Beruflich Dokumente

Kultur Dokumente

En16 8

Hochgeladen von

tonicmiraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

En16 8

Hochgeladen von

tonicmiraCopyright:

Verfügbare Formate

EN 13445-3/16.

8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

Contents in English and German

Literature: www.beuth.com

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln .................................... 2

Programmbeschreibung.......................................................................................... 2

a) 16.8.4 Bedingungen fr Sattellager ohne Festigkeitsnachweis ....................... 3

b) 16.8.5 Krfte und Momente an den Stteln..................................................... 3

c) 16.8.6 Lastgrenze zwischen den Stteln ......................................................... 4

d) 16.8.7 Lastgrenze am Sattel ohne Verstrkungsblech .................................... 4

e) 16.8.8 Lastgrenze am Sattel mit zustzlichem Verstrkungsblech.................. 4

f) 16.6 Streckenlast durch Horizontalkrfte und Momente................................... 4

g) AD-S3/2 Abschnitt 6 Nachweis des Sattels..................................................... 6

EN 13445-3/16.8Design of horizontal vessels on saddles.......................................... 7

Program description ................................................................................................ 7

a) 16.8.4 Conditions for saddles without stress analysis ..................................... 7

b) 16.8.5 Forces and moments at the saddles .................................................... 8

c) 16.8.6 Load limit between the saddles ............................................................ 8

d) 16.8.7 Load limit at the saddle without reinforcement plate............................. 9

e) 16.8.7 Load limit at the saddle with additional reinforcement plate ................. 9

f) 16.6 Line loads due to horizontal forces and moments .................................... 9

g) AD-S3/2:6 Strength calculation of the saddle"............................................... 11

Example for saddle calculation of saddle type A without reinforcement ................... 12

0 Doku(German) ................................................................................................... 13

1 Documentation (English).................................................................................... 14

2 EN16.8.4 ............................................................................................................ 15

3 EN16.8.6 Forces ................................................................................................ 16

4 EN16.8.7 Limit ................................................................................................... 18

5 EN16.8 Line load ............................................................................................... 20

6 EN16.8.6 Increased force .................................................................................. 22

7 EN16.8.7 Limit, increased .................................................................................. 24

8 EN16.8 Line load p=0 ........................................................................................ 26

9 EN16.8 Line load M=0 ....................................................................................... 28

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

Literatur: www.beuth.de

Programmbeschreibung

Mit Modul EN16.8 knnen liegende Behlter ohne Verstrkungsring auf Stteln nach EN

13445-3 Abschnitt 16.8 berechnet werden. Fr den Prffall knnen die zulssigen

Spannungen nach EN 14025 vorgegeben werden, indem der Eingabewert Regelwerk=1

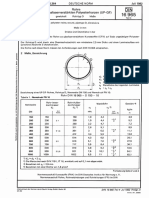

gewhlt wird. Die Lagertypen A, B, C nach EN 13445-3 sind in Bild 16.8-1 unten dargestellt.

Das Programm ist in 7 Berechnungsabschnitte aufgeteilt:

a) 16.8.4 Bedingungen fr Sattellager ohne Festigkeitsnachweis

b) 16.8.5 Krfte und Momente an den Stteln

c) 16.8.6 Lastgrenze zwischen den Stteln

d) 16.8.7 Lastgrenze am Sattel ohne Verstrkungsblech

e) 16.8.8 Lastgrenze am Sattel mit zustzlichem Verstrkungsblech

f) 16.6 Streckenlast durch Horizontalkrfte und Momente

g) AD-S3/2:6 Nachweis des Sattels

Bild 16.8-1 Sattellager - Typ A, B, C

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

a) 16.8.4 Bedingungen fr Sattellager ohne Festigkeitsnachweis

Fr Behlter mit Stteln des Typs A entfllt der Festigkeitsnachweis, wenn einige

Bedingungen erfllt sind, die im Berechnungsbeispiel am Ende aufgefhrt sind. Die

Geometrie des Lagers ist in Bild 16.8-4 dargestellt.

Bild 16.8-4 Zylindrische Behlter ohne Verstrkungsring

b) 16.8.5 Krfte und Momente an den Stteln

Fr die Lagertypen A und B knnen die Krfte und Momente an den Auflagern berechet

werden. Fr Lagertyp A wird das Feldmoment M12 zwischen den Stteln berechnet. Wenn

das Feldmoment grer ist als die Auflagermomente M1, M2, ist ein Festigkeitsnachweis

16.8.6 zwischen den Stteln erforderlich. Bei Lagertyp B ist das Feldmoment nicht

erforderlich.

Bild 16.8-6 Berechnungsmodell

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

c) 16.8.6 Lastgrenze zwischen den Stteln

Der Berechnungsdruck p kann fr Innendruck positiv p>0 und fr Auendruck negativ p<0

vorgegeben werden. Fr Innendruck wird der Festigkeitsnachweis nach Gl. (16.8-10)

ausgewertet. Bei Auendruck gilt die Festigkeitsbedingung (16.8-14). In der Maske werden

nur die zutreffenden Gleichungen dargestellt. Der zulssige Auendruck nach EN 08 und das

zulssige Moment nach EN 16.14 werden zustzlich berechnet. Die Gleichungen fr die

Festigkeitsbedingungen werden angezeigt. Weitere Gleichungen nach EN08 und EN 16.14

knnen mit den entsprechenden Modulen dokumentiert werden.

d) 16.8.7 Lastgrenze am Sattel ohne Verstrkungsblech

Fr einen Sattel ohne Verstrkungsblech werden die Festigkeitsbedingung (16.8-27) und der

Stabilittsnachweis (16.8-28) ausgewertet. Der zulssige Auendruck nach EN 08 und die

zulssigen globalen Krfte und Momente nach EN 16.14 werden zustzlich berechnet. Es

werden alle Gleichungen fr die Zwischenwerte und Festigkeitsnachweise angezeigt. Beim

Drucken knnen die Gleichungen ausgeblendet werden. Weitere Gleichungen nach EN08 und

EN 16.14 knnen mit den entsprechenden Modulen dokumentiert werden.

e) 16.8.8 Lastgrenze am Sattel mit zustzlichem Verstrkungsblech

Bei Stteln mit Verstrkungsblech knnen die Berechnungsflle 0, 1, 2 gewhlt werden. Fr

Berechnungsfall =0 wird geprft ob die Bedingung (16.8-32) fr die Breite des

Verstrkungsblechs erfllt ist und fr die Festigkeitsbedingung (16.8-34) gelten die 1.5fachen zulssigen Krfte. Wenn Bedingung (16.8-32) nicht erfllt ist, mssen die

Berechnungsflle 1 und 2 geprft werden, wobei die Vorgabe des Umschlingungswinkels

delta2 des Sattellagers erforderlich ist. Die Gleichungen werden fr die Berechnungsflle

dynamisch angepasst. Beim Drucken kann die Option <Gleichungen nicht drucken> gewhlt

werden.

f) 16.6 Streckenlast durch Horizontalkrfte und Momente

Da fr das Berechnungsverfahren ohne Festigkeitsnachsweis nach EN 13445-3 Abschnitt

16.8.4 kein spezieller Nachweis fr horizontale Krfte verlangt wird, kann angenommen

werden, dass Horizontalkrfte, die nicht wesentlich grer sind als die Vertikalkrfte,

ebenfalls zulssig sind. Bei groen Horizontalkrften kann auch ein Verstrkungsring nach

Abschnitt 16.9 eingesetzt werden. Das Streckenlastverfahren nach EN 13445-3 Abschnitt 16.6

wird in Anhang L und Abschnitt 16.7 bei Tragstteln, Aufhngesen und Tragpratzen

verwendet.

