 Straightness, flatness Suoruus, tasomaisuus

4 9 and parallelism ja yhdensuuntaisuus

1 1,5 3 4,5 6 8 10 12 14 16

421

C 14 1 404 QUALITY AND ACCEPTANCE LEVELS FOR WELDING OF STEEL CONSTRUCTIONS C

848

HITSILUOKAT JA HYVÄKSYMISRAJAT TERÄSRAKENTEISSA

+16.500 +16.500

1800 QUALITY LEVELS ACC. TO STANDARD ISO 5817

EXAMINATION PROCEDURES, EXAMINATION LEVELS

AND ACCEPTANCE LEVELS OF WELD JOINTS

COMPLEMENTARY INDICATIONS

LISÄMERKINNÄT

ACC. TO ISO 17635

48,3 76,1 76,1 48,3 76,1

HITSILUOKAT STANDARDIN ISO 5817 MUKAAN

HITSILUOKKIEN MUKAISET TARKASTUSMENETELMÄT, INDICATION OF WELDS WITH QUALITY LEVELS

DETAIL C QUALITY LEVEL

HITSILUOKKA

TARKASTUSTASOT JA HYVÄKSYMISRAJAT

ISO 17635 MUKAAN

THAT DIFFERS FROM GENERAL REQUIREMENT

70

HITSAUKSEN MERKINTÄTAPA JOS ERI KUIN

168,3 114,3 SCALE 1 : 5 D

YLEISESTI VAADITTU HITSILUOKKA

817

70

27 33 32 29 30 33 32

EXAMPLE

a5 300

12

GENERALLY REQUIRED QUALITY LEVEL,

C

ESIMERKKI

IF NOT OTHERWISE SPECIFIED IN DRAWING 111 / B

YLEISESTI VAADITTU HITSILUOKKA, MIKÄLI

D 34 25 25 25 35 25 25

PIIRUSTUKSESSA EI OLE TOISIN MÄÄRITELTY

WELDING PROCESS

D

1587

ISO 4063

B

HITSAUSMENETELMÄ

1764

36

QUALITY LEVEL

24 24 24 37 24 24

ISO 5817

HITSILUOKKA

17 18 19 19 20 18 19

8 600 667

2657

2908

634

DETAIL A

3102

SCALE 1 : 10 24 8

25

24

2485,4

2684,7

E E

2092,9

1448,8

804,5

22

868

595

25

0

22

4885

5136

5449

3602

40 39

6556

F 12 39 40 F

9 3410

7 18

18

2746 11 11

2661,3

2444,1 2598

2444,1 2767

G G

2092,9

1448,8

804,5

993,6

2923

1449

1872,5

1800

12

13 2932 H

H

1155,8 1155,8 12

866,2

854

660

14

404 456

J J

0 0

157,6

1

570,9 570,8

K K

580,1 580,1

L 1600 1600,1 L

41 ADAPTER DN40/DN65 159-210-S84-Q4-560 1 7.5

40 ACTUATOR B1C6/ 07 2 15.0 OT SUPPLY

39 BALL VALVE M1MA100AP, PN40, DN 40 2 8.0 OT SUPPLY

38 HEXAGON HEAD SCREW ISO 4014 - M16x90 - 8.8 - tZn 8 0.2

37 HEXAGON NUT ISO 4032 - M20 - 8 - tZn 9 0.1

36 HEXAGON NUT ISO 4032 - M24 - 8 - tZn 24 0.1

35 WASHER ISO 7089 - M20 - 200HV - tZn 17 0.0

2620,1 34 WASHER ISO 7089 - M24 - 200HV - tZn 16 0.0

M 2620,1 33 HEXAGON HEAD SCREW ISO 4017 - M16x60 - 8.8 - tZn 8 0.1

M

2629,3

2629,3 32

31

HEXAGON HEAD SCREW ISO 4017 - M16x70 - 8.8 - tZn

HEXAGON HEAD SCREW ISO 4017 - M16x100 - 8.8 - tZn

16

24

0.2

0.2

30 HEXAGON HEAD SCREW ISO 4014 - M20x80 - 8.8 - tZn 8 0.3

29 HEXAGON HEAD SCREW ISO 4014 - M16x70 - 8.8 - tZn 8 0.2

3006 28 HEXAGON HEAD SCREW ISO 4014 - M20x100 - 8.8 - tZn 8 0.3

27 HEXAGON HEAD SCREW ISO 4014 - M24x80 - 8.8 - tZn 8 0.4

26 HEXAGON HEAD SCREW ISO 4014 - M24x120 - 8.8 - tZn 8 0.6

25 WASHER ISO 7089 - M16 - 200HV - tZn 112 0.0

24 HEXAGON NUT ISO 4032 - M16 - 8 - tZn 112 0.0

23 HEXAGON HEAD SCREW ISO 4017 - M16x90 - 8.8 - tZn 16 0.2

22 HEXAGON HEAD SCREW ISO 4017 - M16x80 - 8.8 - tZn 32 0.2

N 8 21

20

GASKET EN 1514-1/IBC/DN250 x 2/PN 40/KLINGER

GASKET EN 1514-1/IBC/DN100 x 2/PN 40/KLINGER 2

1 0.1

0.0

N

19 GASKET EN 1514-1/IBC/DN65 x 2/PN 40/KLINGER 9 0.0

18 GASKET EN 1514-1/IBC/DN40 x 2/PN 40/KLINGER 10 0.0

17 GASKET EN 1514-1/IBC/DN150 x 2/PN 40/KLINGER 2 0.0

2891,3

2478

2468,8

1448,8

428,8

419,5

6,3

0

16 SPIN VANE SEPARATOR TYPE B, PIPE 2 159-210-S84-Q4-014 1 34

15 SPIN VANE SEPARATOR TYPE B, PIPE 1 159-210-S84-Q4-013 1 46

14 GOOSE NECK PIPING 159-210-S84-Q4-494 1 33.8

13 MAIN NOZZLE PIPING TYPE B 159-210-S84-Q4-495 1 149

12 AUXILIARY NOZZLE PIPING TYPE B 159-210-S84-Q4-496 1 178

VIEW B 11 SPIN VANE SEPARATOR PIPING PART 2 159-210-S84-Q4-301 2 11

P 1:20 10

9

SPIN VANE SEPARATOR PIPING PART 1

MOISTURE JETS PIPING

159-210-S84-Q4-497

159-210-S84-Q4-498

1

1

53

28.6 P

8 OUTLET COOLING PIPING TYPE B 159-210-S84-Q4-499 1 77

7 INLET COOLING PIPING 159-210-S84-Q4-500 1 118.4

6 DECOMPRESSION TUBE 159-210-S84-Q4-284 2 11.5

5 GLOBE VALVE DN40 PN40 STEEL EN 10088-2 - 1.4301 2 30 OT-SUPPLY

4 GATE VALVE DN150 PN40 STEEL EN 10088-2 - 1.4301 1 154.1 OT SUPPLY

3 GATE VALVE DN100 PN40 STEEL EN 10088-2 - 1.4301 1 84.0 OT SUPPLY

2 GATE VALVE DN65 PN40 STEEL EN 10088-2 - 1.4301 3 44.0 OT SUPPLY

1 MANIFOLD 159-210-S84-Q4-285 1 345.2

ITEM NO. DESCRIPTION SUB-DWG.NO. QTY. WEIGHT Remarks

DIMENSIONS & BASIC MATERIAL WEIGHT

Q 1633 kg Q

WELDING TOLERANCES DESIGNED

16.10.2012 MVH

SCALE MACHINING TOLERANCES CHECKED

1:25 16.10.2012 ASV

UNITS MATERIAL No. APPROVED

mm 24.10.2012 JKJO

CLIENT CLIENT'S DRAWING No.

NATIONAL TITANIUM DIOXIDE COMPANY

PROJECT/ PRODUCT PROJECT No.