Da Horizontalkrfte in dem Berechnungsverfahren 16.8 nicht vorgesehen sind, werden die

Horizontalkrfte als Streckenlasten nach EN 13445-3 Abschnitt 16.6 berechnet. Wenn nur die

Streckenlast an einem Sttzblech in Umfangsrichtung bercksichtigt wird, sind die Ergebnisse

konservativer als nach Abschnitt 16.8. Gegebenenfalls ist es ausreichend, die Streckenlast an

den beiden Umfangsnhten der Auflagerbleche zu berprfen. Nach 16.6.4c) werden nur die

Radialspannungen am Behlter nachgewiesen. Streckenlasten, die nicht senkrecht auf die

Oberflche wirken, werden vernachlssigt. Nur wenn Lasten parallel zur Oberflche

wesentlich grer sind als senkrechte Lasten, sollten spezielle berlegungen angestellt

werden. In den folgenden Bildern wird die Lastaufteilung dargestellt.

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

Eine Alternative zu Biegespannungen kann eine statisch quivalente Normalspannung sein,

wie in Bild 16.8-4 unten dargestellt. Bei Lngskrften msste das Zusatzmoment im

Feldbereich bercksichtigt werden. In dem Beispiel weiter unten ist der Einfluss gering. In

Umfangsrichtung wre eine genauere Analyse des Modells beispielsweise mit Streckenlasten

mglich.

Bild 16-6-3 Streckenlasten

Bild 16.8-4a) mit Ankerkrften in Lngsrichtung.

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

Bild 16.8-4b) mit Ankerkrften in Umfangsrichtung.

Ein FEM-Modell kann genauere lokale Spannungen liefern, bercksichtigt gewhnlich jedoch

nicht die bleibende Vorverformung bei Sttzwirkung elastischer Bereiche und das plastische

Materialverhalten bei statischer Last.

g) AD-S3/2 Abschnitt 6 Nachweis des Sattels

Nach AD2000 S3/2 Abschnitt 6 knnen die Auflagerbleche und Stegbleche nachgewiesen

werden. Fr die Geometrie gelten die Variablenbezeichnungen nach Bild 8.

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

EN 13445-3/16.8Design of horizontal vessels on saddles

Literature: www.beuth.com

Program description

Module EN16.8 can be used for the design of horizontal vessels without reinforcement rings

on saddles acc. EN 13445-3 section 16.8. The allowable stresses for testing pressure can be

specified acc. EN 14025 by selecting the input value: Regulation = 1. The saddle types A, B,

C acc. EN 13445-3 are illustrated in Fig. 16.8-1 below. The program is divided into 7

calculation sections:

16.8.4 Conditions for saddles without stress analysis

16.8.5 Forces and moments at the saddles

16.8.6 Load limit between the saddles

16.8.7 Load limit at the saddle without reinforcement plate

16.8.7 Load limit at the saddle with additional reinforcement plate

16.6 Line loads due to horizontal forces and moments

AD-S3/2:6 Strength calculation of the saddle"

Fig. 16.8-1 Saddle types A, B, C

a) 16.8.4 Conditions for saddles without stress analysis

For vessels with saddles of type A the stress calculation can be omitted, when some

conditions are satisfied, which are listed in the calculation example at the end. The geometry

of the saddle is illustrated in Fig. 16.8-4.

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

Fig. 16.8-4 Cylindrical vessels without reinforcement ring.

b) 16.8.5 Forces and moments at the saddles

Section 16.8.5 can be used for the calculation of forces and moments of saddle types A and B.

For type A the field moment M12 between the saddles are calculated. When the field moment

is greater than the saddle support moments M1, M2, a stress proof acc. 16.8.6 between the

saddles is required. For saddle type B, the field moment is not required.

Fig. 16.8-6 Calculation model

c) 16.8.6 Load limit between the saddles

The calculation pressure p can be positive for internal pressure p>0 and negative for external

pressure p<0. For internal pressure the stress proof acc. Eq. (16.8-10) is evaluated. For

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

external pressure holds the stress condition (16.8-14). Only the appropriate equations are

displayed in the calculation mask. The allowable external pressure acc. EN08 and the

allowable moment acc. EN 16.14 are calculated additionally. The equation for the stress proof

are presented. Additional equations acc. EN08 and EN 16.14 can be documented using the

corresponding modules.

d) 16.8.7 Load limit at the saddle without reinforcement plate

For a saddle without reinforcement plate, the stress conditions (16.8-27) and the stability

proof (16.8-28) are evaluated. The allowable pressure acc. EN 08 and the allowable global

fores and moments acc. EN 16.14 are calculated additionally. All equations for the

intermediate values are displayed. For printing, the equation can be omitted. More equations

acc. EN08 and EN16.14 can be documented using the corresponding modules.

e) 16.8.7 Load limit at the saddle with additional reinforcement plate

For saddles with reinforcement plates the calculation cases 0, 1, 2 can be selected. For

calculation case = 0 condition (16.8.-32) for the reinforcement width is checked and for the

stress limit hold 1.5 times the allowable values. If condition (16.8-32) is not satisfied,

calculation cases 1 and 2 must be checked and the enclosing angle delta2 of the saddle

support plate must be specified. The equations are dynamically adapted to the calculation

case. For printing, the option <Dont print equations> can be selected.

f) 16.6 Line loads due to horizontal forces and moments

Because the calculation method without strength proof EN 13445-3 section 16.8.4 requires no

special proof for horizontal forces, it can be assumed that horizontal forces, which are not

substantially greater than vertival forces, are also allowed. For large horizontal forces a

reinforcement ring acc. section 16.9 can be used. The line load method acc. En 13445-3

section 16.6 is used for saddles, lugs and brackets, acc. Appendix L and section 16.7.

Since horizontal forces are not considered in the calculation method 16.8, the horizontal

forces are calculated as line loads acc. section 16.6. If only one line load acts on a support

plate in peripheral direction, the results are more conservative as in section 16.8. Therefore, it

may be sufficient to check the line loads acting on 4 circumferential weld seams at the saddle

plate. Acc. 16.6.4c) only radial stresses in the saddle are checked. Line loads, which are not

perpendicular to the surface, are neglected, but if their values are substantially greater then the

perpendicular load, special considerations are required. In the following figures the load

distribution is illustrated.

An alternative model for bending stress may be a statically equivalent normal stress by an

increased normal load, as shown in the figures 16.8-4 below. For axial forces, an additional

moment between the saddles could be considered. In the example, the influence is small. In

circumferential direction, a more precise analysis of the model using line forces may be

possible.

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Fig. 16-6-3 Line loads

Fig. 16.8-4a) with support forces in longitudinal direction.

Module EN 16.8

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

Fig. 16.8-4b) with support forces in peripheral direction.

A FEM model can provide more accurate local stresses, but usually it does not consider the

permanent deformation with local elastic support and the plastic material behavior for static

loads.

g) AD-S3/2:6 Strength calculation of the saddle"

Acc. AD2000 S3/2 section 6 the support plates and saddle plates can be verified. For the

geometry hold the variable notation acc. to Fig. 8.

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Example for saddle calculation of saddle type A without reinforcement

Appearance

Input values:

Calculated values:

Critical values:

Estimated values:

1.234

1.234

1.234

1.234

or

or

or

or

1.234

1.234

1.234

1.234

Module EN 16.8

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

0 Doku(German)

Documentation

Beispiel zur Lagerberechnung fr Lager Typ A ohne Verstrkungsblech

16.6.4c) Bei Horizontalkrften werden nur die Radialspannungen am

Behlter nachgewiesen. Streckenlasten, die nicht senkrecht auf die

Oberflche wirken, werden vernachlssigt. Nur wenn Lasten parallel zur

Oberflche wesentlich grer sind als senkrechte Lasten, sollten

spezielle berlegungen angestellt werden. Bei dem Beispiel fr eine

Horizontalkraft von 0.15*Gewichtskraft wird im Sttzblech quer zum

Behlter eine Streckenlast auf der Lnge von 3.14*D/4 auf 2 Lagern

angenommen. Die Sttzbleche in Lngsrichtung werden nicht bercksichtigt.

Da die Ergebnisse sehr konservativ sind, kann alternativ auch eine Streckenlast an 4 Auflagerblechnhten der beiden Lager angenommen werden.

Ein FEM-Modell kann genauere lokale Spannungen liefern, bercksichtigt

gewhnlich jedoch nicht die bleibende Vorverformung bei elastischer

Sttzwirkung und das plastische Materialverhalten bei statischer Last.

In Abschnitt '2 EN16.8.4' werden die Bedingungen fr Sattellager ohne

Nachweis geprft. Da alle Bedingungen erfllt sind, ist das Lager

ohne Nachweis zulssig.

In Abschnitt '3 EN16.8.6' werden Auflagerkrfte und Momente berechnet.

In Abschnitt '4 EN16.8.7' wird die Festigkeitsbedingung fr einen

Sattel ohne Verstrkungblech geprft. Die zulssige Auflagerkraft

FiMax = 521.9 kN und Fi=F1=150 kN ergibt eine Auslastung 0.2874.

In Abschnitt '5 EN16.8' wird eine Horizontalkraft quer zum Behlter

Fy = 0.15*W = 0.15*300kN = 75 kN angesetzt. Die zulssige Radialkraft

FLymax = 301.1 kN ist kleiner als nach Abschnitt 4. Das zulssige

lokale Moment MLxmax = 66.11 kNm ergibt mit Mx/2 = 30 kNm, Fy/2 = 150kN

eine Auslastung von 0.952. Da die Berechnung konservativer ist als

nach Abschnitt 16.8.7 ist diese Horizontalkraft zulssig. Alternativ

kann das Lager fr erhhte Gewichtskrfte Wx und Wy geprft werden.

In Abschnitt '6 EN 16.8.5' werden Auflagerkrfte und -momente fr

eine erhhte Gewichtskraft Wy = 615 kN berechnet.

Abschnitt '7 EN16.8.7' wird die Festigkeit fr erhhte Gewichtskrfte

geprft.

Abschnitt '8 EN16.8.7' berechnet die Auslastung bei Streckenlast

ohne Innendruck. Die zulssigen Krfte und Momente sind etwas grer.

Abschnitt '9 EN16.8' berechnet die Auslastung durch Streckenlast

ohne Horizontalkraft Fy=0. Die Auslastung = 0.4982 fr W=300kN

ist grer als 0.2874 nach EN 16.8.7, d.h. das Streckenlastmodell

rechnet konservativ.

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

1 Documentation (English)

Documentation

Example for a type-A saddle calculation without reinforcement

According to section 16.6.4c) only radial stresses on the vessel are

considered. Loadings not perpendicular to the shell surface are neglected

but if their values are essentially greater than normal loads, special

considerations are required. In this example, a horizontal force the

size of 0.15*weight is applied lateral to the vessel on two web plate

lines of 3.14*D/4 (90). The axial web plates at the two saddles are

not considered. Because the results are very conservative, an

alternative model with line loads acting on 4 circumferential support

plate weldings at the two saddles may also be considered.

A FEM-model can give more precise local stresses, but it usually neither

considers the permanent deformation with elastic support effect nor

the plastic material behaviour under static loading

In section '2 EN 16.8.4' the conditions for saddles without stress

proof are checked. The saddle is allowable without stress analysis,

because all conditions are satisfied.

In section '3 EN16.8.6' the support forces and moments are calculated.

In section '4 EN16.8.7' the stress conditions for a saddle without

reinforcement are checked. The allowable support force FiMax=521.9 kN

and Fi=F1=150kN give a utilisation of 0.2874.

In section '5 EN16.8' a horizontal force Fy = 0.15W = 0.15*300kN = 75 kN

is applied lateral to the vessel. The allowable radial force

FLymax = 301.1 kN is less than the result in section '4 EN16.8.7'.

The allowable local moment MLxmax = 66.11 kNm, Mx/2 = 30kNm and

Fy/2 = 150kN give a utilisation of 0.952. Since the calculation is more

conservative than results acc. to section 16.8.7, this horizontal force

is allowable. Alternatively, the saddle may be checked for statically

equivalent increased weights Wx and Wy.

In section '6 EN 16.8.5' the support forces and moments for an increased

weight of Wy = 615 kN are calculated.

In section '7 EN16.8.7' the strength for increased weight is checked.

Section '8 EN16.8.7' calculates line loads without internal pressure

and gives greater allowable forces and moments than '5 EN16.8.7'.

Section '9 EN16.8' calculates line loading without horizontal force

Fy=0. The utilisation = 0.4982 for W=300 kN ist greater than 0.2874

acc. to '4 EN 16.8.7', i.e. the line loading model is conservative.

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

2 EN16.8.4

Design of horizontal vessels on saddles EN 13445-3:2005-03

16.8.4 16.8.4 Conditions for saddles without stress analysis (Type A)

Specifications for symmetric support on two saddles

Cylinder inside diameter

Final wall thickness

Enclosing angle of saddle support plate (90,120)

Saddle support plate thickness without allowances

Reinforcement plate thickness without allowances

Cylinder length

Distance between cylinder end and adjacent support

Axial width of saddle support plate

Axial width of reinforcement plate (b2>b1)

Reinforcement plate projection, peripheral

Weld joint factor

Density of filling medium

Calculation pressure

(Type A)

D

se

delta

en

e2

L

a1

b1

b2

a2

v

Rf

p

Material:

Calculation temperature

Material code

Material strength

Safety factor

Manufacturing wall thickness allowance

Corrosion allowance

Allowable calculation stress

T

WNr

K

S

c1

c2

f

Intermediate results

Wall thickness without allowances ea = se-c1-c2

Parameter K11 (acc. section 16.8.4)

Max. cylinder length (acc. Fig. 16.8-5)

ea

K11

Lmax

Condition acc. 16.8.4

a) p =

16

b) Rf =

1000

c) f =

136.7

d) v =

1

e) a1 =

780

f) L =

3960

g) b1 =

240

0

1000 kg/m

130 MPa

0.8

800 = 0.5 D

16703 = Lmax

152.4 = 1.1 (D*en)

1600 mm

16 mm

90 (90,120)

12 mm

0 mm

3960 mm

780 mm

240 mm

0 mm

0 mm

1 1000 Kg/m

16 bar

200

1.4539(P

205

1.5

0

0

136.7

16

0.1143

16703

mm

mm

1

1

(satisfied=1, violated=0)

1

1

16.8.3b) For saddles with reinforcement (e2>0):

e2 =

0 en =

12

Reinforcement plate projection a2 =

0

Evaluated geometrical conditions are:

N/mm

mm

mm

N/mm

(satisfied=1, violated=0)

1

1

1

1

1

1

1

16.8.4 Only for saddles with reinforcement plate (e2>0)

a) e2 =

0

12 = en

542.9 = K11 D + 1.5 b1

b) b2 =

0

16.8.3a) Geometrical conditions

60 delta =

90 180

0.0075 0.05

0.001 en/D =

satisfied

160 = 0.1*D

1

1

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

3 EN16.8.6 Forces

Design of horizontal vessels on saddles EN 13445-3:2005-03

16.8.6 Load limit between the saddles

Specifications

Regulation (0=EN13445-3, 1=EN14025)

TFZ

EN 13445-3: Unfired pressure vessels

Load case (Operation=1, testing und installation=2) Cs

Total weight of vessel with contents

W

Fluid weight (of contents, e.g. WF=W)