SPHINX DE-120001

0 FOR ERECTION 24.10.2012 MVH ASV JKJO DRAWING TITLE

PIPING ASSEMBLY TYPE B

REF. DRAWING No.

R 1 UPDATED. ITEM 14,15 ADDED 14.12.2012 MVH ASV AEC FURNACE SCRUBBER TYPE B PREVIOUS DRAWING No. R

2 SPIN VANE SEPARATOR PIPE LINE CHANGED. DRAWING UPDATED 25.01.2013 HEL TVZ JKJO SMELTING AREA BILL OF MATERIAL No.

3 ADD ITEM 41 (ADAPTER) AND DECOMPRESSION TUBE, GOOSE NECK PIPELINE ROUTE CHANGED 11.03.2013 MVH LAR JKJO INSTALLATION DRAWING

SIZE SHEET / SHEETS DRAWING No. REV.

4 AS BUILT, DIMENSIONS CHANGED, UPDATED HEL LAR JKJO

8 9 10

REV No. REVISIONS

14 15

31.10.2013

DATE DRAWN CHECKED APPROVED A0 1/1 159-210-S84-Q4-012 4

1 2 3 4 5 6 7 11 12 13 16 17 18 19 20 21 22 23 24

Das könnte Ihnen auch gefallen

- VDI 3479 Emissionsminderung 2002Dokument56 SeitenVDI 3479 Emissionsminderung 2002Brian RobertsNoch keine Bewertungen

- RasenfibelDokument17 SeitenRasenfibelFrank FozNoch keine Bewertungen

- Vdi 2230 Nebenschluss Blatt 2Dokument94 SeitenVdi 2230 Nebenschluss Blatt 2Yudha SutantoNoch keine Bewertungen

- VDI VDE DGQ 2618 Blatt 5.2 Prüfanweisung Für HaarlinealeDokument12 SeitenVDI VDE DGQ 2618 Blatt 5.2 Prüfanweisung Für Haarlineale03121980100% (1)

- 0210-FAA-0037 0210-FAA-0038 0210-TKS-0039: Hydraulic AccumulatorDokument1 Seite0210-FAA-0037 0210-FAA-0038 0210-TKS-0039: Hydraulic Accumulatornestor159357Noch keine Bewertungen

- Eng CD 1564416 H5Dokument1 SeiteEng CD 1564416 H5ZorbanfrNoch keine Bewertungen

- 5.0.3 Hydr. Circuit Diagram CM1250Dokument1 Seite5.0.3 Hydr. Circuit Diagram CM1250murat ünverNoch keine Bewertungen

- Eng Id 208-18134 ADokument1 SeiteEng Id 208-18134 AhulaneNoch keine Bewertungen

- 85 99126 0079 - 1Dokument1 Seite85 99126 0079 - 1Arshed RosalesNoch keine Bewertungen

- Rysunek 1 967587 3Dokument1 SeiteRysunek 1 967587 3kamil.tomasz.jakubiakNoch keine Bewertungen

- Min. N (2 X 56x) 1.2: Revisions CDokument1 SeiteMin. N (2 X 56x) 1.2: Revisions CEL AMRANI AMARNoch keine Bewertungen

- PDF Technische Zeichnungen Caddy Kombi Langer Radstand Standard en KW31 2016 NeuDokument1 SeitePDF Technische Zeichnungen Caddy Kombi Langer Radstand Standard en KW31 2016 Neufeherb75Noch keine Bewertungen

- Kurva S Jembatan Rangka BajaDokument1 SeiteKurva S Jembatan Rangka BajaKopi ManaNoch keine Bewertungen

- Map Matrix Process24Dokument1 SeiteMap Matrix Process24Quality System SMGNoch keine Bewertungen

- Silo - Tips - 15 LD LD LD LD LD 440Dokument74 SeitenSilo - Tips - 15 LD LD LD LD LD 440Ol WebNoch keine Bewertungen