WF

Cylinder length

L

Vessel inside diameter

D

Length of head

Hi

Distance from cylinder end to adjacent support

a1

Protruding cantilever length of tank a1 + 2/3*Hi

a3

Final wall thickness of vessel

se

Wall thickness of saddle support plate without all. en

Weld joint factor for peripheral weldings z 1

z

Calculation temperature

T

1.6 MPa =

Calculation pressure (external p<0)

p =

Material:

Material number

Austenitic material (N=No, else Yes)

Strength value (operation)

Safety factor

Manufacturing allowance

Corrosion allowance

Allowable calculation stress

Wall thickness without allowance ea = se-c1-c2

WNr

Aust

K

S

c1

c2

f

ea

Loading:

Line load q = W / (L + 4/3 * h2)

Moment

Mo= q * D / 16 * WF/W

Support forces and moments for support type A:

Support forces F1 = F2 = G / 2

Support moments M1, M2

Lateral shear force Q1, Q2

Field moment M12 (between saddles)

Calculation parameter

0 (0,1)

1

300

300

4694

1570

367

780

1025

15

12

0.8

200

16

kN

kN

mm

mm

mm

mm

mm

mm

mm

C

bar

1.4539(P Y

(J/N)

205 N/mm

1.5 0 mm

0 mm

136.7 N/mm

15 mm

q

Mo

57.88

8.916

N/mm

kNm

F1,F2

M1,M2

Q1,Q2

M12

K12

150

21.47

90.69

49.59

1.389

kN

kNm

kN

kNm

-

16.8.6 Stress between the saddles

Is only required when

p

4 * ea * z

4 *

+

M12

49.59

15 *

1570

0.8

kNm

>

21.47

kNm

M1

* K12

3.1415 * D * ea * z

1.6 *

4 *

M12

55.3

4 * 4.959E+7 *

+

3.1415 *

The stress condition is: satisfied

1570 *

136.7 = f

(16.8-10)

1.389

15 *

=

0.8

55.3

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

16.8.3a) Geometrical contition

0.001

en/D = 0.007643

0.05

is:

satisfied

Module EN 16.8

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

4 EN16.8.7 Limit

Design of horizontal vessels on saddles EN 13445-3:2005-03

16.8.7 Load limit at the saddle without reinforcement plate

Regulation (0=EN13445-3, 1=EN14025)

TFZ

EN 13445-3: Unfired pressure vessels

Load case (Operation=1, testing and installation=2) Cs

Calculation temperature

T

Calculation pressure

p

External pressure

pa

Vessel inside diameter

D

Finall wall thickness of vessel

se

Width of saddle

b1

Enclosing angle of saddle support plate

delta

Protruding cantilever length of cylinder

a1

Thickness of saddle support plate

en

1

200

16

0

1570

15

240

90

780

12

C

bar

bar

mm

mm

mm

mm

mm

Specifications for the calculation of allowable forces

Cylinder length (incl. cylindrical part of head)

L

Unroundness (Radius deviation from ideal form)

w

Length of measuring template for shape deviations

l

4694

1

100

mm

mm

mm

Material:

Austenitic material (N=No, else yes)

Strength value

Safety factor

Wall thickness allowance

Corrosion allowance

Allowable calculation pressure

Wall thickness without allowance ea = se-c1-c2

Poisson ratio

Rp02 or Rp1 at 20C

Rp02 or Rp1 at operation temperature

Safety factor for elastic limit

All. elastic limit (Rp02/Sel or Rp1/Sel)

E-Module at 20C

E-Module at operation temperature

E-Module for selected load case

Comparison of allowable values for saddle Nr

Allowable

Saddle load

521.9 kN

Support force

FiMax

Allowable

Stability

Bending moment

Mmax

2247 kNm

9806 kN

Lateral shear force

Qmax

4.481 bar

External pressure

pmax

Axial compr. force

Fmax

5670 kN

Utilisation, stability (16.8-28)

1

Utilisation, strength

1

Strength condition:

Evaluated geometrical conditions:

WNr

Aust

K

S

c1

c2

f

ea

ny

Rp20C

RpT

Sel

e

E20C

ET

E

Fi

Mi

Qi

pa

Fe

0 (0,1)

1.4539(P Y

(Y/N)

205 N/mm

1.5 0 mm

0 mm

136.7 N/mm

15 mm

0.3 260 MPa

205 MPa

1.625 (8.4.2-2)

126.2 MPa

196000 MPa

182000 MPa

182000 MPa

1

Actual

150

Actual

21.47

90.69

0

790.8

0.1491

0.2874

kN

kNm

kN

bar

kN

-

SATISFIED

satisfied

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Strength condition(16.8-27):

Fi =

150000 Min( 929308,

521925) = Min( Fmax2, Fmax3)

Stability condition(16.8-28):

Stblt = Pa /Pmax + Mi /Mmax + Fe/Fmax + ( Qi /Qmax ) =

16.8.3a) Geometrical conditions

60

90 = delta 180

0.001 en/D = 0.007643 0.05

K2

K7

1.25

1.095

ny2,1

-0.00433

0

K3

K8

0.25

0.7138

ny2,2

0.2407

0.4901

K4

K9

0.1491

(satisfied=1, violated=0)

1

1

Intermediate results table 16.8-1:

Global membrane stress due to bending

Pos. ny1

2

-0.4614

-1.138

3

Module EN 16.8

Smx

K1,1

1.104

0.6582

0.6778

0.6841

K5

K10

K1,2

1.304

0.9585

1.308

0.5956

K6

0.7393

Sigb,all

188.6

112.4

0.9192

N/mm

Fmax

929308

521925

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

5 EN16.8 Line load

Design of horizontal vessels on saddles EN 13445-3:2005-03

16.6 Line loads due to horizontal forces and moments for saddle type A

Regulation (0=EN13445-3, 1=EN14025)

TFZ

EN 13445-3: Unfired pressure vessels

Load case (operation=1, testing and installation=2) Cs

Calculation temperature

T

Calculation pressure

P =

1.6 MPa

=

Vessel inside diameer

D

Final wall thickness of vessel

se

Total weight of vessel (with contents)

W

Support force at vessel for saddle type A

F1,F2

Global support moment at vessel

M1,M2

Global additional axial force

FGx

Number of bolts per saddle

nB

Minimum vessel weight for bolt force

Wmin

0 (0,1)

1 200 C

16 bar

1600 mm

15 mm

300 kN

150 kN

21.47 kNm

0 kN

2 (2,4)

50 kN

Total horizontal force lateral to vessel

Lever arm of lateral force

Total moment on saddle support plates Fy*Deq/2

Bolt distance lateral to vessel

Length of one circumferential welding

Total number of circumferential weldings

Fy

Hzy

Mx

Ly

bSy

nSy

75

2100

60

1000

1256

2

kN

mm

kNm

mm

mm

-

Total axial horizontal force

Lever arm of axial force

Total moment on saddle support plates Fx*Deq/2

Bolt distance axial

Length of one axial welding

Total number of axial weldings

Fx

Hzy

My

Lx

bSx

nSx

75

2100

60

2400

kN

mm

kNm

mm

mm

-

Material code of vessel

Austenitic material (N=no, else yes)

Strength value, operation

Safety factor, operation

Strength valu, testing

Safety factor, testing

Allowance for wall thickness

Corrosion allowance

Allowable stress

Wall thickness without allowances ea = se-c1-c2

Poisson?s ratio

Rp02 or Rp1 at 20C

Rp02 or Rp1 at operation temperature

WNr

Aust

K

S

Kp

Sp

c1

c2

f

ea

ny

Rp20C

RpT

Results in circumferential direction

Increased total weight: Wy = W + 2*Hzy/Ly*Fy

Wy

Maximum tensile force per bolt (compression negative)