- Vdi - Vde - DKD 2639 - 2015Dokument24 SeitenVdi - Vde - DKD 2639 - 2015gizemNoch keine Bewertungen

- Z-6 Dry & HV (Oct 2023)Dokument1 SeiteZ-6 Dry & HV (Oct 2023)Erickson MalicsiNoch keine Bewertungen

- VectorDokument66 SeitenVectormhmdraqylyrbyNoch keine Bewertungen

- Nds MBL 2012 37cDokument282 SeitenNds MBL 2012 37cCatweazleNoch keine Bewertungen

- Modulo 5.Dokument1 SeiteModulo 5.Alberto Amador ReyesNoch keine Bewertungen

- 11N 959 442 DRW TZ 001 Mufu Touch CX740 BCS 2022-07Dokument1 Seite11N 959 442 DRW TZ 001 Mufu Touch CX740 BCS 2022-07MedAchrefZoghlamiNoch keine Bewertungen

- At-00613961 - 1Dokument1 SeiteAt-00613961 - 1Ahmad DagamsehNoch keine Bewertungen

- Data SheetDokument1 SeiteData SheetZayene KhmaisNoch keine Bewertungen

- Eng CD 2141847 A3-2027830Dokument2 SeitenEng CD 2141847 A3-2027830marcinNoch keine Bewertungen

- Instaxmini9 Manual 01Dokument2 SeitenInstaxmini9 Manual 01Dayang SenandongNoch keine Bewertungen

- Emr6 W500 D 1Dokument2 SeitenEmr6 W500 D 1Đỗ Xuân BằngNoch keine Bewertungen

- Surface Finish According To ISO 1302 Average Peak-To-Valley Height Ra (M) Oberfl Chenbeschaffenheit Mittenrauhwert Ra (M)Dokument1 SeiteSurface Finish According To ISO 1302 Average Peak-To-Valley Height Ra (M) Oberfl Chenbeschaffenheit Mittenrauhwert Ra (M)Ashraf SaeedNoch keine Bewertungen

- Posicionador 55c-Iss-6017777 PDFDokument6 SeitenPosicionador 55c-Iss-6017777 PDFstefan corjucNoch keine Bewertungen

- Bela CiaoDokument1 SeiteBela CiaoAingeru TorreNoch keine Bewertungen

- Furnace Lifting FrameDokument1 SeiteFurnace Lifting Framemahmoud abdelsatarNoch keine Bewertungen

- X-R Control Chart - Final - 15.05.23Dokument1 SeiteX-R Control Chart - Final - 15.05.23rav.virendraNoch keine Bewertungen

- SMS - BM00010 - 2023.01.14Dokument150 SeitenSMS - BM00010 - 2023.01.14manh hung leNoch keine Bewertungen

- Man Airfix A Airfix DDokument2 SeitenMan Airfix A Airfix DVasile Marian AdrianNoch keine Bewertungen

- STABILUSDokument72 SeitenSTABILUSNebojsa MiljkovicNoch keine Bewertungen

- Manual Objetivo Cámara NikonDokument2 SeitenManual Objetivo Cámara NikonÁlvaro Castro FernándezNoch keine Bewertungen

- FalcoNero Caricatori IdrauliciDokument2 SeitenFalcoNero Caricatori Idrauliciikuzma_1Noch keine Bewertungen

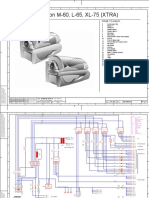

- M 60XL75SoltronDokument25 SeitenM 60XL75SoltronRadoslaw StarzykNoch keine Bewertungen

- Race Face Evolve FR-DH - Crankset - WebDokument2 SeitenRace Face Evolve FR-DH - Crankset - WebMarko A-Gang StigleitnerNoch keine Bewertungen

- C-100 Planta de NivelesDokument1 SeiteC-100 Planta de NivelesEldis RuizNoch keine Bewertungen

- SMS - BM0010 - Rev 2023.03.09.Dokument153 SeitenSMS - BM0010 - Rev 2023.03.09.manh hung leNoch keine Bewertungen