Fby = (Hzy/Ly*Fy-Wmin/2)/nB

FBy

Moment Fy*Hz

Mx

Maximum allowable local radial force at shell

FLymax

Maximum allowable local moment at shell

MLxmax

Utilisation of strength

(W/FLymax + Mx/MLxmax)/nSy

1.4539(P Y

(J/N)

205 N/mm

1.5 260 N/mm

1.05 0 mm

0 mm

136.7 N/mm

15 mm

0.3 260 MPa

205 MPa

615

kN

66.25 kN

60 kNm

301.1 kN

66.11 kNm

0.952 1

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Results in axial direction

Increased weight: Wx = W + 2*Hzx/Lx*Fx

Wx

Maximum tensile force per bolt (compression negative)

FBx = (Hzx/Lx*Fx-Wmin/2)/nB

FBx

Moment Fx*Hz

My

Maximum allowable local radial force at shell

FLxmax

Maximum allowable local moment at shell

MLymax

Utilisation strength

(W/FLxmax + My/MLymax)/nSx

Geometrical condition 16.6.4

a) 0.001 en/Deq = 0.009375 0.05

b) 0 Max(bSx, bSy)/Deq =

0.785

Geometrical conditions are

Module EN 16.8

431.3

kN

20.31

60

kN

kNm

kN

kNm

1

1

1

satisfied

Strength condition Strength condition satisfied

Display axial results (J), circumferential (N) or both (B)

(J/N/B)

Equations in circumferential direction

lam2 = bSy / (Deq*ea)

1E+09 =

1256 / (

(16.6-17)

15)

1600*

ny1 = Min(0.08* lam2, 0.3)

0.3 = Min(0.08*

1E+09, 0.3)

SMX = P * Deq /(4 *ea) + ( FGx + 4*

43.38 =

1.6 *

1600 /(4 *

+ (

0 + 4* 2.147E+7

ny2 = SMX/(K2*fS)

0.2539 =

43.38/(

1.25*

(16.6-18)

M1 / Deq )/( Pi*Deq*ea )

) +

/

1600 )/( Pi*

1600*

(16.6-9)

15 )

(16.6-18)

136.7)

K13y = 1/(1.2* (1+0.6*lam2))

1.076E-9 = 1/(1.2* (1+0.6*

1E+09))

(16.6-19)

K14y = 1/(0.6* (1+0.06*lam2))

6.804E-9 = 1/(0.6* (1+0.06*

1E+09))

(16.6-20)

ny12 = 1/3 + ny1* ny2

K1y = (1- ny2)/( ny12 + (ny12+(1- ny2)* ny1) )

K1y = 8.373E-9, mit ny1 =

0.3, ny2 =

0.2539

Sball,y = K1y*K2*fS

1.44E-06 = 8.373E-9*

1.25*

(16.6-7)

(16.6-6)

136.7

FLymax = Sball,y*ea/ K13

301077 = 1.44E-06*

15/ 1.076E-9

(16.6-21)

MLxmax = Sball,y*ea*bSy/K14y

6.611E+7 = 1.44E-06*

15*

(16.6-22)

1256/ 6.804E-9

Strength condition

Ausy = ( W /FLym + Mx /MLxm) / nSy 1

0.952 = ( 300000 / 301077 + 6.000E+7 / 6.611E+7) /

(16.6-23)

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

6 EN16.8.6 Increased force

Design of horizontal vessels on saddles EN 13445-3:2005-03

16.8.6 Load limit between the saddles

Specifications

Regulation (0=EN13445-3, 1=EN14025)

TFZ

EN 13445-3: Unfired pressure vessels

Load case (Operation=1, testing und installation=2) Cs

Total weight of vessel with contents

W

Fluid weight (of contents, e.g. WF=W)

WF

Cylinder length

L

Vessel inside diameter

D

Length of head

Hi

Distance from cylinder end to adjacent support

a1

Protruding cantilever length of tank a1 + 2/3*Hi

a3

Final wall thickness of vessel

se

Wall thickness of saddle support plate without all. en

Weld joint factor for peripheral weldings z 1

z

Calculation temperature

T

1.6 MPa =

Calculation pressure (external p<0)

p =

Material:

Material number

Austenitic material (N=No, else Yes)

Strength value (operation)

Safety factor

Manufacturing allowance

Corrosion allowance

Allowable calculation stress

Wall thickness without allowance ea = se-c1-c2

WNr

Aust

K

S

c1

c2

f

ea

Loading:

Line load q = W / (L + 4/3 * h2)

Moment

Mo= q * D / 16 * WF/W

Support forces and moments for support type A:

Support forces F1 = F2 = G / 2

Support moments M1, M2

Lateral shear force Q1, Q2

Field moment M12 (between saddles)

Calculation parameter

0 (0,1)

1

615

615

4694

1570

367

780

1025

15

12

0.8

200

16

kN

kN

mm

mm

mm

mm

mm

mm

mm

C

bar

1.4539(P Y

(J/N)

205 N/mm

1.5 0 mm

0 mm

136.7 N/mm

15 mm

q

Mo

118.6

18.28

N/mm

kNm

F1,F2

M1,M2

Q1,Q2

M12

K12

307.5

44.01

185.9

101.7

1.389

kN

kNm

kN

kNm

-

16.8.6 Stress between the saddles

Is only required when

p

4 * ea * z

4 *

+

M12

101.7

15 *

1570

0.8

kNm

>

44.01

kNm

M1

* K12

3.1415 * D * ea * z

1.6 *

4 *

M12

58.41

4 * 1.017E+8 *

+

3.1415 *

The stress condition is: satisfied

1570 *

136.7 = f

(16.8-10)

1.389

15 *

=

0.8

58.41

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

16.8.3a) Geometrical contition

0.001

en/D = 0.007643

0.05

is:

satisfied

Module EN 16.8

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

7 EN16.8.7 Limit, increased

Design of horizontal vessels on saddles EN 13445-3:2005-03

16.8.7 Load limit at the saddle without reinforcement plate

Regulation (0=EN13445-3, 1=EN14025)

TFZ

EN 13445-3: Unfired pressure vessels

Load case (Operation=1, testing and installation=2) Cs

Calculation temperature

T

Calculation pressure

p

External pressure

pa

Vessel inside diameter

D

Finall wall thickness of vessel

se

Width of saddle

b1

Enclosing angle of saddle support plate

delta

Protruding cantilever length of cylinder

a1

Thickness of saddle support plate

en

1

200

16

0

1570

15

240

90

780

12

C

bar

bar

mm

mm

mm

mm

mm

Specifications for the calculation of allowable forces

Cylinder length (incl. cylindrical part of head)

L

Unroundness (Radius deviation from ideal form)

w

Length of measuring template for shape deviations

l

4694

1

100

mm

mm

mm

Material:

Austenitic material (N=No, else yes)

Strength value

Safety factor

Wall thickness allowance

Corrosion allowance

Allowable calculation pressure

Wall thickness without allowance ea = se-c1-c2

Poisson ratio

Rp02 or Rp1 at 20C

Rp02 or Rp1 at operation temperature

Safety factor for elastic limit

All. elastic limit (Rp02/Sel or Rp1/Sel)

E-Module at 20C

E-Module at operation temperature

E-Module for selected load case

Comparison of allowable values for saddle Nr

Allowable

Saddle load

521.9 kN

Support force

FiMax

Allowable

Stability

Bending moment

Mmax

2247 kNm

9806 kN

Lateral shear force

Qmax

4.481 bar

External pressure

pmax

Axial compr. force

Fmax

5670 kN

Utilisation, stability (16.8-28)

1

Utilisation, strength

1

Strength condition:

Evaluated geometrical conditions:

WNr

Aust

K

S

c1

c2

f

ea

ny

Rp20C

RpT

Sel

e

E20C

ET

E

Fi

Mi

Qi

pa

Fe

0 (0,1)

1.4539(P Y

(Y/N)

205 N/mm

1.5 0 mm

0 mm

136.7 N/mm

15 mm

0.3 260 MPa

205 MPa

1.625 (8.4.2-2)

126.2 MPa

196000 MPa

182000 MPa

182000 MPa

Actual

307.5

Actual

44.01

185.9

0

1621

0.3058

0.5892

kN

kNm

kN

bar

kN

-

SATISFIED

satisfied

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Strength condition(16.8-27):

Fi =

307500 Min( 925858,

521925) = Min( Fmax2, Fmax3)

Stability condition(16.8-28):

Stblt = Pa /Pmax + Mi /Mmax + Fe/Fmax + ( Qi /Qmax ) =

16.8.3a) Geometrical conditions

60

90 = delta 180

0.001 en/D = 0.007643 0.05

K2

K7

1.25

1.095

ny2,1

-0.00887

0

K3

K8

0.25

0.7138

ny2,2

0.2362

0.4901

K4

K9

0.3058

(satisfied=1, violated=0)

1

1

Intermediate results table 16.8-1:

Global membrane stress due to bending

Pos. ny1

2

-0.4614

-1.138

3

Module EN 16.8

Smx

K1,1

0.6778

0.6841

1.1

0.6582

K5

K10

K1,2

1.301

0.9585

1.308

0.5956

K6

1.516

Sigb,all

187.9

112.4

0.9192

N/mm

Fmax

925858

521925

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

8 EN16.8 Line load p=0

Design of horizontal vessels on saddles EN 13445-3:2005-03

16.6 Line loads due to horizontal forces and moments for saddle type A

Regulation (0=EN13445-3, 1=EN14025)

TFZ

EN 13445-3: Unfired pressure vessels

Load case (operation=1, testing and installation=2) Cs

Calculation temperature

T

Calculation pressure

P =

0 MPa

=

Vessel inside diameer

D

Final wall thickness of vessel

se

Total weight of vessel (with contents)

W

Support force at vessel for saddle type A

F1,F2

Global support moment at vessel

M1,M2

Global additional axial force

FGx

Number of bolts per saddle

nB

Minimum vessel weight for bolt force

Wmin

0 (0,1)

1

200

0

1600

15

300

150

21.47

0

C

bar

mm

mm

kN

kN

kNm

kN

(2,4)

kN

Total horizontal force lateral to vessel

Lever arm of lateral force

Total moment on saddle support plates Fy*Deq/2

Bolt distance lateral to vessel

Length of one circumferential welding

Total number of circumferential weldings

Fy

Hzy

Mx

Ly

bSy

nSy

75

2100

60

1000

1256

2

kN

mm

kNm

mm

mm

-

Total axial horizontal force

Lever arm of axial force

Total moment on saddle support plates Fx*Deq/2

Bolt distance axial

Length of one axial welding

Total number of axial weldings

Fx

Hzy

My

Lx

bSx

nSx

75

2100

60

2400

kN

mm

kNm

mm

mm

-

Material code of vessel

Austenitic material (N=no, else yes)

Strength value, operation

Safety factor, operation

Strength valu, testing

Safety factor, testing

Allowance for wall thickness

Corrosion allowance

Allowable stress

Wall thickness without allowances ea = se-c1-c2

Poisson?s ratio

Rp02 or Rp1 at 20C

Rp02 or Rp1 at operation temperature

WNr

Aust

K

S

Kp

Sp

c1

c2

f

ea

ny

Rp20C

RpT

Results in circumferential direction

Increased total weight: Wy = W + 2*Hzy/Ly*Fy

Wy

Maximum tensile force per bolt (compression negative)

Fby = (Hzy/Ly*Fy-Wmin/2)/nB

FBy

Moment Fy*Hz

Mx

Maximum allowable local radial force at shell

FLymax

Maximum allowable local moment at shell

MLxmax

Utilisation of strength

(W/FLymax + Mx/MLxmax)/nSy

1.4539(P Y

(J/N)

205 N/mm

1.5 260 N/mm

1.05 0 mm

0 mm

136.7 N/mm

15 mm

0.3 260 MPa

205 MPa

615

kN

kN

60 kNm

374.1 kN

82.15 kNm

0.7661 1

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Results in axial direction

Increased weight: Wx = W + 2*Hzx/Lx*Fx

Wx

Maximum tensile force per bolt (compression negative)

FBx = (Hzx/Lx*Fx-Wmin/2)/nB

FBx

Moment Fx*Hz

My

Maximum allowable local radial force at shell

FLxmax

Maximum allowable local moment at shell

MLymax

Utilisation strength

(W/FLxmax + My/MLymax)/nSx

Geometrical condition 16.6.4

a) 0.001 en/Deq = 0.009375 0.05

b) 0 Max(bSx, bSy)/Deq =

0.785

Geometrical conditions are

Module EN 16.8

431.3

60

kN

kN

kNm

kN

kNm

1

1

1

satisfied

Strength condition Strength condition satisfied

Display axial results (J), circumferential (N) or both (B)

(J/N/B)

Equations in circumferential direction

lam2 = bSy / (Deq*ea)

8.107 =

1256 / (

(16.6-17)

15)

1600*

ny1 = Min(0.08* lam2, 0.3)

0.3 = Min(0.08*

8.107, 0.3)

(16.6-18)

SMX = P * Deq /(4 *ea) + ( FGx + 4*

0.7118 =

0 *

1600 /(4 *

+ (

0 + 4* 2.147E+7

ny2 = SMX/(K2*fS)

0.004167 = 0.7118/(

1.25*

M1 / Deq )/( Pi*Deq*ea )

) +

/

1600 )/( Pi*

1600*

(16.6-9)

15 )

(16.6-18)

136.7)

K13y = 1/(1.2* (1+0.6*lam2))

0.131 = 1/(1.2* (1+0.6*

8.107))

(16.6-19)

K14y = 1/(0.6* (1+0.06*lam2))

0.7496 = 1/(0.6* (1+0.06*

8.107))

(16.6-20)

ny12 = 1/3 + ny1* ny2

K1y = (1- ny2)/( ny12 + (ny12+(1- ny2)* ny1) )

K1y =

1.276, mit ny1 =

0.3, ny2 = 0.004167

Sball,y = K1y*K2*fS

217.9 =

1.276*

1.25*

(16.6-7)

(16.6-6)

136.7

FLymax = Sball,y*ea/ K13

374135 =

217.9*

15/

0.131

MLxmax = Sball,y*ea*bSy/K14y

8.215E+7 =

217.9*

15*

1256/

Strength condition

Ausy = ( W /FLym + Mx /MLxm) / nSy

0.7661 = ( 300000 / 374135 +

(16.6-21)

(16.6-22)

0.7496

1

6E+07 / 8.215E+7) /

(16.6-23)

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

9 EN16.8 Line load M=0

Design of horizontal vessels on saddles EN 13445-3:2005-03

16.6 Line loads due to horizontal forces and moments for saddle type A

Regulation (0=EN13445-3, 1=EN14025)

TFZ

EN 13445-3: Unfired pressure vessels

Load case (operation=1, testing and installation=2) Cs

Calculation temperature

T

Calculation pressure

P =

1.6 MPa

=

Vessel inside diameer

D

Final wall thickness of vessel

se

Total weight of vessel (with contents)

W

Support force at vessel for saddle type A

F1,F2

Global support moment at vessel

M1,M2

Global additional axial force

FGx

Number of bolts per saddle

nB

Minimum vessel weight for bolt force

Wmin

0 (0,1)