- EBRO-1051-FL Z400 DIN A4 6-Seiter DE R9 SCREENDokument2 SeitenEBRO-1051-FL Z400 DIN A4 6-Seiter DE R9 SCREENIehab MereenNoch keine Bewertungen

- 2580NC1Dokument86 Seiten2580NC1sanyNoch keine Bewertungen

- Metrado de Tuberia y AccesoriosDokument93 SeitenMetrado de Tuberia y AccesoriosFrank VegasNoch keine Bewertungen

- At-00614118 - 1Dokument2 SeitenAt-00614118 - 1Ahmad DagamsehNoch keine Bewertungen

- Bewehrung Untere Und Obere Über 2.OG - 404Dokument1 SeiteBewehrung Untere Und Obere Über 2.OG - 404Jacob CîrcuNoch keine Bewertungen

- L 1 N Led: Anno IT Anni AnniDokument2 SeitenL 1 N Led: Anno IT Anni AnniDAWGONoch keine Bewertungen

- New Assiut Combined Cycle Add-On Power Plant: Piping & Instrumentation DiagramDokument1 SeiteNew Assiut Combined Cycle Add-On Power Plant: Piping & Instrumentation Diagramwael zakariaNoch keine Bewertungen

- Ropa de CasaDokument109 SeitenRopa de CasaDaniela PioliNoch keine Bewertungen

- Limites de Presion Temperatura /: Temperature Pressure LimitDokument232 SeitenLimites de Presion Temperatura /: Temperature Pressure LimitRomanjaviNoch keine Bewertungen

- SMS - BM00020 - 2023.01.28Dokument11 SeitenSMS - BM00020 - 2023.01.28manh hung leNoch keine Bewertungen

- GR 63x25 8844201221 PDFDokument1 SeiteGR 63x25 8844201221 PDFMahesa SanggadipaNoch keine Bewertungen

- Reference Skid Sketch PDFDokument1 SeiteReference Skid Sketch PDFMohamedNoch keine Bewertungen

- Cable ReelDokument1 SeiteCable ReelDityCjNoch keine Bewertungen

- 30.10.2021 Galerie PDFDokument1 Seite30.10.2021 Galerie PDFAdmir SkenderovicNoch keine Bewertungen

- D BETRIEBSANLEITUNG Steuerteil Ab V F5.MDB-K320Dokument36 SeitenD BETRIEBSANLEITUNG Steuerteil Ab V F5.MDB-K320derbalijalelNoch keine Bewertungen

- Wil o 600953Dokument436 SeitenWil o 600953Amir AmiroNoch keine Bewertungen

- Beko 1e SchemeDokument1 SeiteBeko 1e Schemelulupardave36Noch keine Bewertungen

- IG N E D: Xstrata Bechtel Alliance Proyecto Antapaccay - Expansion TintayaDokument1 SeiteIG N E D: Xstrata Bechtel Alliance Proyecto Antapaccay - Expansion TintayaCristhian Alexander Aguilar ChavezNoch keine Bewertungen

- E49668C Unteres LuftleitblechDokument1 SeiteE49668C Unteres LuftleitblechdanijelpartoviNoch keine Bewertungen

- Data ScienceDokument56 SeitenData Sciencegerardoelguera25Noch keine Bewertungen

- der selfpublisher 19, 3-2020, Heft 19, September 2020: Deutschlands 1. Selfpublishing-MagazinVon Everandder selfpublisher 19, 3-2020, Heft 19, September 2020: Deutschlands 1. Selfpublishing-MagazinNoch keine Bewertungen

- KA SamenpflanzenDokument2 SeitenKA SamenpflanzenLoreen Kaiser-SoltészNoch keine Bewertungen

- Prehistoric V2 deDokument27 SeitenPrehistoric V2 deKALFERNoch keine Bewertungen

- Tabel Z Normal KumulatifDokument4 SeitenTabel Z Normal KumulatifFirda PutriNoch keine Bewertungen