1

200

16

1600

15

300

150

21.47

0

C

bar

mm

mm

kN

kN

kNm

kN

(2,4)

kN

Total horizontal force lateral to vessel

Lever arm of lateral force

Total moment on saddle support plates Fy*Deq/2

Bolt distance lateral to vessel

Length of one circumferential welding

Total number of circumferential weldings

Fy

Hzy

Mx

Ly

bSy

nSy

0

2100

0

1000

1256

2

kN

mm

kNm

mm

mm

-

Total axial horizontal force

Lever arm of axial force

Total moment on saddle support plates Fx*Deq/2

Bolt distance axial

Length of one axial welding

Total number of axial weldings

Fx

Hzy

My

Lx

bSx

nSx

75

2100

60

2400

kN

mm

kNm

mm

mm

-

Material code of vessel

Austenitic material (N=no, else yes)

Strength value, operation

Safety factor, operation

Strength valu, testing

Safety factor, testing

Allowance for wall thickness

Corrosion allowance

Allowable stress

Wall thickness without allowances ea = se-c1-c2

Poisson?s ratio

Rp02 or Rp1 at 20C

Rp02 or Rp1 at operation temperature

WNr

Aust

K

S

Kp

Sp

c1

c2

f

ea

ny

Rp20C

RpT

Results in circumferential direction

Increased total weight: Wy = W + 2*Hzy/Ly*Fy

Wy

Maximum tensile force per bolt (compression negative)

Fby = (Hzy/Ly*Fy-Wmin/2)/nB

FBy

Moment Fy*Hz

Mx

Maximum allowable local radial force at shell

FLymax

Maximum allowable local moment at shell

MLxmax

Utilisation of strength

(W/FLymax + Mx/MLxmax)/nSy

1.4539(P Y

(J/N)

205 N/mm

1.5 260 N/mm

1.05 0 mm

0 mm

136.7 N/mm

15 mm

0.3 260 MPa

205 MPa

300

kN

kN

0 kNm

301.1 kN

66.11 kNm

0.4982 1

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Results in axial direction

Increased weight: Wx = W + 2*Hzx/Lx*Fx

Wx

Maximum tensile force per bolt (compression negative)

FBx = (Hzx/Lx*Fx-Wmin/2)/nB

FBx

Moment Fx*Hz

My

Maximum allowable local radial force at shell

FLxmax

Maximum allowable local moment at shell

MLymax

Utilisation strength

(W/FLxmax + My/MLymax)/nSx

Geometrical condition 16.6.4

a) 0.001 en/Deq = 0.009375 0.05

b) 0 Max(bSx, bSy)/Deq =

0.785

Geometrical conditions are

Module EN 16.8

431.3

60

kN

kN

kNm

kN

kNm

1

1

1

satisfied

Strength condition Strength condition satisfied

Display axial results (J), circumferential (N) or both (B)

(J/N/B)

Equations in circumferential direction

lam2 = bSy / (Deq*ea)

8.107 =

1256 / (

(16.6-17)

15)

1600*

ny1 = Min(0.08* lam2, 0.3)

0.3 = Min(0.08*

8.107, 0.3)

(16.6-18)

SMX = P * Deq /(4 *ea) + ( FGx + 4*

43.38 =

1.6 *

1600 /(4 *

+ (

0 + 4* 2.147E+7

ny2 = SMX/(K2*fS)

0.2539 =

43.38/(

1.25*

M1 / Deq )/( Pi*Deq*ea )

) +

/

1600 )/( Pi*

1600*

(16.6-9)

15 )

(16.6-18)

136.7)

K13y = 1/(1.2* (1+0.6*lam2))

0.131 = 1/(1.2* (1+0.6*

8.107))

(16.6-19)

K14y = 1/(0.6* (1+0.06*lam2))

0.7496 = 1/(0.6* (1+0.06*

8.107))

(16.6-20)

ny12 = 1/3 + ny1* ny2

K1y = (1- ny2)/( ny12 + (ny12+(1- ny2)* ny1) )

K1y =

1.026, mit ny1 =

0.3, ny2 =

0.2539

Sball,y = K1y*K2*fS

175.4 =

1.026*

1.25*

(16.6-7)

(16.6-6)

136.7

FLymax = Sball,y*ea/ K13

301077 =

175.4*

15/

0.131

MLxmax = Sball,y*ea*bSy/K14y

6.611E+7 =

175.4*

15*

1256/

Strength condition

Ausy = ( W /FLym + Mx /MLxm) / nSy

0.4982 = ( 300000 / 301077 +

(16.6-21)

(16.6-22)

0.7496

1

0 / 6.611E+7) /

(16.6-23)

EN 13445-3/16.8 Nachweis fr liegende Behlter auf Stteln

EN 13445-3/16.8 Stress proof for horizonal vessels on saddles

Module EN 16.8

Das könnte Ihnen auch gefallen

- NozzleSpecApp 2007Dokument13 SeitenNozzleSpecApp 2007Gustavo CarrilloNoch keine Bewertungen

- Wasserstoffinduzierte SprödbrücheDokument4 SeitenWasserstoffinduzierte SprödbrüchesusanwebNoch keine Bewertungen

- Bolt CalculationDokument5 SeitenBolt CalculationbennyfergusonNoch keine Bewertungen

- Kühltürme DesignDokument199 SeitenKühltürme DesignmaligorkiNoch keine Bewertungen

- SCHR 02fcDokument18 SeitenSCHR 02fcIvana OomingmakNoch keine Bewertungen

- Berechnungsgrundlagen Stirnradverzahnungen 2010-10Dokument16 SeitenBerechnungsgrundlagen Stirnradverzahnungen 2010-10Wolfgang Speiser100% (1)

- DGFDB RegelwerkDokument43 SeitenDGFDB RegelwerkMaksimiljan PlanincNoch keine Bewertungen

- T35 1Dokument4 SeitenT35 1Zsolt NagyNoch keine Bewertungen

- Ansys Ubung FEM SchrumpfsitzDokument17 SeitenAnsys Ubung FEM SchrumpfsitzmehdilaserNoch keine Bewertungen

- Din 16965-4 - 1982-07Dokument6 SeitenDin 16965-4 - 1982-07sdewfefNoch keine Bewertungen

- Abschlusselemente DruckbehälterDokument75 SeitenAbschlusselemente DruckbehälterJEELE77Noch keine Bewertungen

- Technical Description AGSD15-DIN86044 Deutsch Silenciador 1Dokument5 SeitenTechnical Description AGSD15-DIN86044 Deutsch Silenciador 1Oscar Eduardo Parra GuerreroNoch keine Bewertungen

- FDBRDokument44 SeitenFDBREalumalai MuthuNoch keine Bewertungen

- DVS 2205-2-2008Dokument13 SeitenDVS 2205-2-2008BarsoumNoch keine Bewertungen

- Silos SD BuS 2006Dokument15 SeitenSilos SD BuS 2006wilsonmeneses2014Noch keine Bewertungen

- Catalog KompaflexDokument134 SeitenCatalog KompaflexLaurikNoch keine Bewertungen

- Din 28021 2006Dokument13 SeitenDin 28021 2006Janez PartNoch keine Bewertungen

- Form AnschweißflanschDokument22 SeitenForm AnschweißflanschNilsNoch keine Bewertungen

- Dehnstarr PDFDokument4 SeitenDehnstarr PDFhorstiillingNoch keine Bewertungen

- (Dr.-Ing. Habil. Ernst R. G. Eckert (Auth.) ) Einfà (Bokos-Z1)Dokument325 Seiten(Dr.-Ing. Habil. Ernst R. G. Eckert (Auth.) ) Einfà (Bokos-Z1)Anonymous lHiaDxlpkxNoch keine Bewertungen

- En 12369-2Dokument19 SeitenEn 12369-2Yuri De SantisNoch keine Bewertungen

- Behälterberechnungen Excel Egmont JankDokument12 SeitenBehälterberechnungen Excel Egmont JankCabra VolklingenNoch keine Bewertungen

- Din 28005-2 2001-04Dokument9 SeitenDin 28005-2 2001-04georgedjNoch keine Bewertungen

- Din en 13458-2Dokument110 SeitenDin en 13458-2NamikDzibricNoch keine Bewertungen

- VDI 3839 Blatt-2 Berichtigung 2008-02Dokument2 SeitenVDI 3839 Blatt-2 Berichtigung 2008-02Ibrahim RebhiNoch keine Bewertungen

- Berechnungsbeispiel DruckbehälterDokument7 SeitenBerechnungsbeispiel DruckbehälterJLZ972Noch keine Bewertungen

- 54 - Dimensionierung DruckbehälterDokument2 Seiten54 - Dimensionierung DruckbehälterDenial BasanovicNoch keine Bewertungen

- Katalog - Standardni Elasticni VijciDokument20 SeitenKatalog - Standardni Elasticni VijciSlobodan LoncarevicNoch keine Bewertungen

- II UebungDokument9 SeitenII Uebungpich222Noch keine Bewertungen

- Kaltriss Feinkornbaustahl PDFDokument169 SeitenKaltriss Feinkornbaustahl PDFyilmazerolNoch keine Bewertungen

- Din 4133 Steel StacksDokument50 SeitenDin 4133 Steel StacksTaesik Kim100% (3)

- Schubspannung Infolge Querkraft Bei Biegung - 1Dokument16 SeitenSchubspannung Infolge Querkraft Bei Biegung - 1verliebt12345Noch keine Bewertungen

- DIN EN 1993-1-4/NA: Dezember 2010 Deutsche NormDokument4 SeitenDIN EN 1993-1-4/NA: Dezember 2010 Deutsche NormMariana VelaNoch keine Bewertungen

- Emissionsberechnung Nach APIDokument28 SeitenEmissionsberechnung Nach APIMikeRenderNoch keine Bewertungen

- Din en 1993-1-2 Na (2010-12)Dokument8 SeitenDin en 1993-1-2 Na (2010-12)Mariana VelaNoch keine Bewertungen

- TRD 421Dokument15 SeitenTRD 421prabumunishNoch keine Bewertungen

- DD 2009 03 DimyDokument4 SeitenDD 2009 03 DimyBruno CostaNoch keine Bewertungen

- (DIN 28138-1 - 2006-06) - Gleitringdichtungen Für Rührwellen - Teil 1 - Aus Unlegiertem Oder Nichtrostendem Stahl - Betriebsdaten, Einbaumaße PDFDokument7 Seiten(DIN 28138-1 - 2006-06) - Gleitringdichtungen Für Rührwellen - Teil 1 - Aus Unlegiertem Oder Nichtrostendem Stahl - Betriebsdaten, Einbaumaße PDFNaveen Suresh KumarNoch keine Bewertungen

- (DIN 28115 - 2003-02) - Stutzen Aus Unlegiertem Stahl - PN 10 Bis PN 40 PDFDokument6 Seiten(DIN 28115 - 2003-02) - Stutzen Aus Unlegiertem Stahl - PN 10 Bis PN 40 PDFNaveen Suresh KumarNoch keine Bewertungen

- Schweisstechnik Erfa09 Din en 1090Dokument37 SeitenSchweisstechnik Erfa09 Din en 1090DrNoSchillerNoch keine Bewertungen

- Konstruktion I-II Lsungen H2008Dokument8 SeitenKonstruktion I-II Lsungen H2008quaho100% (1)

- VDI 2230 Nachrechung KISSsoft 2002Dokument20 SeitenVDI 2230 Nachrechung KISSsoft 2002Ibrahim Rebhi AlzoubiNoch keine Bewertungen

- Design Rules For Steel Box Girder BridgesDokument13 SeitenDesign Rules For Steel Box Girder Bridgeserky arkvathonejhNoch keine Bewertungen

- Final Erlaeuvci Leitfadendinen Version 5 2Dokument71 SeitenFinal Erlaeuvci Leitfadendinen Version 5 2consultor9010Noch keine Bewertungen

- Din 28124Dokument26 SeitenDin 28124InKiLiNo26Noch keine Bewertungen

- Anlagen QS Im RohrleitungsbauDokument28 SeitenAnlagen QS Im RohrleitungsbaupuetzfuNoch keine Bewertungen

- Din en 1991-3-Na 2010-12Dokument5 SeitenDin en 1991-3-Na 2010-12Mahmoud Akram AburidaNoch keine Bewertungen

- Leitfaden Zur Montage Von Flanschverbindungen in Verfahrenstechnischen Anlagen 3Dokument21 SeitenLeitfaden Zur Montage Von Flanschverbindungen in Verfahrenstechnischen Anlagen 3Reza SharafiNoch keine Bewertungen

- 6 1 Montage Schraubenverbindungen Vorspannkraefte AnziehdrehmomenteDokument5 Seiten6 1 Montage Schraubenverbindungen Vorspannkraefte Anziehdrehmomentehelmut123Noch keine Bewertungen

- Federal Mogul Glycodur Cat De-EnDokument60 SeitenFederal Mogul Glycodur Cat De-EnLuka BornaNoch keine Bewertungen

- Din en 1591-4 e 2011-11Dokument20 SeitenDin en 1591-4 e 2011-11George BogdanNoch keine Bewertungen

- DIN 7060 Curcular Sight Glass PDFDokument14 SeitenDIN 7060 Curcular Sight Glass PDFPedro Montes MarinNoch keine Bewertungen

- Din 105-5 e 2011-04Dokument16 SeitenDin 105-5 e 2011-04CementarNoch keine Bewertungen

- Thielmann GTS Cartridge FiltreDokument8 SeitenThielmann GTS Cartridge FiltreAlienshowNoch keine Bewertungen

- Deutsche Norm: Januar 2005Dokument10 SeitenDeutsche Norm: Januar 2005Naveen Suresh KumarNoch keine Bewertungen

- Ad 2000-1Dokument56 SeitenAd 2000-1tonicmiraNoch keine Bewertungen

- Bachelorarbeit 2010 Lengwinat CFD KRISO CS-AnalysisDokument71 SeitenBachelorarbeit 2010 Lengwinat CFD KRISO CS-AnalysismedievoloNoch keine Bewertungen

- Flettner Rotor ESHIP1Dokument9 SeitenFlettner Rotor ESHIP1Cealîcu SebastianNoch keine Bewertungen

- Sinus-S40 Komplet DEDokument21 SeitenSinus-S40 Komplet DEDamirNoch keine Bewertungen

- KrahnbanDokument9 SeitenKrahnbanOkanSukruNoch keine Bewertungen

- TVT FSDokument62 SeitenTVT FSChristian HamelNoch keine Bewertungen

- lx200 AnleitungDokument8 Seitenlx200 AnleitungjweingrillNoch keine Bewertungen

- 3 - 5 - Neuentwicklung Schlichten. - Giesserei Praxis-3 - 2006 - S100-105Dokument6 Seiten3 - 5 - Neuentwicklung Schlichten. - Giesserei Praxis-3 - 2006 - S100-105Andi SpitzNoch keine Bewertungen

- à - BUNG MASSIVBAU I Beispiel - Biegebemessung Plattenbalken ...Dokument3 Seitenà - BUNG MASSIVBAU I Beispiel - Biegebemessung Plattenbalken ...Balázs BozsóNoch keine Bewertungen

- Berechnung NVHDokument21 SeitenBerechnung NVHDixi AnonümNoch keine Bewertungen

- HTW E41 ETG2 Klausur SS21 1er TerminDokument2 SeitenHTW E41 ETG2 Klausur SS21 1er TerminshahatafbhuiyanNoch keine Bewertungen

- WL373e-V0 3 PDFDokument26 SeitenWL373e-V0 3 PDFAvinash GanesanNoch keine Bewertungen